grease ducts Safety Certifications

Grease ducts, integral components in commercial kitchen ventilation systems, dispose of smoke, heat, and grease-laden vapors. Adhering to stringent safety certifications ensures these ducts mitigate fire hazards effectively. Key certifications include:

1. UL 1978: Certification under UL 1978 ensures that grease ducts can withstand high temperatures and resist internal fires. It focuses on the structural integrity and fire-resistance of ducts designed specifically for use in commercial kitchens.

2. UL 2221: This certification tests the fire-rated assemblies of grease ducts. It ensures ducts maintain their integrity during an external fire, offering crucial time for safe evacuations and fire-fighting operations.

3. NFPA 96: This standard, set by the National Fire Protection Association (NFPA), provides comprehensive requirements for the design, installation, operation, inspection, and maintenance of grease ducts. Compliance with NFPA 96 is essential for reducing fire risks associated with commercial cooking operations.

4. IMC (International Mechanical Code) & IFC (International Fire Code): These codes, developed by the International Code Council (ICC), outline requirements for the safe installation and operation of grease ducts. Compliance ensures adherence to international safety standards.

5. NSF Certification: While NSF International primarily focuses on public health and safety, its certification ensures grease duct systems meet rigorous sanitation and safety standards, contributing to a safer kitchen environment.

Fire safety and regulatory compliance in commercial kitchen ventilation hinge on these certifications, underscoring the importance of employing certified grease duct systems in mitigating risks and promoting a secure cooking environment.

List Reference Technical Parameters of “grease ducts”

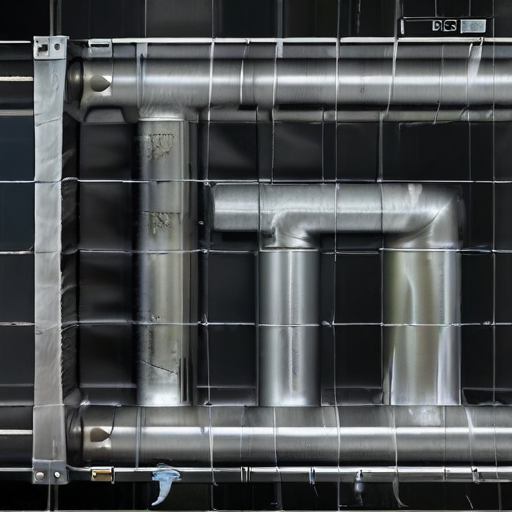

Certainly. Grease ducts are specialized duct systems designed to vent grease-laden vapors and exhaust from commercial kitchens to the exterior of buildings. Key technical parameters for grease ducts include:

1. Material: Typically constructed from stainless steel (16-gauge minimum) for its corrosion resistance and ability to withstand high temperatures.

2. Temperature Rating: Must accommodate high-temperature ranges up to around 500°F (260°C) to handle heat from cooking appliances.

3. Pressure Ratings: Should be capable of withstanding positive pressures and draft conditions typical in commercial kitchen exhaust systems.

4. Clearances: Required minimum clearances to combustible materials, usually specified as 18 inches unless protected by listed and labeled grease duct enclosures complying with the appropriate codes.

5. Airflow: Designed to maintain minimum airflow rates to prevent the accumulation of grease, which may require compliance with standard airflow velocities, often around 1500 to 2500 feet per minute.

6. Fire Resistance: Constructed and installed to support fire-resistance ratings, often requiring compliance with NFPA 96 standards which dictate items like access panel requirements and construction methodologies.

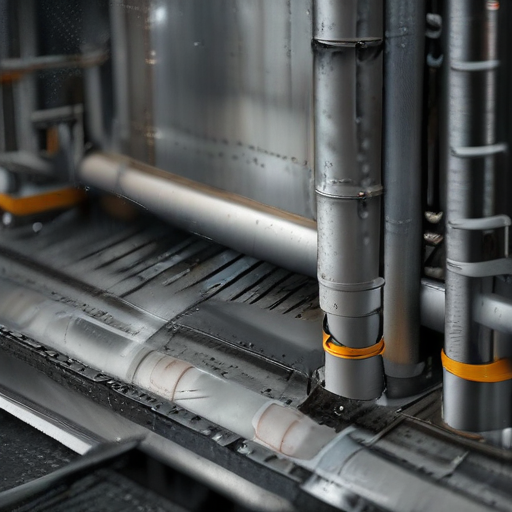

7. Access Panels: Must have easily accessible and properly sized maintenance panels for regular cleaning, inspection, and servicing. NFPA 96 requires these at intervals of no more than 12 feet and at every change in ductwork direction.

8. Sealing and Joints: Airtight assembly with leak-proof joints and seams using welding or approved sealants to prevent grease leakage and ensure structural integrity.

9. Slope: Ducts should be installed with a minimum slope of 1/4 inch per linear foot towards a collection point for grease.

10. Termination: Should include grease drain points and terminus at locations compliant with code requirements to safely expel exhaust away from the building.

11. Regulatory Compliance: Must meet local building codes, mechanical codes, and standards such as UL 1978, NFPA 96, and IMC (International Mechanical Code).

These technical parameters ensure that grease ducts function efficiently, safely, and comply with the necessary legal requirements for commercial kitchen operations.

List Product features of “grease ducts”

Grease ducts are specialized ventilation systems essential for kitchens and various industrial applications where grease-laden vapors require safe and efficient extraction. Here are the key product features:

1. Material Durability: Typically constructed from stainless steel or galvanized steel, grease ducts are corrosion-resistant and capable of withstanding high temperatures.

2. Fire Resistance: Designed to meet stringent fire safety standards, many grease ducts are fire-wrapped or feature fire-rated materials to prevent the spread of flames.

3. Ease of Installation: Modular designs and customizable lengths facilitate swift on-site assembly, ensuring a precise fit within existing architectural frameworks.

4. Compliance and Certification: Adherence to NFPA (National Fire Protection Association) standards and local building codes ensures safety and reliability.

5. Access Panels: Removable panels provide easy access for routine inspection, cleaning, and maintenance, helping to adhere to health and safety regulations.

6. Grease Collection: Strategically placed grease traps and collection points minimize the risk of grease buildup within the system, enhancing overall efficiency.

7. Sealing and Leak-Proofing: High-quality seals and gaskets ensure the ductwork is leak-proof, mitigating the risk of grease leaks that can lead to fire hazards.

8. Installation Versatility: Available in various shapes (round, rectangular) and sizes to accommodate different spatial constraints and kitchen layouts.

9. Pressure and Airflow Performance: Engineered to maintain optimal airflow and pressure levels, minimizing the risk of grease particle accumulation.

10. Aesthetic Options: For visible ductwork, options are available for finishes that blend seamlessly with the kitchen or industrial design.

11. Energy Efficiency: Proper insulation and efficient air movement features contribute to lower energy consumption for exhaust systems.

12. Customization: Can be tailored to specific project requirements, including bespoke configurations and finishes.

In essence, grease ducts are integral to maintaining a safe, hygienic, and efficient cooking or processing environment, combining robustness, compliance, and ease of maintenance.

List Various Types of “grease ducts”

Certainly! Here are various types of grease ducts commonly used in commercial kitchens and industrial settings:

1. Single-Wall Grease Ducts:

– Typically made of stainless steel or galvanized steel.

– Cost-effective but less efficient in insulation and fire resistance.

– Suitable for interior applications where insulation and fire codes permit.

2. Double-Wall Grease Ducts:

– Two layers of metal with insulation in between.

– Enhanced safety features: better thermal resistance and fire protection.

– Preferred for penetrating through walls, ceilings, or roofs.

3. Factory-Built Grease Ducts:

– Pre-manufactured and modular, easy to assemble.

– Available in both single-wall and double-wall constructions.

– Reliable and consistent quality, often UL-listed or compliant with specific standards.

4. Field-Fabricated Grease Ducts:

– Custom-built on-site to fit specific configurations and spaces.

– Flexibility in design but potentially less consistent in quality compared to factory-built options.

5. Insulated Grease Ducts:

– Integral insulation to prevent condensation and heat loss.

– Often required in cold climates or where ducts run through unconditioned spaces.

6. Access Door Grease Ducts:

– Feature built-in access doors for easier cleaning and maintenance.

– Vital for meeting health and safety codes, ensuring proper cleaning to prevent grease build-up and fire hazards.

7. High-Temperature Grease Ducts:

– Designed to handle high-temperature exhaust from cooking equipment.

– Typically made from higher grade metals and advanced insulating materials.

8. Ventilated Grease Duct Systems:

– Designed with ventilation features to ensure effective removal of grease-laden vapors.

– Includes components like exhaust fans and filters to improve efficiency.

By considering the specific needs of your kitchen or industrial environment, you can choose the appropriate type of grease duct to ensure safety, compliance, and efficient operation.

List Application of “grease ducts”

Grease ducts play a crucial role in commercial kitchens and industrial environments where cooking and grease-laden vapors are produced. These specialized duct systems are designed to vent grease, smoke, and other by-products effectively and safely. Here are several key applications of grease ducts:

1. Commercial Kitchens:

– Restaurants: Essential for the safe removal of grease-laden vapors, preventing accumulation and reducing fire risks.

– Hotels: Facilitate comprehensive food service operations by ensuring a clean and safe cooking environment.

– Cafeterias: Critical in large-scale food preparation areas found in schools, universities, and corporate offices.

– Catering Services: Mobile or fixed catering setups rely on grease ducts to maintain hygiene and air quality.

2. Industrial Cooking Facilities:

– Food Processing Plants: Manage emissions from large-scale cooking and frying processes.

– Bakeries: Handle vapors from high-volume baking operations, especially those involving fats and oils.

– Meat Packing Plants: Essential in venting grease and smoke from cooking and processing meats.

3. Hospitality Industry:

– Resorts and Clubs: Include large kitchen operations requiring efficient grease and smoke management.

– Cruise Ships: Onboard kitchens use grease ducts to maintain air quality and comply with safety standards.

4. Healthcare Institutions:

– Hospitals: Kitchen facilities in hospitals use grease ducts to ensure a sterile and safe cooking environment.

5. Educational Institutions:

– Schools and Universities: Manage cooking exhaust from cafeteria operations, ensuring a safe environment for students and staff.

6. Entertainment Venues:

– Cinemas and Theaters: Concession stands and kitchens within these venues use grease ducts to control vapors and odors.

7. Specialty Cooking Settings:

– BBQ and Smokehouses: Handle the particular needs of smoke and grease-heavy cooking processes.

– Fast Food Chains: Ensure quick removal of high volumes of grease-filled air typical in fast food kitchens.

Grease ducts are indispensable for maintaining safe, clean, and efficient kitchen and cooking environments in these various settings. Their proper installation and maintenance help mitigate fire hazards, improve air quality, and comply with health and building codes.

List Buyer Types of “grease ducts”

Grease ducts are critical components in commercial kitchen ventilation systems, designed to safely convey grease-laden vapors from cooking appliances to the outdoors. Various buyer types for grease ducts include:

1. Restaurant Owners: Primary buyers who need to ensure their kitchens comply with health and safety regulations. Proper grease duct installation is vital for preventing fires and ensuring a safe working environment.

2. Commercial Kitchen Designers and Contractors: Professionals who design and build commercial kitchens. They need grease ducts that meet both operational and regulatory standards. Their choices influence the overall kitchen layout and functionality.

3. Hospitality Chains: Large hotel and restaurant chains that often undertake large-scale installations or renovations. They seek standardized, reliable solutions that can be replicated across multiple locations.

4. Institutional Facility Managers: Managers of institutional facilities such as schools, hospitals, and correctional facilities. They require durable, low-maintenance solutions to handle large volumes of cooking output efficiently and safely.

5. Food Service Consultants: Experts hired to integrate efficient and compliant venting systems into commercial kitchens. They provide recommendations based on performance, safety, and cost-effectiveness.

6. Architects and Engineers: They specify grease duct systems in the design phase of building projects. Their decisions are influenced by factors such as space constraints, building codes, and overall kitchen efficiency.

7. Industrial Food Production Facilities: Large-scale food production units where cooking operations are extensive and require heavy-duty grease management systems.

8. Maintenance and Facility Service Companies: Firms contracted to maintain commercial kitchen ventilation systems. They may be involved in both the selection of new systems and the maintenance of existing ones to ensure continued compliance and safety.

9. Fire Protection and Insurance Companies: Indirect buyers who influence the choice by setting standards and providing recommendations for fire-safe installations. They ensure that grease ducts meet industry standards for fire protection.

Understanding the diverse buyer landscape helps manufacturers and sellers tailor their products and services to meet the specific needs and regulatory requirements of each segment.

List “grease ducts” Project Types for Different Industries

Grease ducts are specialized ventilation systems designed to manage and safely remove grease-laden vapors from commercial cooking operations. Different industries utilize grease ducts in various ways, depending on their unique requirements and standards for safety, hygiene, and functionality. Here are common project types for different industries:

1. Restaurant Industry:

– Fast Food Chains: High-capacity grease ducts to handle rapid cooking turnover, often integrated with extensive hood systems.

– Fine Dining: Custom-engineered grease ducts to complement aesthetic designs while maintaining efficiency in grease removal.

– Food Courts: Centralized systems managing multiple cooking stations with shared ductwork.

2. Hospitality Industry:

– Hotels and Resorts: Large-scale, multi-kitchen grease duct systems to accommodate diverse culinary operations, often spanning multiple floors.

– Catering Halls: Modular and scalable grease duct systems for flexibility in handling varying event sizes.

3. Educational Institutions:

– University Cafeterias: Robust grease ducts designed to manage heavy, day-long usage with easy maintenance options.

– School Kitchens: Smaller, more straightforward systems focused on safety and efficiency for student meal preparation areas.

4. Healthcare Industry:

– Hospital Kitchens: Grease ducts with high standards for cleanliness and safety, often integrating advanced filtration systems to ensure air quality.

– Nursing Homes: Systems emphasizing low maintenance and reliability to support continuous meal services.

5. Corporate Sector:

– Company Cafeterias: Medium-scale grease duct systems, balancing efficiency and noise reduction within office environments.

– Industrial Facilities: Heavy-duty systems capable of managing extensive cooking operations for large workforces.

6. Retail and Entertainment Complexes:

– Shopping Malls: Integrated grease duct systems for food courts, necessitating a balance between individual restaurant needs and overall air quality.

– Movie Theaters: Compact systems designed to handle high grease outputs from concession areas while maintaining a discreet presence.

7. Transportation Sector:

– Airports: Comprehensive grease duct systems for varied food service outlets, emphasizing fire safety and air quality.

– Train Stations: Efficient and streamlined systems to handle diverse food vendors within confined spaces.

These grease duct systems are critical in maintaining safe, clean, and efficient cooking environments across various industries.

grease ducts Accessories Upgrades and Custom Manufacturing Options

Grease ducts play a critical role in commercial kitchens by channeling flammable grease vapors safely out of the building. To enhance their functionality and ensure compliance with stringent safety standards, various accessories, upgrades, and custom manufacturing options are available.

Accessories:

1. Access Panels: These allow for easy inspection and cleaning, ensuring that duct interiors remain free from grease buildup, thereby reducing fire risk.

2. Fire Wraps: High-temperature insulation wraps provide an additional layer of fire protection, essential for maintaining safety in high-risk kitchen environments.

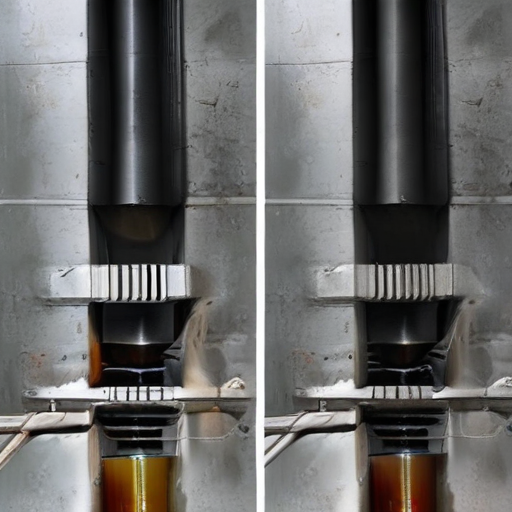

3. Grease Duct Clean-Outs: These fittings facilitate the removal of grease and are crucial for maintaining system efficiency and safety.

4. Exhaust Fans: Properly selected exhaust fans optimize airflow, ensuring that grease-laden air is effectively removed from the kitchen.

Upgrades:

1. Enhanced Sealing: Upgrading to better sealing materials can prevent leaks and improve the duct system’s overall efficiency.

2. High-Efficiency Designs: Implementing aerodynamic designs reduces airflow resistance, which can lead to better performance and lower energy costs.

3. Corrosion-Resistant Materials: Using stainless steel or other corrosion-resistant materials extends the duct system’s lifespan, even in high-moisture environments.

Custom Manufacturing Options:

1. Bespoke Sizes and Shapes: Custom manufacturing can produce ducts tailored to specific kitchen layouts, ensuring optimal fit and performance.

2. Special Coatings: Custom coatings can be applied to improve fire resistance and longevity, depending on the kitchen’s unique requirements.

3. Hybrid Systems: Combining different materials and technologies can meet specialized needs, such as improved resistance to extreme temperatures or chemicals.

In conclusion, leveraging the right accessories, upgrades, and custom manufacturing options can significantly enhance the performance, safety, and lifespan of grease duct systems in commercial kitchens.

List Quality Control and The Manufacturing Process of “grease ducts”

Quality Control:

1. Material Inspection: Raw materials are inspected for composition, thickness, and defects.

2. Dimensional Verification: Ensure all dimensions meet specified tolerances.

3. Welding Inspection: Check welds for integrity and compliance with standards.

4. Leak Testing: Conduct pressure tests to ensure no leaks.

5. Surface Finish Inspection: Verify smoothness, cleanliness, and proper coating.

6. Documentation Review: Examine records for compliance with standards.

Manufacturing Process:

1. Design & Specifications: Engineers draft specifications and design the duct based on regulatory standards.

2. Material Selection: Choose appropriate materials (usually stainless steel or galvanized steel).

3. Cutting: Use laser or plasma cutters to shape raw sheets into required dimensions.

4. Forming: Bend, roll, or press sheets into duct shape.

5. Welding: Weld sections together using TIG, MIG, or spot welding processes.

6. Leak Testing: Test welded ducts under pressure for leakage.

7. Surface Treatment: Apply a protective coating or finish to prevent corrosion.

8. Inspection: Conduct a final inspection for dimensional accuracy, weld quality, and surface finish.

9. Packaging: Pack the finished ducts securely for transport to prevent damage.

This concise process ensures grease ducts are strong, leak-free, and compliant with safety and durability standards.

How to use “grease ducts”

Grease ducts are essential components in commercial kitchens where cooking generates grease-laden vapors. Proper use and maintenance ensure safety and compliance with fire codes.

Installation:

1. Design and Layout: Collaborate with a mechanical engineer to design an efficient system that minimizes duct lengths and has the fewest possible bends to enhance airflow and grease collection.

2. Material Selection: Use stainless steel or galvanized steel as these are durable and meet fire safety standards.

3. Compliance: Ensure the duct system complies with local building codes, NFPA 96, and IMC standards. This typically involves fire-rated materials and specific installation procedures.

Operation:

1. Regular Cleaning: Accumulated grease is a fire hazard. Schedule regular cleanings based on cooking volume. Professional cleaning services should clean ducts, hoods, and exhaust fans comprehensively.

2. Ventilation: Always run exhaust fans while cooking to direct grease-laden vapors into the ducts and out of the kitchen.

3. Inspection: Periodically inspect ducts for any signs of wear, leaks, or grease buildup. Address issues promptly to maintain safety.

Maintenance:

1. Grease Filters: Clean or replace grease filters regularly. Clogged filters reduce efficiency and can increase grease buildup in ducts.

2. Access Panels: Install access panels at intervals, allowing easy cleaning and inspection.

3. Fire Suppression: Ensure the fire suppression system is operational and linked to the grease duct system. Regularly check and maintain it according to the manufacturer’s guidelines.

Safety Tips:

1. Train Staff: Ensure kitchen staff understand the importance of running exhaust fans and the dangers of grease accumulation.

2. Emergency Protocols: Have clear protocols for dealing with kitchen fires, including proper use of fire extinguishers.

By following these guidelines, grease ducts can operate safely, efficiently, and in compliance with legal standards, mitigating fire risks and ensuring a safe kitchen environment.

“grease ducts” Comparative Analysis

Grease ducts are specialized systems designed to vent grease-laden vapors and smoke from commercial kitchens, where high-volume cooking operations occur. Ensuring efficient and safe operation of these ducts is essential due to the potential fire hazards grease can present. This analysis compares various aspects of grease ducts, including materials, construction standards, cleaning processes, and safety features.

Materials:

Grease ducts are primarily constructed from stainless steel or galvanized steel. Stainless steel is preferred due to its superior resistance to corrosion, higher durability, and easier cleaning. However, it is more expensive compared to galvanized steel, which is more cost-effective but may suffer from corrosion over time, particularly in harsh kitchen environments.

Construction Standards:

Grease ducts must adhere to strict fire and building codes. Common standards include NFPA 96 (National Fire Protection Association) in the United States, which specifies installation requirements for ventilation control and fire protection. Additionally, compliance with UL 1978 (Underwriters Laboratories) ensures grease ducts can withstand internal grease fires without compromising structural integrity.

Cleaning Processes:

Regular cleaning is critical to maintaining grease ducts. Manual cleaning involves physically scrubbing the ducts, which can be labor-intensive and inconsistent. Alternatively, automated cleaning systems, such as water-based or chemical foam methods, can enhance cleanliness and reduce manual labor. These systems are often integrated into the ducts and programmed to operate at scheduled intervals or when grease accumulation reaches certain levels.

Safety Features:

Fire suppression systems, such as automatic sprinklers and fire dampers, are crucial for mitigating fire risks. Fire-rated duct enclosures or fire wrap insulation can provide additional layers of protection, ensuring that ducts can contain fires and prevent them from spreading to other parts of the building.

In conclusion, while stainless steel ducts offer superior performance at a higher cost, galvanized steel provides a budget-friendly alternative. Following stringent construction standards and employing effective cleaning processes and safety features are essential to ensuring the safe and efficient operation of grease ducts in commercial kitchens.

“grease ducts” Warranty and Support

Warranty and Support for Grease Ducts

When investing in grease ducts, ensuring a robust warranty and reliable support is crucial for long-term performance and safety. Our grease ducts come with a comprehensive warranty that underscores our commitment to quality and customer satisfaction.

#### Warranty

Our grease ducts are backed by a limited warranty that covers defects in materials and workmanship for a specified period, typically ranging from 1 to 5 years depending on the product line and usage conditions. This warranty ensures that any defects arising under normal operating conditions will be addressed promptly, providing peace of mind to our clients. However, it’s important to note that the warranty does not cover damages resulting from improper installation, maintenance neglect, modifications, or misuse.

#### Support

We pride ourselves on offering exceptional support services to complement our high-quality grease ducts. Our support team is available to assist with several key areas:

1. Installation Guidance: Our technical experts provide detailed installation instructions and best practices to ensure optimal performance and compliance with NFPA 96 standards.

2. Maintenance Tips: Regular maintenance is crucial for the efficiency and longevity of grease ducts. We offer detailed maintenance guidelines and schedules to help you keep your system in top condition.

3. Troubleshooting and Repairs: Should any issue arise, our dedicated support team is on hand to offer troubleshooting advice and coordinate repair services when necessary. Our goal is to minimize downtime and ensure your system operates smoothly.

4. Customer Service: Our customer service department is easily reachable for any questions or concerns regarding the warranty, product information, or service requests.

By choosing our grease ducts, you not only get a product built to last but also a dedicated team ready to support your needs. For more detailed information on our warranty terms and support services, please refer to the warranty document or contact our customer service team.

List “grease ducts” FAQ

Grease Ducts FAQ

1. What are grease ducts?

Grease ducts are ventilation systems specifically designed for exhausting grease-laden vapors from commercial kitchens to the exterior of a building.

2. Why are grease ducts important?

They are crucial for maintaining air quality, preventing fire hazards, and ensuring compliance with health and safety regulations.

3. What materials are common for grease ducts?

Typically made from stainless steel or galvanized steel, materials are chosen for their durability and resistance to grease and heat.

4. How should grease ducts be installed?

Installation must follow local building codes and standards such as NFPA 96, and involve proper sealing and welding of joints to prevent leakage.

5. Do grease ducts need regular cleaning?

Yes, regular cleaning is essential to prevent grease buildup, which can become a significant fire hazard. The frequency depends on the kitchen’s usage and local regulations.

6. Can grease ducts be used for other types of exhaust?

No, they are specifically designed for grease-laden vapors and should not be used for other exhaust systems.

7. How are grease ducts maintained?

Routine inspections, professional cleanings, and checking for blockages or damages are key for maintenance. Access panels should facilitate easy cleaning.

8. What are the fire safety requirements for grease ducts?

Fire safety standards require the use of fire-rated duct assemblies and fire suppression systems like sprinklers or chemical agents.

9. What are common issues with grease ducts?

Common issues include grease buildup, inadequate sealing, corrosion, and mechanical damages. Regular inspections are vital to catch these issues early.

10. What is the cost of installing grease ducts?

The cost varies depending on the kitchen size, complexity of the ductwork, and local labor rates. Consulting with a professional installer will provide the most accurate estimate.

11. Is insulation necessary for grease ducts?

Yes, insulation can prevent heat transfer to surrounding structures and enhance fire safety. It also helps in reducing condensation.

12. Are there any specific design considerations?

Design should minimize horizontal runs, use smooth-walled ducts to reduce grease buildup, and incorporate adequate access for cleaning.

Regular maintenance and adherence to safety standards ensure a safe and efficient grease duct system. For specific guidance, always consult professional HVAC contractors.

Top 10 FAQ with answer about grease ducts for Buyer Sourcing from China

Certainly! Here are the top 10 FAQs with answers regarding sourcing grease ducts from China:

1. What are grease ducts?

Grease ducts are specially designed conduits for venting grease-laden vapors from commercial kitchens and industrial environments. They help prevent fire hazards by safely directing these vapors to external exhaust systems.

2. Why should I source grease ducts from China?

China offers competitive pricing, a wide variety of manufacturers, and high-quality production capabilities. Moreover, the country has advanced infrastructure and logistics systems that can efficiently handle international deliveries.

3. How do I ensure the quality of grease ducts?

Look for suppliers with international certifications such as ISO 9001. Request product samples, and conduct factory audits either personally or through third-party inspection services.

4. What materials are typically used in grease ducts?

Common materials include stainless steel (Grade 304 or 316) and galvanized steel. Stainless steel is often preferred for its corrosion resistance and durability.

5. How do I verify manufacturer credentials?

Check the company’s business license, ask for testimonials or references, and look at their export history. Online platforms like Alibaba often have verification systems in place.

6. What are the common specifications I should check?

Ensure proper gauge thickness, size (diameter and length), and compliance with international standards like NFPA 96 or UL 1978.

7. Are there minimum order quantities (MOQs)?

Yes, most manufacturers have MOQs. These usually range from 50 to 200 units but can vary. Always confirm with the supplier.

8. What is the typical lead time for manufacturing?

Lead times can vary depending on order size and factory capacity. Usually, it ranges from 4 to 8 weeks. Confirm with your supplier for precise timelines.

9. Can I customize my grease ducts?

Yes, many manufacturers offer customization options for dimensions, materials, and additional features such as insulation or access doors.

10. What are the payment terms?

Common payment terms include T/T (Telegraphic Transfer), with a deposit (usually 30%) before production and the balance before shipment. L/C (Letter of Credit) is also an option for larger orders.

By addressing these FAQs, buyers can make more informed decisions when sourcing grease ducts from China, ensuring both quality and cost-efficiency.