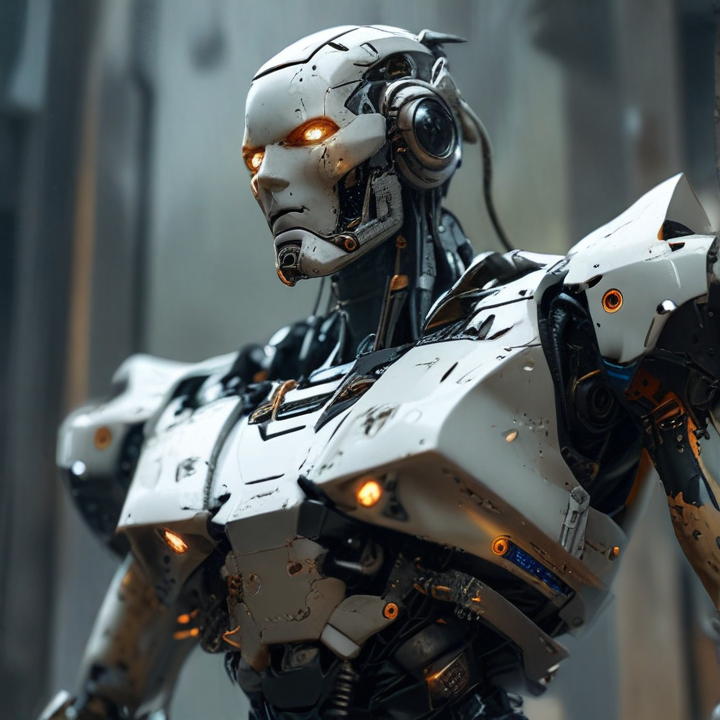

elite robotic Safety Certifications

Obtaining elite robotic safety certifications is critical for ensuring the safe operation, maintenance, and integration of robotic systems in various industries. Here are some of the most recognized certifications:

1. ISO 10218-1 and ISO 10218-2:

– ISO 10218-1: Outlines the safety requirements for the design and manufacturing of industrial robots.

– ISO 10218-2: Focuses on the integration of robots into industrial applications, covering installation, operation, and maintenance safety requirements.

2. R15.06 (Robotic Industries Association – RIA):

– Based on ISO 10218 standards, this certification provides detailed guidelines for the safe design, application, installation, and use of industrial robots and robot systems.

3. ISO/TS 15066:

– A technical specification that provides guidelines for collaborative robot safety, defining limits on speed, force, and other factors to minimize risks when humans work in close proximity to robots.

4. CE Marking:

– Required for robots used in the European Economic Area (EEA), ensuring compliance with all relevant EU safety, health, and environmental protection standards.

5. ANSI/RIA R15.08:

– For mobile robotic systems, detailing safety requirements for the autonomous operation of industrial mobile robots.

6. UL 1740:

– A standard developed by Underwriters Laboratories for the safety of robotic equipment, focusing on electrical systems, controls, and protection against mechanical hazards.

These certifications ensure that robotic systems are designed, built, and implemented following stringent safety guidelines to protect workers and enhance operational efficiency. It’s essential for manufacturers, integrators, and users to adhere to these standards to minimize risks and foster a safe working environment.

List Reference Technical Parameters of “elite robotic”

Elite Robotic is a leading robotics brand known for its advanced technological solutions. Here are the key reference technical parameters that define Elite Robotic systems:

1. Payload Capacity: Varies across models, typically ranging from 5 kg to 300 kg, accommodating industries from electronics to heavy manufacturing.

2. Degrees of Freedom (DOF): Most models offer 6 DOF, ensuring versatile movement and intricate operations.

3. Repeatability: High precision with repeatability within ±0.01 mm to ±0.05 mm, essential for tasks requiring exact replication.

4. Reach: Arm length varies by model, generally from 500 mm to 3000 mm, suited for various spatial requirements.

5. Speed: Maximum joint speed ranges between 60°/sec to 300°/sec, depending on robot size and application.

6. Control System: Utilizes advanced control algorithms for motion planning, often featuring real-time trajectory adjustments.

7. Power Consumption: Models are designed to be energy-efficient, with typical power consumption ranging from 1 kW to 10 kW.

8. Interface: Compatible with major industrial protocols including EtherCAT, PROFINET, and Modbus, facilitating seamless integration.

9. Safety Features: Includes safety-rated motion, collision detection, and compliance with ISO 10218 standards for robotic safety.

10. Programming Environment: Supports multiple programming languages (e.g., Python, C++, proprietary languages) and features user-friendly GUIs to simplify complex tasks.

11. Environmental Tolerance: Designed to operate in a wide range of environmental conditions, including cleanrooms (ISO Class 3) and harsh manufacturing settings (IP67-rated).

12. End-Effector Compatibility: Compatible with a variety of end-effectors, including grippers, welders, and vision systems, enhancing functional versatility.

13. Sensor Integration: Equipped with integrated vision systems and force sensors for adaptive operations and quality control.

14. Network Capability: Supports IoT-based remote monitoring and diagnostics for predictive maintenance.

Elite Robotic continues to innovate, delivering efficient, reliable, and adaptable robotic solutions across various industries.

List Product features of “elite robotic”

Elite Robotic is a cutting-edge automation solution designed to streamline operations and enhance productivity across various industries. Here are its key product features:

1. High Precision and Accuracy: Elite Robotic boasts advanced sensors and algorithms that ensure precise movements and accurate task execution, minimizing errors and improving efficiency.

2. Flexibility and Adaptability: The robot can be programmed for a wide range of tasks and is adaptable to different environments, making it suitable for various industrial applications, from manufacturing to logistics.

3. Intuitive User Interface: The easy-to-use interface allows operators to program and control the robot with minimal technical knowledge, reducing training time and increasing usability.

4. AI and Machine Learning Integration: With built-in AI and machine learning capabilities, Elite Robotic continuously learns and optimizes its performance, enhancing productivity and operational efficiency over time.

5. Durability and Reliability: Constructed with high-quality materials, Elite Robotic is designed to withstand harsh industrial environments, ensuring long-term durability and consistent performance.

6. Safety Features: Equipped with multiple safety sensors and emergency stop functions, the robot provides a safe working environment, reducing the risk of accidents and injuries.

7. Energy Efficiency: Elite Robotic is engineered to be energy-efficient, reducing operational costs and minimizing environmental impact.

8. Scalability: As your business grows, Elite Robotic can easily scale up to meet increased demand, ensuring continuous productivity without significant additional investment.

9. Remote Monitoring and Control: The robot can be monitored and controlled remotely via a secure network, allowing for real-time adjustments and troubleshooting from anywhere.

10. Collaborative Functionality: Designed to work alongside human operators, Elite Robotic supports collaborative operations, enhancing overall workforce efficiency.

11. Maintenance and Support: Comes with robust customer support and easy maintenance procedures to ensure minimal downtime and seamless operation.

Overall, Elite Robotic is a versatile and powerful tool designed to drive innovation and efficiency in various industrial settings.

List Various Types of “elite robotic”

Certainly! Here are various types of elite robots across different fields, highlighting their advanced capabilities:

1. Humanoid Robots:

– Sophia: A social robot by Hanson Robotics, Sophia can engage in human-like conversation and facial expressions.

– Atlas: Developed by Boston Dynamics, Atlas excels in tasks requiring dynamic motion, such as running, jumping, and even parkour.

2. Industrial Robots:

– KUKA KR Quantec: Known for its strength and precision in manufacturing, handling heavy materials with high efficiency.

– FANUC M-2000iA: Renowned for its ability to handle extreme payloads, this robot is used in automotive and heavy industries.

3. Medical Robots:

– Da Vinci Surgical System: Allows surgeons to perform minimally invasive operations with enhanced precision and control.

– CyberKnife: A robotic system for radio-surgery, used for treating tumors with high precision.

4. Military Robots:

– BigDog: A quadruped robot from Boston Dynamics, designed to transport heavy loads across rough terrains.

– SWORDS: A weaponized robot system for battlefield use, providing remote-control capabilities for dangerous tasks.

5. Exploration Robots:

– Curiosity Rover: A Mars rover designed by NASA to explore the Martian surface, equipped with advanced scientific instruments.

– PELAsBot: An autonomous underwater vehicle developed for deep-sea exploration and research.

6. Service Robots:

– Jibo: An interactive, social robot for home use, offering assistance and companionship.

– Pepper: By SoftBank Robotics, this humanoid robot interacts with customers in retail settings, answering questions and providing entertainment.

7. Agricultural Robots:

– Ecorobotix: An autonomous weeding robot that reduces the need for chemical herbicides.

– See & Spray: By Blue River Technology, this robot uses computer vision to identify and treat individual plants in agricultural fields.

These elite robots represent the forefront of robotic technology, each tailored to excel in its specific domain through advanced AI, precise engineering, and innovative design.

List Application of “elite robotic”

Elite robotics refers to high-performance, advanced robots designed for specialized tasks across various fields. Here are some key applications:

1. Medical Surgeries: Elite robots assist in performing intricate surgical procedures with precision and minimal invasiveness, leading to reduced recovery times and improved patient outcomes.

2. Automated Manufacturing: These robots are used in high-end manufacturing processes for tasks requiring high precision and efficiency, such as assembling microelectronics and automotive components.

3. Space Exploration: Advanced robots conduct exploratory missions, handle spacecraft repairs, and collect data from environments that are extreme for human astronauts.

4. Military and Defense: Elite robots perform reconnaissance, bomb disposal, and other high-risk tasks, enhancing safety and operational efficiency.

5. Search and Rescue: These robots operate in disaster zones to locate and aid victims, navigating through debris and hazardous conditions that are difficult for human rescuers.

6. Agriculture: Precision farming utilizes advanced robots for planting, monitoring crop health, and harvesting, leading to increased productivity and sustainability.

7. Oil and Gas: Robotics in this field perform inspections, maintenance, and repairs of offshore rigs and subsea installations, improving safety and reducing downtime.

8. Logistics and Warehousing: Elite robots automate warehouse management, including sorting, packing, and transporting goods, which streamlines operations and reduces costs.

9. Robots in Education: These cutting-edge robotic platforms facilitate learning in STEM subjects, providing hands-on experiences that enhance students’ understanding and interest.

10. Entertainment and Leisure: Advanced robots are also a part of interactive exhibits, theme parks, and even performances, adding a futuristic and engaging element.

These applications demonstrate how elite robotics contributes to various sectors by enhancing efficiency, precision, and safety while driving innovation and technological advancement.

List Buyer Types of “elite robotic”

Sure, let’s explore the different types of buyers for “Elite Robotic,” a hypothetical company that specializes in high-end robotics technology. Here are the primary buyer types:

1. Industrial Manufacturers

Description: These are large-scale manufacturers that incorporate advanced robotics to enhance productivity, precision, and safety in their operations.

Needs: Efficiency, scalability, and integration with existing systems.

2. Healthcare Institutions

Description: Hospitals and medical research facilities that use robotics for surgeries, diagnostics, and patient care.

Needs: Reliability, precision, and regulatory compliance.

3. Educational Institutions

Description: Universities and technical colleges that offer courses in robotics, engineering, and AI.

Needs: Versatile platforms for research and teaching, ease of use, and robust support.

4. Defense Sector

Description: Military and defense organizations seeking robotics for surveillance, logistics, and combat.

Needs: Durability, advanced capabilities, and security features.

5. Tech Startups

Description: Emerging companies focusing on innovative applications of robotics.

Needs: Cutting-edge technology, agility in customization, and competitive pricing.

6. Entertainment and Service Industries

Description: Companies in sectors like gaming, theme parks, and hospitality that deploy robots for attractions, customer service, and maintenance.

Needs: Interactivity, reliability, and user-friendliness.

7. Consumers

Description: High-net-worth individuals and tech enthusiasts investing in robotics for personal use, such as home automation, entertainment, or hobby projects.

Needs: User experience, ease of use, and aesthetic design.

8. Agricultural Enterprises

Description: Farming companies that use robotics for tasks like harvesting, planting, and monitoring crops.

Needs: Durability, efficiency, and integration with other agricultural technologies.

9. Retail and Logistics Companies

Description: Businesses that use robotics to optimize warehousing, inventory management, and delivery services.

Needs: Efficiency, reliability, and scalability.

Each buyer type has unique requirements and priorities, which Elite Robotic must understand and address to successfully market their advanced robotic solutions.

List “elite robotic” Project Types for Different Industries

Elite Robotic Projects Across Different Industries

1. Manufacturing:

– Robotic Assembly Lines: Automated systems capable of assembling complex products with precision and speed.

– Quality Assurance Robots: Vision systems integrated with AI to detect defects in real-time.

– Collaborative Robots (Cobots): Robots working alongside human operators to enhance productivity and safety.

2. Healthcare:

– Surgical Robots: Precision instruments controlled by surgeons for minimally invasive procedures.

– Robotic Rehabilitation Devices: Machines that aid in physical therapy and rehabilitation movements.

– Telepresence Robots: Robots enabling remote consultations and monitoring patient conditions.

3. Agriculture:

– Autonomous Harvesting Robots: Robots using AI and machine vision to pick crops efficiently.

– Robotic Milking Systems: Automated units for milking cows, increasing yield and efficiency.

– Agricultural Drones: UAVs used for field analysis, crop health monitoring, and precision spraying.

4. Logistics and Warehousing:

– Automated Guided Vehicles (AGVs): Self-driving vehicles for transporting goods within facilities.

– Robotic Sortation Systems: High-speed sorting solutions for handling parcels and packages.

– Inventory Management Robots: Robots equipped with RFID and sensors for real-time inventory tracking.

5. Automotive:

– Autonomous Vehicles: Self-driving cars leveraging AI, sensors, and connectivity for navigation.

– Robotic Painting Systems: Robots providing consistent and high-quality automotive paint jobs.

– Crash Testing Robots: Machines designed to replicate human responses in simulated crash conditions.

6. Construction:

– 3D Printing Robots: Machines capable of constructing building elements layer by layer.

– Demolition Robots: Remote-controlled units for safely demolishing structures.

– Robotic Surveyors: Autonomous systems for creating detailed site maps and conducting inspections.

7. Retail:

– Robotic Customer Service Assistants: AI-driven robots providing assistance and information to shoppers.

– Automated Checkout Systems: Robotic solutions facilitating quicker and more efficient checkouts.

– Stock Management Robots: Systems monitoring stock levels and restocking shelves autonomously.

8. Hospitality:

– Room Service Robots: Autonomous units delivering items to hotel guests.

– Cleaning Robots: Automated systems maintaining cleanliness in public spaces.

– Concierge Robots: AI-driven robots providing directions and recommendations to guests.

9. Defense:

– Unmanned Systems (Drones/UGVs): Robots used for reconnaissance, surveillance, and logistical support.

– Explosive Ordnance Disposal (EOD) Robots: Machines designed to safely disarm explosives.

– Robotic Soldiers: Autonomous units designed for various combat and support roles.

Conclusion

Innovative robotic projects are revolutionizing various industries by enhancing efficiency, safety, and service quality. From manufacturing to defense, the applications of robotics continue to expand, offering unique solutions tailored to each sector’s specific needs.

elite robotic Accessories Upgrades and Custom Manufacturing Options

Elite Robotic Accessories offers cutting-edge upgrades and custom manufacturing options tailored for diverse industrial applications. Our product line encompasses high-precision end-effectors, advanced sensor integration, and robust mobility enhancements, ensuring your robots perform tasks with unmatched accuracy and efficiency.

Upgrades:

1. Advanced End-Effectors: Upgrade your robots with versatile grippers, welders, and precision tools designed for tasks ranging from delicate assembly to heavy-duty material handling.

2. Enhanced Sensors: Improve your robots’ situational awareness with state-of-the-art cameras, LiDAR, and ultrasonic sensors for superior object detection and obstacle avoidance.

3. Power Management: Maximize uptime with high-capacity batteries and intelligent charging systems that ensure sustained operation in demanding environments.

4. Control Systems: Integrate AI-driven control units and haptic feedback systems to enable more intuitive and precise robot operations.

Custom Manufacturing:

1. Tailored Designs: Collaborate with our engineering team to develop custom components and modules that perfectly fit your unique specifications and operational needs.

2. Material Selection: Choose from an array of high-quality materials, including lightweight alloys, high-strength composites, and corrosion-resistant coatings, to enhance durability and performance.

3. Precision Fabrication: Leverage our state-of-the-art manufacturing facilities equipped with CNC machining, 3D printing, and laser cutting technologies to achieve impeccable accuracy and quality.

4. Rapid Prototyping: Benefit from expedited prototyping services that allow for quick iteration and testing, ensuring a seamless transition from concept to final product.

Elite Robotic Accessories is committed to advancing robotic capabilities through innovative upgrades and bespoke manufacturing solutions. Our expertise and cutting-edge technology ensure your robotic systems achieve exceptional performance, reliability, and adaptability in any industrial setting.

List Quality Control and The Manufacturing Process of “elite robotic”

Quality Control and Manufacturing Process of “Elite Robotic”

1. Design and Development:

– Conceptualization: Involves brainstorming and conceptualizing designs based on market needs.

– Prototyping: Initial designs are converted into prototypes for functional testing.

– Simulation and Testing: Prototypes undergo virtual simulations to ensure operational efficiency and safety.

2. Material Sourcing:

– Supplier Selection: High-quality materials are sourced from certified suppliers.

– Inspection and Validation: Raw materials are inspected upon arrival for compliance with quality standards.

3. Manufacturing:

– Precision Machining: Utilizes CNC machines for high-precision component manufacturing.

– Assembly Line: Components are assembled in a controlled environment to ensure precision.

– Wiring and Electronics: Installation of wiring and electronic components with thorough checks for proper alignment.

4. Quality Control Measures:

– In-Process Inspections: Continuous inspection during various manufacturing stages to detect and address issues early.

– Functional Testing: Assembled robots undergo rigorous operational testing to assess performance.

– Calibration: Precision instruments are used to calibrate sensors and actuators.

– Software Integrity: Verification of software systems to ensure reliability and effectiveness.

5. Final Inspection and Testing:

– Performance Validation: Final products are subjected to endurance and performance tests under simulated real-world conditions.

– Safety Checks: Comprehensive safety checks to ensure compliance with industry standards.

– Quality Assurance Approval: Final approval from the quality assurance team after meeting all specifications and standards.

6. Packaging and Shipping:

– Protective Packaging: Products are packaged using materials that ensure protection during transit.

– Logistics and Distribution: Managed through reliable logistics to ensure timely delivery without damage.

7. Customer Feedback and Continuous Improvement:

– Feedback Loop: Gathering customer feedback to identify areas of improvement.

– Iterative Development: Continual refinement of designs and processes based on feedback and technological advancements.

By adhering to these meticulous processes, Elite Robotic ensures the production of high-quality, reliable, and efficient robots that meet and exceed customer expectations.

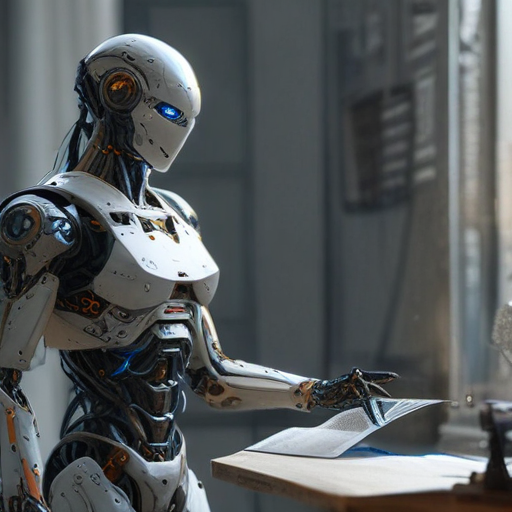

How to use “elite robotic”

“Elite robotic” generally refers to high-quality, advanced robotic systems or technologies that are superior in terms of performance, functionality, and innovation. Using “elite robotic” in a sentence or context depends on the subject matter. Here’s a concise guide on how to incorporate the term effectively:

1. Contextual Introduction:

– Start by establishing the topic or industry where elite robotic systems are relevant, such as manufacturing, healthcare, or research.

2. Definition or Description:

– Briefly describe what makes these robotic systems “elite.” Mention their advanced capabilities, precision, high performance, or innovative technologies.

3. Application:

– Illustrate how these elite robotic systems are used in the specific industry or field. Highlight their impact or benefits, such as increased efficiency, accuracy, or cost savings.

4. Real-World Example:

– Provide a specific example or case study where elite robotic systems have been successfully implemented.

Example Paragraph:

In the field of modern medicine, *elite robotic* systems have revolutionized surgical procedures. These advanced technologies, characterized by their unmatched precision and reliability, enable surgeons to perform minimally invasive operations with greater accuracy than ever before. For instance, the Da Vinci Surgical System is an elite robotic tool that offers surgeons enhanced dexterity and control, significantly reducing patient recovery times and surgical risks. This elite robotic innovation is not just limited to surgery; it’s also being employed in rehabilitation, where robots assist patients in regaining mobility through tailored, precise movements that adjust in real-time to patient feedback. By integrating elite robotic systems into healthcare, we are witnessing a transformative leap towards more effective and efficient medical treatments.

In this paragraph, “elite robotic” is effectively defined, contextualized, and exemplified within a specific field, highlighting its advantages and applications.

“elite robotic” Comparative Analysis

“Elite robotic” typically denotes advanced, high-performance robotic systems used in diverse industries, including manufacturing, healthcare, defense, and space exploration. These robots are distinguished by their cutting-edge technology, superior functionality, and high efficiency. In a comparative analysis, several critical factors distinguish elite robotics from standard robotic systems:

1. Technology and Innovation:

– Elite Robots: Utilize state-of-the-art technologies like AI, machine learning, advanced sensors, and real-time data processing. Examples include autonomous vehicles, surgical robots, and humanoid robots like Boston Dynamics’ Atlas.

– Standard Robots: Employ basic automation and limited AI, primarily used for repetitive tasks in controlled environments, like assembly line robots.

2. Performance and Precision:

– Elite Robots: Possess high levels of accuracy, speed, and adaptability. Surgical robots, for instance, perform precise movements that surpass human capabilities.

– Standard Robots: Offer reliable but less precise performances, appropriate for tasks where ultra-high accuracy is not critical.

3. Adaptability and Learning:

– Elite Robots: Can learn from experiences and adapt to new tasks without human intervention, increasing versatility. Autonomous drones used in surveillance and agriculture exemplify this.

– Standard Robots: Typically need reprogramming for new tasks, with limited adaptability.

4. Cost and Accessibility:

– Elite Robots: High development and operational costs, making them accessible to larger enterprises and specialized sectors. NASA’s Mars rovers are illustrative of high-budget, expansive projects.

– Standard Robots: More affordable, widely used in small to medium-sized businesses for cost-effective automation.

5. Application Domain:

– Elite Robots: Serve in high-stakes, precision-demanding fields like space missions, advanced healthcare, and defense. Examples include surgical robots like the da Vinci system and exploration robots like Curiosity Rover.

– Standard Robots: Predominantly used in industrial automation, material handling, and simple human assistance tasks like cleaning robots.

In summary, elite robotic systems are characterized by their advanced technology, superior performance, high adaptability, and specialized applications, whereas standard robots cater to more routine, cost-effective automation needs.

“elite robotic” Warranty and Support

At Elite Robotic, we prioritize your satisfaction and ensure that our products meet the highest standards of quality and reliability. Our comprehensive warranty and support services are designed to give you peace of mind and maximize the value of your investment.

Warranty

Elite Robotic offers a standard one-year limited warranty on all of our products, covering defects in materials and workmanship. This warranty ensures that any malfunction or defect under normal use conditions will be repaired or replaced at no cost to you. For detailed terms and conditions, please refer to your warranty documentation included with your purchase.

Extended Warranty Options

For additional peace of mind, we offer extended warranty plans that can be purchased at the time of sale or within 90 days of purchase. These plans extend the coverage period beyond the standard one year and may include additional benefits such as priority support and faster turnaround times for repairs.

Support

We understand that having reliable support is crucial for the uninterrupted operation of your robotic systems. Elite Robotic provides a variety of support options:

1. Customer Service Hotline: Our dedicated customer service team is available 24/7 to assist you with any questions or issues. You can reach us at (XXX) XXX-XXXX.

2. Email Support: For less urgent inquiries, you can contact us via email at support@eliterobotic.com, and our team will respond within one business day.

3. Online Resources: Our website features a comprehensive support section with user manuals, troubleshooting guides, and instructional videos to help you resolve common issues on your own.

4. On-Site Support: For critical situations that require immediate attention, we offer on-site support services where our skilled technicians can visit your location to diagnose and resolve issues.

At Elite Robotic, we are committed to providing exceptional customer service and support to ensure your complete satisfaction with our products.

List “elite robotic” FAQ

Elite Robotic: Frequently Asked Questions (FAQ)

1. What services does Elite Robotic offer?

Elite Robotic provides advanced robotics solutions including design, manufacturing, integration, and maintenance of robotics systems for various industries such as manufacturing, logistics, healthcare, and service sectors.

2. Which industries do you specialize in?

We specialize in manufacturing, healthcare, logistics, automotive, agriculture, and service industries.

3. Can you customize robots to fit specific needs?

Absolutely. We offer custom solutions tailored to meet the unique requirements and challenges of your specific industry or application.

4. What types of robots do you provide?

We offer a wide range of robots including industrial robots, collaborative robots (cobots), mobile robots, service robots, and specialized robots for healthcare applications.

5. How can I get a quote for your services?

You can request a quote by visiting our website and filling out the contact form or by reaching out directly to our sales team via email or phone.

6. Do you offer post-installation support and maintenance?

Yes, we provide comprehensive post-installation support, including maintenance services, software updates, and troubleshooting.

7. What are the benefits of using your robotic solutions?

Our robotic solutions boost productivity, enhance efficiency, reduce operational costs, and improve safety by automating repetitive and hazardous tasks.

8. How do you ensure the quality of your robots?

We comply with international quality standards and conduct rigorous testing and quality control procedures to ensure our robots meet high levels of performance and reliability.

9. Is training provided for operating the robots?

Yes, we offer training programs for operators and maintenance staff to ensure smooth and efficient operation of our robotic systems.

10. How can I contact customer support?

You can reach our customer support team through the contact details provided on our website or through our dedicated support helpline.

For more information, please visit our website or contact our customer support team.

Top 10 FAQ with answer about elite robotic for Buyer Sourcing from China

Top 10 FAQs About Elite Robotics for Buyer Sourcing from China

1. What is Elite Robotics?

Elite Robotics is a manufacturer specialized in creating advanced and high-precision robotics used across various sectors like manufacturing, healthcare, and logistics.

2. Why should I source Elite Robotics from China?

China offers competitive pricing, a robust supply chain, advanced manufacturing techniques, and a wide talent pool in engineering and robotics.

3. How do I ensure the quality of Elite Robotics products?

Look for certifications such as ISO 9001, CE, and RoHS. Request sample products for testing, and consider hiring a third-party inspection service to verify quality.

4. Are Elite Robotics products customizable?

Yes, many Chinese manufacturers offer customization services to meet specific needs. Specify your requirements clearly during the initial discussions.

5. What is the typical lead time for an order?

Lead times can range from 4-12 weeks depending on the complexity of the order and the manufacturer’s production schedule. Always discuss this upfront.

6. Can I visit the manufacturing facility?

Most reputable manufacturers welcome factory visits. This helps build trust and allows you to inspect the facilities firsthand.

7. What are the payment terms?

Common payment terms include T/T (Telegraphic Transfer), L/C (Letter of Credit), and sometimes Escrow. Down payments of 30% are typical, with the balance paid before shipment.

8. How do I handle shipping and logistics?

Many manufacturers offer FOB (Free on Board) or CIF (Cost, Insurance, and Freight) terms, but it’s wise to engage a trusted freight forwarder to handle shipping.

9. What post-sale support is available?

Ensure the manufacturer offers technical support, spare parts, and a warranty. Service contracts can provide peace of mind.

10. How do I safeguard intellectual property?

Use Non-Disclosure Agreements (NDAs) and ensure IP terms are clear in the contract. Collaborate with well-established companies with good reputations to minimize risks.

These FAQs address critical aspects of sourcing Elite Robotics from China, providing a balance of quality assurance, logistical considerations, and protective measures for intellectual property.