culvert pipe Safety Certifications

Ensuring that culvert pipes meet specific safety certifications is crucial for infrastructure integrity and public safety. These certifications and standards help guarantee that the culvert pipes are robust, durable, and suitable for their intended applications. Several key certifications and standards are commonly referenced:

1. AASHTO (American Association of State Highway and Transportation Officials) Standards: AASHTO sets guidelines for materials, design, and construction. Culvert pipes made from concrete, metal, and plastic often adhere to these standards to ensure they meet the required load-bearing and durability criteria.

2. ASTM (American Society for Testing and Materials) Standards: ASTM provides comprehensive specifications for various materials used in culvert pipes. For example, ASTM C76 is a standard for reinforced concrete pipes, ensuring they can withstand specific loads and environmental conditions. Other relevant ASTM standards include ASTM F667 for corrugated polyethylene pipes and ASTM A760 for corrugated steel pipes.

3. ISO (International Organization for Standardization) Certifications: ISO standards offer a global perspective on quality and safety. Standards like ISO 9001 focus on quality management systems, ensuring culvert pipe manufacturers consistently produce high-quality products.

4. DOT (Department of Transportation) Approvals: Many state DOTs have their own set of requirements and approvals for materials used in infrastructure projects. Compliance with local DOT standards is often mandatory for public works projects.

5. EN (European Norms) Standards: For projects in Europe, EN standards like EN 1916 for concrete pipes and EN 13476 for plastic pipes define essential performance and safety benchmarks.

Manufacturers should rigorously test culvert pipes against these standards for compression, impact resistance, and durability under various environmental conditions. Adherence to these certifications ensures the pipes can safely support the loads and stresses they will encounter, promoting long-term reliability and safety in infrastructure projects.

List Reference Technical Parameters of “culvert pipe”

Culvert pipes are essential infrastructural elements designed to allow water to pass beneath roads, railways, and other embankments. Here are the key technical parameters to consider:

1. Material Composition: Common materials include concrete, steel, aluminum, and plastic (HDPE or PVC). Each material has specific properties affecting strength, durability, and resistance to environmental factors.

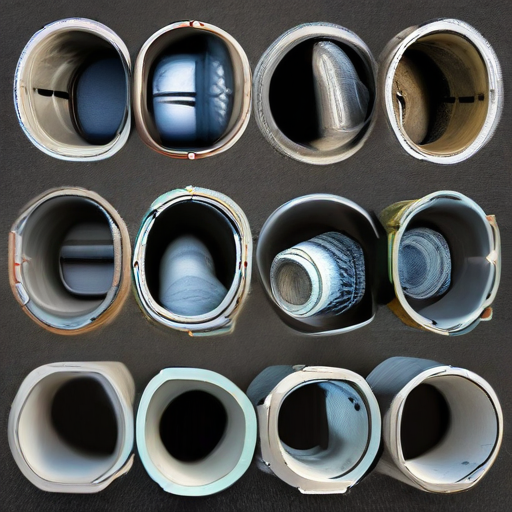

2. Diameter and Size: Pipe diameters typically range from 300mm to over 3000mm, depending on the volume of water flow required. Lengths and shapes can be adjusted based on project needs.

3. Load Capacity: This is determined by the pipe’s design and material. It must withstand vehicular or train loads above, categorized under HS-20, HS-25 (for highways), and higher standards for railways.

4. Hydraulic Performance: Includes factors like Manning’s roughness coefficient, slope, and flow rate, which influence the pipe’s ability to convey water efficiently and prevent blockage.

5. Structural Design Standards: Governed by engineering standards such as ASTM, AASHTO, or EN norms, which specify the requirements for strength, flexibility, and durability.

6. Installation Conditions: Soil type, bedding quality, backfill material, and compaction rates are vital for proper installation and long-term performance.

7. Corrosion and Abrasion Resistance: Materials are chosen based on environmental conditions, including soil pH and the presence of abrasive substances. Protective coatings or liners may be used for additional resistance.

8. Joint Types and Seals: Gaskets, O-rings, and other sealing mechanisms ensure water tightness and prevent leakage at joints. The joint design also affects the pipe’s flexibility and ability to accommodate soil movement.

9. Environmental Considerations: Includes factors like eco-friendliness of materials, impact on local flora/fauna, and adherence to environmental regulations.

10. Maintenance Requirements: Longevity and ease of access for inspection, cleaning, and repairs are crucial in determining operational efficiency and safety over time.

Understanding these parameters ensures the selection and installation of culvert pipes that meet functionality, durability, and regulatory compliance for a given application.

List Product features of “culvert pipe”

Culvert pipes are critical components in infrastructure, specifically designed to allow water to pass through either under a road, railway, or embankment. Here are the key product features of culvert pipes:

1. Material Variety: Culvert pipes come in different materials including concrete, corrugated metal, and high-density polyethylene (HDPE). Each material has distinct properties and use cases.

2. Durability: Culvert pipes are engineered to withstand environmental stresses such as heavy loads, corrosive substances, and temperature fluctuations. Concrete and metal variants are particularly noted for their strength and longevity.

3. Corrosion Resistance: HDPE and certain metal culverts are treated or coated to resist corrosion, extending their service life even in harsh conditions.

4. Load Bearing Capacity: Culvert pipes are designed to support significant loads, including that from vehicular traffic. Specifications often indicate the maximum load they can bear, making them suitable for various applications.

5. Hydraulic Efficiency: They are constructed to facilitate smooth water flow, preventing blockages and minimizing erosion around the pipe. The internal design, often smooth for HDPE and corrugated for metal, optimizes hydraulic performance.

6. Versatility in Sizes: Available in a range of diameters and lengths to accommodate various project requirements, from small residential areas to large industrial or municipal projects.

7. Ease of Installation: Many culvert pipes are designed for straightforward installation. HDPE pipes, for instance, are lightweight and easier to handle on site compared to concrete or metal counterparts.

8. Environmental Compatibility: Modern culvert designs consider environmental impacts, employing eco-friendly materials or designs that minimally interact with natural habitats.

9. Cost-effectiveness: Varies by material, but options like HDPE offer a balance of durability and lower installation costs, making them a viable alternative for budget-conscious projects.

10. Customization Options: Some manufacturers offer customization in terms of length, shape (circular, elliptical), and wall thickness to meet specific project needs.

These features collectively make culvert pipes essential for effective water management in civil engineering projects.

List Various Types of “culvert pipe”

Culvert pipes are essential structural elements used to channel water through embankments, roadways, and other structures. They come in various types, each suited to specific conditions and requirements. Here is a brief overview:

1. Concrete Culvert Pipes:

– Reinforced Concrete Pipes (RCP): Durable and strong, ideal for high-load applications and long lifespan requirements.

– Precast Concrete: Manufactured off-site and assembled on-site, which accelerates construction.

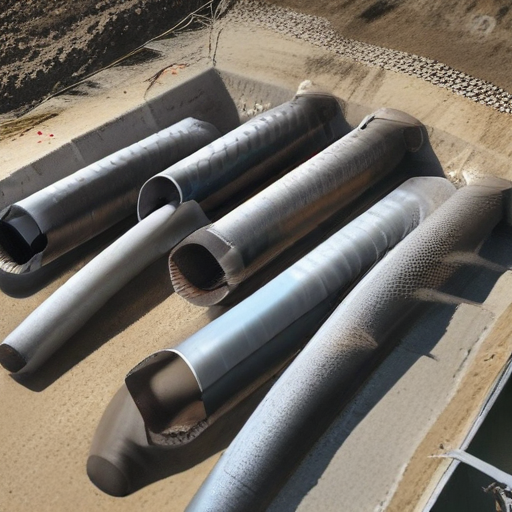

2. Metal Culvert Pipes:

– Corrugated Metal Pipes (CMP): Made from galvanized steel or aluminum; flexible and suitable for both temporary and permanent installations.

– Steel Culverts: Known for high strength but prone to corrosion if not properly treated.

– Aluminum Culverts: Lightweight and corrosion-resistant, used in environments prone to rust.

3. Plastic Culvert Pipes:

– High-Density Polyethylene (HDPE): Resistant to chemicals and abrasion, lightweight and easy to install.

– Polyvinyl Chloride (PVC): Common for smaller drainage applications, resistant to corrosion and easy to handle.

4. Polymer-Concrete Culverts:

– Polymer-Concrete Composite: Incorporates polymers to enhance durability and resistance to environmental damage.

5. Dual-Wall and Smooth-Wall Pipe:

– Dual-Wall Pipe: Features a corrugated exterior and a smooth interior, combining strength with efficient fluid flow.

– Smooth-Wall Pipe: Typically used where smooth interior surfaces are necessary to maintain high flow rates.

Each type has its specific use case depending on factors such as load capacity, environmental conditions, installation requirements, and cost. Proper selection of a culvert pipe type is critical for ensuring the longevity and effectiveness of the drainage system.

List Application of “culvert pipe”

Culvert pipes are vital infrastructure components primarily used for managing water flow and ensuring the integrity of transportation and utility systems. Below are key applications of culvert pipes:

1. Drainage Systems: Culvert pipes facilitate water drainage under roadways, railways, and pathways, preventing potential flooding, erosion, and structural damage.

2. Stream Crossings: They allow streams or small rivers to pass beneath roads and pathways, maintaining natural watercourses while providing uninterrupted transport routes.

3. Irrigation Channels: Used in agricultural settings, culvert pipes manage water distribution for irrigation, aiding in efficient agricultural productivity.

4. Fish Passage: Specialized culvert designs enable fish and other aquatic organisms to migrate upstream, supporting ecosystem connectivity and biodiversity.

5. Stormwater Management: Culverts are integral to stormwater drainage systems in urban areas, mitigating flood risks by directing stormwater away from inhabited and commercial regions.

6. Culverts in Recreational Paths: Used in parks and recreational areas, they ensure that trails and paths remain usable even in the presence of streams and small water bodies.

7. Wildlife Crossings: Installing culverts beneath roads can provide safe passage for wildlife, reducing the risk of animal-vehicle collisions and promoting biodiversity.

8. Utility Ducts: Culvert pipes can also be used to house utility cables and pipes (e.g., water, electricity, gas), protecting them from environmental elements and physical damage.

9. Temporary Water Management: During construction activities, culvert pipes are often employed to temporarily redirect water flow, ensuring dry and stable work environments.

10. Driveway and Entrance Installations: Residential and commercial properties use culverts to manage water flow from driveways and entrances without obstructing natural drainage patterns.

By effectively managing water and maintaining structural integrity, culvert pipes play a crucial role in sustainable infrastructure development and environmental conservation.

List Buyer Types of “culvert pipe”

Buyer Types of Culvert Pipe

1. Government Agencies:

– Departments of Transportation (DOTs): Often require culvert pipes for highway and road infrastructure projects.

– Municipal Authorities: Local government bodies purchase these pipes for stormwater management, sewage systems, and public works projects.

– Environmental Agencies: Use culvert pipes in projects related to erosion control, wetland restoration, and habitat management.

2. Construction Companies:

– Contractors: Private construction firms involved in residential, commercial, or industrial development frequently buy culvert pipes for drainage and foundation work.

– Engineering Firms: Need culverts for the design and build phase of infrastructure projects.

3. Agricultural Sector:

– Farmers: Use culvert pipes for field drainage, irrigation, and preventing waterlogging in farmlands.

– Ranchers: Require them for runoff management and to facilitate livestock crossings over waterways.

4. Real Estate Developers:

– Residential Developers: Purchase culvert pipes for developing drainage systems in new housing projects.

– Commercial Developers: Need them to manage stormwater in commercial real estate projects.

5. Industrial Sector:

– Mining Companies: Use culvert pipes for water management in mining operations.

– Factory Sites: Require durable culverts for site drainage to manage waste and runoff.

6. Utility Companies:

– Water and Sewer Services: Need culverts for stormwater and sanitary sewer systems.

– Power Companies: Use culvert pipes for site access roads and to manage water around electrical substations.

7. Private Landowners:

– Purchase small quantities of culvert pipes for personal property improvements like driveway crossings, landscaping, or water management on private land.

8. Infrastructure Expansion Projects:

– Organizations aiming to expand and modernize existing infrastructure such as railways, airports, and ports use culvert pipes for drainage solutions.

By understanding these buyer types, sellers of culvert pipes can better target their marketing efforts and meet specific industry demands.

List “culvert pipe” Project Types for Different Industries

1. Transportation and Highways:

– Roadway Drainage: Culvert pipes are essential in managing stormwater runoff and preventing roadway flooding by channeling water away from the road surface.

– Underpasses: Used to allow water flow beneath roads, ensuring uninterrupted traffic and protecting road infrastructure.

2. Railways:

– Track Drainage: Ensures the stability and longevity of railway tracks by diverting water away, reducing erosion and washouts.

– Overpasses and Underpasses: Facilitate water flow under railway lines, preserving the integrity of the track bed.

3. Residential and Commercial Development:

– Driveway Crossings: Enable property access across drainage ditches or streams, maintaining continuous driveway surfaces.

– Stormwater Management Systems: Integrated into broader drainage plans to manage runoff in parking lots, landscaped areas, and building foundations.

4. Agriculture:

– Field Drainage: Helps maintain soil health by preventing waterlogging and managing irrigation runoff.

– Livestock Access: Provides safe crossings over watercourses, safeguarding both animal welfare and water quality.

5. Mining:

– Site Drainage: Essential for managing groundwater and surface water, reducing flooding risk and facilitating safe, continuous operations.

– Access Road Crossings: Ensure heavy machinery and vehicles can cross streams and drainage paths safely.

6. Forestry:

– Logging Roads: Durable culverts are necessary for temporary or permanent roads used for timber extraction, preventing environmental erosion.

– Stream Crossings: Maintains natural watercourses while allowing access for forest management activities.

7. Utilities:

– Pipeline Protection: Incorporated into utility infrastructure to protect pipelines and cables from water damage by diverting surface runoff.

– Access Routes: Used in constructing access roads for maintenance crews, ensuring infrastructure is not disrupted by water flow.

In summary, culvert pipes are versatile structures critical to various industries, effectively managing water flow to protect infrastructure and ensure operational efficiency.

culvert pipe Accessories Upgrades and Custom Manufacturing Options

Culvert pipes play a crucial role in infrastructure by providing drainage and preventing flooding. To enhance their functionality and lifespan, various accessories, upgrades, and custom manufacturing options are available:

1. End Treatments: Flared end sections and headwalls improve hydraulic efficiency and structural stability, reducing erosion and sediment build-up.

2. Protective Coatings: Galvanizing, bituminous coatings, and polymer linings extend the pipe’s life by protecting it from corrosion, abrasion, and chemical damage.

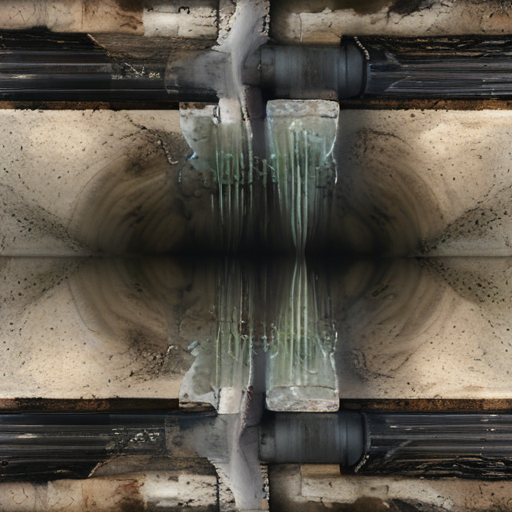

3. Joint Systems: Advanced coupling systems like bell-and-spigot or gasketed joints ensure tight seals, preventing leaks and infiltration of unwanted materials.

4. Bedding Materials: Enhanced bedding options such as gravel or concrete improve load-bearing capacity and distribute stress more evenly, protecting the pipe from settling or deformation.

5. Grates and Screens: Installing trash racks, debris grates, and screens at the pipe entrance minimizes blockages, maintaining efficient water flow.

6. Flow Control Devices: Valves, weirs, and flow regulators can be incorporated to control water discharge, manage stormwater, or maintain desired water levels.

7. Enhanced Materials: Custom material options like high-density polyethylene (HDPE), reinforced concrete, or advanced composites offer better performance under specific environmental conditions.

8. Prefabricated Sections: Custom-designed, prefabricated pipe sections, including bends, branches, and reducers, enable more complex and tailored installations.

9. Maintenance Features: Access points like manholes and inspection ports facilitate easier maintenance and inspection, improving long-term operability.

Each of these enhancements and custom options can be specified based on project requirements, environmental conditions, and regulatory standards, ensuring optimal performance and durability of the culvert system.

List Quality Control and The Manufacturing Process of “culvert pipe”

Quality Control for Culvert Pipe:

1. Raw Material Inspection

– Verify the quality of raw materials (e.g., steel, concrete).

– Ensure compliance with standards (ASTM, AASHTO).

2. Dimensional Accuracy

– Regular measurement of length, diameter, and wall thickness.

– Tolerance checks using calibrated tools.

3. Strength Testing

– Conduct compressive strength tests for concrete pipes.

– Perform tensile strength tests for steel or plastic pipes.

4. Surface Finish

– Inspection for defects like cracks, dents, or uneven coatings.

– Ensure smooth interior and exterior surfaces.

5. Hydraulic Testing

– Test for water tightness and flow efficiency.

– Check for leakage under simulated conditions.

6. Durability Checks

– Assess resistance to environmental factors (corrosion, chemicals).

– Conduct freeze-thaw cycle tests for concrete pipes.

7. Documentation and Traceability

– Maintain records of inspections, tests, and production batches.

– Implement barcoding or RFID for tracking.

Manufacturing Process of Culvert Pipe:

1. Material Preparation

– Source and prepare raw materials (steel sheets, concrete mix).

– Additives and reinforcements are mixed as needed.

2. Forming

– Concrete Pipes: Use slip forming or packerhead machines to shape the pipe.

– Steel Pipes: Roll and weld steel sheets into a circular shape.

– Plastic Pipes: Extrude thermoplastic material through a die.

3. Reinforcement

– Concrete: Insert steel rebars or mesh during forming.

– Steel/Plastic: Reinforce with additional material layers if necessary.

4. Curing and Hardening

– Concrete: Cure in controlled environments to attain desired strength.

– Cooling and handling precautions for steel and plastic pipes.

5. Finishing

– Apply coatings (e.g., galvanizing for steel) and linings.

– Smooth and treat surfaces to prevent corrosion and wear.

6. Inspection and Testing

– Perform quality control checks (dimensional, strength, surface).

– Conduct pressure and hydraulic tests.

7. Packaging and Delivery

– Package pipes securely to avoid damage during transit.

– Label and prepare for shipment following regulatory guidelines.

How to use “culvert pipe”

A culvert pipe is commonly used to allow water to flow under a road, railroad, trail, or similar obstruction. Here’s a concise guide on how to use a culvert pipe:

1. Site Assessment: Begin by evaluating the area where the culvert will be installed. Ensure the location is suitable for directing water flow and mitigating flood risks.

2. Sizing: Select the appropriate culvert size. The diameter should accommodate the expected water flow during peak conditions. Consult local regulations for specific sizing requirements.

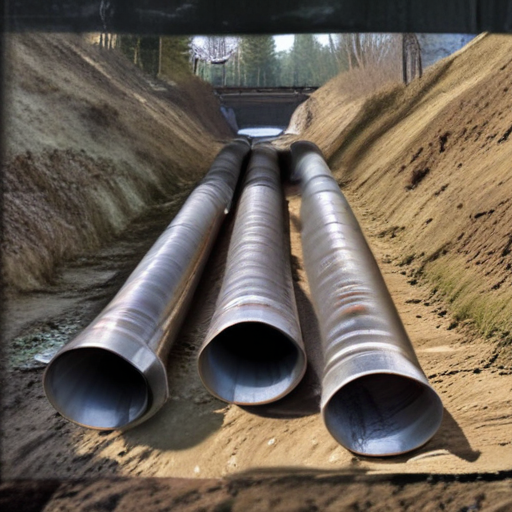

3. Excavation: Excavate a trench where the culvert will be placed. The trench should be wide enough to allow for stable placement and deep enough to provide adequate cover over the pipe.

4. Base Preparation: Create a stable base by laying a layer of gravel or crushed stone at the bottom of the trench. This helps with drainage and supports the pipe.

5. Placement: Position the culvert pipe in the trench, ensuring it follows the natural slope of the terrain for efficient water flow. Connect segments securely if multiple pipes are needed.

6. Backfilling: Cover the culvert pipe with gravel or crushed stone, ensuring the material is well-compacted around the pipe. Gradually backfill with soil, compacting in layers to prevent settling.

7. End Treatments: Install headwalls or end sections to protect the ends of the culvert. This helps prevent erosion and ensures stability.

8. Surface Restoration: Restore the surface above the culvert, whether it’s a road, trail, or landscape. Ensure the covering material is adequately compacted and reinstated.

9. Maintenance: Regularly inspect the culvert for blockages, sediment buildup, or damage. Clear any obstructions and make necessary repairs to maintain functionality.

By following these steps, you can effectively install and maintain a culvert pipe, ensuring proper water management and structural integrity.

“culvert pipe” Comparative Analysis

Culvert pipes are essential infrastructure components used for guiding water through obstructions like roads, railways, and embankments. There are various types of culvert pipes, with the most common being concrete, metal, and plastic. Each has distinct characteristics that make them suitable for different applications.

Concrete Culvert Pipes:

Renowned for their durability and strength, concrete culvert pipes have a long service life, often exceeding 50 years. They can withstand heavy loads and resist corrosion, although they are susceptible to cracking under extreme conditions. Installation tends to be labor-intensive due to their weight, which increases transportation and handling costs.

Metal Culvert Pipes:

Typically made of galvanized steel or aluminum, metal culvert pipes are lauded for their high strength-to-weight ratio. They are lightweight compared to concrete pipes, making them easier and more cost-effective to transport and install. Metal pipes are highly resistant to impact and can be manufactured in various shapes and sizes. However, they’re prone to corrosion over time, especially in environments with acidic or saline water, necessitating protective coatings or more frequent maintenance.

Plastic Culvert Pipes:

Usually made from high-density polyethylene (HDPE) or polyvinyl chloride (PVC), plastic culvert pipes are noted for their flexibility and resistance to chemical corrosion. They are lightweight, allowing for easy transport and low installation costs. Plastic pipes are ideal for areas with shifting ground conditions as they can flex without cracking. However, they generally have lower load-bearing capacity compared to concrete and metal pipes and may not be suitable for heavy traffic areas without sufficient support.

Comparative Summary:

Concrete pipes are best for high-load, long-term installations but come with higher handling costs. Metal pipes offer strength and ease of installation but need corrosion protection. Plastic pipes provide flexibility and cost efficiency, albeit with lower load capacities.

In summary, the choice of culvert pipe largely depends on the specific requirements of the project, environmental conditions, and budget constraints.

“culvert pipe” Warranty and Support

Culvert Pipe Warranty and Support

At [Your Company Name], we take pride in the quality and durability of our culvert pipes, designed to meet and exceed industry standards. We offer a comprehensive warranty and support service to ensure your satisfaction and peace of mind.

Warranty

Our culvert pipes come with a 5-year limited warranty, covering defects in materials and workmanship under normal use and service conditions. The warranty period commences from the date of purchase. Should any defect arise, we will either replace the defective section or provide a full refund, subject to our inspection and assessment.

Please note, the warranty does not cover:

– Damage due to improper installation or handling

– Wear and tear from normal use

– Damage caused by neglect, misuse, or acts of nature

– Modifications or repairs made by unauthorized personnel

To claim warranty, please retain your proof of purchase and contact our customer service department. We aim to address and resolve all warranty claims within 30 days.

Support

Our dedicated support team is available to assist you throughout the lifecycle of your culvert pipe. Whether you have questions about installation, maintenance, or troubleshooting, our experts are ready to help.

For immediate assistance, you can contact us via:

– Phone: [Customer Support Phone Number]

– Email: [Customer Support Email Address]

– Live Chat: Available on our website during business hours

Additionally, we provide a comprehensive online resource library, including installation guides, maintenance tips, and FAQs, accessible anytime on our website.

At [Your Company Name], your satisfaction is our priority. We are committed to providing reliable products and exceptional support to ensure the successful performance of our culvert pipes in your projects.

List “culvert pipe” FAQ

Culvert Pipe FAQ

1. What is a culvert pipe?

A culvert pipe is a structure that allows water to flow under a road, railway, trail, or similar obstruction. It is often made from materials like concrete, steel, or plastic.

2. What are the types of culvert pipes?

Common types include circular pipes, box culverts, arch culverts, and elliptical pipes. Each type serves different hydraulic and structural needs.

3. What materials are used for culvert pipes?

Culvert pipes are typically made from concrete, corrugated steel, aluminum, high-density polyethylene (HDPE), or polyvinyl chloride (PVC).

4. How is the size of a culvert pipe determined?

The size is determined based on factors like the flow rate of water, the area of the watershed, soil type, and load-bearing requirements. Engineers often use hydraulic modeling for accurate sizing.

5. What is the lifespan of a culvert pipe?

The lifespan varies by material. Concrete pipes can last 50-100 years, while plastic and metal pipes generally last 25-50 years, depending on environmental conditions and maintenance.

6. How do you install a culvert pipe?

Installation involves excavating a trench, laying a bedding layer, placing the culvert, backfilling, and compacting the soil. Proper alignment and gradient are crucial to ensure effective water flow.

7. How do you maintain a culvert pipe?

Regular inspections for blockages, debris removal, erosion control, and structural integrity checks are essential. Repairs might include patching leaks, replacing damaged sections, or relining.

8. What are the common issues with culvert pipes?

Common issues include clogging from debris, erosion around the pipe, corrosion or rusting (in metal pipes), and structural damage due to heavy loads or shifting soil.

9. Can culvert pipes be extended?

Yes, culvert pipes can be extended to accommodate changes in road width or increased water flow. Extensions must be properly aligned and connected to maintain hydraulic efficiency.

10. What are the environmental impacts of culvert pipes?

Improperly designed or installed culverts can disrupt natural water flow, affect fish migration, and alter local ecosystems. Environmental assessments and eco-friendly designs can mitigate these impacts.

Top 10 FAQ with answer about culvert pipe for Buyer Sourcing from China

Here are the top 10 frequently asked questions (FAQ) with answers about sourcing culvert pipes from China, particularly for buyers:

1. What types of culvert pipes are available in China?

– In China, you can source a variety of culvert pipes, including concrete, steel, plastic (HDPE, PVC), and corrugated metal pipes. Each type has its specific applications and benefits.

2. Are Chinese culvert pipes compliant with international standards?

– Many Chinese manufacturers adhere to international standards such as ASTM, ISO, and EN. It’s crucial to request certification and quality documentation to ensure compliance.

3. How do I verify the quality of culvert pipes from Chinese suppliers?

– Conduct due diligence by requesting samples, visiting the factory if possible, and hiring third-party inspection firms to check the quality before shipment.

4. What is the typical lead time for orders?

– Lead time can vary depending on the complexity and size of the order. Generally, it ranges from 30 to 60 days. Confirm with the supplier during negotiations.

5. Can I get customized culvert pipes in terms of dimensions and materials?

– Yes, many Chinese manufacturers offer customization services. Provide detailed specifications and ensure they understand your requirements thoroughly.

6. What is the typical minimum order quantity (MOQ)?

– MOQs can differ between suppliers, but typical MOQs range from 100 to 500 pieces. Negotiations are often possible based on your needs and the supplier’s capacity.

7. How is freight and shipping handled?

– Chinese suppliers usually handle freight and shipping. They can offer FOB (Free On Board), CIF (Cost, Insurance, and Freight), or other terms based on your preference.

8. What are the common payment terms?

– Payment terms often include TT (Telegraphic Transfer), L/C (Letter of Credit), or a combination of advance payment and balance upon delivery. Negotiate terms that ensure security for both parties.

9. Can I rely on after-sales support from Chinese suppliers?

– Reputable suppliers provide after-sales support, including installation guidance, warranty services, and replacement policies. Confirm these services before finalizing your purchase.

10. What are the common challenges when sourcing culvert pipes from China?

– Challenges include language barriers, quality control, and logistics. Overcome these by working with experienced agents, employing quality inspection services, and maintaining clear and regular communication.

By addressing these FAQs, buyers can make more informed decisions when sourcing culvert pipes from China.