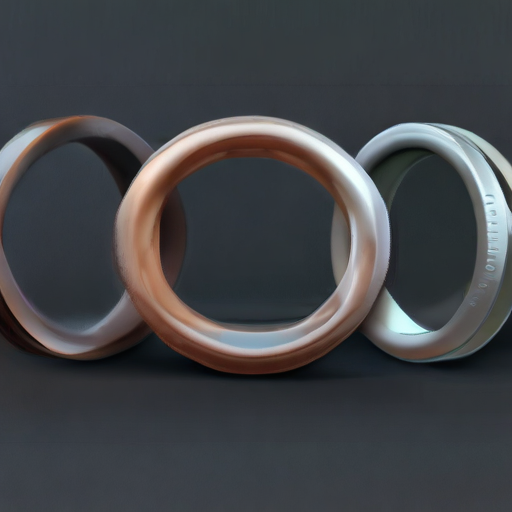

u ring seal Safety Certifications

U-ring seals are critical components in numerous industrial applications, ensuring efficient sealing and preventing leaks. Gaining relevant safety certifications for these seals is crucial for ensuring their reliability, safety, and compliance with industry standards. Key safety certifications for U-ring seals include:

1. ISO 9001: This certification confirms that the manufacturing process of the U-ring seals adheres to international quality management standards. It ensures consistent product quality and continuous improvement in manufacturing practices.

2. ISO 14001: This specifies requirements for an effective environmental management system (EMS). It guarantees that the U-ring seals are produced in an environmentally responsible manner, minimizing negative impacts on the environment.

3. CE Marking: Compliance with European Union safety, health, and environmental requirements. U-ring seals with CE marking meet essential directives and can be marketed within the EU.

4. RoHS Compliance: Ensures that U-ring seals do not contain hazardous substances such as lead, mercury, cadmium, and other restricted materials. Compliance with the Restriction of Hazardous Substances directive indicates safer and environmentally friendly products.

5. FDA Certification: For U-ring seals used in the food, beverage, and pharmaceutical industries, FDA certification is mandatory. This ensures that the materials used are safe and suitable for contact with consumable products, meeting stringent health and safety guidelines.

6. REACH Compliance: Adherence to the Registration, Evaluation, Authorization, and Restriction of Chemicals regulation in the EU, ensuring that the chemicals used in the U-ring seals are safe for human health and the environment.

7. ATEX Certification: Required for U-ring seals used in explosive atmospheres, ensuring that they meet the necessary health and safety requirements to prevent explosions.

8. NSF Certification: Relevant for water treatment and food service applications, this certification confirms that the U-ring seals meet public health and safety standards as set by the National Sanitation Foundation.

Achieving these certifications ensures that U-ring seals are safe, reliable, and compliant with global standards, facilitating their acceptance in various regulatory environments.

List Reference Technical Parameters of “u ring seal”

A U-ring seal, commonly used in hydraulic and pneumatic systems, is a type of dynamic seal known for its versatility and efficacy. Here are the key technical parameters typically considered for U-ring seals:

1. Material Composition: U-ring seals can be made from materials like nitrile rubber (NBR), fluoroelastomer (FKM), polyurethane (PU), and others. Material choice affects temperature and chemical resistance.

2. Temperature Range: Defined by the material, U-rings can typically operate within -30°C to 200°C. For example, NBR suits -30°C to +120°C, while FKM can handle -20°C to +200°C.

3. Pressure Rating: U-rings are designed to withstand a variety of pressures. Standard applications can see up to 400 bar, but specialized designs can endure more.

4. Hardness (Shore A): Measured on the Shore A scale, common values range from 70 to 95. Hardness affects sealing performance and wear resistance.

5. Cross-Sectional Profile: U-rings have a U-shaped cross-section with a lip that enhances sealing. It’s crucial for the seal profile to match the application to ensure effectiveness under pressure.

6. Size Range: Diameters and cross-sections vary widely to suit different cylinder sizes. Standardized sizing helps in achieving compatibility with various housing dimensions.

7. Dynamic Sealing Capability: U-rings excel in dynamic applications where there is movement between the sealed surfaces. They maintain contact, ensuring effective sealing under motion.

8. Surface Finish Compatibility: The mating surfaces’ quality is critical. Typically, a surface roughness (Ra) of 0.4 to 0.8 micrometers is recommended to ensure optimal sealing without excessive wear.

9. Speed: U-ring seals are generally suitable for applications with speeds up to 0.5 m/s. Beyond this, special designs are required to prevent overheating and wear.

10. Chemical Resistance: Depending on the material, U-rings resist various fluids, including oils, hydraulic fluids, and some chemicals, making material selection crucial for compatibility.

Understanding these parameters ensures the correct selection and application of U-ring seals, enhancing performance and longevity in mechanical systems.

List Product features of “u ring seal”

Certainly! Here are some key product features of the “U Ring Seal”:

1. Superior Sealing Capability:

– Designed to provide a dependable and tight seal to prevent leakage.

– Handles both static and dynamic sealing applications efficiently.

2. Material Versatility:

– Available in various materials including NBR, FKM, EPDM, and Polyurethane.

– Selected material based on compatibility with different fluids and temperatures.

3. Durability and Longevity:

– Exhibits high resistance to wear, extrusion, and aging.

– Suitable for long-term use in demanding environments.

4. Wide Operating Temperature Range:

– Capable of functioning effectively in a broad range of temperatures.

– Depending on the material, can work in extreme hot and cold conditions.

5. Chemical Resistance:

– Resistant to a wide range of chemicals including oils, solvents, and hydraulic fluids.

– Suitable for various industrial applications.

6. Pressure Handling:

– Designed to withstand high pressure, making it ideal for hydraulic and pneumatic systems.

– Ensures reliable performance under varying pressure conditions.

7. Ease of Installation:

– Simple to install, reducing downtime during maintenance or replacement.

– Lessens the complexity involved in sealing mechanisms.

8. Customized Options:

– Available in a range of sizes and cross-sections to meet specific application needs.

– Custom designs available for specialized requirements.

9. Versatile Applications:

– Used in hydraulic cylinders, valve systems, pumps, and industrial machinery.

– Suitable for automotive, aerospace, marine, and manufacturing industries.

10. Cost-Effective Solution:

– Provides a cost-effective sealing solution compared to other sealing types.

– Low maintenance and high reliability result in long-term savings.

11. Compliance and Standards:

– Meets various industry standards and certifications for quality and performance.

– Assures safety and reliability in critical applications.

These features collectively make U Ring Seals an excellent choice for a wide range of sealing applications requiring robust performance and durability.

List Various Types of “u ring seal”

U-ring seals, commonly used in hydraulic and pneumatic systems for sealing applications, come in various types, each designed for specific functions and environments. Here are some prominent types:

1. Single Lip U-Ring Seals

– Description: Feature a single sealing lip.

– Applications: Ideal for low-pressure systems.

2. Double Lip U-Ring Seals

– Description: Have two sealing lips for enhanced sealing performance.

– Applications: Suitable for applications with higher pressures and dynamic movements.

3. Symmetrical U-Ring Seals

– Description: Symmetrical design allows usage in both rod and piston applications.

– Applications: Versatile usage in general hydraulic systems.

4. Asymmetrical U-Ring Seals

– Description: Asymmetrical design where one lip is longer or thicker.

– Applications: Optimized for either rod or piston sealing specifically.

5. Fabric-Reinforced U-Ring Seals

– Description: Reinforced with fabric for added strength and durability.

– Applications: High-pressure systems and heavy-duty applications.

6. PTFE U-Ring Seals

– Description: Made from Polytetrafluoroethylene (PTFE) for chemical resistance and low friction.

– Applications: Chemical industries and applications requiring minimal friction.

7. Rubber U-Ring Seals

– Description: Constructed from various rubber compounds like NBR, EPDM, or Viton.

– Applications: General-purpose sealing in hydraulic and pneumatic systems.

8. High-Temperature U-Ring Seals

– Description: Made from materials like Viton or silicone designed to withstand high temperatures.

– Applications: Engines, and other high-temperature environments.

9. Low-Temperature U-Ring Seals

– Description: Designed for reliable performance in cold conditions.

– Applications: Cold storage, arctic environments.

10. Specialty U-Ring Seals

– Description: Includes custom-designed U-rings for specific applications.

– Applications: Unique or uncommon sealing requirements.

Each type of U-ring seal offers distinct advantages based on the application requirements, such as pressure, temperature, and environmental conditions. Selecting the appropriate type ensures efficient and reliable sealing performance.

List Application of “u ring seal”

A U-ring seal, also known as a U-cup seal, is a type of seal commonly used in various industrial applications for effective fluid and pressure control. Here are some key applications of U-ring seals:

1. Hydraulic Systems:

– Hydraulic Cylinders: Provides dynamic sealing between the piston and cylinder walls, ensuring efficient operation of the hydraulic system.

– Hydraulic Pumps and Motors: Used to prevent fluid leakage and maintain pressure in different components.

2. Pneumatic Systems:

– Pneumatic Cylinders: Ensures air-tight seals for efficient pneumatic actuation.

– Valves: Prevents leaks and maintains pneumatic pressure within various valve systems.

3. Automotive Industry:

– Suspension Systems: Used in shock absorbers and struts for sealing hydraulic fluids.

– Braking Systems: Provides sealing in brake calipers and master cylinders.

4. Agricultural Equipment:

– Tractors and Harvesters: Utilized in hydraulic controls for steering, lifting, and other mechanical operations.

5. Manufacturing Machinery:

– Injection Molding Machines: Ensures proper sealing in hydraulic circuits for mold clamping.

– Presses: Used in hydraulic presses to maintain pressure and prevent fluid leakage.

6. Oil and Gas Industry:

– Drilling Equipment: Seals in hydraulic systems of drilling rigs and other equipment.

– Pump Systems: Ensures efficient operation by preventing leaks in pump mechanisms.

7. Mining Equipment:

– Excavators and Loaders: Vital for hydraulic sealing in heavy machinery, ensuring durability and reliability in harsh conditions.

8. Aerospace:

– Flight Control Systems: Used in hydraulic actuators and control systems for precise movement and fluid management.

9. Marine Engineering:

– Propulsion Systems: Utilized in hydraulic systems of ships and submersibles for efficient fluid control.

U-ring seals are valued for their ability to withstand high pressures, wide temperature ranges, and dynamic motion, making them integral to the performance and longevity of various mechanical and hydraulic systems.

List Buyer Types of “u ring seal”

The “u ring seal” is a specialized sealing component used in various applications to prevent leakage of fluids or gases. Below are some common buyer types for u ring seals:

1. Manufacturing Companies: These companies use u ring seals in their machinery and equipment for ensuring efficient operation. Sectors include automotive, aerospace, and heavy machinery.

2. Hydraulic System Manufacturers: U ring seals are vital in hydraulic cylinders and systems to maintain pressure and prevent fluid leakage.

3. Industrial Maintenance Services: Companies specializing in the maintenance and repair of industrial equipment regularly purchase u ring seals to replace worn-out components.

4. OEMs (Original Equipment Manufacturers): OEMs integrate u ring seals into their products during the manufacturing process, providing a complete solution to their customers.

5. Distributors and Wholesalers: These entities buy u ring seals in bulk from manufacturers and resell them to smaller businesses, maintenance companies, and other end-users.

6. Automotive Workshops and Garages: Mechanics and technicians in this sector utilize u ring seals during the repair and maintenance of vehicle components.

7. Petrochemical and Oil & Gas Companies: In these industries, u ring seals are used in pipeline systems, pumps, and valves to ensure the containment of hazardous substances.

8. Construction Equipment Suppliers: Companies that supply parts for construction machinery often need u ring seals for various hydraulic and mechanical applications.

9. Agricultural Machinery Suppliers: The agricultural sector uses u ring seals in the equipment for maintaining fluid systems and machinery parts.

10. Manufacturing and R&D Departments: Research and development units within companies that specialize in designing and testing new machinery and components frequently buy u ring seals for prototyping and testing.

Each of these buyer types seeks u ring seals to ensure optimal performance, longevity, and reliability in their respective applications.

List “u ring seal” Project Types for Different Industries

U-ring seals, known for their versatile and robust sealing capabilities, are extensively deployed across various industries. Here are some project types where U-ring seals are commonly used:

1. Automotive:

– Brake Systems: Used in master cylinders and calipers to ensure efficient and safe braking.

– Fuel Injection Systems: Provide reliable sealing to prevent fuel leakage and contamination.

– Shock Absorbers: Seal hydraulic fluid to maintain performance and longevity of the shock absorbers.

2. Aerospace:

– Hydraulic Actuators: Ensure precise control and movement in aircraft’s control surfaces and landing gear.

– Fuel Systems: Maintain integrity of fuel lines to prevent leaks and enhance safety.

– Cabin Pressure Management: Seal environmental control systems to maintain cabin pressure and comfort.

3. Industrial Machinery:

– Hydraulic Cylinders: Essential in providing a leak-proof seal for hydraulic systems in heavy machinery and robots.

– Pneumatic Systems: Used in compressors and actuators for reliable air flow control.

– Pumps and Valves: Ensure tight sealing in various types of pumps and industrial valves to prevent leaks and maintain operational efficiency.

4. Marine:

– Engine Components: Used in sealing various parts of marine engines to ensure endurance against harsh sea conditions.

– Hydraulic Winches: Maintain the integrity of hydraulic systems in winches and cranes on ships.

– Steering Mechanisms: Vital in ensuring non-leakage in hydraulic steering systems.

5. Oil and Gas:

– Drilling Equipment: Used in sealing drilling equipment to withstand high-pressure and high-temperature conditions.

– Pipelines: Maintain the integrity of joints and connections in oil and gas pipelines.

– Valves and Control Systems: Ensure safe and steady operation of valves and control systems in extraction and refining processes.

6. Medical Devices:

– Fluid Delivery Systems: Provide reliable sealing in medical pumps and syringes.

– Prosthetics: Ensure airtight sealing in hydraulic prosthetic limbs.

– Diagnostic Equipment: Used in sealing various fluidic modules in diagnostic instruments to prevent contamination.

In conclusion, U-ring seals are integral components in diverse industries due to their reliable sealing properties, enhancing the safety, efficiency, and performance of various systems and machinery.

u ring seal Accessories Upgrades and Custom Manufacturing Options

Upgrading and customizing U-ring seals can enhance their performance and extend their service life. Here are some accessories, upgrades, and custom manufacturing options to consider:

1. Material Options:

– Elastomers: Choose from a variety of elastomers like NBR, FKM, EPDM, and HNBR based on application requirements such as chemical resistance, temperature range, and wear resistance.

– Thermoplastics: For high-load or high-pressure applications, consider thermoplastics like PTFE or UHMWPE for their low friction and high durability.

2. Back-up Rings:

– Single & Double Back-up Rings: These are used to prevent extrusion in high-pressure applications, thereby extending seal life.

3. Design Variations:

– Lip Configurations: Custom lip designs can be tailored for specific sealing environments. For instance, dual-lip designs offer extra protection against contamination.

– Pre-loaded U-Rings: Applying a pre-load during manufacturing can enhance initial sealing performance.

4. Surface Treatments:

– Coatings: Anti-friction coatings or surface treatments, such as PTFE impregnation, can reduce wear and friction, enhancing the seal’s operational efficiency.

– Metallic Coatings: In some cases, adding a metallic coat can offer extra protection against extreme temperatures and chemicals.

5. Customized Dimensions:

– Precision Machining: Custom machining services allow for U-ring seals to be tailored to precise dimensions, ensuring a perfect fit in unique or non-standard applications.

6. Integrated Components:

– Spring Energizers: Incorporating spring energizers can help maintain seal contact under varying pressure and temperature conditions.

7. Enhanced Durability:

– Dual Materials: Using two-layer composites can provide a balance of flexibility and strength, with an inner elastomer providing elasticity and an outer layer offering wear resistance.

Investing in these accessories, upgrades, and custom manufacturing options can significantly boost the performance and longevity of U-ring seals, making them more effective and efficient for specific applications.

List Quality Control and The Manufacturing Process of “u ring seal”

Quality Control

1. Material Verification: Ensure raw materials meet specifications (e.g., resilience, hardness).

2. Dimensional Inspection: Use calipers and micrometers for precise measurements.

3. Visual Inspection: Check for surface defects like cracks or deformities.

4. Hardness Testing: Measure durometer hardness to ensure it meets standards.

5. Tensile Testing: Verify material strength under tension to prevent breakage.

6. Pressure Testing: Ensure seals can withstand operational pressures without leakage.

7. Aging Tests: Simulate long-term use to check for material degradation.

8. Certification: Document and certify compliance with industry standards.

Manufacturing Process

1. Design and Prototyping: CAD designs are created, followed by prototyping for initial fit and function tests.

2. Material Selection: Choose appropriate elastomer (e.g., NBR, FKM) based on application requirements.

3. Mixing: Combine base elastomer with additives like fillers, plasticizers, and curing agents.

4. Molding:

– Compression Molding: Place material in a heated mold to form shape.

– Injection Molding: Inject molten elastomer into a mold.

5. Curing: Heat under controlled conditions to vulcanize the elastomer, enhancing elasticity and strength.

6. Trimming and Finishing: Remove excess material and finish edges for a clean seal.

7. Post-Curing: Additional heating to stabilize physical properties.

8. Inspection and Testing: Execute all quality control steps, such as hardness and pressure testing.

9. Packaging: Use protective packaging to avoid contamination and deformation during transportation.

10. Distribution: Ensure timely delivery to customers or storage facilities.

This concise overview ensures that each u ring seal meets rigorous standards and performs reliably in its intended application.

How to use “u ring seal”

A “u ring seal,” often referred to as a “U-cup seal,” is a type of sealing device commonly used in hydraulic and pneumatic systems to prevent fluid or air leakage. Here’s a brief guide on how to use a u ring seal:

Materials Needed:

– U ring seal

– Properly sized cylinder or housing

– Appropriate tools (e.g., screwdrivers, pliers)

– Lubricant compatible with the fluids being sealed

– Clean cloth

Steps:

1. Selection: Ensure you have the correct size and material of the u ring seal for your application. Factors include diameter, cross-sectional thickness, and compatibility with the fluid type.

2. Prepare the Surface:

– Clean the housing or cylinder and the sealing groove thoroughly. Remove any debris, dirt, or old seal remnants.

– Inspect the sealing surface for scratches, pitting, or other damage that might compromise the seal.

3. Lubrication:

– Apply a thin layer of lubricant on both the U-ring seal and the sealing groove. This reduces friction and helps with proper placement.

4. Installation:

– Place the u ring seal into the groove gently. If the seal is stretched or twisted, it won’t perform correctly.

– Make sure the “U” shape faces the correct direction. For rod seals, the lip should face the pressure side. For piston seals, the lip should face outward.

5. Assembly:

– Once the seal is in place, carefully reassemble the cylinder or housing. Ensure not to pinch or damage the u ring seal during this process.

6. Testing:

– After installation, conduct a pressure test to ensure there are no leaks. Monitor the system under operating conditions to verify proper sealing.

Tips:

– Always refer to the manufacturer’s guidelines for specific installation instructions.

– Replace seals during routine maintenance to prevent unexpected failures.

By following these steps, you can effectively use a u ring seal in various hydraulic and pneumatic applications.

“u ring seal” Comparative Analysis

The U-ring seal is a critical component in various industrial applications where fluid or gas retention and pressure resistance are essential. Here’s a comparative analysis focusing on design, materials, performance, and applications.

Design

U-ring seals feature a U-shaped cross-section, enabling effective sealing through the axial deformation of the legs. This shape allows for a high level of flexibility and adaptability to different groove dimensions. They are designed to maintain a tight seal under both high and low pressure.

Materials

U-ring seals are typically made from elastomeric materials such as Nitrile (Buna-N), Viton, or EPDM. Nitrile is known for its good resistance to oil, fuels, and other chemicals. Viton offers superior thermal and chemical resistance, making it suitable for extreme conditions. EPDM is noteworthy for its excellent performance in water and steam applications.

Performance

U-rings provide excellent sealing capabilities due to their unique design. They can withstand significant pressure variations and maintain integrity under dynamic conditions. The elastomeric nature of the materials allows them to adapt to minor surface irregularities, ensuring a robust seal. However, the performance can be influenced by temperature, pressure, and chemical exposure, necessitating the correct material choice for specific applications.

Applications

U-ring seals are versatile and are used in a variety of industries including automotive, aerospace, hydraulic systems, and pneumatic devices. In hydraulic systems, they prevent fluid leakage and maintain pressure, while in pneumatic systems, they ensure air-tight sealing. Their adaptability to different operating environments makes them a go-to choice for applications requiring reliable performance under diverse conditions.

Comparison with Alternatives

Compared to O-rings, U-rings offer superior performance in dynamic applications due to their ability to maintain a seal with minor deformation. However, O-rings might be preferred in static applications for their simplicity. Lip seals offer similar advantages but can be more complex and costlier to manufacture.

Conclusion

U-ring seals stand out for their flexible design, material versatility, and robust performance in dynamic environments. Selection should be based on specific application requirements, balancing factors such as pressure, temperature, and chemical exposure.

“u ring seal” Warranty and Support

U Ring Seal Warranty and Support

At U Ring Seal, our commitment to quality ensures that our seals meet the highest standards of excellence. To provide further assurance, we offer a comprehensive warranty and robust support to our customers.

Warranty Terms

1. Coverage Duration: Our U Ring Seal comes with a 12-month warranty from the date of purchase.

2. Scope: The warranty covers defects in materials and workmanship under normal usage conditions.

3. Exclusions: Damage resulting from misuse, improper installation, unauthorized repairs, or modifications will void the warranty.

Claim Process

1. Initial Steps: If a defect is identified, contact our Customer Support within the warranty period.

2. Required Information: Provide proof of purchase, a description of the defect, and relevant photos if necessary.

3. Evaluation: Our team will evaluate the claim and determine if it meets the warranty criteria.

4. Resolution: Approved claims will result in repair, replacement, or refund, as deemed appropriate by U Ring Seal.

Customer Support

1. Contact Methods: Reach us via phone, email, or our online support portal 24/7.

2. Response Time: Expect a response within 24 hours for all inquiries and support requests.

3. Technical Assistance: Our skilled technicians are available to assist with installation guidance and troubleshooting.

4. Documentation: Access a comprehensive library of user manuals, installation guides, and FAQ documents on our website.

Additional Support Services

1. Training: We offer training sessions for optimal use and maintenance of U Ring Seals.

2. Custom Solutions: Our engineering team can provide tailored solutions to meet specific industry requirements.

At U Ring Seal, customer satisfaction is our priority. Rest assured that with our warranty and dedicated support, you are in good hands. For further details, please visit our website or contact our support team.

List “u ring seal” FAQ

Certainly! Here is a concise FAQ for U-ring seals:

U-Ring Seal FAQ

#### What is a U-ring seal?

A U-ring seal is a type of hydraulic sealing element with a U-shaped cross-section, commonly used to prevent fluid leakage in cylinders and other hydraulic components.

#### What materials are U-ring seals made from?

U-ring seals are typically made from materials such as Nitrile Rubber (NBR), Fluorocarbon (Viton), polyurethane (PU), and Ethylene Propylene Diene Monomer (EPDM), chosen based on the application’s specific needs.

#### Where are U-ring seals commonly used?

They are widely used in hydraulic and pneumatic systems, including applications in machinery, automotive systems, and industrial equipment.

#### What are the advantages of using U-ring seals?

– Effective Sealing: The U-shaped design provides excellent sealing capability under pressure.

– Durability: Made from robust materials that withstand wear and tear.

– Flexibility: Suitable for a wide range of temperatures and pressures.

#### How do I choose the right U-ring seal for my application?

Consider factors such as:

– Operating temperature: Ensure the material can withstand your application’s temperature range.

– Pressure: Choose a seal that can handle the pressure levels in your system.

– Chemical compatibility: Select a material that is resistant to the fluids and chemicals it will encounter.

#### How do I install a U-ring seal?

– Cleanliness: Ensure both the seal and the groove are clean.

– Lubrication: Apply a compatible lubricant for easier installation.

– Alignment: Properly align the seal in its groove to avoid twisting or stretching.

#### How long do U-ring seals last?

Lifespan depends on operating conditions such as temperature, pressure, and exposure to chemicals. Regular maintenance and inspection can help extend their service life.

#### Can U-ring seals be reused?

Reusing is generally not recommended as the seal may have deformed or degraded, compromising its effectiveness. Always inspect used seals thoroughly before deciding.

By considering these key points, you can ensure the proper functioning and longevity of your hydraulic systems using U-ring seals.

Top 10 FAQ with answer about u ring seal for Buyer Sourcing from China

Sure, here are the top 10 Frequently Asked Questions (FAQs) about sourcing U-ring seals from China, concise and under 300 words:

1. What Are U-Ring Seals?

U-ring seals are elastomeric seals used to prevent fluid leakage in hydraulic and pneumatic systems. They are durable and provide a tight seal under pressure.

2. How Do I Identify Quality U-Ring Seals?

Quality U-ring seals should meet international standards like ISO or DIN. Check for consistent material properties, precise dimensions, and good elasticity.

3. What Materials Are Common for U-Ring Seals?

U-ring seals are typically made from Nitrile Rubber (NBR), Fluorocarbon (Viton), or Polyurethane (PU). Each material offers distinct advantages in terms of wear resistance and temperature tolerance.

4. How Can I Verify a Chinese Supplier’s Credibility?

Check the supplier’s certifications, request product samples, and read reviews or ask for references from previous clients. Platforms like Alibaba offer verified supplier statuses.

5. What Is the Typical Lead Time?

Lead time depends on the order quantity and customization requirements but generally ranges from 2 to 6 weeks. Always confirm with the supplier.

6. What Are the Payment Terms?

Standard options include T/T (Telegraphic Transfer), L/C (Letter of Credit), or PayPal for smaller orders. T/T is most common, usually requiring a 30% deposit and 70% before shipment.

7. Can I Customize U-Ring Seals?

Yes, most Chinese manufacturers offer customization for size, material, and hardness. Provide detailed specifications and drawings to ensure accurate customization.

8. Is Bulk Order Pricing Available?

Yes, bulk orders generally come with discounted pricing. Discuss your order volume with the supplier to negotiate better rates.

9. What Shipping Methods Are Available?

Common shipping methods include air freight for fast delivery or sea freight for cost-effective bulk shipping. DDP (Delivered Duty Paid) terms can simplify import processes.

10. How Do I Handle Quality Issues?

Establish a clear quality agreement before purchase. In case of issues, communicate promptly with the supplier for replacements or refunds. Using an escrow service can offer added security.

These FAQs should help you navigate the process of sourcing U-ring seals from China efficiently.