types of cnc Safety Certifications

Safety is paramount in operating Computer Numerical Control (CNC) machinery, making certifications essential for both companies and individuals. Here are some notable CNC Safety Certifications:

1. OSHA (Occupational Safety and Health Administration) Certification:

– OSHA 10/30-Hour Certification: Basic (10-Hour) and advanced (30-Hour) safety training programs designed for various industries, including manufacturing. These programs cover workplace hazards, safety protocols, and regulatory standards.

2. ISO (International Organization for Standardization) Certifications:

– ISO 45001: Focuses on Occupational Health and Safety Management Systems. It helps organizations improve employee safety, reduce workplace risks, and create better, safer working conditions.

– ISO 9001: While primarily a Quality Management System standard, it also emphasizes regulatory compliance and continual improvement, indirectly supporting safety initiatives.

3. NFPA (National Fire Protection Association) Certification:

– NFPA 70E: Standard for Electrical Safety in the Workplace. This certification ensures that workers are knowledgeable about electrical safety procedures, which are crucial for CNC operations that involve significant electrical equipment.

4. SME (Society of Manufacturing Engineers) Certifications:

– Certified Manufacturing Technologist (CMfgT): While primarily a technologist certification, it includes safety protocols and procedures essential for managing CNC operations.

5. American Safety Council (ASC) Certifications:

– Various online courses and certifications that cover general workplace safety, machinery safety, and specific topics related to manufacturing environments.

6. First Aid and CPR Certification:

– Often required for CNC operators to ensure they can handle emergency situations until professional medical help arrives.

7. Hazardous Materials Handling Certification:

– Ensures that CNC operators can safely handle and dispose of materials that may be hazardous, reducing the risk of workplace accidents.

These certifications collectively aim to enhance the safety knowledge and practices within CNC operations, ensuring a safer working environment.

List Reference Technical Parameters of “types of cnc”

Certainly! CNC (Computer Numerical Control) machines are critical in manufacturing, providing precision, repeatability, and automation. Here’s a brief overview of the technical parameters for various types of CNC machines:

1. CNC Milling Machines

– Axes: Typically 3 (X, Y, Z), can have up to 5 (X, Y, Z, A, B).

– Spindle Speed: Up to 20,000 RPM or higher.

– Feed Rate: Up to 500 inches/minute.

– Table Size: Varies; can be as large as several meters.

– Precision: Can achieve tolerances within ±0.001 inches.

2. CNC Lathes

– Axes: Usually 2 (X, Z).

– Spindle Speed: Ranges from 50 to 6,000 RPM.

– Chuck Size: Typically between 6 to 15 inches.

– Maximum Turning Diameter: Up to 15 inches.

– Maximum Turning Length: Up to 40 inches.

– Precision: Tolerances within ±0.0005 inches.

3. CNC Plasma Cutters

– Axes: Usually 2 to 3 (X, Y, and optional Z).

– Cutting Speed: Up to 500 inches/minute.

– Cut Thickness: Up to 2 inches for steel.

– Table Size: Varies; typically around 4×8 feet or larger.

– Precision: Can achieve ±0.01 inches.

4. CNC Laser Cutters

– Axes: Typically 2 to 3 (X, Y, Z).

– Laser Power: Ranges from 40W to several kW.

– Cutting Speed: Up to 600 inches/minute.

– Cut Thickness: Up to 1 inch for metal.

– Precision: Tolerances within ±0.001 inches.

5. CNC Electrical Discharge Machines (EDM)

– Axes: Usually 2 to 5.

– Material Removal Rate: Accurate, though slower compared to milling.

– Electrode Used: Typically copper or graphite.

– Surface Finish: High precision finish achievable.

– Precision: Tolerances within ± 0.0002 inches.

6. CNC Routers

– Axes: Typically 3, but can have 4 or 5.

– Spindle Speed: Up to 24,000 RPM.

– Cutting Speed: Up to 800 inches/minute.

– Table Size: Generally large, such as 4×8 feet.

– Precision: Tolerances within ±0.005 inches.

By understanding these key technical parameters, you can better select the appropriate CNC machine for your specific manufacturing requirements.

List Product features of “types of cnc”

CNC (Computer Numerical Control) machines are versatile devices used in the manufacturing industry for sculpting materials into desired shapes. Here are some key features of various types of CNC machines:

1. CNC Mills:

– Axis Configuration: Typically 3-axis, but can extend to 4, 5, and even 7 axes.

– Materials: Works with metals, plastics, and wood.

– Precision: High accuracy and repeatability.

2. CNC Lathes:

– Rotation Speed: High-speed rotation for precision turning.

– Tool Turret: Multiple tools can be loaded for various operations.

– Automation: Often equipped with bar feeders for continuous operation.

3. CNC Routers:

– Cutting Area: Large worktables to accommodate big sheets.

– Materials: Ideal for wood, foam, composites, and soft metals.

– Spindle Power: Powerful spindles for high-speed cutting.

4. CNC Plasma Cutters:

– Cutting Speed: Fast cutting of conductive metals.

– Torch Types: Equipped with plasma torches suited for different thicknesses.

– Software Control: Advanced software for intricate designs.

5. CNC Laser Cutters:

– Laser Types: CO2 or fiber lasers for precise cutting.

– Precision: Micron-level accuracy.

– Application: Cuts, engraves, and marks various materials.

6. CNC EDM (Electric Discharge Machining):

– Types: Wire EDM and die-sinking EDM.

– Material Removal: Removes material using electrical discharges.

– Non-Contact: Ideal for hard materials.

7. CNC Grinders:

– Grinding Types: Surface, cylindrical, and centerless grinding.

– Precision: High surface finish and precise tolerances.

– Automation: Often includes tool changers and inspection tools.

8. CNC Waterjet Cutters:

– Cutting Method: Uses high-pressure water, sometimes combined with abrasives.

– Materials: Cuts almost any material without thermal damage.

– Environmentally Friendly: Minimal waste.

General Features:

– Software Integration: Advanced CAM software for design and control.

– CAD/CAM Compatibility: Seamless integration with design software.

– Real-Time Monitoring: Sensors and feedback systems for quality control.

– Automation and Flexibility: Capable of handling complex and custom jobs with minimal human intervention.

These features make CNC machines indispensable in modern manufacturing, providing precision, efficiency, and versatility.

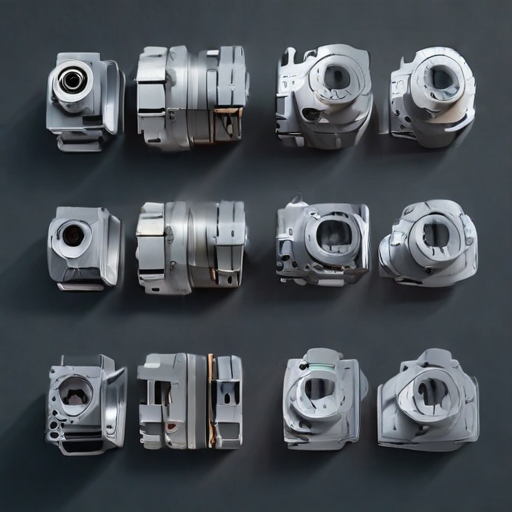

List Various Types of “types of cnc”

Certainly! CNC (Computer Numerical Control) machines come in various types, each designed to perform different machining tasks. Below is a concise list of the main types:

1. CNC Milling Machines:

– Used to cut and shape materials like metal, wood, and plastic.

– Capable of 3 to 5-axis operations for complex shapes and designs.

2. CNC Lathes:

– Primarily used for turning operations, creating cylindrical parts by rotating the material against a cutting tool.

– Enables operations like threading, boring, and grooving.

3. CNC Routers:

– Ideal for cutting, drilling, and engraving on large flat materials such as wood, composite, aluminum, and plastics.

– Often used in woodworking, sign making, and cabinet making.

4. CNC Plasma Cutters:

– Utilizes a high-velocity jet of ionized gas (plasma) to cut through metals.

– Commonly used for cutting steel, stainless steel, and aluminum.

5. CNC Laser Cutters:

– Employ a laser beam to cut, engrave, or mark materials.

– Suitable for precision cutting in materials like metal, plastics, wood, and glass.

6. CNC EDM (Electrical Discharge Machines):

– Includes Wire EDM and Die-Sinking EDM.

– Uses electrical sparks to erode material, useful for intricate and very hard materials.

7. CNC Grinders:

– Used for precision grinding operations. Types include surface, cylindrical, and centerless grinders.

– Essential for achieving high levels of accuracy and surface finish.

8. CNC Drilling Machines:

– Specialized for drilling holes in various materials.

– Efficient and precise for repetitive drilling tasks.

9. CNC Punch Presses:

– Designed to punch holes in sheet metal.

– High-speed operation for producing components with multiple holes and shapes.

10. CNC Swiss Lathes:

– Used for producing small, intricate parts with high precision.

– Common in watchmaking, medical devices, and electronics industries.

These machines revolutionize modern manufacturing by improving precision, speed, and efficiency across various industries, from aerospace to automotive to consumer goods.

List Application of “types of cnc”

Computer Numerical Control (CNC) machines offer precision and efficiency across a range of industries. Below are the types of CNC machines and their applications:

1. CNC Milling Machines:

– Aerospace: Manufacturing complex parts like turbine blades, panels, and other components.

– Automotive: Producing engine blocks, gears, and other precise components.

– Electronics: Milling circuit boards and enclosures for electronic devices.

2. CNC Lathes:

– Automotive: Crafting engine parts, such as camshafts and crankshafts.

– Medical: Producing precise parts for medical devices and implants.

– Plumbing: Manufacturing fittings, connectors, and threaded components.

3. CNC Routers:

– Woodworking: Creating intricate wood designs, furniture, and cabinetry.

– Signage: Cutting and carving signs and logos from various materials.

– Prototyping: Developing rapid prototypes for product design and development.

4. CNC Plasma Cutters:

– Metal Fabrication: Cutting through thick metal plates with high precision.

– Automotive Restoration: Shaping and restoring metal components.

– Construction: Creating structural components for buildings and bridges.

5. CNC Laser Cutters:

– Textiles: Cutting complex patterns in fabrics for fashion and upholstery.

– Jewelry: Precision engraving and cutting of intricate designs in metal and gemstones.

– Advertising: Producing high-detail promotional materials and displays.

6. CNC EDM (Electrical Discharge Machining):

– Mold Making: Creating precise molds for plastic injection molding.

– Aerospace: Machining hard metals used in aircraft engines and turbines.

– Tooling: Manufacturing specialty tools and dies.

7. CNC Grinders:

– Manufacturing: Sharpening tools and producing high-precision industrial components.

– Medical: Crafting surgical instruments requiring exceptional accuracy.

– Aerospace: Grinding turbine blades and other high-stress components.

Each type of CNC machine is tailored for specific applications, enhancing productivity and accuracy across a range of fields. These machines support the creation of detailed, high-quality products, ensuring consistent output and reducing manual labor.

List Buyer Types of “types of cnc”

When considering the types of CNC (Computer Numerical Control) machines, it’s essential to understand the distinct buyer types, as this can influence the selection process. Here are several buyer types:

1. Small Business Owners/Startups:

– Primary Concern: Budget and versatility.

– They often look for affordable, multi-functional machines that can handle a variety of tasks, such as CNC routers, due to their flexibility and cost-effectiveness.

2. Medium-Sized Enterprises:

– Primary Concern: Balance between cost and performance.

– These buyers might invest in CNC milling machines or lathes that offer a good mix of efficiency, precision, and scalability for production runs.

3. Large Enterprises/Manufacturing Plants:

– Primary Concern: High production capacity and advanced features.

– These buyers seek high-end CNC machining centers, capable of complex, high-volume production, often integrating automation and multi-axis capabilities for diverse manufacturing needs.

4. Prototyping Labs/Design Studios:

– Primary Concern: Precision and adaptability.

– These entities usually opt for CNC machines like 3D printers or small CNC mills that offer high precision to create detailed prototypes and custom designs.

5. Educational Institutions:

– Primary Concern: Learning tools and safety.

– These buyers often look for entry-level, user-friendly CNC machines that can be used for training purposes. Desktop CNC mills or small CNC routers are common for teaching basic concepts and safety protocols.

6. Hobbyists and DIY Enthusiasts:

– Primary Concern: Affordability and ease of use.

– Budget-friendly, compact CNC machines such as desktop CNC routers, laser cutters, or DIY CNC kits cater to personal projects and small-scale creations.

Understanding these buyer types helps in selecting the right CNC machine suited to their specific needs, thereby enhancing workflow efficiency and ensuring appropriate investment in technology.

List “types of cnc” Project Types for Different Industries

CNC (Computer Numerical Control) machining has revolutionized various industries by automating complex tasks with high precision. Different project types in various industries include:

1. Automotive Industry:

– Engine Components: Machining of combustion engine parts like pistons, cylinders, and valves.

– Transmission Parts: Precision manufacturing of gears, shafts, and gearboxes.

– Exterior Body Parts: Custom fabrication of panels, frames, and chassis components.

2. Aerospace Industry:

– Structural Components: Machining of fuselage parts and wing structures, focusing on lightweight and high-strength materials.

– Engine Parts: High-precision manufacturing of turbine blades, shafts, and casings.

– Avionics Housings: Production of enclosures for electronic components.

3. Medical Industry:

– Surgical Instruments: Creation of precision tools like scalpels and forceps.

– Prosthetics and Implants: Custom manufacturing of hip joints, dental implants, and bone plates.

– Diagnostic Equipment: Precision parts for MRI machines, CT scanners, and other medical devices.

4. Electronics Industry:

– PCB Prototyping: CNC routing for drilling and cutting printed circuit boards.

– Enclosures: Machining of custom housings for electronic devices.

– Heat Sinks: Precision milling of components for thermal management.

5. Energy Industry:

– Wind Turbine Components: Machining of hubs, blades, and gearbox parts.

– Oil & Gas Parts: High-pressure valve components and pipeline connectors.

– Solar Panel Frames: Custom frames and mounting systems for solar panels.

6. Furniture Industry:

– Custom Designs: CNC routing for intricate wood designs and custom furniture pieces.

– Mass Production: Automated production of standardized components like legs, panels, and frames.

– Decorative Elements: Engraving and inlay work on various materials.

7. Tool and Die Industry:

– Mold Making: High-precision molds for injection molding and casting.

– Dies: Production of dies for stamping, forging, and extrusion processes.

– Jigs and Fixtures: Custom tooling to assist in manufacturing processes.

CNC technology is essential across these industries for its precision, efficiency, and ability to handle complex designs, enabling the production of high-quality components consistently.

types of cnc Accessories Upgrades and Custom Manufacturing Options

CNC machining has witnessed significant advancements, leading to a variety of accessories and upgrades that enhance functionality, precision, and efficiency. Below are categories of upgrades and custom manufacturing options:

Accessories & Upgrades:

1. Tool Holders & Fixtures:

– Automatic Tool Changers (ATCs): Expands tool capacity, reducing manual intervention and increasing productivity.

– Rotary Tables & Trunnions: Adds additional axes for complex machining tasks.

2. Probes & Sensors:

– Touch Probes: Measure and set up workpieces with high precision.

– Tool Length Sensors: Monitor tool wear and length automatically.

3. Coolant Systems:

– High-pressure Coolant: Enhances chip removal and cooling for better surface finishes and tool life.

– Mist Collectors: Ensures a clean working environment by removing coolant mist and oil particles.

4. Software Upgrades:

– CAD/CAM Software: Offers advanced design and machining capabilities.

– Real-time Monitoring Systems: Tracks machine performance and predicts maintenance needs.

5. Table & Work Area Enhancements:

– Vacuum Tables: Secure workpieces quickly and uniformly.

– Workholding Clamps: Improve precision in part holding.

Custom Manufacturing Options:

1. Tailored Tooling:

– Custom end mills, drills, and inserts designed for specific material properties and machining tasks.

2. Bespoke Fixtures:

– Custom jigs and fixtures tailored for unique or complex parts, enhancing repeatability and accuracy.

3. Automation Solutions:

– Robotic Integration: Automates material handling and secondary operations.

– Pallet Changers: Reduces downtime by enabling faster part swaps.

4. Specialized Spindles:

– High-speed or high-torque spindles for materials ranging from delicate plastics to hardened steels.

5. Adaptive Enhancements:

– Modifications like extended gantries or bed sizes for machining larger workpieces.

These accessories and custom upgrades cater to diverse industry needs, driving efficiency, accuracy, and versatility in CNC machining operations.

List Quality Control and The Manufacturing Process of “types of cnc”

Quality Control in CNC Manufacturing:

1. Material Testing: Assess the raw materials’ properties to ensure consistency and reliability.

2. Calibration: Regular calibration of CNC machines ensures precision and accuracy.

3. First Article Inspection (FAI): Initial sample products are inspected to check conformance to design specifications.

4. In-Process Monitoring: Real-time monitoring of the CNC process to detect and correct deviations immediately.

5. Final Inspection: Comprehensive evaluation of the finished product using tools like Coordinate Measuring Machines (CMM) to verify adherence to specifications.

6. Documentation and Traceability: Maintain detailed records for traceability and future reference.

Types of CNC Machines and Their Manufacturing Process:

1. CNC Milling Machines:

– Process: Uses rotary cutters to remove material.

– Steps:

1. Design parts with CAD software.

2. Convert design to machine-readable code (usually G-code).

3. Mount material and secure tool on the CNC mill.

4. Execute the code; the machine follows the programmed path to shape the material.

5. Inspect and finish the product.

2. CNC Turning Machines (Lathes):

– Process: Rotates the workpiece while a stationary cutting tool shapes it.

– Steps:

1. Develop CAD designs.

2. Generate G-code for the specific turning operations.

3. Fix the material into the lathe’s chuck.

4. Run the turning program; the machine shapes the material by removing layers.

5. Perform post-process inspections and finishing.

3. CNC Plasma Cutting Machines:

– Process: Uses a high-velocity jet of ionized gas to cut metals.

– Steps:

1. Create CAD drawings.

2. Convert to CNC-compatible code.

3. Configure the machine with the correct settings and material.

4. Initiate the cutting sequence, where plasma torch follows the programmed path.

5. Evaluate the cuts and perform any necessary finishing.

4. CNC Laser Cutting Machines:

– Process: Utilizes laser beams to cut materials precisely.

– Steps:

1. CAD design and conversion to G-code.

2. Setup material and machine parameters.

3. Execute the laser cutting program.

4. Inspect the final components for accuracy.

5. CNC EDM (Electrical Discharge Machining):

– Process: Uses electrical discharges to shape materials.

– Steps:

1. Design and code generation.

2. Submerge material in dielectric fluid.

3. Position the electrode and initiate discharge cycles.

4. Inspect and refine the finished product.

Maintaining strict quality control measures throughout these processes ensures the production of high-precision and reliable components in CNC manufacturing.

How to use “types of cnc”

CNC, which stands for Computer Numerical Control, involves the use of computers to control machine tools. There are various types of CNC machines, each designed for specific applications. Here’s how to use different types of CNC machines efficiently:

1. CNC Milling Machines: These are used for cutting and drilling materials. To use a CNC milling machine:

– Load the CAD (Computer-Aided Design) file into the CNC software.

– Secure the material on the machine bed.

– Select the appropriate milling tool and make sure it’s properly secured.

– Set the machine parameters, such as cutting speed and feed rate.

– Start the machine, ensuring to monitor its operation to adjust settings if necessary.

2. CNC Lathes: These are primarily used for machining cylindrical parts.

– Load the design into the CNC software.

– Place and clamp the workpiece in the lathe chuck.

– Choose the suitable tool for the operation.

– Specify parameters like spindle speed and depth of cut.

– Execute the program, while supervising to ensure accurate operations.

3. CNC Plasma Cutters: Used for cutting metal and other materials with a plasma torch.

– Import the design file into the CNC software.

– Place the material on the cutting bed and secure it.

– Set the plasma cutter parameters such as cutting speed and pierce height.

– Begin the operation and watch closely to ensure precision.

4. CNC Routers: These are for cutting various materials, including wood, composites, and plastic.

– Import the design file.

– Place the material on the table and secure it.

– Choose the correct router bit for the material.

– Set the appropriate speed and feed rate.

– Start the machine and monitor the process.

5. CNC Electrical Discharge Machines (EDM): Used for hard metals or those that are difficult to machine.

– Set up the electrode and workpiece.

– Load the design program.

– Adjust the machining parameters like current and voltage.

– Start the machine, closely monitoring the process.

Using CNC machines involves understanding the specific type and adjusting parameters accordingly to ensure precision and efficiency. Proper maintenance and safety protocols are essential for optimal operation.

“types of cnc” Comparative Analysis

Computer Numerical Control (CNC) machines have revolutionized modern manufacturing, making processes faster, more accurate, and highly repeatable. Various types of CNC machines serve diverse applications, each with specific strengths and drawbacks. Here’s a comparative analysis of the most common types:

1. CNC Milling Machines:

– Functionality: Uses rotary cutters to remove material.

– Strengths: Versatile; capable of creating complex shapes; high precision; suitable for both prototyping and mass production.

– Drawbacks: Higher cost; requires skilled operators; more setup time.

2. CNC Lathes:

– Functionality: Rotates the workpiece around a stationary cutting tool.

– Strengths: Excellent for producing symmetrical objects; efficient for large runs of cylindrical parts; high speed.

– Drawbacks: Limited to axial symmetry; less versatile than milling machines; lower precision for intricate parts.

3. CNC Plasma Cutters:

– Functionality: Uses a high-powered plasma torch to cut through conductive materials.

– Strengths: Fast cutting speeds; good for thick materials; lower initial cost compared to other types.

– Drawbacks: Only works on conductive materials; produces rougher edges; generates a lot of heat, affecting precision.

4. CNC Laser Cutters:

– Functionality: Uses a focused laser beam to cut or engrave materials.

– Strengths: High precision; capable of intricate designs; cleaner cuts; versatile for various materials.

– Drawbacks: Slower than plasma cutters; limited to thinner materials; higher cost.

5. CNC Routers:

– Functionality: Similar to milling machines but typically used for softer materials.

– Strengths: Ideal for woodworking, plastics, and soft metals; high-speed operation; lower cost.

– Drawbacks: Limited to softer materials; less precision than milling machines.

6. CNC Electric Discharge Machines (EDM):

– Functionality: Uses electrical discharges to shape materials.

– Strengths: Excellent for hard materials; fine finishes; complex cavities and shapes.

– Drawbacks: Slow process; higher operational costs; conductive materials only.

In summary, the choice of a CNC machine largely depends on the specific manufacturing needs—whether it’s the complexity of the parts, materials used, production volume, or cost considerations. Each type has unique advantages and limitations that make them suitable for different applications.

“types of cnc” Warranty and Support

When purchasing CNC machines, understanding the types available along with warranty and support options is pivotal for ensuring optimal performance and longevity of your investment.

Types of CNC Machines

1. CNC Milling Machines: Utilized for shaping solid materials like metal, wood, or plastic.

2. CNC Lathes: Used for detailed cutting and precise shaping of cylindrical materials.

3. CNC Routers: Ideal for cutting various materials including wood, composites, aluminum, and plastics.

4. CNC Plasma Cutters: Employ plasma torches to cut electrically conductive materials.

5. CNC Laser Cutters: Use laser beams for precise cutting and engraving of materials.

6. CNC Electrical Discharge Machining (EDM): Utilizes electrical discharges to shape materials.

7. CNC Grinders: Used for precise grinding of hard materials.

Warranty

Warranties for CNC machines generally cover parts, labor, and service for a specific period, commonly ranging from one to five years. Here are the aspects to consider:

– Scope: Understand what parts are included and if consumables like belts and blades are covered.

– Duration: Check the length of coverage and specific components covered under different time frames.

– Conditions: Ensure the warranty remains valid under normal usage conditions and know the process for claims.

Support

High-quality support is crucial for minimizing downtime and maximizing productivity. Essential support services include:

– Technical Assistance: 24/7 helpline or online support can be invaluable for troubleshooting.

– Training: On-site training sessions ensure that your staff knows how to operate and maintain the machine effectively.

– Preventive Maintenance: Regular maintenance schedules help in early detection of possible issues.

– Spare Parts Availability: Quick access to spare parts can be critical for reducing downtime.

– Software Updates: Continuous software updates ensure your machine operates with the latest features and improvements.

In summary, selecting the right type of CNC machine tailored to your needs, coupled with comprehensive warranty and robust support services, will significantly influence the efficiency and reliability of your operations.

List “types of cnc” FAQ

Types of CNC: FAQ

1. What is a CNC machine?

– CNC (Computer Numerical Control) machines are automated tools controlled by computers executing pre-programmed sequences of machine control commands.

2. How many types of CNC machines are there?

– There are several types, each designed for specific tasks. Common types include CNC milling machines, lathes, routers, plasma cutters, and laser cutters.

3. What is a CNC milling machine?

– CNC milling machines use rotating cutting tools to remove material from a workpiece, allowing for the creation of complex shapes.

4. What is a CNC lathe?

– CNC lathes rotate the workpiece on a spindle while applying various tools to shape it. They are ideal for producing symmetrical objects like cylinders and cones.

5. What is a CNC router?

– CNC routers are similar to milling machines but are typically used for cutting softer materials like wood, plastic, and foam.

6. What is a CNC plasma cutter?

– CNC plasma cutters use a high-velocity jet of ionized gas (plasma) to cut through electrically conductive materials like steel, stainless steel, and aluminum.

7. What is a CNC laser cutter?

– CNC laser cutters utilize a focused laser beam to cut or engrave materials ranging from metals to plastics and wood, offering high precision and detail.

8. What is the difference between a CNC mill and a CNC router?

– CNC mills are more robust and designed for cutting harder materials like metals, while CNC routers are lighter and better suited for softer materials.

9. How do CNC machining centers differ?

– CNC machining centers are sophisticated CNC mills that can perform multiple operations, typically equipped with automated tool changers and advanced control systems for complex manufacturing processes.

10. What are CNC grinders?

– CNC grinders are used for precision grinding operations, allowing for high-precision removal of material.

11. What industries use CNC machines?

– CNC machines are utilized across various industries, including aerospace, automotive, manufacturing, and woodworking.

12. How does CNC enhance manufacturing?

– CNC machines increase production speed, improve precision and repeatability, reduce labor costs, and allow for complex and intricate designs.

By understanding the types and applications of CNC machines, users can better select the appropriate technology to meet their manufacturing needs.

Top 10 FAQ with answer about types of cnc for Buyer Sourcing from China

Certainly! Here are the top 10 Frequently Asked Questions (FAQs) with answers regarding the sourcing of CNC machines from China:

1. What types of CNC machines are available from China?

– China offers a variety of CNC machines, including CNC milling machines, CNC lathes, CNC routers, CNC plasma cutters, CNC lasers, CNC drilling machines, and CNC grinding machines.

2. How do I verify the quality of CNC machines from Chinese manufacturers?

– Check for ISO certifications, request detailed product specifications, ask for videos or live demonstrations, and read reviews or ask for references from previous international buyers.

3. What are the common materials used in Chinese CNC machines?

– Typically, CNC machines are made from cast iron, steel, aluminum, and sometimes composite materials, ensuring durability and precision.

4. Are Chinese CNC machines compatible with international software and controls?

– Most reputable Chinese manufacturers ensure compatibility with globally recognized CNC controllers like Fanuc, Siemens, and Mitsubishi. Always confirm this with the supplier.

5. What is the typical lead time for manufacturing and shipping CNC machines from China?

– Lead times may vary, but generally, it ranges from 30 to 60 days for production, with additional shipping time based on the destination. Confirm specifics with your supplier.

6. What is the average cost range for CNC machines from China?

– Costs can vary widely based on type and specifications. Entry-level CNC routers can start from $2,000, while industrial-grade CNC mills and lathes can exceed $50,000.

7. Can I customize my CNC machine order?

– Many Chinese manufacturers offer customization options to suit specific requirements, such as machine size, power specifications, and additional features.

8. What are the payment terms typically offered by Chinese CNC manufacturers?

– Common payment terms include a 30% deposit upfront and 70% balance before shipment. Other terms can be negotiated based on your relationship with the supplier.

9. How do I handle warranty and after-sales service?

– Confirm the warranty period, usually 1-2 years, and clarify the terms. Ensure the manufacturer provides remote support and can ship spare parts if needed.

10. What should I consider regarding import duties and logistics?

– Research your country’s import duties for CNC machines. Use a reliable freight forwarder or work with the manufacturer’s recommended logistics partners to handle shipping and customs clearance.

By addressing these FAQs, buyers can make informed decisions when sourcing CNC machines from China.