y pipe fitting Safety Certifications

When selecting a Y pipe fitting, it’s crucial to ensure it meets safety and industry standards. Various certifications indicate that a fitting has undergone rigorous testing and complies with safety regulations. Some key safety certifications and standards for Y pipe fittings include:

1. ASTM International: The American Society for Testing and Materials (ASTM) sets technical standards for a wide range of materials and products, including pipe fittings. Commonly referred ASTM standards for Y pipe fittings include ASTM A234 for carbon steel and ASTM A403 for stainless steel.

2. ASME (American Society of Mechanical Engineers): The ASME Boiler and Pressure Vessel Code (BPVC) outlines standards for the design, fabrication, and inspection of boilers and pressure vessels. ASME B16.9 and ASME B16.11 cover factory-made wrought and socket-welding fittings, respectively.

3. ISO (International Organization for Standardization): ISO standards ensure that products and services are safe, reliable, and of good quality. ISO 9001 certification indicates that the manufacturer of the Y pipe fitting has a quality management system in place.

4. UL (Underwriters Laboratories): UL certification ensures that the products have been tested for safety risks such as flammability and pressure integrity.

5. ANSI (American National Standards Institute): Although ANSI itself doesn’t develop standards, it accredits standards developed by other organizations to ensure they meet rigorous requirements for due process and consensus. ANSI B16.9 and ANSI B16.11 are standards pertinent to pipe fittings.

6. DIN (Deutsches Institut für Normung): European standards provided by DIN can apply to pipe fittings, ensuring high levels of quality and safety for international use.

7. PED (Pressure Equipment Directive): For pipe fittings used in the European Union, compliance with the PED is mandatory to ensure they meet the necessary safety standards.

Ensuring that a Y pipe fitting is compliant with these certifications and standards mitigates risks and ensures reliability and safety in its application. Always check for these certifications to make informed purchasing decisions.

List Reference Technical Parameters of “y pipe fitting”

A “Y pipe fitting” is commonly used in plumbing, HVAC systems, and various fluid-handling applications to combine or split flow paths. Here are some key technical parameters:

1. Material:

– Metals: Stainless steel, copper, aluminum

– Plastics: PVC, CPVC, polypropylene

2. Size and Dimensions:

– Nominal Pipe Size (NPS): Typically ranges from 1/2″ to 24″, depending on the application

– Branch Angle: Usually 45° or 60°, but can vary

3. Wall Thickness:

– According to standards like SCH 10, SCH 40, SCH 80 for metallic pipes

– Specific SDR (Standard Dimension Ratio) for plastic pipes

4. Pressure Rating:

– PSI (Pounds per Square Inch): Commonly ranges from 150 PSI to over 3000 PSI for high-pressure applications

– Temperature Rating: Varies with material, often specified per material standards (e.g., -20°F to 1500°F)

5. Connection Types:

– Socket Weld

– Butt Weld

– Threaded

– Flanged

6. Flow Characteristics:

– Cv (Flow Coefficient): Indicates the flow rate through the fitting

– Pressure Drop: Must be calculated to ensure efficient system performance

7. Compliance and Standards:

– ASME B16.9: For factory-made wrought steel butt-welding fittings

– ASTM (various standards): Material specifications for different compositions

– ISO 9001: Quality management system standard

8. Corrosion Resistance:

– Depends on material, critical for longevity in specific environments

9. Manufacturing Tolerances:

– Adherence to specific tolerances as defined by engineering standards/codes ensures proper fit and function

10. Surface Finish:

– Affects the fitting’s resistance to friction and corrosion, relevant in sanitary applications (e.g., SPI Class I to Class VII for plastics)

In summary, selecting the right Y pipe fitting involves considering these technical parameters in relation to the specific application requirements and industry standards.

List Product features of “y pipe fitting”

A Y pipe fitting, also known as a wye fitting, is an essential component in plumbing, exhaust systems, and various industrial applications. Here are its key features:

1. Material: Y pipe fittings are available in a variety of materials including PVC, stainless steel, cast iron, copper, and more. The choice of material depends on the application and the type of fluid being transported.

2. Design: The Y shape allows for a smooth transition in flow direction, reducing back pressure and turbulence. It combines or splits flows efficiently.

3. Angle: Typically features a 45-degree branch line, but other angles can be available based on specific requirements.

4. Sizes: Comes in a wide range of sizes to fit different pipe diameters, ensuring compatibility with existing piping systems.

5. Pressure Rating: Designed to withstand specific pressure ratings, making them suitable for both low-pressure and high-pressure systems.

6. Temperature Range: Depending on the material, Y pipe fittings can operate over a wide range of temperatures, making them suitable for various environments.

7. Connection Types: Available in different connection types such as threaded, socket weld, and butt weld to cater to different installation needs.

8. Durability: Constructed to resist corrosion, mechanical wear, and impact, enhancing the longevity and reliability of the piping system.

9. Certifications: Many Y pipe fittings come with industry-standard certifications, ensuring they meet regulatory and safety standards.

10. Versatility: Suitable for a variety of applications including HVAC systems, chemical processing, water treatment, and the automotive industry.

11. Ease of Installation: Designed for easy and quick installation, reducing labor and downtime in maintenance and setup.

12. Cost-Effective: Provides a cost-effective solution for merging or dividing flow paths within a piping system.

These features collectively make the Y pipe fitting a versatile and dependable choice for various plumbing and industrial system needs.

List Various Types of “y pipe fitting”

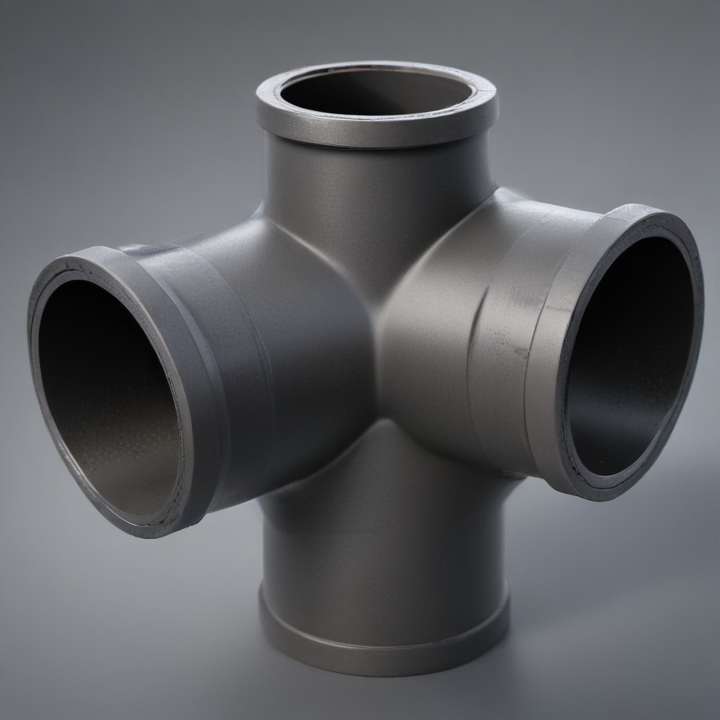

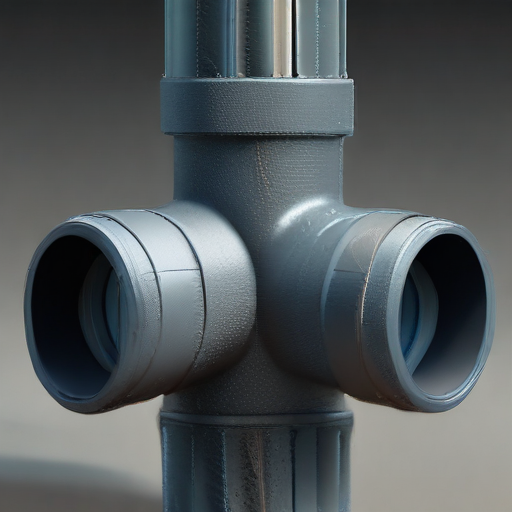

A Y pipe fitting, also known as a wye fitting, is used in plumbing to combine or split flows in piping systems with minimal turbulence. Here are various types of Y pipe fittings:

1. Standard Wye: Connects three pipes of the same diameter at a 45-degree angle.

2. Reducing Wye: Has different diameters on its outlets or inlets, facilitating connection between pipes of varying sizes.

3. Double Wye: Combines two Y fittings back-to-back, enabling the connection of four pipes—ideal for complex systems.

4. Long-Turn Wye: Provides a wider curve to reduce friction and improve flow efficiency.

5. Sanitary Wye: Specifically designed for waste and drainage systems, ensuring minimal clogging and ease of maintenance.

6. Vent Wye: Used in venting systems to maintain proper airflow and pressure.

7. Drain Wye: Built to handle drainage applications, typically found in residential and commercial plumbing systems.

8. Durable Wye: Constructed from tougher materials like stainless steel or cast iron, suitable for industrial applications.

9. Slip-On Wye: Has a socket end allowing for pipes to slip into place, aiding quick installation.

10. Threaded Wye: Features threading for secure, leak-proof connections.

11. Socket Weld Wye: Designed for welding applications, especially in high-pressure systems.

12. Barbed Wye: Features barbed ends for use with flexible tubing, ensuring a secure connection without clamps.

13. Grooved Wye: Has grooved ends for a mechanical joint, often found in fire protection systems.

These fittings are available in various materials, including PVC, copper, brass, stainless steel, and cast iron, each suited to specific applications.

List Application of “y pipe fitting”

A Y-pipe fitting, also known as a wye fitting, is a type of pipe junction that allows for the merging or splitting of flow in various piping systems. The shape resembles the letter ‘Y,’ providing a smoother directional change for fluid compared to T-junctions. Here are key applications of Y-pipe fittings:

1. Plumbing Systems: Used in residential and commercial plumbing to join two branches of drainage or to split flow into two directions, ensuring efficient wastewater management.

2. Irrigation Systems: Applied in agricultural and landscaping irrigation to distribute water from main lines to multiple sprinklers or drip lines.

3. HVAC Systems: Utilized in heating, ventilation, and air conditioning to connect ducts and allow for the distribution of air between different zones, enhancing even airflow and temperature control.

4. Industrial Piping: Essential in various industries, such as chemical, food and beverage, and pharmaceutical, for diverting or combining process fluids, ensuring efficient flow management in complex pipelines.

5. Automotive Exhaust Systems: Commonly found in vehicles to merge exhaust from multiple cylinders into a single pipe, optimizing exhaust flow, performance, and sound.

6. Oil and Gas Pipelines: Employed to split or merge streams in transportation pipelines, ensuring balanced flow distribution and reduced turbulence, crucial for operational efficiency.

7. Wastewater Treatment: Integral in sewage systems and treatment plants to direct flows from different sources into a treatment tank or multiple treatment paths.

8. Fire Sprinkler Systems: Used to connect multiple sprinkler heads to a main supply line, ensuring adequate distribution of water for fire suppression.

9. Hydraulic Systems: Essential in hydraulic circuits to direct fluid from pumps to multiple actuators or to converge returns to a single reservoir.

Y-pipe fittings are indispensable in systems requiring smooth directional change and efficient flow management. Their versatility and reliability make them a fundamental component across diverse sectors.

List Buyer Types of “y pipe fitting”

When it comes to purchasing “Y pipe fittings,” there is a diverse array of buyer types, each with unique needs and considerations depending on their industry or application. Below is an overview of varying buyer types:

1. Plumbing Contractors: These professionals often require Y pipe fittings for residential, commercial, and industrial plumbing systems. Their priority is typically on durability, compliance with regulations, and cost-effectiveness.

2. HVAC Technicians: Heating, ventilation, and air conditioning experts might use Y pipe fittings in systems designed for efficient air flow and ductwork installations. Here, factors like material (e.g., galvanized steel, aluminum), ease of installation, and pressure ratings are crucial.

3. Automotive Manufacturers and Mechanics: In the automotive industry, Y pipe fittings are common in exhaust systems. Buyers in this sector value products that offer high resistance to heat and stress, often preferring stainless steel or other high-temperature materials.

4. Industrial Engineers: These professionals work with complex piping systems in plants and factories, dealing with gases, liquids, or chemicals. Their focus is typically on fittings that can withstand high pressure, temperature variations, and potential corrosive materials.

5. Agricultural Sector: Farmers and irrigation specialists use Y pipe fittings in water distribution and drainage systems. Durability, resistance to varying environmental conditions, and ease of maintenance are significant considerations.

6. DIY Enthusiasts and Homeowners: These individual buyers might use Y pipe fittings for various home improvement projects, such as gardening or setting up custom water systems. Cost, availability, and simplicity are key factors for this group.

7. Distributors and Suppliers: Entities that buy in bulk to resell may prioritize factors like wholesale pricing, supplier reliability, and inventory turnaround time. They may also focus on a broad range of specifications to cater to diverse customer needs.

8. Municipal and Utility Companies: These buyers use Y pipe fittings in public infrastructure projects such as water treatment plants and sewer systems. Compliance with government regulations, long-term durability, and reliability are paramount.

Each buyer type has its own specific requirements and priorities, influencing their choices in the market for Y pipe fittings.

List “y pipe fitting” Project Types for Different Industries

Certainly! Here are some common project types for “Y Pipe Fittings” across different industries:

1. HVAC (Heating, Ventilation, and Air Conditioning) Systems:

– Air Distribution: Y pipe fittings are used for efficient air routing in duct systems to split airflow from a single input source into two separate output paths.

– Ventilation: Employed in ventilation systems to facilitate balanced air supply and exhaust in various building zones.

2. Plumbing:

– Drainage Systems: Utilized to merge or split water flow in residential and commercial drainage systems, optimizing space and flow management.

– Wastewater Systems: Ideal for directing greywater and sewage in treatment plants or septic systems.

3. Oil and Gas Industry:

– Pipeline Distribution: Y fittings are used in pipeline systems to divert oil, gas, or other hydrocarbons into multiple streams for processing or distribution.

– Refinery Equipment: Employed in refining units for efficient multi-path routing of various petrochemical products.

4. Chemical Processing:

– Fluid Transfer Systems: Essential in chemical plants for splitting and routing chemicals between different process stages or storage units.

– Reactor Feed Lines: Used to distribute reactants to multiple reactors for optimal processing.

5. Water Treatment Plants:

– Filtration Systems: Vital for distributing water between different filtration units to maximize efficiency.

– Supply and Distribution: Helps in balancing water distribution across various treatment stages.

6. Food and Beverage Industry:

– Beverage Dispensing: Used in systems for carbonated beverage production to manage flow and carbonation levels.

– Processing and Packaging: Employed to route liquids or semi-liquids efficiently between processing units and packaging lines.

7. Pharmaceuticals:

– Liquid Transfer Systems: Critical in managing the flow of pharmaceutical liquids between different production stages.

– Sterilization Processes: Used in systems where precise splitting of chemicals or purified water is required for sterilization.

Each of these industries leverages the unique design and utility of Y pipe fittings to enhance operational efficiency, streamline processes, and ensure safe and effective fluid or air transfer.

y pipe fitting Accessories Upgrades and Custom Manufacturing Options

Y pipe fitting accessories encompass a wide range of options tailored to enhance functionality and meet specific project requirements. These fittings are integral for diverting and distributing fluid or gas flow in various industrial, commercial, and residential applications. Let’s delve into the upgrades and custom manufacturing options that can elevate the performance and adaptability of Y fittings.

Material Upgrades: Standard Y pipe fittings are typically made from stainless steel, PVC, or copper. However, custom manufacturing allows for the selection of specialized materials such as high-grade alloys, Teflon-lined fittings for enhanced chemical resistance, or high-density polyethylene for better durability and flexibility.

Coatings and Finishings: Custom coatings like epoxy, galvanization, or anodization can be applied to extend the lifespan and improve the resistance of Y pipe fittings to corrosion, abrasion, or chemical exposure. These finishes are particularly beneficial in harsh environments.

Connection Types: Standard Y pipe fittings usually come with threaded or solvent weld connections. Upgrading to quick-connect, flanged, or grooved ends can significantly simplify installation and maintenance, especially in large-scale or high-frequency operations.

Dimensions and Specifications: Custom manufacturing allows for precise tailoring of the fitting’s dimensions to fit unique spatial requirements or to ensure compatibility with non-standard piping systems. This can be especially critical in retrofit projects or specialized industrial applications.

Integrated Features: Enhancements such as built-in flow control valves, smart sensors for monitoring pressure and flow, or additional ports for instrumentation can be integrated into Y fittings during the manufacturing process. These features can provide real-time data and control, optimizing overall system performance.

In conclusion, upgrading Y pipe fittings with customized materials, coatings, connections, dimensions, and integrated features can significantly improve their suitability, durability, and efficiency in diverse applications. This flexibility in design and functionality ensures that Y fittings can meet the most demanding project needs.

List Quality Control and The Manufacturing Process of “y pipe fitting”

Quality Control of Y Pipe Fitting

1. Material Inspection: Ensure raw materials meet specifications.

2. Dimensional Check: Use calipers and micrometers to verify dimensions.

3. Visual Inspection: Identify surface defects like cracks or deformities.

4. Pressure Testing: Assess if the fitting can withstand the designated pressure.

5. Nondestructive Testing (NDT): Employ methods like X-ray or ultrasonic testing to detect internal flaws.

6. Chemical Analysis: Verify material composition, especially for corrosion-resistant alloys.

7. Hardness Test: Confirm material hardness meets required standards.

8. Documentation Review: Ensure all testing and inspection records are complete.

Manufacturing Process of Y Pipe Fitting

1. Design & Engineering:

– Create technical drawings and specifications.

– Utilize CAD software for precision.

2. Material Selection:

– Choose appropriate metal/alloy (e.g., stainless steel, copper).

3. Cutting & Shaping:

– Cut the raw material into the required lengths.

– Use hot or cold forming techniques to shape the arms of the Y fitting.

4. Welding:

– Weld the shaped sections together.

– Ensure precise alignment to maintain flow efficiency.

5. Heat Treatment:

– Apply heat treatment to relieve stress and improve mechanical properties.

6. Machining:

– Perform machining processes like milling and turning for finer details.

– Ensure internal and external threading if required.

7. Surface Finishing:

– Conduct processes such as polishing, coating, or galvanizing to enhance surface properties.

8. Quality Control:

– Perform the outlined quality checks at various stages.

9. Marking & Documentation:

– Mark the fittings with essential information (e.g., size, material grade).

– Compile quality assurance documents.

10. Packaging & Dispatch:

– Properly pack to prevent damage during transport.

– Ensure labeling for identification and handling instructions.

Conclusion

Adhering to rigorous quality control measures and a meticulous manufacturing process ensures the production of reliable and durable Y pipe fittings suitable for various applications.

How to use “y pipe fitting”

A Y pipe fitting, often used in plumbing and HVAC systems, is designed to split or combine fluid flow in pipelines at a Y-shaped junction. Here’s a guide on how to use it effectively:

1. Identify Needs: Determine whether you need to split or combine the flow. The Y fitting can direct water, air, or other fluids from one pipe into two or vice versa.

2. Select Material: Choose a Y fitting made of the same material as your existing pipes (e.g., PVC, copper, stainless steel).

3. Measure Pipes: Ensure the Y fitting matches the diameter of your existing pipes for a secure fit.

4. Cut Pipes: Using a pipe cutter or saw, carefully cut the pipes to accommodate the Y fitting. Check local codes for proper cut lengths to maintain system integrity.

5. Clean Ends: Clean the cut ends of the pipes to remove burrs. This ensures a smooth connection and reduces leakage risk.

6. Dry Fit: Position the Y fitting to ensure it aligns correctly with the existing pipes.

7. Prepare Joints:

– For PVC: Apply primer and glue to both the pipe ends and the Y fitting.

– For metal pipes: Use appropriate threading compounds or Teflon tape.

8. Assemble: Insert the pipes into the Y fitting and rotate slightly to distribute the adhesive evenly if using PVC. For metal pipes, tighten the connections using a wrench.

9. Secure: Ensure all connections are tight and properly seated. Support the pipes with clamps or brackets if necessary.

10. Test: Once installed, test the system by running water or air through it to check for leaks. Tighten connections if needed.

By following these steps, a Y pipe fitting can efficiently manage the flow in your piping system, optimizing performance and reliability.

“y pipe fitting” Comparative Analysis

A “Y pipe fitting,” also known as a wye fitting, is a plumbing component used to join three sections of pipe at a 45-degree angle, forming a Y-shape. This design contrasts with other fittings like the T-fitting, which connects pipes at 90-degree angles. Below is a comparative analysis of Y pipe fittings in terms of application, functionality, and material considerations:

1. Application:

– Y Pipe Fitting: Primarily used in drainage systems, Y pipe fittings help to direct the flow of waste at angles that minimize blockages and resistance. Their design is ideal for smooth transitions, particularly in horizontal installations where maintaining fluid velocity is critical.

– T Fitting: More common in supply systems, T-fittings offer a straightforward right-angle connection, commonly used in water supply lines and some drainage systems but are less efficient in reducing turbulence and resistance in fluid flow.

2. Functionality:

– Flow Dynamics: The 45-degree branch of a Y pipe fitting ensures a smoother transition for fluids, reducing friction and turbulence. This improves flow efficiency and reduces the likelihood of clogs.

– Maintenance and Cleaning: Y fittings are advantageous in maintenance as they offer better access points for cleaning equipment and inspection tools, simplifying upkeep efforts.

3. Material Considerations:

– Plastic (PVC/ABS): Widely used for their cost-effectiveness and resistance to corrosion, making them suitable for residential and light commercial applications.

– Metal (Stainless Steel/Copper): Preferred in industrial and high-pressure systems due to their durability and high-temperature resistance.

Comparison Summary:

While T fittings are sufficient for many scenarios, Y pipe fittings offer superior flow dynamics and are better suited for drainage systems where maintaining fluid velocity and minimizing clogs are essential. Material choice for Y fittings should be based on the specific needs of the installation, considering factors such as chemical compatibility, pressure, and temperature requirements. Overall, Y pipe fittings are an essential component in efficient and effective plumbing systems.

“y pipe fitting” Warranty and Support

Warranty and Support for Y Pipe Fitting

At [Your Company Name], we stand behind the quality and durability of our Y pipe fittings. We offer a comprehensive warranty and support program to ensure your complete satisfaction and peace of mind.

Warranty:

Our Y pipe fittings come with a standard [__ year] warranty from the date of purchase. This warranty covers any manufacturing defects or issues related to material quality under normal use conditions. If a defect is found within the warranty period, we will repair or replace the product at no additional charge.

What’s Covered:

– Manufacturing defects

– Material flaws

What’s Not Covered:

– Damage due to misuse or improper installation

– Normal wear and tear

– Alterations or modifications to the product

Support:

We are committed to providing top-notch support to all our customers. Our dedicated support team is available to assist you with any queries or concerns you might have regarding our Y pipe fittings. You can reach us via:

– Email: [support@yourcompany.com] – Phone: [+1-800-123-4567] – Live Chat: Available on our website [www.yourcompany.com]

How to Claim Warranty:

1. Contact Us: Reach out to our support team with details of the issue.

2. Provide Proof: Share proof of purchase and photos of the defect.

3. Review: Our team will review your claim within [__ business days].

4. Resolution: If the claim is approved, we will arrange for repair or replacement.

Additional Services:

– Installation guides and videos

– Troubleshooting assistance

– Regular updates on product enhancements

With our robust warranty and exceptional support services, you can be confident in choosing our Y pipe fittings for your plumbing needs. Your satisfaction is our priority.

List “y pipe fitting” FAQ

Y Pipe Fitting FAQs

1. What is a Y pipe fitting?

A Y pipe fitting, also known as a wye fitting, is a type of plumbing connector that splits or combines flow paths in a Y shape, typically connecting three pipes at a 45-degree angle.

2. What materials are Y pipe fittings made from?

Y pipe fittings are commonly made from materials such as PVC, ABS, stainless steel, cast iron, and copper, depending on the application and required durability.

3. Where are Y pipe fittings commonly used?

They are frequently used in plumbing systems, HVAC systems, and industrial applications to manage the directional flow of liquids and gases.

4. What is the difference between a Y fitting and a T fitting?

While both are used to join three pipes, a Y fitting joins them at a 45-degree angle for smoother flow, and a T fitting joins them at a 90-degree angle, causing a more abrupt change in direction.

5. How do I choose the right size Y pipe fitting?

Match the fitting size to the diameter of the pipes you are connecting. Sizes typically range from 1/2 inch to several inches in diameter.

6. Can Y pipe fittings be used for both horizontal and vertical applications?

Yes, Y pipe fittings can be used in both horizontal and vertical piping systems, offering flexibility for various installation needs.

7. Are there any limitations on using Y pipe fittings?

Y pipe fittings are ideal for applications requiring smooth flow transitions but may not be suitable for systems needing sharp directional changes or specific pressure ratings.

8. How are Y pipe fittings installed?

Installation methods vary by material. For example, PVC Y fittings usually require solvent cement, while metal ones may need threading or welding.

9. Do Y pipe fittings meet specific standards?

Many Y fittings conform to standards like ASTM for plastic pipe fittings or ANSI/ASME for metal fittings, ensuring quality and performance.

10. Where can I purchase Y pipe fittings?

They are available at hardware stores, specialized plumbing supply stores, and online retailers, offering a range of materials and sizes to suit different needs.

Top 10 FAQ with answer about y pipe fitting for Buyer Sourcing from China

Top 10 FAQs About Y Pipe Fitting for Buyer Sourcing from China

1. What materials are Y pipe fittings made from?

– Y pipe fittings are commonly made from materials such as stainless steel, carbon steel, PVC, ABS, and copper. The choice of material depends on the application, temperature, and pressure requirements.

2. Are Chinese manufacturers compliant with international standards?

– Many reputable Chinese manufacturers comply with international standards like ASTM, ANSI, DIN, and ISO. Always request compliance certificates and conduct due diligence when sourcing.

3. How can I verify the quality of Y pipe fittings from Chinese suppliers?

– Request product samples, third-party inspections, and quality assurance certificates. Additionally, visiting the manufacturer’s facility can provide further assurance of quality control measures.

4. What are the common sizes and angles available for Y pipe fittings?

– Y pipe fittings typically come in a variety of sizes ranging from 1/2 inch to 48 inches. The standard angles are 45 degrees and 60 degrees, but custom angles can often be manufactured.

5. What is the typical lead time for Y pipe fittings from China?

– Standard lead times range from 4 to 8 weeks, depending on order size, complexity, and whether the items are custom-made. Always confirm lead times with the supplier.

6. Can Chinese manufacturers provide custom Y pipe fittings?

– Yes, many Chinese manufacturers offer customization services to meet specific design and material requirements. Detailed specifications and drawings will be necessary for custom orders.

7. What is the typical MOQ (Minimum Order Quantity) for Y pipe fittings?

– MOQs vary widely among manufacturers. While some offer low MOQs (e.g., 10-50 units), high-volume orders may receive better pricing. Discuss with suppliers to understand their requirements.

8. What are the common shipping methods for Y pipe fittings from China?

– Common shipping methods include sea freight, air freight, and courier services. The choice depends on the size of the order, urgency, and budget constraints.

9. How can I handle payment safely when sourcing from China?

– Use secure payment methods like Letters of Credit (LC), Telegraphic Transfer (T/T), or escrow services. It is advisable to start with smaller orders to establish trust before placing larger ones.

10. What are the import duties and taxes for Y pipe fittings?

– Import duties and taxes vary by country and product classification under the HS code. Consult with a customs broker or use online duty calculators to estimate additional costs.

By understanding these key points, buyers can make more informed decisions when sourcing Y pipe fittings from China.