two way ball valve Safety Certifications

Two-way ball valves are commonly used in various industries to control the flow of liquids and gases. Ensuring their safety and reliability is critical, and this is where safety certifications come into play. These certifications often serve as a benchmark for quality and compliance with industry standards.

1. ISO 9001:2015

This certification ensures that the manufacturing process of the two-way ball valve adheres to quality management principles. It emphasizes customer focus, process approach, and continuous improvement.

2. ANSI/ASME B16.34

The American National Standards Institute (ANSI) and the American Society of Mechanical Engineers (ASME) provide this certification to ensure valves are designed, manufactured, and tested according to stringent guidelines, particularly relevant to pressure-temperature ratings.

3. API 6D and API 607

The American Petroleum Institute (API) certifications focus on the safety and performance of valves used in pipeline transportation systems. API 6D pertains to general pipeline valves, while API 607 deals with fire testing of valves, ensuring they maintain integrity under extreme conditions.

4. PED CE Mark (EU Pressure Equipment Directive)

This certification is mandatory for valves used in the European Union. It ensures compliance with EU safety, health, and environmental requirements for pressure equipment.

5. SIL (Safety Integrity Level)

Issued as part of the IEC 61508 standards, SIL certification ensures that the valve meets specified safety functions in fail-safe conditions. Higher SIL ratings indicate higher levels of reliability and safety.

6. ATEX Certification

For valves used in explosive atmospheres, ATEX certification is crucial. It confirms that the ball valves can be safely operated in environments where potentially explosive gases or dust are present.

Conclusion

These certifications provide a comprehensive framework for ensuring the safety, reliability, and performance of two-way ball valves. Adhering to these standards can significantly mitigate risks and enhance overall operational efficiency.

List Reference Technical Parameters of “two way ball valve”

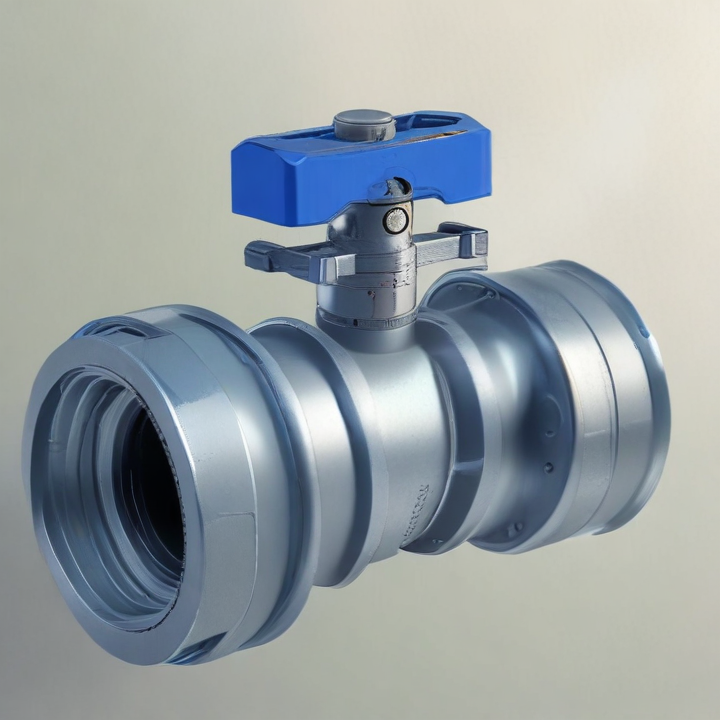

Two-way ball valves are fundamental components in fluid control systems, offering simplicity, reliability, and efficiency. Below are the key technical parameters for two-way ball valves:

1. Size Range: Typically ranges from 0.25 inches to several inches in diameter, depending on application needs.

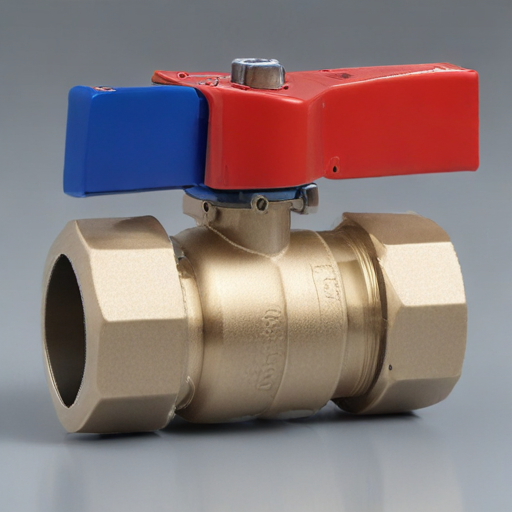

2. Material: Can be constructed from stainless steel, brass, PVC, CPVC, or other materials suitable for specific fluids and environments.

3. Pressure Rating: Varies but common ratings include 150 PSI, 300 PSI, and up to 1000 PSI or more for specialized applications.

4. Temperature Range: Operates effectively between -20°C and 200°C, subject to material compatibility.

5. Connection Types: Flanged, threaded (NPT or BSP), socket weld, butt weld, and compression fittings are available for diverse installation requirements.

6. Ball Design: Full port (bore) for minimal flow restriction, or reduced port for flow control applications.

7. Seat Material: Common materials include PTFE, Teflon, or other specialized elastomers to ensure a tight seal and durability.

8. Actuation Method: Manual (lever or gear-operated), pneumatic, electric, or hydraulic actuation options for remote or automated control.

9. Flow Coefficient (Cv): Specifies the valve’s capacity to allow flow, important for system design calculations; a typical value can range from 10 to over 200.

10. Leakage Class: ANSI/FCI standards such as Class VI (soft seats) ensure minimal permissible leakage.

11. Compliance and Standards: Often conforms to ASME, API, ISO, and ANSI standards for design, manufacturing, and testing.

12. Endurance: Rated for a substantial number of cycles, indicating longevity and wear resistance.

13. Corrosion Resistance: Depending on the material, offers varying degrees of resistance to corrosive media.

These parameters guide the selection and application of two-way ball valves in industries like water treatment, oil and gas, chemical processing, and HVAC systems. The exact specifications should always align with the application’s operational demands and environmental conditions.

List Product features of “two way ball valve”

A two-way ball valve is an essential component widely used in various industrial and plumbing applications. Here are the key features of a two-way ball valve:

1. Flow Control: Allows bi-directional flow, enabling fluid or gas to pass through in either direction.

2. Shut-off Capability: Provides excellent shut-off capabilities, ensuring a tight seal to prevent any leakage.

3. Simple Operation: Easy to operate, typically requiring a 90-degree turn to open or close the valve.

4. Durability: Constructed from robust materials such as stainless steel, brass, or PVC, offering long-term durability and resistance to corrosion.

5. Low Maintenance: Designed for minimal maintenance, often featuring self-cleaning capabilities to reduce the buildup of debris.

6. Pressure Ratings: Suitable for various pressure ranges, making them versatile for different applications, from low-pressure systems to high-pressure industrial environments.

7. Temperature Tolerance: Capable of operating effectively in a wide range of temperatures, accommodating both cold and hot applications.

8. Compact Design: Features a compact and straightforward design, allowing for easy integration into tight spaces.

9. Various Sizes: Available in multiple sizes (diameters), catering to different piping systems and flow requirements.

10. Multiple End Connections: Comes with various types of end connections like threaded, welded, or flanged to adapt to different piping setups.

11. Smooth Flow Path: Offers a smooth flow path, reducing turbulence and pressure drop across the valve.

12. Quarter-Turn Operation: The quarter-turn mechanism allows for rapid operation, ensuring quick opening and closing.

13. Versatility: Suitable for use with a wide range of media, including water, oil, gas, chemicals, and steam.

14. Manual or Actuated: Can be manually operated or fitted with actuators for automated control in sophisticated systems.

15. Sealing Mechanisms: Equipped with high-quality seals, such as PTFE (Teflon), ensuring optimal performance and longevity.

These features make the two-way ball valve a highly efficient and reliable option for controlling flow in various systems.

List Various Types of “two way ball valve”

Two-way ball valves are essential components used to control the flow of liquids and gases in various applications. They feature a simple design with a straight-through flow path and a ball with a hole through its middle that rotates to open or close the valve. Here are various types of two-way ball valves:

1. Floating Ball Valve:

– The ball is not fixed and is held in place by the compression of the seat rings. When closed, the pressure pushes the ball against the downstream seat to create a tight seal.

2. Trunnion Ball Valve:

– The ball is fixed and supported by trunnions, which helps in handling higher pressures. Trunnion ball valves have lower operating torque and are suitable for larger and high-pressure applications.

3. Full Port Ball Valve:

– Features an oversized ball that allows for full flow with minimal pressure drop, ideal for processes requiring unobstructed flow.

4. Reduced Port Ball Valve:

– Has a smaller ball with a reduced bore, causing some restriction and pressure drop but typically more cost-effective and used where such losses are acceptable.

5. V-Port Ball Valve:

– The ball or the seats have a V-shaped cut, which allows for more precise flow control. Excellent for applications requiring flow regulation.

6. Top Entry Ball Valve:

– Allows for maintenance or repairs without removing the valve from the pipeline, making it convenient for high-maintenance or critical operations.

7. Welded Body Ball Valve:

– The body is welded, making it leak-proof and suitable for applications requiring high integrity and minimal maintenance.

8. Split Body Ball Valve:

– Consists of two or three pieces bolted together, allowing for easier assembly, disassembly, and maintenance.

Each type has its specific advantages and ideal applications, such as in water treatment, chemical processing, oil and gas, and manufacturing industries. The choice of a two-way ball valve depends on factors like pressure, temperature, and nature of the fluid, as well as maintenance requirements.

List Application of “two way ball valve”

A two-way ball valve is a versatile and widely employed component in fluid control systems, offering effective shutoff and flow regulation capabilities. Here are some key applications:

1. Water Distribution Systems: Utilized for controlling water flow in residential, commercial, and industrial plumbing. They offer reliable shutoff to isolate sections for maintenance or repairs.

2. Oil and Gas Industry: Essential in oil extraction and refining processes to control the flow of crude oil, natural gas, and other hydrocarbons. Their durability and tight seal prevent leaks and help maintain safety standards.

3. Chemical Processing: Used to handle aggressive chemicals, providing accurate flow control and ensuring no cross-contamination. The valves often feature corrosion-resistant materials to withstand harsh environments.

4. HVAC Systems: Employed in heating, ventilation, and air conditioning systems to regulate coolant and hot water flow, enhancing system efficiency and temperature control.

5. Food and Beverage Industry: Ensures hygiene and safety in food production lines by managing the flow of liquids and gases. They are often made of stainless steel to meet sanitation standards.

6. Pharmaceutical Manufacturing: Critical in maintaining sterile conditions and precise control over fluid handling processes, ensuring consistency and purity in drug production.

7. Agricultural Irrigation: Used in irrigation systems for controlled water distribution, improving water efficiency and crop yield.

8. Automotive Industry: Utilized in various vehicle systems, such as fuel and cooling systems, to ensure optimal performance and safety.

9. Marine Applications: Essential in managing ballast systems and onboard water treatment, offering corrosion resistance in saltwater environments.

10. Fire Protection Systems: Integral in sprinkler systems, offering reliable operation to control water flow during fire emergencies.

In summary, two-way ball valves are integral to many industries for their reliability, durability, and precise flow control capabilities.

List Buyer Types of “two way ball valve”

When dealing with two-way ball valves, several types of buyers need such components for various applications. Here is a brief overview:

Industrial Manufacturers

– Chemical Processing Plants: Require durable and corrosion-resistant valves for handling aggressive chemicals.

– Oil and Gas Industries: Need robust valves that can withstand high pressure and high-temperature conditions.

– Pharmaceutical and Food & Beverage Industries: Seek sanitary, cleanable valves to meet stringent hygiene standards.

Utility Providers

– Water Treatment Facilities: Utilize two-way ball valves for isolating and controlling water flow.

– Power Generation Companies: Require these valves for controlling various fluids in cooling and heating systems.

Contractors and Engineers

– HVAC System Installers: Use two-way ball valves for proper fluid regulation in heating and cooling systems.

– Plumbing Contractors: Need reliable valves for residential, commercial, and industrial plumbing systems.

OEMs (Original Equipment Manufacturers)

– Machinery and Equipment Manufacturers: Integrate two-way ball valves into their creations for fluid control in various types of equipment.

Marine Industry

– Shipbuilders and Marine Engineers: Use ball valves suitable for the harsh marine environment to control and direct fluid flow.

Agricultural Sector

– Irrigation and Farm Equipment Suppliers: Need these valves for reliable water flow control in irrigation systems.

Retailers and Distributors

– Hardware and Plumbing Supply Stores: Stock two-way ball valves to meet the demand of DIY consumers and small contractors.

Each buyer type has distinct requirements regarding material, pressure rating, size, and durability, making it essential for suppliers to understand and cater to these diverse needs accurately.

List “two way ball valve” Project Types for Different Industries

Two-way ball valves are crucial components used across various industries for controlling the flow of liquids and gases. Below are examples of projects within different industries where two-way ball valves are essential:

1. Oil & Gas Industry

– Pipeline Infrastructure Project: Two-way ball valves are used to regulate the flow of crude oil and natural gas through pipelines. Their ability to provide tight shutoff makes them ideal for isolating sections of the pipeline for maintenance or emergencies.

– Refinery Operation Project: In refinery operations, two-way ball valves are critical for controlling the flow of various hydrocarbons and chemical reagents during the refining process. Their durability and reliability ensure seamless operation under high-pressure and high-temperature conditions.

2. Water Treatment and Supply

– Municipal Water Treatment Plant: Two-way ball valves are implemented in water treatment plants to manage the flow of untreated and treated water through various stages of purification, including filtration, chlorination, and distribution.

– Desalination Project: In desalination plants, two-way ball valves manage the flow of seawater and freshwater, facilitating efficient desalination through reverse osmosis or other technologies. Their corrosion-resistant properties are essential for handling saline environments.

3. Chemical Processing Industry

– Chemical Reactor Control Project: In chemical manufacturing, two-way ball valves are used to control the input and output of reactants and products in reactors. They provide the precision needed to manage complex chemical reactions.

– Bulk Chemical Transfer Project: For transferring chemicals between containers, storage tanks, and processing units, two-way ball valves offer a reliable solution to control the flow and minimize the risk of leaks and spills.

4. Pharmaceutical Industry

– Sterile Fluid Handling Project: Two-way ball valves are used in pharmaceutical plants to ensure the sterile transfer of liquids and gases during drug manufacturing, contributing to strict hygiene standards and contamination control.

– Bioprocessing Pipeline System: In bioprocessing, two-way ball valves manage the flow of biological materials and reagents, ensuring precise control needed for sensitive biotechnological applications.

In summary, two-way ball valves are versatile and vital components across multiple industries, enhancing operational efficiency, safety, and reliability in various projects.

two way ball valve Accessories Upgrades and Custom Manufacturing Options

Two-way ball valves are essential components in various industrial applications, offering reliable control of fluid flow. To enhance their functionality, several accessories, upgrades, and custom manufacturing options are available.

1. Automated Actuators:

– Electric Actuators: Enable remote control and automation, useful for integrating with control systems.

– Pneumatic Actuators: Provide rapid response and reliability in harsh environments.

2. Positioners and Limit Switches:

– Positioners: Ensure precise valve positioning, improving flow control accuracy.

– Limit Switches: Offer feedback on valve position, useful for monitoring and safety systems.

3. Enhanced Sealing Systems:

– Teflon Seals: Improve chemical resistance and temperature tolerance.

– Graphite Seals: Offer high temperature and pressure resistance, suitable for extreme conditions.

4. Customized End Connections:

– Flanged Ends: Easier installation and removal, promotes system maintenance.

– Threaded Ends: Common in smaller applications, providing simplicity and security.

5. Materials of Construction:

– Stainless Steel: Provides corrosion resistance for chemical and food industries.

– Brass: Cost-effective for low-pressure applications.

– PVC: Lightweight and corrosion-resistant for less aggressive applications.

6. Fire-Safe Designs:

– Comply with industry safety standards, offering additional security in volatile environments.

7. Extended Stems and Locking Devices:

– Extended Stems: Facilitate operation in insulated piping systems.

– Locking Devices: Prevent unauthorized operation, adding a layer of security.

8. Custom Port Sizes:

– Adjusted for specific flow requirements, enhancing efficiency and performance.

9. Anti-Static Devices:

– Critical for applications involving flammable or hazardous fluids, ensuring safe operation.

10. Cryogenic and High-Temperature Options:

– Custom designs to handle extreme temperatures, ensuring reliability across various applications.

By integrating these accessories, upgrades, and custom options, two-way ball valves can be tailored to meet specific industry needs, enhancing performance, safety, and durability.

List Quality Control and The Manufacturing Process of “two way ball valve”

Quality Control of Two-Way Ball Valve

1. Material Inspection: Raw materials undergo rigorous testing to ensure they meet specified standards. Certifications for material properties, like chemical composition and mechanical strength, are verified.

2. Dimensional Accuracy: Components are measured using precision instruments to ensure they meet design specifications.

3. Non-Destructive Testing: Techniques like ultrasonic and radiographic testing check for internal defects without damaging the components.

4. Pressure Testing: Valves are subjected to hydrostatic or pneumatic pressure tests to ensure they can handle the required pressure without leaking.

5. Operational Testing: Valves are tested for smooth operation, ensuring the ball moves freely and seals correctly in both open and closed positions.

6. Visual Inspection: Detailed examination for surface defects, proper finishing, and cleanliness.

7. Documentation Review: All quality control steps and results are documented for traceability and compliance.

Manufacturing Process of Two-Way Ball Valve

1. Design and Engineering: Detailed designs are created, including CAD models and technical drawings, which specify dimensions, materials, and tolerances.

2. Material Procurement: High-quality materials (e.g., stainless steel, brass) are sourced based on the design specifications.

3. Cutting and Shaping: Raw materials are cut and shaped using CNC machines, lathes, and milling machines to create the valve body and other components.

4. Heat Treatment: Components undergo heat treatment processes like annealing or hardening to enhance mechanical properties.

5. Machining: Precision machining of the valve body, ball, stem, and seats to exact dimensions.

6. Surface Treatment: Surfaces are treated with processes like electroplating, polishing, or coating to enhance corrosion resistance and appearance.

7. Assembly: Components are assembled, ensuring the ball fits snugly within the valve body and seals correctly.

8. Testing: Assembled valves undergo rigorous testing as per the quality control protocols.

9. Final Inspection: Comprehensive checks ensure all specifications and standards are met.

10. Packaging and Dispatch: Valves are cleaned, packaged, and labelled for dispatch, ensuring they reach customers in optimal condition.

How to use “two way ball valve”

A two-way ball valve is used to control the flow of a liquid or gas through a pipeline. Here’s how you can use it:

Components of a Two-Way Ball Valve:

1. Valve Body: Main part holding the components.

2. Ball: Spherical component with a hole through the middle.

3. Handle/Actuator: Used to rotate the ball.

4. Ports: Entry and exit points for the fluid.

Steps to Operate:

1. Identify Ports:

– Inlet Port: Where the fluid enters.

– Outlet Port: Where the fluid exits.

2. Handle Orientation:

– Handle aligned with the pipeline: Open Position.

– Handle perpendicular to the pipeline: Closed Position.

3. Open the Valve:

– Rotate the handle 90° so it aligns with the pipeline path.

– This aligns the hole in the ball with the inlet and outlet ports, allowing fluid to pass through.

4. Close the Valve:

– Rotate the handle 90° in the opposite direction.

– This turns the ball, blocking the flow path and sealing the valve.

Maintenance Tips:

1. Regular Inspection:

– Check for leaks and ensure the handle moves smoothly.

2. Clean Periodically:

– Remove build-up to maintain efficiency.

3. Lubricate:

– If required, to prevent handle stiffness.

Safety Precautions:

1. Wear Protective Gear:

– Prevent injuries from pressurized fluids.

2. Check Pressure Ratings:

– Ensure the valve’s specifications match your system’s pressure.

3. Proper Installation:

– Ensure the valve is correctly mounted to avoid malfunctions.

By following these steps and precautions, you can effectively use a two-way ball valve to manage fluid flow in various applications.

“two way ball valve” Comparative Analysis

A two-way ball valve is a critical component in fluid control systems, offering reliable and efficient flow regulation. It operates with a ball having a bore through the center, which in the open position allows fluid to pass through and, when rotated 90 degrees, halts the flow. When comparing two-way ball valves, several factors come into play: material, size, pressure rating, and actuation method.

Material: Common materials include brass, stainless steel, and PVC. Brass valves offer good corrosion resistance and are suitable for general-purpose applications. Stainless steel is preferred for high-pressure and high-temperature environments due to its superior strength and resistance to corrosion. Conversely, PVC valves are ideal for low-pressure, non-corrosive applications and are the most cost-effective option.

Size: Sizes for two-way ball valves generally range from 1/4 inch to several inches in diameter. The selection depends on the required flow rate and pipe size. Larger valves accommodate higher flow rates but are more expensive and bulky.

Pressure Rating: The pressure rating, usually measured in PSI, indicates the maximum pressure the valve can withstand. Higher ratings mean the valve can handle more demanding industrial applications. For instance, a valve rated at 1000 PSI is suitable for heavy-duty use, while a 200 PSI-rated valve might be more appropriate for residential or light commercial applications.

Actuation Method: Two-way ball valves can be manually operated with a lever, which is straightforward and cost-effective. Automated options include electric actuators for remote control or pneumatic actuators that use air pressure to operate. Manual valves are simple and inexpensive but lack the convenience and precision offered by automated systems.

In conclusion, the choice of a two-way ball valve depends on the specific application requirements, balancing material durability, appropriate sizing, pressure tolerance, and the convenience of actuation. Understanding these factors ensures the selection of the most suitable valve, enhancing the efficiency and reliability of the fluid control system.

“two way ball valve” Warranty and Support

When purchasing a two-way ball valve, it is essential to consider the warranty and support options offered by the manufacturer or supplier to ensure product reliability and performance longevity.

Warranty

A standard warranty for a two-way ball valve typically covers manufacturing defects and material flaws. Warranties can range from one to five years, depending on the manufacturer. Some premium models might come with extended warranties. Key aspects covered often include:

– Defective parts: Free replacement or repair of faulty components.

– Workmanship: Assurance that the valve meets industry standards.

– Materials: Protection against material degradation under normal operational conditions.

It is crucial to read the warranty terms carefully to understand what is and isn’t covered, as misuse, improper installation, or modifications usually void the warranty.

Support

Quality customer support is a key consideration for maximizing the utility of your two-way ball valve. Effective support should encompass:

1. Technical Assistance: Experts should be available to assist with installation, troubleshooting, and maintenance questions.

2. Documentation: Comprehensive manuals and guides that provide clear instructions for installation, operation, and maintenance.

3. Spare Parts Availability: Ready access to genuine spare parts ensures quick replacements and minimal downtime.

4. Emergency Support: 24/7 helplines or rapid response teams can be crucial for industrial applications where valve failure might lead to significant disruptions.

5. Training: Some suppliers offer training sessions for your staff on proper handling and maintenance procedures to enhance operational efficiency and prolong product life.

Together, a solid warranty and robust support system provide peace of mind and ensure the long-term optimal performance of your two-way ball valve. Always choose a trusted supplier with a proven track record in both product quality and customer support.

List “two way ball valve” FAQ

Two-Way Ball Valve FAQ

#### 1. What is a two-way ball valve?

A two-way ball valve is a type of valve that has two ports: an inlet and an outlet. It uses a rotatable ball with a bore through its center to control the flow of fluids or gases by turning the ball, which either aligns with the flow path (open) or blocks it (closed).

#### 2. How does a two-way ball valve work?

The valve operates by rotating the ball inside the valve body. When the bore of the ball aligns with the flow path, the valve is open, allowing fluid or gas to pass through. Turning the ball 90 degrees blocks the flow, effectively closing the valve.

#### 3. What are the common applications?

Two-way ball valves are used in various industries, including water treatment, oil and gas, chemical processing, and HVAC systems. They are ideal for shut-off and flow control applications.

#### 4. What materials are two-way ball valves made from?

They are typically made from materials like brass, stainless steel, PVC, and polyethylene. The choice of material depends on the application’s pressure, temperature, and type of fluid or gas.

#### 5. What are the benefits of using a two-way ball valve?

Some key benefits include:

– Easy operation

– Quick opening and closing

– Low pressure drop

– Excellent sealing properties

– Versatility in handling different types of media

#### 6. How do you maintain a two-way ball valve?

Regular maintenance involves:

– Inspecting for leaks or wear

– Cleaning to remove any deposits

– Lubrication of moving parts

– Replacing worn seals or gaskets

#### 7. Can two-way ball valves handle high pressure?

Yes, many two-way ball valves are designed to withstand high-pressure conditions. The pressure rating varies based on the valve’s material and design specifications.

#### 8. Are there different types of two-way ball valves?

Yes, they come in various designs such as full port, standard port, and reduced port, affecting the flow rate and pressure drop through the valve.

These FAQs cover the basics of two-way ball valves, providing insights into their functionality, applications, benefits, and maintenance.

Top 10 FAQ with answer about two way ball valve for Buyer Sourcing from China

Top 10 FAQs about Two-Way Ball Valve Sourcing from China

1. What is a two-way ball valve?

– A two-way ball valve controls fluid flow with a spherical disc, allowing or blocking flow through two ports.

2. What materials are commonly used in their construction?

– Common materials include stainless steel, brass, and PVC, chosen based on the application’s requirements and fluid compatibility.

3. What sizes are available?

– Two-way ball valves come in various sizes, typically ranging from 1/4 inch to several inches. Custom sizes may also be available on request.

4. Are these valves suitable for high-pressure applications?

– Yes, many two-way ball valves are designed to handle high-pressure conditions, but it’s essential to check the specific pressure ratings from the manufacturer.

5. What are the key standards and certifications to look for?

– Look for ISO, CE, API, and ANSI certifications, ensuring compliance with international quality and safety standards.

6. What is the typical lead time for orders?

– Lead times can vary but generally range from 2 to 6 weeks, depending on order size and customization requirements.

7. Can I get a sample before placing a bulk order?

– Most manufacturers offer samples for a small fee or even free, to ensure the product meets your specifications before bulk purchasing.

8. What is the minimum order quantity (MOQ)?

– MOQs vary by manufacturer but typically range from 100 to 500 units. Some suppliers might offer lower MOQs for initial orders.

9. What are the common payment terms?

– Common payment terms include T/T (Telegraphic Transfer), L/C (Letter of Credit), and sometimes PayPal for initial or sample orders.

10. How do I verify the reliability of a Chinese supplier?

– Conduct thorough background checks, request references, read online reviews, and consider ordering through verified platforms like Alibaba or Global Sources.

By addressing these frequently asked questions, you can better navigate the sourcing process and ensure you choose the right two-way ball valve supplier from China.