diaphragm valve diagram Safety Certifications

Diaphragm Valve Diagram and Safety Certifications

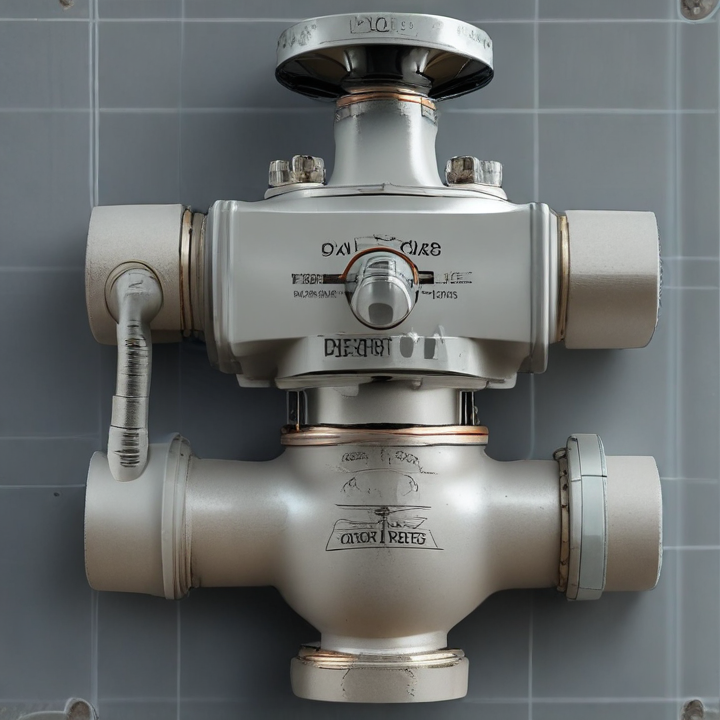

A diaphragm valve is a versatile and crucial component in fluid control systems. Here’s a simplified diagram of a typical diaphragm valve:

Diagram Description:

1. Body: The main structure that holds the fluid.

2. Diaphragm: A flexible membrane that controls fluid flow.

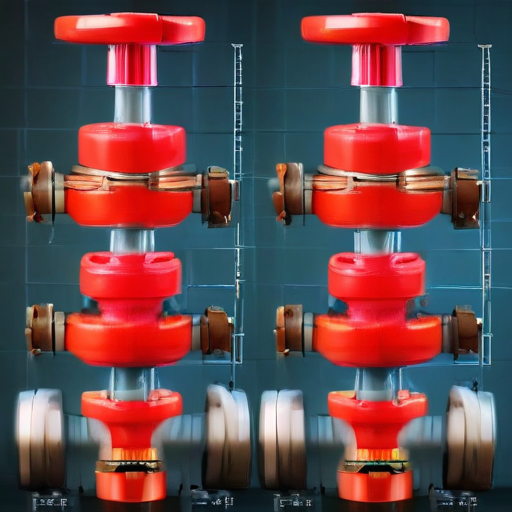

3. Stem and Handwheel/Actuator: Used to move the diaphragm up or down.

4. Seat: The area where the diaphragm seals to stop flow.

5. Flow Port: Entry and exit points for fluid.

—

__

Handwheel/Actuator | |

| |

Stem ________|_ _|_________

| |

| |

| Diaphragm |

Flow ——| |—– Flow

Port |_____________|

| Body |

|___________|

—

Safety Certifications

1. ISO 9001: This certification ensures that the diaphragm valve is manufactured under a quality management system, guaranteeing consistent quality and safety.

2. ANSI/ASME B16.34: This standard specifies the design, materials, and construction methods for valves, ensuring they can withstand various pressure and temperature conditions safely.

3. CE Marking: Compliance with European Union safety, health, and environmental requirements, making the diaphragm valve suitable for use in EU markets.

4. API 609: This American Petroleum Institute standard applies to butterfly valves but also sets a precedent for other types such as diaphragm valves, ensuring they meet rigorous industry safety and performance criteria.

5. PED (Pressure Equipment Directive): Ensures the valve conforms to EU standards for pressure equipment, guaranteeing its safety and reliability under pressure.

6. 3-A Sanitary Standards: Relevant for valves used in food, dairy, and pharmaceutical industries, ensuring they meet stringent hygiene and safety standards.

These certifications assure users that diaphragm valves are reliable, safe, and compliant with high industry standards.

List Reference Technical Parameters of “diaphragm valve diagram”

Certainly! The diaphragm valve is a type of valve that uses a flexible diaphragm to separate the flow of media from the operating parts of the valve. It is commonly used in applications requiring clean or sterile conditions. Below are some key technical parameters often associated with a diaphragm valve diagram:

1. Diaphragm Material: The material of the diaphragm is crucial because it determines the chemical compatibility and temperature tolerance. Common materials include EPDM, PTFE, NBR, and silicone.

2. Body Material: The valve body material can vary depending on the application and required durability. Common materials include stainless steel, cast iron, and plastic (PVC, PP).

3. Size: Diaphragm valves come in various sizes, typically measured by the internal diameter of the valve (from 1/2 inch to several inches). The size affects the flow rate and pressure rating.

4. Pressure Rating: The maximum pressure the valve can withstand, usually measured in PSI or bar, varies depending on the design and materials used.

5. Temperature Range: Indicates the minimum and maximum temperatures the valve can endure. This is influenced by the materials used for both the diaphragm and body.

6. Connection Types: Various connection options like threaded, flanged, socket weld, or butt weld can affect ease of installation and compatibility with existing systems.

7. Actuation Method: Diaphragm valves can be manually, electrically, pneumatically, or hydraulically actuated, which dictates the control mechanism.

8. Flow Characteristics: The Cv (flow coefficient) value indicates the valve’s capacity to pass fluid; higher Cv values correspond to higher flow rates.

9. Seal Design: Ensures a leak-proof operation. The sealing mechanism can vary, influencing both performance and suitability for certain applications.

10. Surface Finish: Particularly important in sanitary applications, the interior finish of the valve dictates the level of cleanliness, often measured in Ra (average roughness).

These parameters help in selecting the appropriate diaphragm valve for specific industrial applications, ensuring reliability, efficiency, and compliance with operational requirements.

List Product features of “diaphragm valve diagram”

A diaphragm valve diagram typically details the structure and operation of a diaphragm valve, which is widely used for fluid control in various industries. Below are the key features often highlighted in such diagrams:

1. Body: The valve body houses all internal components and connects to the pipeline. Materials can vary depending on the application, including metals, plastics, and composites.

2. Diaphragm: A flexible membrane that makes contact with the valve seat to control flow. Materials like rubber, elastomers, or PTFE (Teflon) are common to ensure chemical compatibility and durability.

3. Actuator: This mechanism operates the valve, which can be manually controlled (handwheel/lever) or automated (pneumatic, electric, or hydraulic actuators).

4. Bonnet: Covers and encloses the upper part of the valve, housing the diaphragm and actuator connections. It also protects internal components from external environmental factors.

5. Valve Seat: The seating surface where the diaphragm makes contact to close the valve. It typically forms a leak-tight seal when the diaphragm is pressed against it.

6. Stem: Connects the diaphragm to the actuator, moving up and down to control the diaphragm’s position. It is usually sealed with a stuffing box or other packing materials to prevent leaks.

7. Weir or Saddle: An elevated portion inside the valve body that the diaphragm presses against to block flow. A weir type has a dam-like structure, while a straight-through type (saddle) has a more gradual shape.

8. Flow Paths: The diagram shows the flow direction and paths through the valve, indicating positions for open, closed, and throttling states.

9. Seal Integrity: Diagrams often highlight points where sealing must be robust to prevent leakage, especially around the stem, diaphragm, and connections.

10. Maintenance Points: Visuals often indicate areas that may require regular inspection or maintenance, such as the diaphragm, actuator connections, and seals.

Understanding these features through a diaphragm valve diagram aids in proper installation, operation, and maintenance, ensuring optimal performance and longevity of the valve in its intended application.

List Various Types of “diaphragm valve diagram”

Diaphragm valves are versatile and used for various applications in industries due to their excellent shut-off and control capabilities. Here are several types of diaphragm valve diagrams, each illustrating different design and operational features:

1. Weir Type Diaphragm Valve: This design features a shallow saddle or “weir” over which the diaphragm closes. It is well-suited for throttling applications and handling dirty or corrosive fluids. The diagram of a weir type emphasizes its shallow seat and flow path.

2. Straight Through Diaphragm Valve: Unlike the weir type, this valve has a straight-through flow path with a flat seat. It’s ideal for applications requiring minimal resistance to flow, making it suitable for handling viscous or sludgy media. The diagram highlights the flat diaphragm seating directly onto the flat bed.

3. Pinch Type Diaphragm Valve: In this design, the diaphragm is pinched by applying pressure from the valve body. This type is particularly used in applications requiring complete isolation of the fluid from the moving parts of the valve. The diagram shows the pinch mechanism and the enclosed flow path.

4. Bi-Directional Diaphragm Valve: It features a symmetrical design allowing for fluid flow in both directions with equal efficiency. Often used in systems where the direction of flow needs to be reversible. The diagram illustrates the symmetrical diaphragm and flow chamber.

5. Manual Diaphragm Valve: Operated by a handwheel or lever, the diagram shows the manual actuator mechanisms and the diaphragm’s opening/closing action.

6. Pneumatically Actuated Diaphragm Valve: Utilizes pneumatic pressure to actuate the diaphragm. The diagram includes the pneumatic actuator components, such as the air supply lines, actuator cylinder, and control solenoid valves.

7. Electrically Actuated Diaphragm Valve: Controlled via an electric actuator, the diagram outlines the integration of electrical components with the valve, including motor, gears, and control circuits.

Each type of diaphragm valve diagram will typically detail the core components such as the body, diaphragm, actuator, and flow path, highlighting the distinctive features relevant to their specific types and applications.

List Application of “diaphragm valve diagram”

A diaphragm valve is a versatile and reliable component used in various industries for fluid control. Here are key applications of diaphragm valves:

1. Water Treatment:

Diaphragm valves are commonly used in water treatment plants to control the flow of water and chemicals. They help in processes like filtration, softening, and disinfection.

2. Pharmaceutical Industry:

Due to their sanitary design, diaphragm valves are essential in pharmaceutical manufacturing. They prevent contamination, ensuring sterile conditions for product integrity.

3. Food and Beverage Industry:

These valves are used in the food and beverage sector to ensure hygiene and prevent contamination, especially in processes involving dairy, brewing, or juice production.

4. Chemical Processing:

Diaphragm valves are resistant to corrosion and can handle aggressive chemicals, making them suitable for chemical processing plants.

5. Biotechnology:

In biotechnology, diaphragm valves are used for processes requiring sterile conditions, such as fermentation and filtration.

6. Semiconductor Manufacturing:

They are employed in semiconductor manufacturing for their precision and ability to handle ultra-pure water and chemicals without leakage or contamination.

7. Oil and Gas Industry:

Diaphragm valves are used in upstream and downstream operations to manage the flow of crude oil, natural gas, and other petroleum products efficiently.

8. Pulp and Paper Industry:

These valves regulate the flow of slurries and other fluids involved in papermaking, ensuring smooth operation and high-quality output.

9. HVAC Systems:

Diaphragm valves control the flow of refrigerants and other fluids in heating, ventilation, and air conditioning systems.

10. Power Generation:

They are used in power plants to manage the flow of steam, water, and cooling fluids, ensuring optimal performance and safety.

11. Mining Operations:

Diaphragm valves help control abrasive slurries and fluids in mining operations, contributing to the efficiency and safety of extraction processes.

These applications highlight the versatility, reliability, and hygienic benefits of diaphragm valves across various critical industries.

List Buyer Types of “diaphragm valve diagram”

The types of buyers interested in a “diaphragm valve diagram” can generally be segmented into the following categories:

1. Industrial Engineers and Plant Designers:

– Purpose: To design or upgrade fluid control systems in industries such as chemicals, pharmaceuticals, and food processing.

– Requirement: Detailed diagrams for integration and compatibility assessments.

2. Maintenance and Repair Technicians:

– Purpose: For diagnosing issues, performing repairs, and conducting routine maintenance on existing diaphragm valve installations.

– Requirement: Detailed and easily interpretable diagrams for efficient troubleshooting.

3. Procurement Officers and Purchasing Departments:

– Purpose: To assess technical specifications and compatibility with existing systems during the procurement of new diaphragm valves.

– Requirement: Comprehensive diagrams to ensure the chosen valves meet all required standards and specifications.

4. Quality Control Managers:

– Purpose: To enforce and check compliance with industry standards and safety regulations.

– Requirement: Accurate diagrams that help in verifying that the valves and their installations meet quality benchmarks.

5. Educational Institutions and Training Centers:

– Purpose: For educational purposes, providing students and trainees with practical, real-world examples of diaphragm valve designs.

– Requirement: Clear and illustrative diagrams to aid in teaching complex concepts.

6. R&D Departments:

– Purpose: To innovate or develop new types of diaphragm valves or enhance existing designs.

– Requirement: Detailed diagrams for a deep understanding of existing designs and areas for potential improvements.

7. Regulatory and Compliance Auditors:

– Purpose: To ensure that the valve systems comply with industry regulations and standards for safety and performance.

– Requirement: Precise diagrams to cross-verify adherence to regulatory requirements.

Each of these buyer types would be looking for different specifics within the diagrams to suit their unique needs, be it for design, maintenance, procurement, education, development, or compliance.

List “diaphragm valve diagram” Project Types for Different Industries

Diaphragm valve diagrams find relevance across various industries due to their functionality and material versatility. Here are some project types for different sectors:

1. Water Treatment:

– Project: Water Filtration Plant

– Usage: Controlling the flow of corrosive chemicals and clean water throughout the filtration process.

2. Pharmaceutical:

– Project: Drug Manufacturing Facility

– Usage: Ensuring contaminant-free flow in cleanrooms and production lines due to easy sanitization.

3. Food and Beverage:

– Project: Pasteurization Unit

– Usage: Regulating steam, water, and product flow, essential for hygiene control.

4. Chemical Processing:

– Project: Acid Production Plant

– Usage: Handling aggressive fluids and ensuring safe, leak-proof fluid control.

5. Biotechnology:

– Project: Bioreactor System

– Usage: Maintaining sterile conditions and precise control of media and gases.

6. Pulp and Paper Industry:

– Project: Paper Mill

– Usage: Managing abrasive slurry and chemicals used in paper production.

7. Marine:

– Project: Ballast Water Management

– Usage: Ensuring controlled loading and discharge of ballast water to prevent bio-contamination.

8. Oil and Gas:

– Project: Offshore Drilling Platform

– Usage: Handling brine, chemicals, and crude oil in a corrosive marine environment.

9. Mining:

– Project: Mineral Processing Plant

– Usage: Regulating slurry and ore concentrates under harsh conditions.

10. HVAC:

– Project: Urban Heating System

– Usage: Controlling the flow of heated water and steam for heating purposes.

11. Semiconductor:

– Project: Wafer Fabrication Facility

– Usage: Managing ultra-pure water and chemicals for wafer processing.

Diaphragm valves prove invaluable across these industries due to their reliability, ease of cleaning, and ability to handle a variety of harsh and sterile environments.

diaphragm valve diagram Accessories Upgrades and Custom Manufacturing Options

A diaphragm valve is an essential component in various fluid control applications, noted for its ability to provide a tight seal and handle corrosive fluids. Below is a diagram of a typical diaphragm valve, followed by information on accessories, upgrades, and custom manufacturing options.

Diagram:

“`

|——————-|

| Actuator |

|——————-|

|

|——-|——-| (Connecting Stem)

|

|——————————|

| Diaphragm |

|——————————|

|

|——-|——-| (Valve Body)

| Inlet Outlet |

|——————————

“`

Accessories:

1. Positioners: Enhance control accuracy by ensuring the valve attains the desired position.

2. Limit Switches: Provide feedback on the valve’s open or closed status.

3. Manual Override: Allows manual operation during automated system failure or maintenance.

4. Solenoid Valves: Facilitate remote operation by controlling the actuator via electrical signals.

5. Pressure Gauges: Monitor the pressure to ensure safe operation and system integrity.

Upgrades:

1. Advanced Actuators: Options include pneumatic, electric, or hydraulic actuators for varying operational needs.

2. Lining Materials: Upgrading the internal lining with materials like PTFE, PFA, or rubber to handle more corrosive or abrasive fluids.

3. Enhanced Diaphragms: Utilizing higher-quality materials like EPDM, VITON, or Silicone for increased durability and chemical resistance.

4. Automation Integration: Incorporate IoT and smart valve technology for real-time monitoring and control.

5. High-Pressure Ratings: Customizing the valve to operate safely under higher pressure conditions by fortifying its structure.

Custom Manufacturing Options:

1. Size and Dimensions: Tailor the valve dimensions to fit unique pipeline specifications.

2. Valve Body Materials: Custom materials like stainless steel, Hastelloy, or PVC to suit varying application environments.

3. Connection Types: Options for flanged, threaded, welded, or tri-clamp connections to match existing systems.

4. Special Coatings: Apply specific coatings for additional protection against extreme temperatures, chemicals, or abrasives.

5. Unique Configurations: Design bespoke configurations (e.g., multi-port valves) to meet specialized operational requirements.

In conclusion, diaphragm valves are versatile components that can be enhanced and customized through various accessories, upgrades, and manufacturing options, making them suitable for a wide range of applications.

List Quality Control and The Manufacturing Process of “diaphragm valve diagram”

Quality Control of Diaphragm Valves

1. Material Inspection:

– Verify raw materials through certifications.

– Conduct spectrometry to confirm material composition.

2. Dimensional Accuracy:

– Perform dimensional inspections using calipers and micrometers.

– Use Coordinate Measuring Machines (CMM) for precision measurements.

3. Pressure Testing:

– Conduct hydrostatic and pneumatic tests to ensure valve integrity.

– Verify leak tightness at different pressure levels.

4. Surface Finish:

– Inspect surface roughness using profilometers.

– Ensure adequate surface treatment, e.g., passivation for metal components.

5. Functionality Tests:

– Perform cycling tests to assess operational reliability.

– Check for smoothness in valve operation and proper seating.

6. Non-destructive Testing (NDT):

– Utilize methods like ultrasonic testing or dye penetrant testing to detect internal defects.

7. Compliance Check:

– Ensure valves meet industry standards (e.g., ASME, API).

– Verify documentation and traceability for each valve batch.

Manufacturing Process of Diaphragm Valves

1. Design & Engineering:

– Develop detailed CAD drawings and specifications.

– Prototype using 3D printing for design validation.

2. Casting & Machining:

– Use processes like sand casting or investment casting to form valve bodies.

– Machine valve components to precise tolerances via CNC machining.

3. Forging & Molding:

– Forge metal parts for increased strength and durability.

– Mold diaphragms using elastomers to specified shapes and sizes.

4. Assembly:

– Assemble diaphragm, valve body, bonnet, and actuator according to design.

– Apply appropriate seals and fasteners to ensure leak-proof construction.

5. Surface Treatment:

– Conduct treatments such as electro-polishing or coating for corrosion resistance.

– Apply paint or other finishes as required.

6. Testing & Validation:

– Perform comprehensive testing (pressure, functionality, NDT).

– Address anomalies and validate against design specifications.

7. Packaging & Dispatch:

– Securely package valves to prevent damage during transportation.

– Instruct handling procedures to ensure product integrity on delivery.

In summary, the quality control ensures diaphragm valves meet rigorous standards, while the manufacturing process emphasizes precision engineering and stringent testing to deliver reliable and durable products.

How to use “diaphragm valve diagram”

A diaphragm valve diagram is a useful tool for understanding the internal structure and functioning of a diaphragm valve, commonly used in fluid control systems. Here’s how to use and interpret it:

1. Identify Key Components: Locate the main parts of the valve:

– Body: The outer casing that holds the valve components.

– Diaphragm: The flexible membrane that regulates flow.

– Actuator: The mechanism that moves the diaphragm, commonly operated manually, pneumatically, or electrically.

– Stem: Connects the actuator to the diaphragm.

– Seat: The surface against which the diaphragm seals to stop flow.

2. Flow Path: Trace the flow path through the valve body, which the diagram typically illustrates with arrows. Note the direction of fluid flow.

3. Operation Mechanism:

– Open Position: Identify the position of the diaphragm when the valve is open. An opened diaphragm will show a gap between it and the seat, allowing fluid to pass.

– Closed Position: Identify the diaphragm’s position when the valve is closed. The diaphragm will be pressed against the seat, preventing fluid flow.

4. Material Indications: Some diagrams may indicate material types for different parts, which is crucial for chemical compatibility and durability assessments.

5. Maintenance Points: Look for indications of parts that may require regular maintenance or have a higher wear rate, such as the diaphragm and seals.

6. Safety Information: Note any symbols or annotations indicating safety precautions, especially if dealing with high-pressure or hazardous fluids.

Using a diaphragm valve diagram effectively requires understanding these key components and their function within the valve system. Analyzing the diagram can aid in installation, troubleshooting, and maintenance of the valve.

“diaphragm valve diagram” Comparative Analysis

A diaphragm valve comprises a rubber or elastomer diaphragm that prevents the flow of fluid by pressing against a weir or saddle within the valve body. This valve design offers several advantages and some drawbacks compared to other types of valves like ball valves, gate valves, and butterfly valves.

Diaphragm Valve Components:

1. Body: Encases the flow passage and supports other components.

2. Diaphragm: A flexible membrane that regulates the flow by moving up and down.

3. Weir/Saddle: The surface that the diaphragm seals against.

4. Actuator: Operates the diaphragm, available in manual, pneumatic, or electric types.

Comparative Analysis:

#### Advantages:

1. Leak Tightness: Due to the flexible diaphragm, these valves provide excellent sealing, minimizing leakage, which is beneficial in applications requiring high purity and cleanliness.

2. Versatility: Suitable for handling abrasive, corrosive fluids and slurries as there are fewer crevices for the fluid to lodge in.

3. Maintenance: Generally low maintenance compared to gate valves or ball valves, as they have fewer moving parts and the diaphragm can be easily replaced.

#### Disadvantages:

1. Pressure Limitations: Typically not suitable for high-pressure applications; butterfly and ball valves excel here.

2. Temperature Sensitivity: Diaphragms are sensitive to high temperatures; metal-seated ball valves or gate valves can handle higher temperatures.

3. Flow Restriction: The presence of the weir can cause a greater pressure drop compared to gate valves, ball valves, or butterfly valves, which offer a less obstructive path.

#### Key Comparisons:

– Gate Valves: Best for full-off/full-on applications. Unlike diaphragm valves, they allow unidirectional flow with minimal pressure drop but involve more complex maintenance.

– Ball Valves: Provide a tighter seal and can withstand higher pressures. They have a quicker operation than diaphragm valves. However, ball valves can be more expensive and less suited to handling slurries and viscous fluids.

– Butterfly Valves: Lightweight and cost-effective for large-scale applications with low-pressure drops. They are not as effective in providing a tight seal compared to diaphragm valves.

In summary, diaphragm valves are highly effective in specific applications requiring leak-tight sealing, handling corrosive and slurry environments, and low maintenance. They are outperformed by ball and gate valves in high-pressure environments but remain a preferable choice for many industrial applications owing to their versatility and reliability in managing complex fluids.

“diaphragm valve diagram” Warranty and Support

Warranty and Support for Diaphragm Valve Diagram

Warranty:

Our diaphragm valves come with a comprehensive warranty to ensure your complete satisfaction and peace of mind. Each diaphragm valve is covered by a 24-month warranty from the date of purchase. This warranty covers any defects in material or workmanship under normal use and conditions. If a defect arises during this period, please contact our customer service team for assessment and resolution.

Exclusions:

The warranty does not cover:

– Damage caused by misuse, neglect, or unauthorized modifications.

– Wear and tear items such as the diaphragm itself, which may need replacement depending on the frequency and conditions of use.

– Valves used in applications not specified in the user manual or product specifications.

Support:

Our dedicated support team is here to assist you with any questions or issues you may encounter with your diaphragm valve. We offer various channels to get the support you need:

1. Customer Hotline: Speak directly with our technical support team by calling our hotline, available Monday to Friday from 9 AM to 5 PM.

2. Email Support: Send your inquiries or issues to our email, and we aim to respond within 24 hours.

3. Online Resources: Visit our website for a comprehensive FAQ section, user manuals, and troubleshooting guides.

4. On-site Service: For complex issues, we provide on-site support by our certified technicians. Schedule an appointment through our customer service.

To make a warranty claim or request support, please have your purchase receipt and the valve’s serial number handy. This information is crucial for quick resolution and accurate service.

Your satisfaction is paramount. We are committed to providing reliable products and exceptional service to ensure the longevity and efficiency of your diaphragm valve.

List “diaphragm valve diagram” FAQ

Diaphragm Valve Diagram FAQ

1. What is a diaphragm valve?

A diaphragm valve is a type of valve that uses a flexible diaphragm to control the flow of liquids or gases. It seals over a weir or saddle to obstruct flow and can be operated manually or automatically.

2. What are the main components shown in a diaphragm valve diagram?

Typical components include:

– Body: The main structure that houses the other parts.

– Diaphragm: The flexible membrane that regulates flow.

– Compressor: Pushes the diaphragm down to seal.

– Stem: Connects the actuator to the diaphragm.

– Actuator: The mechanism that moves the stem and diaphragm.

– Bonnet: Encases the upper parts of the valve including the diaphragm and stem.

3. How does a diaphragm valve work?

When the actuator or handle is turned, it moves the stem and compressor down, pressing the diaphragm against the valve seat or weir, thereby blocking the flow. Reversing this motion lifts the diaphragm, allowing flow.

4. What are the types of diaphragm valves?

– Weir (saddle) type: Features a weir that the diaphragm seals against, providing better throttling.

– Straight-through type: Diaphragm seals against a flat seat, allowing unobstructed flow – ideal for slurries and viscous fluids.

5. What materials are used in diaphragm valves?

– Body: Often made from metals (stainless steel, bronze) or thermoplastics (PVC, PP).

– Diaphragm: Typically elastomers (EPDM, PTFE) for chemical resistance.

6. What are the advantages of diaphragm valves?

– Ideal for handling corrosive, abrasive, and viscous fluids.

– Superior shut-off capability.

– Low maintenance and easy cleaning.

– Suitable for sanitary applications.

7. What are the common applications?

– Water treatment

– Chemical processing

– Food and beverage industry

– Pharmaceuticals

8. What should be considered when selecting a diaphragm valve?

– Compatibility with the type of fluid.

– Pressure and temperature requirements.

– Operation type (manual or automated).

– Required flow control precision.

Understanding these FAQs helps in choosing the right diaphragm valve for your application and maintaining its functionality.

Top 10 FAQ with answer about diaphragm valve diagram for Buyer Sourcing from China

Sure, here are the top 10 frequently asked questions (FAQ) about diaphragm valve diagrams for buyer sourcing from China:

1. What is a diaphragm valve?

– A diaphragm valve is a type of valve that uses a flexible diaphragm to regulate the flow of fluid. When the diaphragm is pressed down, it seals off the flow, and when it is lifted, the flow passes through.

2. How does a diaphragm valve diagram help in sourcing?

– A diaphragm valve diagram provides clear visual representation, showing internal components and flow paths, which aids in understanding valve function, ensuring compatibility with your system, and verifying the quality.

3. What materials are used in diaphragm valves?

– Common materials include stainless steel, plastic (PVC, CPVC), and elastomers for the diaphragm such as EPDM, PTFE, and Viton.

4. What certifications should I look for?

– Look for ISO, CE, and RoHS certifications to ensure the products meet international standards for quality, safety, and environmental compliance.

5. Can China suppliers provide custom diaphragm valves?

– Many Chinese manufacturers offer customization options for specific requirements, including size, material, and design adjustments.

6. What are the common applications of diaphragm valves?

– Diaphragm valves are commonly used in industries such as pharmaceuticals, food and beverage, water treatment, and chemical processing.

7. How do I verify the quality of a diaphragm valve from a supplier in China?

– Request detailed product specifications, material certificates, and third-party inspection reports. Additionally, consider requesting samples for testing.

8. What are the benefits of sourcing diaphragm valves from China?

– Sourcing from China often provides cost advantages, a broad range of options, and access to a large manufacturing base capable of handling bulk orders.

9. What should be included in a contract with a Chinese supplier?

– Ensure the contract includes detailed product specifications, quantity, pricing, lead times, payment terms, and quality assurance clauses.

10. How can I ensure reliable shipping and delivery?

– Work with suppliers who have established logistics channels, utilize reliable freight forwarders, and track shipments through the supply chain to ensure timely delivery.

This concise FAQ should help streamline your sourcing process and ensure you acquire high-quality diaphragm valves from China.