brush making machine Safety Certifications

When selecting a brush-making machine, safety certifications ensure that the equipment adheres to stringent safety, performance, and environmental standards. The key safety certifications and standards to look out for include:

1. CE Marking (Conformité Européenne): This certification indicates that the machine complies with the European Union’s safety, health, and environmental requirements. It is crucial for any machinery being marketed or used within the EU.

2. ISO 12100: This international standard sets out the general principles for risk assessment and risk reduction to ensure the safety of machinery throughout its lifecycle.

3. UL Certification (Underwriters Laboratories): Popular in North America, UL certification ensures that the machine meets stringent safety standards. It covers electrical safety, fire hazards, and mechanical risks.

4. CSA Certification (Canadian Standards Association): This is a crucial certification for machinery used in Canada, similar to UL but tailored to Canadian safety standards.

5. RoHS Compliance (Restriction of Hazardous Substances Directive): This certification ensures that the machine is free from hazardous materials, which is important for both operator safety and environmental sustainability.

6. OSHA Regulations (Occupational Safety and Health Administration): While not a certification per se, compliance with OSHA guidelines ensures that machines meet the safety requirements mandated in the United States workplaces.

7. ANSI Standards (American National Standards Institute): ANSI develops norms and guidelines to ensure that products are safe, reliable, and of good quality. For brush-making machines, standards like ANSI B11.19 for machine safeguarding and ANSI Z136 for safe use of lasers may be relevant.

8. TÜV Certification (Technischer Überwachungsverein): TÜV is a German organization providing certification for safety standards, and it’s widely recognized for its rigorous testing and quality checks.

Ensuring these certifications are in place not only guarantees regulatory compliance but also enhances worker safety, operational efficiency, and overall machine reliability. Always check for these certifications before purchasing or operating a brush-making machine.

List Reference Technical Parameters of “brush making machine”

Certainly! Here’s a concise list of reference technical parameters for a brush-making machine:

1. Production Capacity:

– Units per hour

– Units per day

2. Speed:

– Operating speed (brushes per minute)

– Spindle speed (RPM)

3. Brush Size Range:

– Minimum and maximum length

– Minimum and maximum width

4. Hole Specifications:

– Drilling speed

– Hole diameter range

– Hole depth

5. Filling Parameters:

– Filling material types (e.g., synthetic, natural fibers)

– Tufting speed

– Tuft density (tufts per inch/cm)

– Tuft pattern

6. Motor Power:

– Power rating (kW/hp)

– Voltage (V)

– Frequency (Hz)

7. Control System:

– Type (e.g., PLC, CNC)

– Interface (e.g., touchscreen, button-operated)

– Software capabilities

8. Machine Dimensions:

– Length

– Width

– Height

– Weight

9. Compressed Air Requirements:

– Pressure (bar/psi)

– Flow rate (L/min, CFM)

10. Noise Level:

– Decibel rating (dB)

11. Machine Tolerance and Accuracy:

– Positional accuracy (mm/inches)

– Repeatability

12. Environmental Conditions:

– Operating temperature range

– Humidity range

13. Material Compatibility:

– Compatible handle materials

– Compatible filament materials

14. Safety Features:

– Safety sensors

– Emergency stop

15. Energy Consumption:

– Average energy usage (kWh)

16. Maintenance Needs:

– Recommended service intervals

– Lubrication points

17. Support and Warranty:

– Technical support availability

– Warranty period

18. Customization Options:

– Custom brush shapes

– Custom filament types

These parameters are crucial for evaluating and selecting the appropriate brush-making machine for specific industrial needs, ensuring efficient and high-quality production.

List Product features of “brush making machine”

Certainly! Here are the product features of a brush making machine summarized within 300 words:

Product Features of Brush Making Machine

1. Automated Operation:

– Fully automated process from filament feeding to brush trimming.

– Reduces manual intervention, enhancing efficiency and consistency.

2. High Precision:

– Advanced CNC control for precise filament insertion and trimming.

– Accuracy in bristle placement and length ensures uniform brush quality.

3. Versatility:

– Supports multiple brush types (e.g., household, industrial, cosmetic).

– Accommodates various filament materials like nylon, horsehair, or synthetic fibers.

4. Customizable Settings:

– Adjustable parameters for filament length, density, and tufting patterns.

– Software for easy customization and program storage.

5. Speed and Efficiency:

– High-speed motors and optimized mechanics for rapid production.

– Capable of producing several thousand brushes per day.

6. User-Friendly Interface:

– Touchscreen display for intuitive operation.

– Multilingual support and easy-to-follow menus.

7. Durability and Robust Design:

– Built with high-quality materials to withstand continuous operation.

– Low maintenance requirements due to robust construction.

8. Safety Features:

– Equipped with emergency stop buttons and safety guards.

– Compliance with international safety standards.

9. Energy Efficiency:

– Designed to minimize power consumption.

– Eco-friendly operations reducing operational costs.

10. Modular Design:

– Easy to upgrade with additional modules for enhanced functionality.

– Simplifies maintenance and part replacement.

11. Quality Control:

– Integrated sensor systems for real-time monitoring and quality checks.

– Automatic detection and rejection of defective units.

Conclusion

A brush making machine offers a blend of high precision, versatility, and efficiency, making it an indispensable tool for brush manufacturers aiming for quality and productivity. Its advanced features and customizable settings ensure it can meet diverse production needs while maintaining high safety and operational standards.

List Various Types of “brush making machine”

Certainly! Here’s a list of various types of brush-making machines commonly used in the industry:

1. Manual Brush Making Machines

– Simple, hand-operated machines primarily used for small-scale productions or artisan crafts.

2. Automatic Brush Making Machines

– Fully automated machines designed for mass production of brushes, increasing efficiency and consistency.

3. Injection Molding Machines

– Used to create brush handles or bodies by injecting molten material into molds.

4. Tufting Machines

– Automated to insert bristle fibers into pre-drilled holes in the brush base, securing them with adhesives or by heating.

5. Coreless Brush Making Machines

– Specialized for making brushes without a core, suitable for specific industrial applications.

6. Trimming and Flagging Machines

– Used to trim the bristles to the desired length and shape, and to flag the ends for a refined finish.

7. Staple and Anchor Set Machines

– These machines use metal staples or anchors to attach the bristles securely to the brush base.

8. Twisted-In-Wire Machines

– Ideal for producing twisted-wire brushes, where bristles are twisted between wire strands.

9. Roller Brush Making Machines

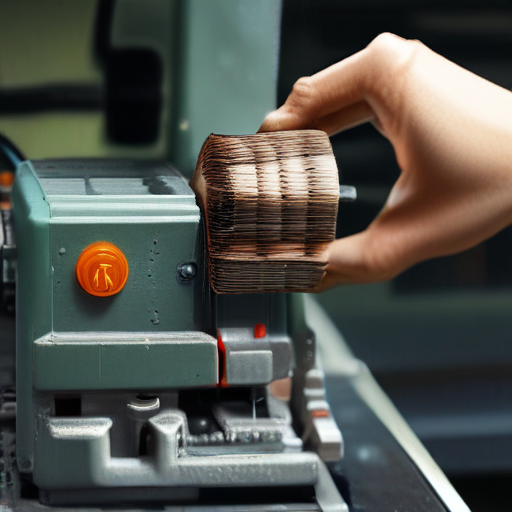

– Designed for creating cylindrical or roller brushes used in various industrial settings.

10. Painting Brush Making Machines

– Tailored specifically for manufacturing paint brushes, ensuring even distribution and proper bristle alignment.

11. Personal Care Brush Making Machines

– Specialized for producing hairbrushes, toothbrushes, and cosmetic brushes, often with precision tufting and ergonomic handle designs.

12. Disc Brush Making Machines

– Used for creating disc-shaped brushes often used in floor cleaning or industrial polishing.

Each type of machine is tailored for specific brush types and production needs, ranging from manual operations to highly automated systems for large-scale manufacturing.

List Application of “brush making machine”

A brush making machine is a specialized piece of equipment designed to automate the production of various types of brushes. Its applications are diverse and span multiple industries, making it an invaluable tool in both commercial and industrial settings. Below are some key applications:

1. Household Brushes: These machines efficiently produce everyday household brushes, including brooms, scrub brushes, and dish brushes. They ensure consistent quality and can handle high-volume production, meeting the demands of large retailers and consumers.

2. Industrial Brushes: Brush making machines are used to manufacture heavy-duty brushes for industrial applications. These include wire brushes, strip brushes, and conveyor cleaning brushes that are essential for maintenance and cleaning in factories, workshops, and production lines.

3. Personal Care: The machines are effective in producing personal care brushes such as hairbrushes, toothbrushes, and cosmetic brushes. Automation ensures precision and hygiene standards, which are crucial in these applications.

4. Automotive Industry: In this sector, brush making machines are utilized to create brushes for car washes, detailing, and maintenance. They produce specialized brushes with specific bristle arrangements that can reach into tight spaces and handle rigorous cleaning tasks.

5. Agriculture: Agricultural applications include the production of brushes used in sorting and cleaning produce, as well as in livestock farming for grooming and cleaning animals. These specialized brushes help in maintaining hygiene and improving productivity.

6. Electronics and Electrical: Fine brushes manufactured by these machines are used in cleaning electronic circuit boards, electrical contacts, and other delicate parts. The precision and quality control offered by brush making machines are critical in these sensitive applications.

7. Art and Craft: Artists’ brushes, including paintbrushes, are also produced using brush making machines. These brushes require careful attention to detail, and automated production ensures that each brush meets specific standards required by artists.

In summary, brush making machines are versatile and essential tools that cater to a wide range of industries, from household and personal care to industrial, automotive, agricultural, and artistic applications. This versatility, coupled with the ability to produce high-quality, consistent products, makes these machines a cornerstone in brush manufacturing.

List Buyer Types of “brush making machine”

When considering the types of buyers for a brush making machine, it is essential to recognize the diverse industrial and commercial applications. These buyers span various sectors and have differing needs based on their production requirements and business models. Here are the primary types of buyers:

1. Manufacturers of Household Brushes:

– Toothbrush Manufacturers: Companies specializing in producing manual and electric toothbrushes for the consumer market.

– Cleaning Brush Producers: Manufacturers of cleaning brushes used in homes, such as brooms, scrubbing brushes, and dusters.

2. Industrial Brush Manufacturers:

– Metalworking and Engineering Firms: These companies produce brushes used in grinding, polishing, and deburring of metal parts.

– Automotive Industry Suppliers: Producers of brushes used in vehicle manufacturing processes, including parts cleaning and finishing.

3. Personal Care and Cosmetics Companies:

– These firms manufacture brushes for personal grooming, such as hairbrushes and makeup applicators.

4. Specialty Brush Manufacturers:

– Art Supply Companies: Companies creating high-quality paintbrushes for artists.

– Medical and Laboratory Suppliers: Producers of specialized brushes for cleaning and preparing medical instruments and lab equipment.

5. Contract Manufacturers:

– Firms providing brush manufacturing services on behalf of other brands and companies, often operating on a made-to-order basis.

6. Startups and Small Enterprises:

– New entrants into the brush market seeking to establish production capabilities with scalable machinery.

7. Educational Institutions and Training Centers:

– Vocational schools and educational institutions that purchase brush making machines for training purposes in manufacturing techniques.

8. Exporters and Trading Companies:

– These entities purchase brush making machines to resell in international markets or to meet the needs of overseas clients.

Understanding these buyer types helps manufacturers and sellers of brush making machines tailor their marketing and sales strategies to meet the unique needs and operational scales of each category.

List “brush making machine” Project Types for Different Industries

Sure, here is a list of brush-making machine project types for different industries:

1. Household Cleaning Brushes:

– Broom Making Machines: For large-scale production of various broom types.

– Toilet Brush Manufacturing Machines: Specialized for producing durable and hygienic toilet brushes.

– Scrubber Brush Machines: Ideal for making brushes used for scrubbing floors, tiles, and surfaces.

2. Personal Care Brushes:

– Toothbrush Manufacturing Machines: For the mass production of manual toothbrushes.

– Hairbrush Production Machines: Used for creating a variety of hairbrushes with different bristle configurations.

– Cosmetic Brush Making Machines: Precision machines for making makeup brushes and applicators.

3. Industrial Brushes:

– Roller Brush Making Machines: Utilized in the production of brushes used in machinery, conveyors, and printing presses.

– Abrasive Brush Machines: For manufacturing abrasive brushes used in metalworking and carpentry for polishing, grinding, and deburring.

– Strip Brush Machines: Used to produce strip brushes that are often used in sealing, sweeping, and conveyor belt cleaning.

4. Automotive Brushes:

– Car Wash Brush Machines: Equipment for producing brushes used in automatic car wash systems.

– Engine Cleaning Brush Machines: Specialized for making brushes used in cleaning engine compartments and parts.

5. Agricultural Brushes:

– Milking Brush Machines: For the production of milking equipment brushes used in dairy farms.

– Crop Cleaning Brush Machines: These machines produce brushes used in cleaning harvested crops.

6. Medical and Lab Brushes:

– Surgical Cleaning Brush Machines: For making brushes that ensure sterilization and cleanliness of surgical instruments.

– Lab Test Tube Brush Machines: Used to produce small, specialized brushes for cleaning test tubes and laboratory glassware.

7. Pet Care Brushes:

– Pet Grooming Brush Machines: For creating brushes used in grooming pets, such as dogs and cats.

– Equestrian Brush Machines: Equipment specialized for making horse grooming brushes.

This structured overview comprehensively covers the variety of brush-making machines tailored for different industrial needs, ensuring efficient and specialized production processes across all sectors.

brush making machine Accessories Upgrades and Custom Manufacturing Options

Brush making machines are crucial for the efficient production of various types of brushes used in multiple industries. To enhance the performance and versatility of these machines, several accessories, upgrades, and custom manufacturing options are available:

1. Advanced Control Systems: Upgrading to state-of-the-art control panels can offer better precision, automated monitoring, and ease of use. These systems often come with touchscreens and can be integrated with existing manufacturing processes for seamless operation.

2. High-Speed Motors: Installing high-speed motors can significantly boost production rates. These motors are designed for durability and consistent performance under high-stress conditions.

3. Interchangeable Tooling: Customizable tooling options allow for quick changeovers between different brush types, reducing downtime and increasing productivity. Tooling can be tailored to specific manufacturing needs, such as different bristle materials or brush sizes.

4. Robotic Automation: Introducing robotic arms for tasks such as material handling, trimming, or packaging can streamline production and reduce labor costs. These robots can be programmed for high precision and repeatability.

5. Specialized Feeding Systems: Custom feeding systems can handle a variety of raw materials, including synthetic fibers, animal hair, or wire. These feeders ensure consistent material supply and reduce waste.

6. Quality Control Integration: Automated quality control systems, including vision systems and laser measurement tools, can be integrated into the production line to ensure each brush meets stringent quality standards.

7. Energy-Efficient Components: Upgrading to energy-efficient motors, drives, and lighting can reduce operational costs and contribute to sustainability goals.

8. Custom Machine Design: For specialized brush applications, custom machine designs can be developed. These designs consider factors such as space constraints, specific production requirements, and integrate seamlessly into existing workflows.

By opting for these accessories, upgrades, and custom manufacturing solutions, businesses can significantly enhance the efficiency, quality, and versatility of their brush making operations, leading to increased profitability and market competitiveness.

List Quality Control and The Manufacturing Process of “brush making machine”

Quality Control and Manufacturing Process of a Brush Making Machine

Manufacturing Process:

1. Design and Planning: Engineers design the brush making machine based on desired specifications and customer needs. CAD tools are used for precision.

2. Material Selection: High-quality materials like steel, aluminum, and specialized polymers are selected for durability and performance.

3. Component Manufacturing: Parts are fabricated using processes such as CNC machining, laser cutting, and injection molding. Precision is key to ensure all parts fit and function correctly.

4. Assembly: Skilled technicians assemble the machine, carefully fitting components together. Each part is checked for compatibility and proper alignment.

5. Electrical and Software Integration: Electrical systems and software controls are installed. Wiring, sensors, and control units are integrated for automated operation.

6. Testing and Calibration: The entire machine is tested for functionality. Calibration ensures the machine meets the exact specifications for brush production.

7. Quality Check: A final quality check is conducted before packaging. This includes operational tests to confirm the machine can produce brushes to the required standards.

Quality Control:

1. Incoming Material Inspection: All raw materials and components undergo rigorous inspection for defects and compliance with specifications.

2. In-Process Inspections: During manufacturing, periodic checks are performed to ensure components meet design specifications and quality standards.

3. Dimensional Accuracy: Precision measuring tools such as calipers, micrometers, and coordinate measuring machines (CMM) are used to maintain dimensional accuracy.

4. Performance Testing: The machine’s performance is tested through trial runs. This includes checking for operating speed, consistency, and defect rates in brush production.

5. Software Validation: Software controls are tested to ensure they function as intended. This includes debugging and validation of automated processes.

6. Final Quality Audit: A comprehensive audit is performed before shipment. This includes verifying assembly, electrical systems, and overall machine performance.

7. Documentation and Certification: Detailed documentation is maintained, including inspection reports, calibration certificates, and compliance with industry standards.

By adhering to a stringent manufacturing process and quality control measures, the reliability and efficiency of the brush making machine are ensured, meeting both customer and industry standards.

How to use “brush making machine”

Using a brush making machine involves several steps to ensure efficient and high-quality production. Here’s a simplified guide:

Preparation:

1. Read the Manual: Always start by reading the manufacturer’s manual to understand specific machine features and safety guidelines.

2. Materials: Gather all necessary materials, such as bristles, handles, wires, or adhesives.

Machine Setup:

1. Power On: Switch on the machine and ensure it is properly calibrated and aligned.

2. Load Materials: Place the bristle material into the designated area of the machine.

3. Adjust Settings: Depending on the type of brush, adjust the machine settings for bristle length, density, and distribution.

Production Process:

1. Feed Material: The machine will typically have an automated feeding mechanism that directs the bristles to the handle.

2. Assembly: The machine will insert, trim, and secure the bristles into the handle using wire or adhesive.

3. Quality Check: Monitor the process to ensure that each brush meets quality standards. Make adjustments as needed.

Post-Production:

1. Inspect and Test: Conduct a visual inspection and functional test on a sample batch of brushes.

2. Package: Once satisfied with the quality, package the brushes for distribution.

Maintenance:

1. Clean the Machine: Regularly clean and lubricate the machine to prevent malfunctions.

2. Parts Check: Periodically check for worn-out parts and replace them as necessary.

Safety:

1. Protective Gear: Always wear protective gear such as gloves and goggles.

2. Emergency Stop: Familiarize yourself with the emergency stop button and ensure it’s accessible.

By following these steps, you can efficiently use a brush making machine to produce a variety of brushes while maintaining safety and quality.

“brush making machine” Comparative Analysis

When evaluating brush-making machines, several factors come into play, including technology, efficiency, versatility, and cost. Here’s a comparative analysis of some leading brush-making machines:

1. Technology:

– Mechanical Machines: Traditional mechanical brush-making machines are known for their robustness and reliability. However, they lack the flexibility and precision of modern systems.

– CNC Machines: Computer Numerical Control (CNC) brush-making machines offer high precision and automation, making them ideal for producing complex brush designs with minimal human intervention.

2. Efficiency:

– Manual Machines: These machines are labor-intensive and have lower production speeds. They are best suited for small-scale production or specialized brushes.

– Automated Machines: Fully automated brush-making machines significantly enhance production speed and consistency, making them ideal for high-volume manufacturing.

3. Versatility:

– Single-Type Machines: Some machines are optimized for a specific type of brush (e.g., toothbrushes, paintbrushes) and excel in that niche but lack flexibility.

– Multi-Function Machines: Advanced models offer interchangeable parts and multi-functional capabilities, allowing manufacturers to produce a wide variety of brushes with a single machine.

4. Cost:

– Initial Investment: CNC and fully automated machines require a higher upfront investment but provide long-term savings through efficiency and reduced labor costs.

– Operational Costs: Manual and mechanical machines might have lower maintenance costs but result in higher labor expenses over time.

Comparative Example:

– CNC Brush Making Machine: Offers precision, high speed, and multi-functionality. Ideal for large manufacturers looking for versatility and efficiency. Higher initial costs are offset by operational efficiency and reduced labor.

– Mechanical Brush Making Machine: Budget-friendly upfront, suitable for simple brush designs and lower production volumes. Requires more manual intervention and has higher long-term labor costs.

Conclusion:

Selecting the right brush-making machine depends on production needs, budget, and desired product flexibility. While mechanical machines are suitable for smaller or more straightforward operations, CNC and automated machines are ideal for high-volume, diverse, and intricate brush manufacturing.

“brush making machine” Warranty and Support

When investing in a brush making machine, understanding the warranty and support offered by the manufacturer is crucial to ensuring long-term productivity and reliability. Typically, these machines come with a manufacturer’s warranty ranging from one to three years, covering defects in materials and workmanship. It is essential to review the warranty details to understand what is included and any conditions that may void coverage.

Many manufacturers offer extended warranties for an additional fee, providing peace of mind and financial protection against unexpected repair costs. Standard warranties often cover the replacement of faulty parts and repair services. However, consumable parts like brushes, belts, and sensors might not be included. Ensure you have clarity on what exactly is covered under the warranty terms.

Support is another critical aspect, as effective after-sales service can significantly impact your machine’s performance and lifespan. Most reputable manufacturers offer comprehensive support, including technical assistance, troubleshooting guides, and maintenance tips. This support can be available through various channels, such as phone, email, or online chat, ensuring you get timely help when needed.

Having access to a dedicated customer service team or your account manager can be immensely beneficial. Some companies also offer on-site support visits for installation and training, helping your team become proficient in operating and maintaining the machine.

In addition, look for manufacturers that provide easy access to spare parts and have a robust supply chain ensuring quick delivery. Joining user forums and manufacturer-sponsored communities can also be valuable, offering user-shared tips and solutions to common issues. Remember, a well-supported machine is a reliable machine, so prioritize manufacturers known for their strong warranty policies and exceptional customer service.

List “brush making machine” FAQ

Sure, here are some frequently asked questions (FAQ) about brush making machines in under 300 words:

1. What is a brush making machine?

– A brush making machine is a specialized piece of equipment designed for manufacturing various types of brushes, including toothbrushes, brooms, paintbrushes, and industrial brushes.

2. What types of brushes can it produce?

– Depending on the machine, it can produce household brushes, industrial brushes, artistic paintbrushes, brooms, and personal care brushes like toothbrushes.

3. How does a brush making machine work?

– Typically, these machines operate by automating the process of drilling holes into the brush base and inserting bristles, often using a combination of CNC (Computer Numerical Control) technology and manual adjustments.

4. What materials can be used in brush making machines?

– Common materials include synthetic fibers (like nylon and polyester), natural fibers (like animal hair and plant bristles), and various handle materials (plastics, wood, or metal).

5. Are these machines customizable?

– Yes, many manufacturers offer customization options to suit specific brush types, sizes, and production volumes.

6. What is the production capacity?

– Production capacity varies based on the machine model and specifications but can range from a few hundred to thousands of brushes per hour.

7. Is training required to operate these machines?

– Yes, operators typically require training to understand machine functions, maintenance, and troubleshooting procedures.

8. What are the maintenance requirements?

– Regular maintenance includes cleaning, lubricating moving parts, replacing worn components, and software updates if applicable.

9. How much does a brush making machine cost?

– Costs vary widely based on machine capabilities, ranging from a few thousand to several hundred thousand dollars.

10. Where can I purchase one?

– Brush making machines can be purchased from specialized manufacturers and distributors, available both online and through industry trade shows.

This summary should give you a good overview of brush making machines and address some common questions about their operation, capabilities, and requirements.

Top 10 FAQ with answer about brush making machine for Buyer Sourcing from China

Certainly! Here are the top 10 frequently asked questions (FAQ) about sourcing brush making machines from China for buyers:

1. What types of brush making machines are available?

– Various machines are available including those for toothbrushes, paintbrushes, industrial brushes, and cosmetic brushes. Each type has specific models catering to different production needs.

2. What are the key features to look for in a brush making machine?

– Look for reliability, production speed, ease of maintenance, precision, versatility, and automation level. Ensure the machine meets your specific brush type and production volume requirements.

3. How do I verify the quality of the machine before purchasing?

– Request detailed specifications, certifications (e.g., CE, ISO), and references from previous clients. It’s beneficial to visit the factory for an on-site inspection or request a virtual tour.

4. What is the typical lead time for delivery?

– Lead times can vary depending on the manufacturer’s schedule and customization needs. It generally ranges from 30 to 90 days.

5. Are warranties and after-sales support available?

– Most reputable manufacturers offer warranties ranging from one to three years. Ensure they also provide robust after-sales support, including spare parts, technical training, and maintenance services.

6. What is the cost range for brush making machines?

– Prices can vary significantly based on features and capabilities. Entry-level machines might start around $10,000, while advanced models with high automation can exceed $100,000.

7. How do I handle machine installation and operator training?

– Many suppliers offer on-site installation and training as part of their service package. Some may provide remote assistance or detailed instructional materials.

8. What shipping methods are available and how should I handle logistics?

– Machines can be shipped via sea or air freight. It’s often cost-effective to use sea freight for heavy and bulky machinery. Utilize reputable freight forwarders to manage logistics and customs clearance.

9. Can the machine be customized to specific requirements?

– Yes, many manufacturers offer customization options to meet unique production needs, including adjustments in machine design, software modifications, and additional functionalities.

10. How do I handle payments securely?

– Use secure payment methods like Letters of Credit (L/C) or Trade Assurance services provided by platforms such as Alibaba. This helps protect your financial transactions and ensures compliance with the agreement terms.

Understanding these FAQs will help buyers make well-informed decisions when sourcing brush making machines from China.