hyd spool valve Safety Certifications

Hydraulic spool valves are critical components in hydraulic systems, guiding fluid flow to and from actuators. Ensuring their safety and reliability is paramount, typically achieved through various safety certifications. Here are some key safety certifications and standards relevant to hydraulic spool valves:

1. ISO 9001: This is a quality management system certification which ensures that the manufacturing process of the hydraulic spool valve meets high-quality standards consistently. It doesn’t specifically target safety but ensures a reliable production process.

2. CE Marking: Particularly relevant in the European Economic Area, the CE marking indicates that the hydraulic spool valve conforms to the European Union’s health, safety, and environmental protection standards. Compliance ensures that the product is safe for use within the EU.

3. Pressure Equipment Directive (PED) 97/23/EC: This directive applies to the design, manufacturing, and conformity assessment of pressure equipment and assemblies, crucial for components like hydraulic spool valves operating under high pressure.

4. ATEX Certification: For use in explosive atmospheres, this certification confirms that the hydraulic spool valve meets European standards for equipment safety and worker protection in potentially explosive environments.

5. UL (Underwriters Laboratories): UL certification from a global safety certification company assures the product has been tested and meets safety standards applicable in North America.

6. RoHS Compliance: This directive restricts the use of certain hazardous substances in electrical and electronic equipment, ensuring that materials used in hydraulic spool valves do not include harmful elements.

7. REACH Compliance: Ensuring that the hydraulic spool valves do not contain substances of very high concern (SVHC), this European Union regulation is designed to improve the protection of human health and the environment.

Hydraulic spool valve manufacturers often aim to comply with multiple certifications to ensure their products are safe, reliable, and versatile for various applications across different regions and industries. Always check specific certifications relevant to your region and application requirements.

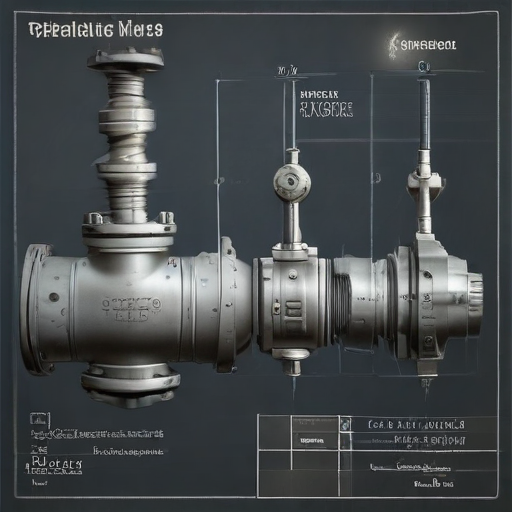

List Reference Technical Parameters of “hyd spool valve”

A hydraulic spool valve is crucial for controlling fluid flow and direction in hydraulic systems. Here are some key technical parameters to consider:

1. Flow Capacity (Qmax): Maximum flow rate through the valve, often measured in liters per minute (L/min) or gallons per minute (GPM).

2. Operating Pressure (Pmax): Maximum allowable pressure that the valve can handle, typically measured in bar or PSI (pounds per square inch).

3. Spool Type/Configuration: Indicates the geometry of the spool, affecting flow paths when the spool is in different positions (e.g., open, closed, or partially open).

4. Spool Positions: Number of discrete positions the spool can be in, such as 2-position, 3-position, etc.

5. Actuation Method: How the valve is operated, which can be manual, hydraulic, pneumatic, electric, or solenoid actuation.

6. Mounting Type: Denotes how the valve is installed, such as subplate mounting, manifold mounting, or in-line mounting.

7. Port Sizes: The size of the ports for fluid entry and exit, often specified in inches or millimeters.

8. Leakage Rate: The amount of fluid that leaks past the spool when in a closed position, usually measured in ml/min.

9. Response Time: The time it takes for the valve to shift from one position to another, often measured in milliseconds (ms).

10. Temperature Range: Operating temperature limits, often specified in degrees Celsius (°C) or Fahrenheit (°F).

11. Filtration Requirements: Recommended filtration levels for the hydraulic fluid to ensure proper valve function, generally given in microns (µm).

12. Material Composition: The materials used in the valve’s construction, impacting durability and compatibility with various fluids (e.g., stainless steel, aluminum).

13. Auxiliary Features: Additional functionalities like position sensors, feedback systems, or integrated electronics for control and monitoring.

Understanding and specifying the correct parameters is crucial for optimal performance and reliability in hydraulic applications.

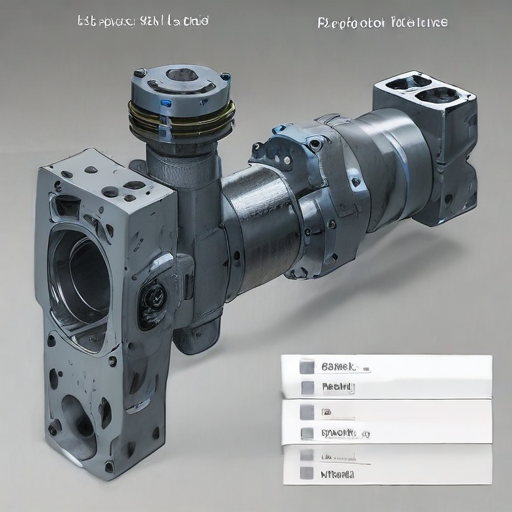

List Product features of “hyd spool valve”

A hydraulic spool valve is a crucial component in fluid control systems, often used in machinery and equipment to manage the direction of hydraulic fluid flow. Here are its key features:

1. Multiple Position Control: The spool valve can often be shifted into various positions to control the direction of fluid flow, typically including neutral, forward, and reverse positions.

2. Flow Rate Capacity: Designed to handle specific flow rates efficiently, thus influencing the overall performance of the hydraulic system.

3. High Pressure Handling: Built to withstand high operating pressures typical in hydraulic systems.

4. Durable Construction: Often manufactured from robust materials such as steel, aluminum, or cast iron to ensure longevity and reliability.

5. Precision Machining: Features accurately machined components to ensure smooth operation and tight sealing of ports in different positions.

6. Compact Design: Engineered to fit into confined spaces while still delivering powerful performance.

7. Versatile Port Configuration: Offers various port sizes and configurations to match specific application needs.

8. Manual or Solenoid Actuation: Can be operated manually or via solenoid actuators for remote and automated control.

9. Corrosion Resistance: Often treated or coated to resist corrosion and wear from hydraulic fluids.

10. Multiple Spool Designs: Available in various spool types (open center, closed center, tandem center) to handle different flow requirements and applications.

11. Mounting Options: Comes with different mounting styles, including subplate, manifold, or in-line mountings to suit diverse system architectures.

12. Leakage Control: Designed to minimize internal and external leakage for efficient system performance.

13. Temperature Tolerance: Built to operate effectively within a broad temperature range to suit various environmental conditions.

14. Quick Response Time: Provides rapid switching actions for enhanced control and operational efficiency.

15. Safety Features: Often integrated with safety mechanisms like pressure relief valves to prevent system damage.

16. Maintenance Accessibility: Constructed for ease of maintenance with accessible components to ensure minimal downtime.

These features ensure that hydraulic spool valves are adaptable, reliable, and efficient components in controlling fluid dynamics across various industrial applications.

List Various Types of “hyd spool valve”

Hydraulic spool valves are essential components in hydraulic systems, used to control the direction and flow of hydraulic fluid. Here are some types:

1. Directional Control Valves:

– Two-Way, Three-Position Spool Valve: Controls the flow between two ports, with three selectable positions: flow, stop, and return.

– Four-Way, Three-Position Spool Valve: Controls flow between four ports, typically used to extend and retract a double-acting cylinder.

2. Proportional Spool Valves:

– Proportional Directional Control Valves: Allows variable flow rates based on the input signal, providing smooth and precise control of actuator movement.

3. Solenoid-Operated Spool Valves:

– Single Solenoid: Uses one solenoid to shift the valve spool from a neutral position to an active position.

– Double Solenoid: Uses two solenoids to shift the spool to either of its two end positions, providing more control options.

4. Manual Spool Valves:

– Lever-Operated: Manually controlled by a lever, commonly used in mobile hydraulic equipment.

– Pedal-Operated: Controlled by foot pedals, often found in machinery where hands-free operation is beneficial.

5. Pressure-Controlled Spool Valves:

– Pressure Relief Spool Valve: Limits the maximum system pressure to prevent damage.

– Pressure Reducing Spool Valve: Maintains a set secondary pressure lower than the primary system pressure.

6. Hydraulic-Operated Spool Valves:

– Pilot-Operated: Uses hydraulic pressure to move the spool, enabling control of larger flow rates than what a direct-operated valve can handle.

Each type serves specific applications and operational requirements within various industries, from manufacturing and construction to aerospace and automotive sectors. Understanding the specific function and application is crucial for selecting the right spool valve for your hydraulic system.

List Application of “hyd spool valve”

A hydraulic spool valve is a crucial component in many hydraulic systems, widely used due to its ability to control the direction, flow, and pressure of hydraulic fluid. Here are some primary applications:

1. Construction Equipment: Hydraulic spool valves are extensively used in excavators, loaders, and bulldozers to control various functions such as arm movement, bucket operation, and blade adjustments.

2. Agricultural Machinery: Tractors, harvesters, and sprayers use spool valves to manage attachments like plows, loaders, and hydraulic lifts, facilitating efficient field operations.

3. Industrial Automation: They play a key role in manufacturing plants for controlling hydraulic cylinders and motors, ensuring precise movement in assembly lines, presses, and robotics.

4. Material Handling: Forklifts and cranes utilize spool valves to regulate hydraulic systems for lifting, lowering, and tilting loads, enhancing control and safety.

5. Aerospace Industry: Hydraulic spool valves are vital in aircraft for controlling landing gear, flaps, and other critical hydraulic functions, contributing to flight safety and performance.

6. Marine Applications: They are used in hydraulic systems on ships for steering, winching, and stabilizers, ensuring smooth and reliable maritime operations.

7. Automotive Sector: In vehicles, spool valves control hydraulic systems in automatic transmissions, power steering, and braking systems, providing better vehicle performance and driver control.

8. Mining Equipment: Heavy-duty machinery such as drills, rock breakers, and shovels use spool valves in their hydraulic systems for precise and powerful operations, crucial in demanding mining environments.

These applications highlight the spool valve’s versatility and adaptability, making it an essential component in various sectors requiring precise hydraulic control.

List Buyer Types of “hyd spool valve”

Sure, here is a concise list of common buyer types for hydraulic spool valves:

1. Manufacturers and Factories: These are large-scale operations that need hydraulic spool valves for their machinery and production lines. They often buy in bulk for use in assembly lines, injection molding machines, and other heavy equipment.

2. Construction Companies: Firms in this sector use hydraulic spool valves in various types of construction machinery, including excavators, bulldozers, and cranes. They tend to prioritize durability and reliability under extreme conditions.

3. Agricultural Businesses: Farms and agricultural enterprises use hydraulic systems in equipment like tractors, harvesters, and irrigation systems. They look for valves that can handle diverse and demanding environments.

4. Mining and Drilling Corporations: These companies require high-performance hydraulic spool valves for mining excavators, drilling rigs, and other heavy-duty equipment. Products need to withstand high pressures and harsh conditions.

5. Oil and Gas Industry: Drilling rigs, pipelines, and refineries use hydraulic spool valves extensively. Buyers in this sector need valves that meet stringent safety and performance standards.

6. Automotive Industry: Manufacturers and service providers in this sector use hydraulic systems in vehicle assembly and automated machinery. They often seek cost-effective and reliable valves for mass production.

7. Retail Distributors and Wholesalers: These entities buy hydraulic spool valves for resale. They focus on a diverse inventory to meet different industry standards and customer needs.

8. Maintenance and Repair Services: Companies offering repair and maintenance services for hydraulic systems purchase these valves for replacement and repair tasks. They prioritize compatibility and ease of installation.

9. Aerospace and Defense Contractors: These buyers need highly specialized, precision-engineered hydraulic spool valves for aircraft, spacecraft, and military machinery. They prioritize reliability and performance under strict regulatory standards.

10. Renewable Energy Companies: Wind turbines and solar panel adjustment systems also employ hydraulic mechanisms, and these companies look for valves that enhance efficiency and reliability.

11. Research and Development Units: Universities, private labs, and R&D departments require hydraulic spool valves for experimental and prototype setups. They seek versatility and customizable options.

Each buyer type has different priorities and requirements, affecting their purchasing decisions and the types of products they choose.

List “hyd spool valve” Project Types for Different Industries

Hydraulic spool valves are essential components in various industries for controlling fluid flow. Here are some project types for different industries:

1. Agriculture:

– Farm Machinery: Designing hydraulic systems for tractors, harvesters, and irrigation systems to ensure efficient fluid movement and control.

– Automated Planters: Implementing spool valves in seed distribution and planting machinery for precise operation.

2. Construction:

– Excavators and Loaders: Developing hydraulic circuits for seamless control of digging arms and lift buckets.

– Cranes: Integrating spool valves to manage the precise movement of cranes for lifting heavy loads.

3. Automotive:

– Hydraulic Suspensions: Enhancing vehicle performance and comfort by designing advanced suspension systems using spool valves.

– Convertible Roof Systems: Using spool valves to control the fluid movement in retractable roofs for cars.

4. Industrial Machinery:

– Press Machines: Engineering hydraulic press systems for manufacturing processes, using spool valves to regulate pressure and flow.

– Robotic Arms: Designing hydraulic circuits with spool valves for precise movement in automated assembly lines.

5. Aerospace:

– Landing Gear Systems: Developing robust hydraulic systems for aircraft, using spool valves to control landing gear extension and retraction.

– Flight Control Systems: Implementing spool valves in hydraulic control systems for maneuvering aircraft surfaces.

6. Marine:

– Steering and Stabilization Systems: Designing hydraulic systems for steering ships and maintaining stability, using spool valves for fluid control.

– Deck Machinery: Applying spool valves in winches and cranes on ships for efficient cargo handling.

7. Renewable Energy:

– Wind Turbines: Engineering hydraulic pitch control systems, using spool valves to adjust blade angles for optimal energy capture.

– Hydroelectric Plants: Utilizing spool valves in the hydraulic control systems of turbines for effective flow regulation.

In each of these industries, hydraulic spool valves are critical for ensuring precise and reliable control of fluid flow, enhancing efficiency and performance in various applications.

hyd spool valve Accessories Upgrades and Custom Manufacturing Options

Hydraulic spool valves are integral components in hydraulic systems, and customizing them can optimize performance and functionality. Here’s a brief overview of accessories, upgrades, and custom manufacturing options:

1. Accessories:

– Lever Kits: Enhance manual control with ergonomic designs.

– Solenoid Actuators: Enable electric control for automated systems.

– Pressure Relief Valves: Provide overpressure protection.

– Flow Control Valves: Adjust and control flow rates for precise operations.

– Seal Kits: Ensure compatibility with various fluids and temperatures.

2. Upgrades:

– Advanced Materials: Corrosion-resistant alloys and high-strength composites for extended lifespan.

– Enhanced Seals: Superior sealing materials to prevent leaks and withstand extreme conditions.

– Electronic Feedback Systems: Real-time monitoring and adjustments for improved precision.

– Multi-function Spools: Customizable spools to combine multiple functions in a single unit.

3. Custom Manufacturing Options:

– Tailored Spool Designs: Custom geometries and sizes for specific applications.

– Bespoke Flow Characteristics: Valve configurations tailored to specific flow rates and pressure requirements.

– Integrated Solutions: Combining multiple components into a single, space-saving unit.

– Custom Mounting Options: Unique mounting configurations to fit into specialized machinery.

– Personalized Branding: Custom labeling and branding to meet corporate standards.

By opting for these customizations and enhancements, hydraulic spool valves can be tailored precisely to meet the specific needs and demands of any industrial application, leading to improved efficiency, reliability, and performance.

List Quality Control and The Manufacturing Process of “hyd spool valve”

Quality Control of Hydraulic Spool Valve

1. Raw Material Inspection: Assess raw materials for chemical composition, hardness, and surface quality.

2. Dimensional Verification: Use tools like calipers and micrometers to confirm dimensions align with design specifications.

3. Surface Finish Testing: Employ methods such as profilometry to ensure surface finish meets required roughness levels.

4. Hardness Testing: Conduct Rockwell or Brinell hardness tests to verify material properties.

5. Leakage Testing: Use hydrostatic or pneumatic pressure tests to check for leaks within the valve’s seals and housing.

6. Flow Rate Testing: Ensure the valve meets specified flow characteristics using hydraulic test benches.

7. Functional Testing: Simulate operational conditions to verify performance metrics such as response time and pressure drop.

8. Visual Inspection: Check for cosmetic defects and ensure proper assembly.

9. Documentation: Maintain detailed records of all tests and inspections for traceability and future reference.

Manufacturing Process of Hydraulic Spool Valve

1. Design and Engineering: Develop detailed design drawings and specifications based on performance requirements.

2. Material Selection: Choose materials like high-strength alloys that meet mechanical and environmental specifications.

3. Machining: Use CNC machining to create the main body and spool, achieving high precision and tight tolerances.

4. Heat Treatment: Improve mechanical properties of metal parts via processes such as quenching and tempering.

5. Grinding and Polishing: Achieve required surface finish and tolerances using precision grinding and polishing techniques.

6. Assembly: Assemble internal components, including seals, springs, and the spool, ensuring they function harmoniously.

7. Surface Coating: Apply coatings such as anodizing or plating for corrosion resistance and enhanced durability.

8. Quality Control: Implement quality control steps outlined above to ensure each valve meets rigorous standards.

9. Final Assembly: Integrate all sub-assemblies and components, ensuring proper alignment and functionality.

10. Packaging and Shipping: Package the finished product suitably to prevent damage during transportation.

By adhering to these quality control and manufacturing steps, hydraulic spool valves meet industry standards and satisfy customer expectations.

How to use “hyd spool valve”

A hydraulic spool valve controls the flow of hydraulic fluid within a hydraulic system. Here’s a concise guide on how to use it:

Safety First

1. Wear Protective Gear: Always wear safety goggles, gloves, and appropriate clothing.

2. Depressurize System: Ensure the hydraulic system is turned off and depressurized before working.

Identification

1. Identify Ports: Locate the input (P), output (A and B), and return (T) ports on the valve.

2. Spool Symbol: Refer to the spool valve symbol to understand its operation configuration (e.g., 3-position, 4-way).

Installation

1. Mounting: Securely mount the spool valve in the desired location.

2. Connect Hoses: Attach hydraulic hoses to the corresponding ports (P, A, B, and T) ensuring secure, leak-free connections.

Operation

1. Control Lever: Use the control lever or actuator to operate the spool.

– Neutral (Center) Position: No flow, the system at rest.

– Extend Position (Shift Spool Down/Right): Directs fluid from P to A, extending an actuator.

– Retract Position (Shift Spool Up/Left): Directs fluid from P to B, retracting an actuator.

Monitoring

1. Check for Leaks: Periodically inspect for any signs of fluid leakage.

2. Smooth Operation: Ensure the valve moves smoothly without sticking.

Maintenance

1. Regular Inspection: Periodically check for wear, corrosion, and proper function.

2. Cleanliness: Keep the environment and hydraulic fluid clean to prevent contamination.

Troubleshooting

1. Inconsistent Actuation: Check for obstructions or air in the lines.

2. Fluid Leaks: Tighten connections or replace seals as necessary.

Shutdown

1. Return to Neutral: Ensure the spool is in the neutral position.

2. Turn Off System: Safely power down the hydraulic system.

This concise guide should help you use a hydraulic spool valve effectively. Always refer to specific manufacturer instructions for detailed procedures.

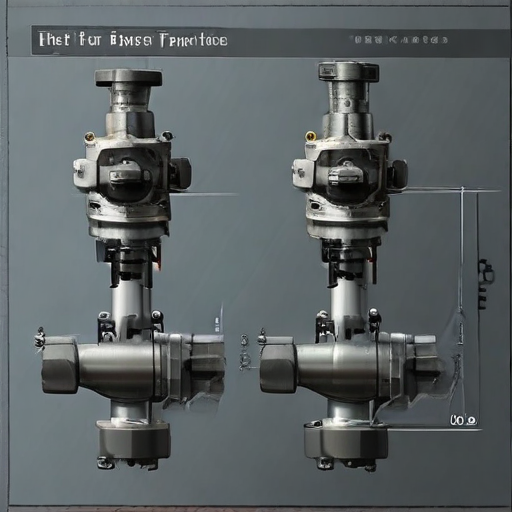

“hyd spool valve” Comparative Analysis

A hydraulic spool valve is an essential component in hydraulic systems, primarily used to control the direction of fluid flow, thereby managing the operation of cylinders, motors, or other hydraulic actuators. These valves are categorized based on their design, functionality, and the control methods they employ.

Design and Functionality

1. Directional Control Spool Valves: These valves have multiple ports and internal passages that direct fluid flow. They are commonly found in configurations such as 2-way, 3-way, or 4-way, depending on the number of ports involved. The spool’s position inside the valve body determines the path the hydraulic fluid takes.

2. Proportional Spool Valves: These offer variable control and are designed to provide precise adjustment over fluid flow and pressure. Unlike traditional directional valves, proportional spool valves allow for fine-tuned control, making them ideal for applications requiring variable speed or force.

Control Methods

– Manually Operated: Simple and cost-effective, these spool valves are controlled by levers or handles. They are typically used in low-complexity systems where precision is not critical.

– Electrically Operated: These use solenoids to shift the spool position. They offer higher precision and can be integrated into automated systems, providing remote control benefits and swift response times.

– Hydraulically or Pneumatically Operated: These are manipulated by fluid power, making them suitable for heavy-duty applications where electrical systems might be hazardous.

Application and Performance

– Industrial Machinery: Spool valves in manufacturing and assembly lines ensure fluid routing for various hydraulic tools and equipment.

– Mobile Equipment: In construction and agricultural machinery, these valves are crucial for operating attachments like lifts and backhoes.

– Aerospace and Defense: Precision and reliability are paramount in this sector, making proportional spool valves especially useful.

Comparative Insights

Manually operated valves are robust but lack precision. Electrically operated types provide better control and integration with modern systems, though they are more complex and expensive. Proportional spool valves, while more costly, offer superior precision and flexibility, essential for advanced applications.

In summary, the choice of a hydraulic spool valve largely depends on the specific application requirements, ranging from cost-efficiency and simplicity to precision and adaptability in complex systems.

“hyd spool valve” Warranty and Support

Warranty and Support for HYD Spool Valve

When purchasing a HYD spool valve, customers can expect comprehensive warranty and support services designed to ensure product reliability and customer satisfaction. Our standard warranty includes coverage for a period of 12 months from the date of purchase, protecting against defects in materials and workmanship under normal use conditions. During this period, any defective parts will be repaired or replaced at no additional cost to the customer.

To initiate a warranty claim, customers should contact our support team with proof of purchase and a detailed description of the issue. Our technical support team is readily available via phone, email, or live chat to provide troubleshooting assistance, answer queries, and guide you through the warranty claim process.

In addition to warranty services, we offer a range of support options to ensure the optimal performance of your HYD spool valve. This includes access to an extensive library of manuals, installation guides, and troubleshooting documents available on our website. For more complex issues, our technical experts can provide in-field support and diagnostic services.

For customers beyond the warranty period, we offer affordable extended service contracts that include annual maintenance checks, priority support, and discounted repair services.

Our commitment to quality and customer satisfaction is evident in our robust warranty and support offerings, ensuring peace of mind for every HYD spool valve owner. Feel free to reach out to our support team for any assistance required.

List “hyd spool valve” FAQ

Hyd Spool Valve FAQ

#### What is a Hyd Spool Valve?

A Hydraulic Spool Valve is a crucial component in a hydraulic system, responsible for controlling the flow of hydraulic fluid within the system.

#### How does a Spool Valve work?

The spool within the valve can shift positions to block or allow fluid flow. It directs hydraulic fluid to specific locations within the system to perform various functions like lifting, lowering, or rotating components.

#### What are the types of Spool Valves?

– Directional Control Valves: Used to control the direction of fluid flow.

– Flow Control Valves: Regulate the flow rate of the fluid.

– Pressure Control Valves: Maintain or limit the pressure within a system.

#### What are common configurations?

Spool valves can have various configurations such as:

– 2-way (two ports)

– 3-way (three ports)

– 4-way (four ports)

These configurations determine how fluid is channeled through the system.

#### How are Spool Valves actuated?

Actuation methods include:

– Manual: Lever or hand control.

– Mechanical: Linkage or cam control.

– Electrical: Solenoid actuation.

– Hydraulic/Pneumatic: Fluid or air pressure actuation.

#### What materials are Spool Valves made from?

Common materials include steel, brass, and aluminum, chosen based on durability, environmental conditions, and specific application needs.

#### What are common issues and troubleshooting tips?

– Sticking: May be caused by contamination or wear. Clean or replace the valve.

– Leaks: Check for damaged seals or connections.

– Inconsistent performance: Ensure proper actuation and pressure levels, check for blockages.

#### How do you maintain a Spool Valve?

Regular maintenance includes:

– Inspection: Regularly check for wear and tear.

– Cleaning: Remove any contamination or debris.

– Lubrication: Ensure moving parts are well-lubricated as required.

#### Where are Spool Valves used?

Common applications include construction machinery, agricultural equipment, industrial automation, and any system requiring precise fluid control.

Understanding these basics will help you select, operate, and maintain hydraulic spool valves effectively.

Top 10 FAQ with answer about hyd spool valve for Buyer Sourcing from China

Top 10 FAQs About Sourcing Hydraulic Spool Valves from China

1. What is a hydraulic spool valve?

A hydraulic spool valve regulates fluid flow in hydraulic systems, directing fluid to different paths in the system, thus controlling the movement and operation of machinery.

2. Why source hydraulic spool valves from China?

China offers competitive pricing due to lower manufacturing costs, a wide variety of suppliers, and advancements in manufacturing technologies. Additionally, many Chinese suppliers meet international quality standards.

3. How do I verify a Chinese supplier’s reliability?

Check for certifications (ISO, CE), request samples, read customer reviews, and conduct factory audits. Utilizing third-party inspection services can also ensure supplier credibility.

4. Are Chinese hydraulic spool valves of good quality?

Yes, many Chinese manufacturers produce high-quality valves that adhere to international standards. However, it’s crucial to assess each supplier individually for quality assurance.

5. What is the typical lead time for orders?

The lead time varies depending on the supplier and order size but generally ranges from 30 to 60 days. Custom orders may require additional time.

6. Can I get customized spool valves?

Many Chinese manufacturers offer customization services to meet specific requirements. Provide detailed specifications to the supplier to ensure they can meet your needs.

7. What about the costs, including shipping?

Costs vary by supplier, order volume, and shipping method. It’s advisable to obtain multiple quotes and consider both the cost of goods and shipping when budgeting.

8. How do I handle payment security?

Use secure payment methods such as letters of credit (LC) or PayPal. Alibaba’s Trade Assurance can also provide a layer of payment protection.

9. What should I include in a purchase agreement?

Clearly outline product specifications, quantities, prices, payment terms, delivery timelines, and quality assurance measures. Including penalties for delays or quality issues is also advisable.

10. What are the import duties and taxes?

Import duties and taxes vary by country. Check your local customs regulations to calculate potential costs. Engage with a customs broker for seamless import processes.

By addressing these FAQs, you can ensure a smoother and more informed sourcing experience when procuring hydraulic spool valves from China.