stainless steel centrifugal pump Safety Certifications

Stainless steel centrifugal pumps are widely used across various industries for their durability, corrosion resistance, and efficiency. Ensuring that these pumps meet specific safety and quality standards is crucial. Several certifications and standards apply to such equipment:

1. ISO (International Organization for Standardization) Certification:

– ISO 9001: This standard specifies requirements for a quality management system and ensures consistency in product quality and customer satisfaction.

– ISO 5199: Pertains to technical specifications for centrifugal pumps, focusing on reliability and safety for industrial use.

2. ANSI (American National Standards Institute):

– ANSI/HI Standards: These cover nomenclature, definitions, design, and application of pumps, promoting safety and efficient operation.

3. ATEX (Appareils destinés à être utilisés en ATmosphères EXplosibles):

– Applicable for pumps used in explosive atmospheres, specifically within the EU. Ensures that the pump design minimizes the risk of ignition in hazardous areas.

4. CE Marking:

– Indicates conformity with EU safety, health, and environmental requirements. Relevant for pumps sold in the European Economic Area (EEA).

5. API (American Petroleum Institute) Standards:

– API 610: Specifically for centrifugal pumps in the petroleum, petrochemical, and natural gas industries. Ensures high safety, reliability, and performance levels.

6. UL (Underwriters Laboratories) Certification:

– Ensures compliance with rigorous safety standards pertinent to electrical components and overall equipment safety.

7. NSF (National Sanitation Foundation):

– Necessary for pumps used in food and beverage industries. Ensures materials and designs meet health and safety guidelines.

8. CSA (Canadian Standards Association):

– Similar to UL, CSA certification ensures the pump meets Canadian standards for electrical safety and performance.

These certifications collectively ensure that stainless steel centrifugal pumps are reliable, efficient, and safe for their intended applications. Always check for these certifications when selecting a pump to ensure compliance with industry norms and safety regulations.

List Reference Technical Parameters of “stainless steel centrifugal pump”

When discussing the technical parameters of a stainless steel centrifugal pump, the primary considerations involve attributes related to the material, mechanical design, performance, and operating conditions. Here’s a concise overview:

Material Specifications

1. Casing and Impeller Material: Typically made from AISI 304 or AISI 316 stainless steel for corrosion resistance.

2. Seal Materials: Often comprises carbon, ceramic, or tungsten carbide for durability under high-stress conditions.

Mechanical Design Parameters

1. Impeller Type: Closed, semi-open, or open designs depending on the application.

2. Shaft Design: Precision-machined stainless steel to minimize deflection and provide high strength.

3. Bearing Type: Sealed ball bearings for minimizing maintenance and prolonging life.

Performance Metrics

1. Flow Rate: Measured in cubic meters per hour (m³/h) or gallons per minute (GPM), typically ranging from 1 up to several hundred m³/h depending on pump size and design.

2. Head: The maximum height (meters or feet) that the pump can raise the fluid, ranging from a few meters up to over 100 meters.

3. Efficiency: Efficiency ratings can vary but typically range from 50% to 90%, depending on the application and operating conditions.

Operating Conditions

1. Temperature Range: Can handle fluid temperatures from -30°C (-22°F) up to +316°C (+600°F) with appropriate seals and materials.

2. Pressure Limits: Maximum allowable working pressures generally range from 10 to 40 bar.

3. Viscosity: Typically designed for fluids with a viscosity range of up to 1000 cP (centipoise).

Electrical Parameters

1. Motor Power: Generally ranges from 0.37 kW to over 200 kW, depending on the application.

2. Voltage and Frequency: Standard options include 230V/460V at 60 Hz or 220V/380V at 50 Hz, but may vary based on regional requirements.

Application Versatility

1. Industries: Widely used in food & beverage, pharmaceuticals, chemical processing, water treatment, and HVAC systems.

These parameters must be meticulously evaluated to ensure the pump meets the specific needs of the application and adheres to operational safety and efficiency standards.

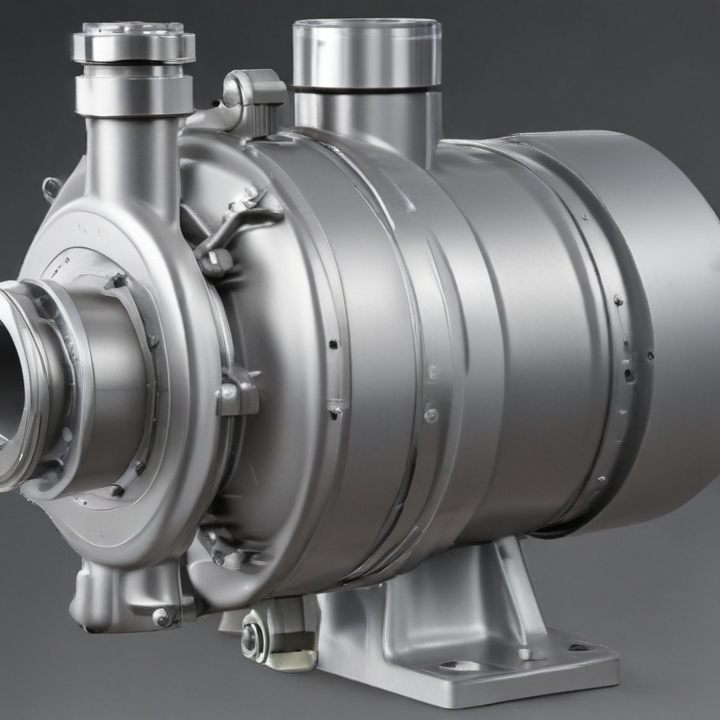

List Product features of “stainless steel centrifugal pump”

Certainly! Here are the key product features of a stainless steel centrifugal pump:

1. Material Construction: Made from high-grade stainless steel, providing excellent corrosion resistance and durability, making it suitable for a variety of fluids including corrosive liquids.

2. Impeller Design: Equipped with a robust impeller made from stainless steel, optimizing fluid flow and enhancing pumping efficiency.

3. Seal Options: Available with various mechanical seal options to ensure leak-proof operation and accommodate different media types.

4. Motor Efficiency: High-efficiency motors to deliver optimal performance and energy savings. Many models comply with IE3 or higher efficiency standards.

5. Flow Rate and Head: Capable of delivering high flow rates and head pressures, making it ideal for a wide range of industrial and commercial applications.

6. Temperature Range: Designed to handle a broad temperature range, allowing for versatile application in both hot and cold fluid systems.

7. Connection Types: Available with multiple connection options such as threaded, flanged, or sanitary fittings for compatibility with existing piping systems.

8. Compact Design: Often designed with a compact footprint to facilitate easy installation in tight spaces.

9. Maintenance-Friendly: Engineered for easy disassembly and reassembly, with readily accessible parts for straightforward maintenance and reduced downtime.

10. Noise and Vibration Reduction: Built with features that minimize noise and vibration, contributing to a quieter and more stable operational environment.

11. Versatility: Suitable for various applications such as water treatment, chemical processing, food and beverage production, and pharmaceutical industries.

12. Safety Features: May include thermal protection and overload relays to ensure safe operation and prevent damage to the pump and motor.

13. Compliance and Standards: Many models meet industry standards such as ANSI, ISO, and CE, ensuring reliable and safe performance.

These features make stainless steel centrifugal pumps a reliable and versatile choice for numerous industrial applications.

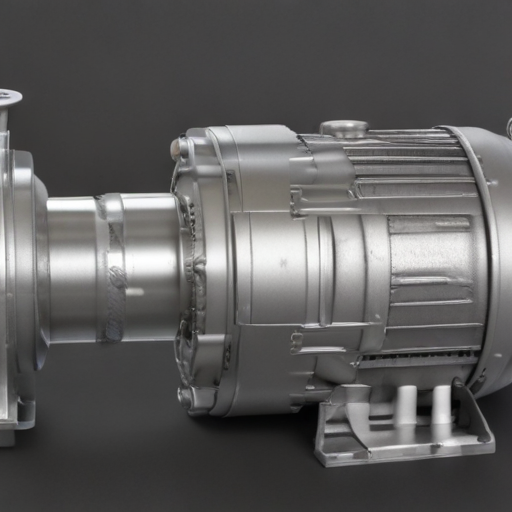

List Various Types of “stainless steel centrifugal pump”

Stainless steel centrifugal pumps are widely used in various industries due to their durability, corrosion resistance, and ability to handle a wide range of fluids. Here are some common types:

1. Single-Stage Centrifugal Pumps: These pumps have one impeller and are used for applications where a moderate increase in fluid pressure is required. Typical uses include water supply, irrigation, and HVAC systems.

2. Multistage Centrifugal Pumps: Equipped with multiple impellers on a single shaft, these pumps are suitable for applications requiring high pressure. They are commonly found in boiler feed systems, high-rise buildings, and pressure washing.

3. Self-Priming Centrifugal Pumps: Designed to re-prime themselves after the initial prime, these pumps are ideal for applications where the pump has to handle air and gases. They are often used in wastewater treatment, chemical processing, and industrial cleaning.

4. Magnetic Drive Centrifugal Pumps: These pumps use a magnetic coupling to drive the impeller, eliminating the need for a shaft seal. This makes them an excellent choice for handling hazardous or corrosive fluids in chemical processing and pharmaceutical industries.

5. Close-Coupled Centrifugal Pumps: In these pumps, the motor and pump are closely connected without the use of a pump bed or baseplate, offering a compact design. They are ideal for space-constrained environments in HVAC, water treatment, and industrial processes.

6. Sealless Centrifugal Pumps: These pumps feature a hermetically sealed chamber, providing an extra layer of safety for handling dangerous or toxic fluids. They are mainly used in fine chemicals and nuclear applications.

7. Vertical Centrifugal Pumps: Often used in sumps and pits, these pumps have a vertical orientation and are ideal for situations where floor space is a concern. Common applications include dewatering, sewage, and condensate removal.

8. Horizontal Centrifugal Pumps: These pumps have a horizontal orientation and are easier to maintain and inspect. They are widely used in agriculture, manufacturing, and mining industries.

By selecting the right type of stainless steel centrifugal pump, you can ensure efficient and reliable operation tailored to your specific application needs.

List Application of “stainless steel centrifugal pump”

Stainless steel centrifugal pumps are versatile and highly durable, making them suitable for a broad range of applications across various industries. Here’s a concise list:

1. Food and Beverage Industry:

– Dairy Processing: Used to handle milk, yogurt, and other dairy products.

– Beverage Production: Ideal for pumping juices, soft drinks, and alcoholic beverages.

– Food Manufacturing: Ensures safe transfer of soups, sauces, and other consumables.

2. Pharmaceutical and Biotechnology:

– Drug Manufacturing: Essential in the sterile transfer of pharmaceuticals.

– Biotech Processes: Used in the production of biopharmaceuticals and vaccines where hygiene is critical.

3. Chemical Industry:

– Chemical Processing: Handles corrosive and abrasive chemicals safely.

– Industrial Applications: Used in the production of polymers, resins, and petrochemicals.

4. Water Treatment and Supply:

– Municipal Water Systems: Pumps clean water to residential and commercial areas.

– Wastewater Treatment: Facilitates the transfer and treatment of wastewater.

5. Oil and Gas:

– Refining: Used in the processing of crude oil into usable fuels and lubricants.

– Transport: Moves hydrocarbons in pipelines and through processing plants.

6. Agriculture:

– Irrigation: Efficiently distributes water for crops.

– Fertilizer and Pesticide Delivery: Pumps chemical solutions for agricultural use.

7. Automotive:

– Manufacturing Processes: Used for cooling systems and in the production of automotive chemicals and oils.

8. HVAC Systems:

– Heating and Cooling: Key component in circulating water for air conditioning and heating systems.

9. Marine Applications:

– Ballast and Bilge Systems: Ensures the stability and drainage of ships.

10. Mining:

– Slurry and Material Transport: Moves slurries and other extracted materials.

Stainless steel centrifugal pumps are preferred for their corrosion resistance, reliability, and ability to handle various fluids, making them indispensable in these sectors.

List Buyer Types of “stainless steel centrifugal pump”

When it comes to purchasing a stainless steel centrifugal pump, the types of buyers can be broadly categorized into the following segments:

1. Industrial Manufacturers:

– Chemical Industry: Bulk buyers requiring stainless steel centrifugal pumps for handling corrosive chemicals and maintaining safety standards.

– Food and Beverage Industry: Necessitate stainless steel pumps due to their resistance to contamination and compliance with hygiene regulations.

– Pharmaceutical Industry: Require these pumps for their non-reactive nature with pharmaceuticals and the ability to maintain sterility.

2. Agricultural Sector:

– These buyers often use stainless steel centrifugal pumps for irrigation systems and livestock water management, benefiting from the pump’s durability and resistance to rust and corrosion.

3. Water Treatment Facilities:

– Municipal and industrial water treatment plants rely on stainless steel centrifugal pumps for processes like filtration, purification, and wastewater management due to their longevity and resistance to various chemicals.

4. Construction Companies:

– Utilize these pumps for dewatering, managing site water, and other fluid handling tasks on construction sites, valuing their robust performance and reliability.

5. HVAC (Heating, Ventilation, and Air Conditioning) Services:

– Service providers in this sector employ stainless steel centrifugal pumps for efficient fluid circulation in heating and cooling systems, where corrosion resistance and efficiency are critical.

6. Marine Industry:

– Shipbuilders and operators use these pumps for ballast systems, bilge pumping, and other onboard fluid-handling requirements, appreciating their effectiveness in resisting sea water corrosion.

Each of these buyer types values stainless steel centrifugal pumps for their specific benefits such as durability, corrosion resistance, efficiency, and compliance with industry-specific regulations.

List “stainless steel centrifugal pump” Project Types for Different Industries

Certainly! Stainless steel centrifugal pumps are versatile equipment used in various industries due to their durability, resistance to corrosion, and efficiency. Here are some project types for different industries:

1. Food & Beverage Industry

– Dairy Processing: Pasteurizing milk, transporting yogurt and cream.

– Beverage Production: Transferring juices, soft drinks, and alcoholic beverages.

– Food Processing: Handling sauces, soups, and broths.

2. Pharmaceutical & Biotechnology

– Production Lines: Transferring sensitive pharmaceuticals and biologics.

– Clean-in-Place (CIP) Systems: Ensuring hygiene and preventing cross-contamination.

– Laboratory Applications: Handling solvents and chemicals with precision.

3. Water Treatment & Supply

– Municipal Water Supply: Distributing potable water.

– Industrial Water Treatment: Treating and circulating cooling water.

– Desalination Plants: Pumping seawater for desalination processes.

4. Chemical & Petrochemical Industries

– Chemical Processing: Moving corrosive acids, solvents, and other chemicals.

– Refineries: Handling different grades of petroleum products, including crude oil.

5. Pulp & Paper Industry

– Pulp Processing: Transporting pulp mixtures.

– Paper Production: Circulating and transferring coatings and additives.

6. Automotive Industry

– Manufacturing Lines: Circulating coolant and lubricants.

– Parts Cleaning Systems: Pumping cleaning solutions during engine and part washing processes.

7. Mining & Mineral Processing

– Ore Processing: Pumping slurry mixtures in ore extraction.

– Water Management: Handling wastewater and recycled water in mining operations.

8. HVAC Systems

– Heating Systems: Circulating hot water or steam for large industrial heating systems.

– Cooling Systems: Pumping chilled water in commercial and industrial cooling applications.

9. Marine Industry

– Ballast Water Treatment: Managing ballast water to comply with regulations.

– Bilge Systems: Removing excess water from the bilge.

Each of these applications benefits from the robust, corrosion-resistant properties of stainless steel centrifugal pumps, ensuring long-term reliability and efficiency in diverse industrial environments.

stainless steel centrifugal pump Accessories Upgrades and Custom Manufacturing Options

Stainless steel centrifugal pumps are robust and effective for various industrial applications. Enhancing their functionality and longevity often involves accessories, upgrades, and custom manufacturing options.

Accessories

1. Mechanical Seals: Advanced seals like double mechanical or cartridge types enhance reliability and leak prevention.

2. Variable Frequency Drives (VFDs): Control and optimize pump speed and efficiency, saving energy and reducing wear.

3. Pressure Gauges and Sensors: Vital for real-time monitoring and maintaining optimal pressure levels.

4. Baseplates and Mounting Kits: Custom-designed to ensure stability and ease of installation.

Upgrades

1. Impeller Upgrades: Enhanced designs or materials like high-grade stainless steel or titanium increase durability and performance.

2. Coatings and Linings: Anti-corrosive and abrasion-resistant coatings extend the life of components in harsh environments.

3. High-Efficiency Motors: Swapping out standard motors for energy-efficient models can significantly reduce operational costs.

Custom Manufacturing Options

1. Material Customization: Options beyond standard stainless steel, such as duplex stainless or alloys, provide superior resistance to specific chemicals or extreme temperatures.

2. Performance Customization: Custom impeller designs and volutes engineered to meet unique flow rates and pressure requirements.

3. Configuration Adaptation: Tailored designs to fit space constraints or integrate with existing systems, including multi-stage configurations for higher pressures.

4. Integration Features: Custom ports and connections for seamless integration with process control systems and other equipment.

These accessories, upgrades, and custom manufacturing options ensure stainless steel centrifugal pumps meet the highest standards of efficiency, reliability, and suitability for specific industrial needs. Investing in these enhancements can lead to significant long-term operational benefits.

List Quality Control and The Manufacturing Process of “stainless steel centrifugal pump”

Quality Control:

1. Material Inspection:

– Verify raw materials (stainless steel) for compliance with specifications.

– Check material certifications and perform chemical composition analysis.

2. Dimensional Accuracy:

– Use precision instruments to measure components for adherence to design tolerances (e.g., casing, impellers).

3. Welding and Assembly Check:

– Inspect welded joints for defects using Non-Destructive Testing (NDT) methods like X-ray or ultrasonic tests.

– Ensure proper alignment and fit of assembled parts.

4. Surface Finishing:

– Check for uniformity in surface finishing to prevent corrosion and ensure proper functionality.

5. Performance Testing:

– Perform hydraulic tests to check for performance metrics like flow rate, pressure, and efficiency.

– Conduct run tests to ensure the pump operates without excessive vibration or noise.

6. Final Inspection:

– Perform a comprehensive inspection before shipping to ensure all components and assemblies meet quality standards.

Manufacturing Process:

1. Design and Engineering:

– Develop detailed engineering drawings and specifications based on customer requirements.

2. Casting:

– Pour molten stainless steel into sand molds to create the pump casing and impeller.

– Allow castings to cool and solidify before removing from molds.

3. Machining:

– Use CNC machines to achieve precise dimensions and smooth surfaces on cast components.

– Machine features like impeller vanes, shaft holes, and flanges.

4. Heat Treatment (if needed):

– Apply heat treatment processes to enhance the mechanical properties of certain components.

5. Welding and Fabrication:

– Weld various parts together (e.g., casing sections) according to welding standards.

6. Assembly:

– Assemble the main components like the casing, impeller, shaft, seals, and bearings.

– Check alignment and balance the rotating parts.

7. Surface Finishing:

– Polish or passivate stainless steel surfaces to improve corrosion resistance and appearance.

8. Testing:

– Conduct hydraulic and mechanical tests to ensure performance and reliability.

– Validate adherence to design specifications and performance parameters.

9. Packaging and Shipment:

– Pack pumps securely to prevent damage during transit.

– Provide detailed documentation for installation and maintenance.

By maintaining rigorous quality control and following a systematic manufacturing process, reliable and efficient stainless steel centrifugal pumps are produced to meet industry standards.

How to use “stainless steel centrifugal pump”

Using a stainless steel centrifugal pump involves several key steps to ensure safety and efficiency:

1. Installation:

– Place the pump on a stable and level surface.

– Connect the inlet (suction) and outlet (discharge) pipes securely. Ensure the inlet is positioned below the liquid source to avoid air pockets.

– Use appropriate gaskets and flanges to prevent leaks.

2. Priming:

– Fill the pump and suction line with liquid to prime it, unless it is a self-priming model.

– Open the vents on the pump casing to allow trapped air to escape, ensuring the pump is fully primed.

3. Initial Checks:

– Ensure that all valves in the suction and discharge lines are open.

– Verify that the power supply matches the pump’s voltage and phase requirements.

– Inspect the pump for any visible damage or blockages.

4. Starting the Pump:

– Turn on the power and gradually bring the pump to its operational speed.

– Monitor the suction and discharge pressure gauges to ensure they are within the recommended range.

5. Operation:

– Keep an eye on the pump’s performance by checking flow rates and pressures.

– Regularly inspect for any unusual noises or vibrations which may indicate potential issues.

– Maintain a consistent flow of liquid to avoid dry running, which can damage the pump.

6. Maintenance:

– Schedule regular maintenance checks, including inspecting seals, bearings, and impellers.

– Replace worn-out parts promptly to prevent breakdowns.

– Clean the pump and ensure that all components are free from scale and debris.

By closely following these steps, you will ensure the optimal performance and longevity of your stainless steel centrifugal pump.

“stainless steel centrifugal pump” Comparative Analysis

Stainless steel centrifugal pumps are prominent in various industries due to their robustness, efficiency, and corrosion resistance. This analysis compares these pumps with alternatives, highlighting key factors such as material durability, application suitability, maintenance, and cost.

Material Durability

Stainless steel centrifugal pumps excel in durability. The stainless steel construction offers excellent resistance to corrosion, oxidation, and extreme temperatures, making them ideal for aggressive environments and fluid transfer applications involving chemicals, saltwater, and high acidity.

Application Suitability

Stainless steel pumps are versatile, commonly used in sectors like food and beverage, pharmaceuticals, chemical processing, and wastewater treatment. They ensure compliance with hygiene standards and withstand frequent cleaning cycles, a feature less prominent in other materials, such as cast iron or plastic, which may not offer the same level of purity or strength.

Comparatively, cast iron pumps provide good structural integrity but are less resistant to corrosion. Plastic pumps are highly resistant to chemicals but may lack the mechanical strength and thermal stability required for heavy-duty applications.

Maintenance

Maintenance of stainless steel centrifugal pumps is relatively straightforward. The inherent resistance to wear and tear reduces the frequency of service intervals compared to cast iron pumps, which may suffer from rust. Additionally, the smooth surface of stainless steel facilitates easier cleaning and sanitation, reducing downtime in sensitive industries like food processing.

Cost

Cost is a significant consideration. Stainless steel pumps are generally more expensive than their cast iron or plastic counterparts due to the superior material properties and extended lifespan. However, the long-term operational savings from lower maintenance requirements and higher efficiency can offset the initial investment.

Conclusion

Stainless steel centrifugal pumps offer unmatched durability, versatile application potential, and low maintenance, justifying their higher cost compared to other materials. For industries where corrosion resistance, hygiene, and longevity are paramount, these pumps are the preferred choice, proving to be a cost-effective solution over time.

“stainless steel centrifugal pump” Warranty and Support

Warranty and Support for Stainless Steel Centrifugal Pump

Warranty:

Our stainless steel centrifugal pump comes with a comprehensive 2-year warranty, ensuring peace of mind and reliable performance. This warranty covers all manufacturing defects, materials, and workmanship under normal operational conditions. Should any issue arise within this period, we pledge to repair or replace the defective parts at no additional cost to you. Please ensure you retain your purchase receipt and register your product within 30 days of purchase to activate the warranty.

Support:

We are committed to providing exceptional customer support to ensure your satisfaction with our product. Our dedicated technical support team is available to assist you with any inquiries, troubleshooting, or guidance needed during the installation, operation, or maintenance of your pump.

Customer Service:

– Hotline: You can reach our customer service hotline from 9 AM to 6 PM, Monday to Friday. For after-hours inquiries, please leave a message, and we will get back to you promptly.

– Email Support: Send your questions or concerns to our support email, and our team will respond within 24 hours.

– Online Resources: Our website features a comprehensive help center with user manuals, FAQs, instructional videos, and maintenance tips to assist you in resolving common issues independently.

Extended Support:

For extended peace of mind, we offer various service plans beyond the warranty period, including annual maintenance contracts and priority repair services. These extended support options ensure optimal performance and longevity of your stainless steel centrifugal pump.

By choosing our product, you not only acquire a high-quality centrifugal pump but also gain access to excellent post-purchase support aimed at maximizing the utility and lifespan of your investment.

List “stainless steel centrifugal pump” FAQ

FAQs about Stainless Steel Centrifugal Pumps

1. What is a stainless steel centrifugal pump?

A stainless steel centrifugal pump is a type of pump that uses a rotating impeller to move fluid through the transfer of rotational energy. The use of stainless steel offers excellent durability, resistance to corrosion, and suitability for hygienic applications.

2. What are the key applications of these pumps?

They are commonly used in the food and beverage industry, pharmaceuticals, chemical processing, and water treatment due to their sanitary design and corrosion resistance.

3. How do you maintain a stainless steel centrifugal pump?

Regular maintenance involves checking for leaks, inspecting the impeller and seals, lubricating moving parts, and ensuring that the pump operates within its design parameters to avoid overheating and wear.

4. What types of fluids can these pumps handle?

They are capable of handling a variety of fluids, including potable water, chemicals, viscous fluids, and abrasive liquids, due to their robust construction and resistance to corrosion.

5. How do I choose the right pump for my application?

Consider the flow rate, head (pressure), fluid type, temperature, and application-specific requirements. Consulting with a pump specialist can help ensure optimal selection.

6. What is the lifespan of a stainless steel centrifugal pump?

When properly maintained, a stainless steel centrifugal pump can last many years, often exceeding a decade, depending on the application and operational conditions.

7. Are these pumps energy efficient?

Yes, centrifugal pumps are generally energy-efficient when operated near their Best Efficiency Point (BEP). Proper sizing and regular maintenance further enhance efficiency.

8. Can they handle solids or slurries?

While they can manage some solids and light slurries, the pumps are usually better suited for clean or slightly contaminated liquids. Specialized impellers can be used for handling more challenging fluids.

9. What are the common issues faced with these pumps?

Common issues include cavitation, seal leaks, and impeller wear. Regular inspection and maintenance can mitigate these problems.

10. Are stainless steel centrifugal pumps easy to install?

Yes, these pumps are generally easy to install and come with comprehensive manuals. However, professional installation is recommended to ensure optimal performance and safety.

Top 10 FAQ with answer about stainless steel centrifugal pump for Buyer Sourcing from China

Sure! Here are the top 10 FAQs about sourcing stainless steel centrifugal pumps from China along with brief answers:

1. What quality standards do Chinese manufacturers adhere to?

Chinese manufacturers often adhere to international quality standards such as ISO 9001, CE, and sometimes even API and FDA standards, depending on the application.

2. What materials are used in stainless steel centrifugal pumps?

Common materials include SS304, SS316, and SS316L. Some manufacturers may offer higher-grade materials upon request.

3. What is the typical lead time for manufacturing and delivery?

Lead times can range from 30 to 60 days, depending on the order size and customization requirements. Shipping times can add another 7 to 30 days based on the destination.

4. What are the common applications for these pumps?

Stainless steel centrifugal pumps are used in various applications including chemical processing, pharmaceuticals, food and beverage processing, water treatment, and more.

5. How do Chinese manufacturers handle customization requests?

Many manufacturers offer customization options for pump size, impeller design, motor specifications, and other features. It’s advisable to provide detailed specifications and consult with the manufacturer.

6. What kind of after-sales support can I expect?

After-sales support may include technical assistance, spare parts supply, and warranty services. It’s important to clarify these terms before placing an order.

7. Are Chinese manufacturers open to third-party inspections?

Yes, most reputable manufacturers are open to third-party inspections and audits to ensure product quality and compliance.

8. What are the payment terms commonly accepted?

Common payment terms include T/T (Telegraphic Transfer), L/C (Letter of Credit), and sometimes DP (Document against Payment). Initial deposits are usually required.

9. What kind of documentation is provided?

Standard documentation includes quality certificates, material test reports, user manuals, and compliance certificates. Ensure all necessary documents are included before finalizing the deal.

10. How can I verify the credibility of a Chinese supplier?

You can verify the credibility through third-party agencies, customer references, site visits, and by checking certifications and industry associations.

By addressing these FAQs, buyers can make more informed decisions when sourcing stainless steel centrifugal pumps from China.