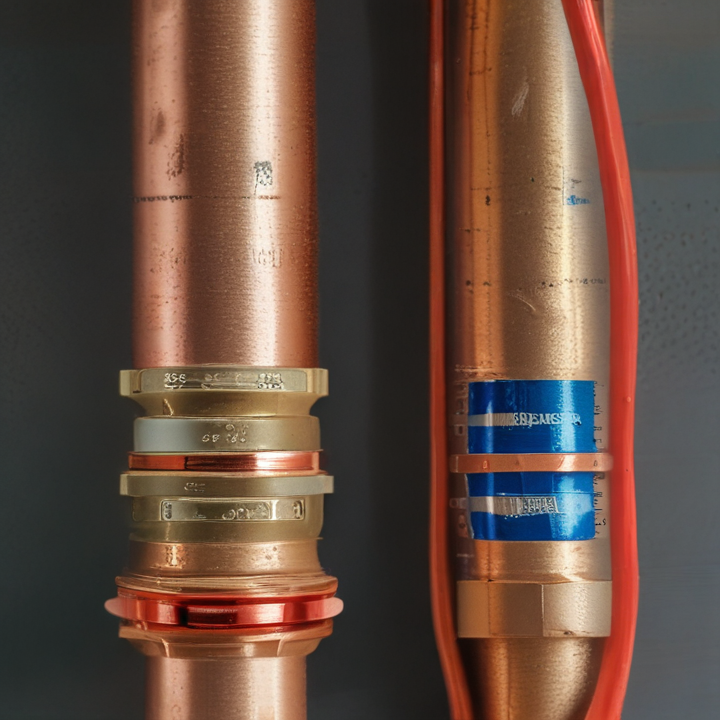

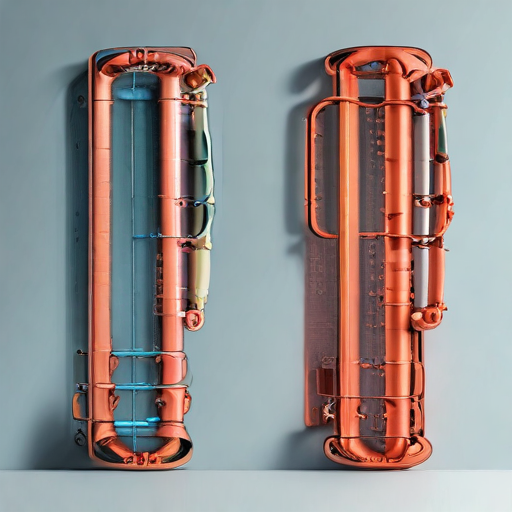

pex vs copper piping Safety Certifications

When considering the safety certifications of PEX (cross-linked polyethylene) versus copper piping, it’s essential to understand the standards and approvals each material must meet to ensure it is safe for use in plumbing systems.

PEX Piping Safety Certifications:

1. NSF/ANSI Standard 61: PEX pipes must comply with NSF/ANSI 61, which ensures the material is safe for drinking water, limiting the leaching of harmful contaminants.

2. ASTM and CSA Standards: PEX piping is evaluated under ASTM F876, F877, F2023, and CSA B137.5 standards for performance and durability.

3. AWWA Standards: Some PEX systems are certified under the American Water Works Association (AWWA) C904 standard.

4. UL Certification: Underwriters Laboratories may certify PEX for safety, ensuring it meets various performance criteria.

Copper Piping Safety Certifications:

1. NSF/ANSI Standard 61: Like PEX, copper piping complies with NSF/ANSI 61 for potable water safety.

2. ASTM Standards: Copper piping is regulated by several ASTM standards, including ASTM B88, B306, and B280, which pertain to tubing and pipe specifications and performance.

3. Lead Content Regulations: Copper pipes must adhere to the Safe Drinking Water Act’s requirements for lead-free materials, which are more stringent than international standards.

Comparison in Safety:

– Water Quality: Both PEX and copper meet stringent standards for potable water use. PEX is resistant to chlorine and won’t corrode, while copper is naturally bacteriostatic.

– Durability: PEX is flexible and resistant to scale and chlorine, while copper is very durable, resisting UV light and high temperatures.

– Installation Safety: PEX is easier and safer to install, reducing the risk of injury, as it doesn’t require soldering with open flames like copper.

In conclusion, both PEX and copper piping have robust safety certifications that make them reliable choices for plumbing. The decision between them often comes down to specific application needs and preferences regarding installation ease and material properties.

List Reference Technical Parameters of “pex vs copper piping”

When comparing PEX (cross-linked polyethylene) piping to copper piping, several technical parameters are essential for understanding the advantages and disadvantages of each. Here are some critical reference parameters:

1. Durability:

– PEX: Resistant to scale and chlorine, flexible, and fewer chances of pinhole leaks, but susceptible to UV degradation.

– Copper: Long-lasting and resistant to bacteria, but can corrode over time, especially in acidic water.

2. Temperature and Pressure Ratings:

– PEX: Typically rated up to 200°F for temperature and 160 psi for pressure.

– Copper: High-temperature tolerance, generally up to 400°F, and pressure ratings around 400 psi, depending on the type and diameter.

3. Ease of Installation:

– PEX: Easier to install due to its flexibility and fewer connections needed; can be snaked through walls.

– Copper: Requires soldering or special fittings (push-to-connect), rigid, and more labor-intensive.

4. Cost:

– PEX: Generally more cost-effective both in material and labor.

– Copper: More expensive, both in raw material cost and installation labor.

5. Flow Rate:

– PEX: Slightly narrower internal diameter compared to copper, which can reduce flow rate.

– Copper: Smoother internal surface may result in better flow rate compared to PEX, for the same diameter.

6. Longevity:

– PEX: Estimated lifespan of 40-50 years.

– Copper: Can last over 50 years if the water chemistry is not too harsh.

7. Environmental Impact:

– PEX: Made from petrochemicals and not biodegradable, but less energy-intensive production.

– Copper: 100% recyclable, but high energy input for extraction and production.

8. Noise and Vibration:

– PEX: Quieter during water flow due to its flexible nature.

– Copper: Can transmit sound (water hammer) and vibrations more readily due to its rigidity.

Choosing between PEX and copper piping involves considering these factors based on specific project needs and local building codes.

List Product features of “pex vs copper piping”

PEX vs. Copper Piping: Product Features

PEX Piping:

1. Flexibility: Can be bent and curved around obstacles, reducing the need for fittings.

2. Cost-Effective: Generally cheaper than copper piping in both material and installation costs.

3. Corrosion Resistance: Immune to rust and corrosion, ensuring a longer lifespan.

4. Quiet: Reduces water hammer noise due to its flexible nature.

5. Insulation: Better thermal insulation properties, reducing heat loss.

6. Ease of Installation: Lightweight and easy to cut, connect, and install.

7. Durability: Resistant to scale buildup and chlorine, extends the longevity.

8. Freeze Resistance: Can expand and contract without breaking, though not entirely freeze-proof.

9. Chemical Resistance: More resistant to acidic or alkaline water and soil conditions.

Copper Piping:

1. Durability: Known for its long lifespan, often lasting over 50 years.

2. Fire Resistance: Non-combustible material, providing a safer option in the event of a fire.

3. Pressure Handling: Excellent at managing high water pressure.

4. Antimicrobial Properties: Naturally inhibits bacterial growth within the pipe.

5. Historical Provenance: Long-standing history of reliability and performance.

6. Environmental Impact: Fully recyclable, making it a more eco-friendly choice.

7. Thermal Conductivity: Superior thermal conductivity, ideal for specific heating systems.

8. Rigid Support: Provides structural integrity that can support fixtures without additional bracing.

9. Chemical Reactivity: Susceptible to corrosion depending on water quality and environmental conditions.

Choosing Between PEX and Copper:

– PEX: Ideal for cost-conscious, flexible installation needs, and areas with corrosive water.

– Copper: Best for high-pressure systems, fire-prone areas, and those seeking a proven, recyclable material.

Each piping system offers distinct advantages, making the choice dependent on specific installation needs, environmental conditions, and budget considerations.

List Various Types of “pex vs copper piping”

When comparing PEX (cross-linked polyethylene) and copper piping for plumbing systems, it’s essential to consider several factors. Here’s a concise comparison of various types:

1. Flexibility and Installation:

– PEX: Highly flexible, making it easier to install and reduce the need for fittings. It can weave through walls and around obstacles.

– Copper: Rigid and less flexible, requiring more fittings and precise measuring and cutting, which can increase labor costs and complexity.

2. Durability and Longevity:

– PEX: Resistant to scale and chlorine, doesn’t corrode or develop pinhole leaks. Lifespan can be up to 50 years or more under optimal conditions.

– Copper: Also very durable with a lifespan of 50+ years, can withstand high temperatures and is bacteriostatic (resists bacteria growth).

3. Cost:

– PEX: Generally cheaper in terms of both material and labor costs, making it cost-effective for many plumbing projects.

– Copper: More expensive due to higher material costs and more intensive labor requirements.

4. Environmental Impact:

– PEX: Made from a type of plastic, requiring petrochemicals. Recycling options are limited but improving.

– Copper: A natural material that is fully recyclable and has a potentially lesser environmental impact once extracted and processed.

5. Temperature and Pressure:

– PEX: Can handle a range of temperatures and pressures but can be more prone to damage by UV light if exposed.

– Copper: Excellent at handling high temperatures and pressures, ideal for hot water applications.

6. Chemical Resistance:

– PEX: Resistant to a variety of chemicals commonly found in water but can be affected by certain substances like petroleum products.

– Copper: Generally resistant to most household chemicals, but acidic water can cause corrosion over time.

7. Noise:

– PEX: Quieter, minimizes water hammer sound due to its flexibility.

– Copper: More prone to noise during water flow and thermal expansion.

Choosing between PEX and copper depends on specific project requirements, budget, and long-term considerations. Both have their unique advantages and potential drawbacks.

List Application of “pex vs copper piping”

PEX vs. Copper Piping: Applications

1. Home Plumbing:

– PEX: Ideal for residential plumbing due to its flexibility, ease of installation, and resistance to freezing. PEX pipes can be snaked into walls and around corners without the need for additional fittings.

– Copper: Traditional choice praised for durability and bacteriostatic properties, making it less prone to bacterial growth. Common in older homes and high-end new constructions.

2. Radiant Heating Systems:

– PEX: Widely used because it can withstand high temperatures and is easy to install in tight spaces under floors.

– Copper: Less commonly used due to higher cost and difficulty in installation compared to PEX.

3. Commercial Plumbing:

– PEX: Gaining popularity for commercial properties due to cost savings and faster installation times.

– Copper: Still preferred in many commercial applications, especially where higher pressure resilience is required.

4. Refrigeration:

– Copper: Predominantly used for refrigerant lines due to its thermal conductivity and durability.

– PEX: Not commonly used in refrigeration systems—limited to specific, low-pressure applications.

5. Retrofitting and Repairs:

– PEX: Excellent for retrofitting older buildings because it can be threaded through existing walls and floors with minimal disruption.

– Copper: More challenging to retrofit due to rigidity and complex fitting requirements, though valued for long-term reliability.

6. Water Service Lines:

– PEX: Increasingly used due to its resistance to corrosion and scale buildup.

– Copper: Traditional choice known for high durability but susceptible to corrosion from aggressive water supply conditions.

7. Underground Installations:

– PEX: Can be used for underground water lines and is preferred for its resistance to soil acidity and compounds.

– Copper: Also used but needs protective coatings or wraps to prevent corrosion when buried.

Summary:

Both PEX and copper piping have distinct advantages and are chosen based on specific needs, budget, and environmental conditions. PEX offers flexibility, cost savings, and ease of installation, while copper is valued for its durability, longevity, and bacteriostatic properties.

List Buyer Types of “pex vs copper piping”

When considering PEX vs. copper piping, buyers typically fall into several distinct categories, each with unique needs and preferences. Here’s a list:

1. Homeowners:

– *Budget-Conscious*: Often lean toward PEX due to its lower material and installation costs.

– *DIY Enthusiasts*: Prefer PEX for easier installation, flexibility, and fewer specialized tools required.

– *Traditionalists*: Might opt for copper, valuing its durability, longevity, and the perceived prestige associated with metal piping.

2. Professional Plumbers:

– *Efficiency Seekers*: Favor PEX for quicker installation, maneuverability around obstacles, and reduced labor costs.

– *Quality Advocates*: Might prefer copper for its long-standing reliability, heat resistance, and resistance to UV degradation.

– *Hybrid Users*: Use both PEX and copper, selecting based on specific project requirements and customer preferences.

3. Real Estate Investors:

– *Return on Investment Focused*: Choose PEX for newer installations to reduce capital expenditure and enhance property appeal with modern plumbing solutions.

– *High-End Property Investors*: Opt for copper in premium properties to leverage its reputation for quality and durability, adding perceived value.

4. Commercial Builders:

– *Cost and Time Efficient*: Primarily select PEX for large-scale projects to save on material and labor costs, speeding up construction timelines.

– *Building Regulations and Codes Adherents*: May opt for copper if local regulations favor its use, or if higher pressure ratings and fire resistance are required.

5. Environmental Advocates:

– *Eco-Conscious Buyers*: Lean towards PEX due to its lower energy consumption during manufacturing and lower likelihood of leaching metals into water.

– *Sustainability Champions*: Prefer copper for its recyclability and long lifespan, which contributes to reducing waste.

Ultimately, the choice between PEX and copper often depends on a mix of budget constraints, installation preferences, property type, and long-term performance considerations.

List “pex vs copper piping” Project Types for Different Industries

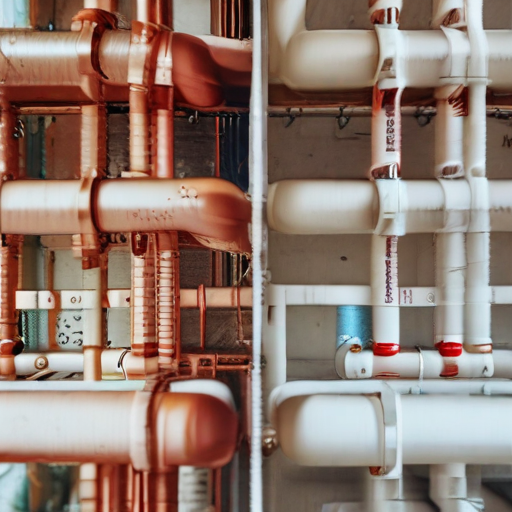

Residential Plumbing

– PEX: Preferred for ease of installation, flexibility, resistance to scaling and chlorine, and lower cost.

– Copper: Used for its durability, long lifespan, and ability to withstand high temperatures; however, it is more expensive and may corrode.

Commercial Buildings

– PEX: Chosen for rapid installation and lower costs, particularly in newer constructions or retrofits.

– Copper: Favored for its strength, reliability, and proven track record, often used in high-rise buildings and complex systems.

Healthcare Facilities

– PEX: Increasingly popular due to its resistance to bacterial growth and efficiency in installation.

– Copper: Still widely used for its antimicrobial properties and long-term reliability in critical environments.

Industrial Applications

– PEX: Suitable for non-corrosive environments and where flexibility is needed; often used in manufacturing plants.

– Copper: Preferred for chemical resistance, high-pressure systems, and where stringent safety standards are in place.

Hospitality Industry

– PEX: Utilized for quick renovations and new installations due to its cost-effectiveness and ease of use.

– Copper: Chosen for high-end establishments that prioritize long-term durability and minimal maintenance.

Educational Institutions

– PEX: Employed in new constructions for budget-friendly, quick installations.

– Copper: Often used in older buildings for compatibility with existing systems and historical consistency.

Food and Beverage Industry

– PEX: Selected where hygiene is paramount and for its ease of cleaning and installation.

– Copper: Common in applications requiring high-temperature tolerance and long-term reliability.

Each industry weighs the benefits of PEX vs. copper based on specific needs, budget constraints, and regulatory requirements.

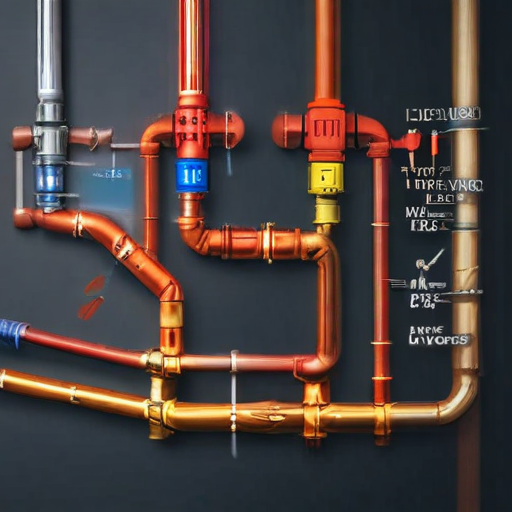

pex vs copper piping Accessories Upgrades and Custom Manufacturing Options

When choosing between PEX and copper piping for plumbing projects, various factors including accessories, upgrades, and custom manufacturing options come into play.

PEX Piping:

*Accessories:*

1. Fittings: PEX systems utilize crimp, clamp, or push-to-connect fittings, ensuring quick installations.

2. Manifolds: These distribution hubs streamline both installation and water delivery.

3. Tools: Special PEX crimping and cutting tools simplify the connection process.

*Upgrades:*

1. Oxygen Barrier PEX: Ideal for radiant heating systems, it prevents oxygen infiltration, enhancing longevity.

2. Pre-insulated PEX: Improves thermal efficiency and prevents heat loss.

*Custom Manufacturing:*

1. Color-Coded Tubing: Red for hot water, blue for cold, and white for general use, aiding in easy identification.

2. Pre-Formed Bends: Custom-shaped pipes reduce the need for additional fittings.

Copper Piping:

*Accessories:*

1. Fittings: Various types, such as elbows, tees, and couplings, offer robust solutions for diverse applications.

2. Flux and Solder: Essential for creating leak-free soldered joints.

3. Valves: Ball valves, gate valves, and others provide control mechanisms for water flow.

*Upgrades:*

1. Type L and K Copper: Thicker walls offer enhanced durability, particularly for underground and high-pressure applications.

2. Insulation: Adding foam or fiberglass insulation prevents heat loss and pipe sweating.

*Custom Manufacturing:*

1. Custom-Length Pipes: Specific lengths can be ordered to reduce waste and installation time.

2. Pre-Fabricated Assemblies: Pre-soldered configurations streamline multi-unit installations.

In conclusion, PEX piping offers flexibility and ease of installation with modern accessories and upgrades, making it popular for residential use. Copper piping, known for its durability and reliability, remains a preferred choice for long-term applications and high-pressure systems. Custom manufacturing options for both materials enhance their adaptability to specific project requirements.

List Quality Control and The Manufacturing Process of “pex vs copper piping”

Quality Control

#### PEX Piping

1. Material Inspection: Raw materials like cross-linked polyethylene are inspected for quality.

2. Dimensional Analysis: Ensuring the diameter and thickness meet specifications.

3. Pressure Testing: Piping undergoes pressure tests to ensure no leaks.

4. Visual Inspection: Checks for defects such as cracks or deformities.

5. Certification: Adherence to standards like ASTM F876 and NSF/ANSI 61.

6. Batch Testing: Samples from each batch are tested to ensure consistency.

#### Copper Piping

1. Material Verification: High-quality raw copper is verified for purity and quality.

2. Dimensional Accuracy: Pipe dimensions are rigorously controlled.

3. Pressure Testing: Subjected to hydrostatic pressure tests.

4. Visual Inspection: Examines for defects like pits and fissures.

5. Adherence to Standards: Standards like ASTM B88 are followed.

6. Corrosion Testing: Checks for resistance to corrosion factors.

Manufacturing Process

#### PEX Piping

1. Extrusion: Cross-linked polyethylene is heated and extruded into pipe shape.

2. Cross-Linking: Chemical or physical cross-linking process (Peroxide, Silane, Radiation).

3. Cooling: The pipes are cooled using controlled methods.

4. Cutting: Pipes are cut to standard lengths.

5. Coiling: Pipes are coiled for easy transportation and installation.

6. Marking and Labeling: Pipes are marked with specifications and standards.

#### Copper Piping

1. Casting: Copper ingots are melted and cast into billets.

2. Extrusion: Billets are extruded into tubes.

3. Drawing: Tubes are stretched to the desired diameter.

4. Annealing: Pipes are heated to eliminate internal stresses.

5. Cutting: Pipes are cut to length.

6. Surface Treatment: Cleaned and polished to remove oxidation.

7. End-Finishing: Ends are finished to prepare for fittings.

These quality control measures and manufacturing processes ensure the reliability, durability, and safety of both PEX and copper piping, catering to different applications and requirements.

How to use “pex vs copper piping”

When deciding between PEX and copper piping for your plumbing needs, it’s crucial to evaluate their respective advantages and disadvantages.

PEX (Cross-linked Polyethylene):

1. Cost-Effective: Generally cheaper than copper, both in material and labor costs.

2. Flexibility: PEX pipes are bendable, which makes them easier to install and reduces the need for fittings.

3. Corrosion Resistance: PEX does not corrode, which can extend its lifespan in certain water conditions.

4. Freeze Resistance: PEX expands under pressure caused by freezing water, reducing the risk of burst pipes.

5. Quick Installation: The plumbing process is faster due to fewer connections and easier handling.

However, PEX is not UV resistant, meaning it degrades if exposed to direct sunlight. Its long-term durability is still somewhat unclear compared to copper.

Copper:

1. Durability: Copper pipes have a long history of reliability and can last over 50 years when properly installed and maintained.

2. Resistance to Bacteria: Copper naturally resists bacterial growth, making it a cleaner option for drinking water.

3. Heat Resistance: Copper can withstand high temperatures and pressures better than PEX, making it more suitable for some applications.

4. Recyclable: Copper is fully recyclable, thus it’s a more environmentally friendly choice.

On the downside, copper is more expensive and requires skilled labor for installation. It is also susceptible to corrosion, especially in areas with acidic water.

Choosing the Right One:

– For DIY Projects: PEX is more user-friendly.

– For Longevity and High Pressure: Copper is more reliable.

– Budget Constraints: PEX offers cost savings.

– Environmental Concerns: Copper is recyclable and more sustainable.

Your specific plumbing needs and project scope will ultimately guide your choice. Always consider consulting a professional for tailored advice.

“pex vs copper piping” Comparative Analysis

PEX vs Copper Piping: Comparative Analysis

Cost:

PEX (cross-linked polyethylene) piping is generally more affordable than copper. The material cost of PEX is lower, and the installation is simpler due to its flexibility, which reduces labor expenses. Copper, on the other hand, is more expensive both in terms of material and installation, which often requires soldering and additional fittings.

Durability and Longevity:

Copper pipes have a long history of reliability, typically lasting 50+ years. They are resistant to UV rays, which makes them suitable for outdoor use. However, they can corrode over time, especially if the water is highly acidic or contains certain minerals. PEX piping is highly resistant to scale and chlorine, does not corrode, and can also last more than 50 years under optimal conditions. However, PEX is vulnerable to UV light and can degrade if exposed to direct sunlight.

Installation:

PEX is far easier to install than copper. Its flexibility allows it to bend around corners and weave through joists, reducing the need for joints and fittings. This can significantly speed up the installation process and reduce the potential for leaks. Copper pipes are rigid and require more fittings and precise measurements, which can make the installation process more labor-intensive.

Health and Safety:

Copper piping naturally resists bacterial growth and has been used for potable water for decades without significant health concerns. PEX, as a relatively newer material, has been approved for potable water use but occasionally raises concerns regarding leaching chemicals. However, modern PEX is generally considered safe and has been rigorously tested to meet health standards.

Environmental Impact:

Copper is a natural and recyclable material, making it an environmentally friendly option. PEX, while plastic-based, is also often recyclable, though not as widely accepted in recycling programs as copper.

Conclusion:

Both PEX and copper piping have their advantages and drawbacks. PEX is cost-effective and easy to install, whereas copper is durable and time-tested. The choice between them often comes down to specific needs, budget, and installation conditions.

“pex vs copper piping” Warranty and Support

When comparing PEX (cross-linked polyethylene) and copper piping, warranty and support are key considerations.

PEX Piping:

Most PEX manufacturers offer extensive warranties, often ranging from 25 to 30 years, primarily due to its durability and resistance to corrosion, scaling, and chlorine. PEX is also less prone to leaks because it uses fewer fittings and connections. Additionally, many PEX systems come with strong manufacturer support, including detailed installation guides, customer services, and access to certified installers. However, ensure you use the recommended fittings and follow the manufacturer’s guidelines strictly, as improper installation might void the warranty.

Copper Piping:

Copper pipes typically come with a warranty spanning from 50 years to a lifetime, reflecting their long history of reliability. Copper’s resistance to UV rays and its antimicrobial properties offer another layer of confidence. Copper piping manufacturers usually provide robust support services, often including professional guidance and an extensive network of expert plumbers. Nevertheless, copper piping can be susceptible to specific water chemistry issues, such as acidic water, which can lead to corrosion and pinhole leaks. It’s crucial to follow the installation guidelines accurately and ensure the piping is suited to your water conditions, as failing to do so might affect the warranty.

In summary, both PEX and copper piping offer strong warranties, but the actual support and longevity can vary based on adherence to installation guidelines and local water conditions. PEX provides flexibility and ease of installation, along with a robust warranty when used correctly. Meanwhile, copper offers time-tested durability and extensive warranties, contingent on proper installation and water conditions.

List “pex vs copper piping” FAQ

PEX vs Copper Piping FAQ

1. What are PEX and Copper Piping?

– PEX (Cross-linked Polyethylene): A flexible, plastic piping material commonly used for plumbing and radiant heating applications.

– Copper Piping: A traditional plumbing material known for its durability and bacteriostatic benefits.

2. What are the advantages of PEX piping?

– Flexibility: Easier to install, especially in tight spaces.

– Corrosion Resistance: Does not corrode like copper.

– Cost: Generally cheaper in terms of both material and labor.

– Reduced Noise: Quieter when water flows through.

3. What are the advantages of Copper piping?

– Durability: Long-lasting and can withstand higher pressures.

– Temperature Tolerance: Handles both extreme hot and cold well.

– Health Safety: Naturally resistant to bacteria growth.

4. Are there any disadvantages to PEX piping?

– UV Sensitivity: Can degrade if exposed to sunlight.

– Chemical Sensitivity: May leach chemicals into water if exposed to certain substances.

5. Are there any disadvantages to Copper piping?

– Corrosion: Can corrode over time, especially in acidic water.

– Cost: More expensive both in material and labor.

– Rigidity: More difficult to install, especially in retrofitting.

6. Which is more suitable for areas prone to freezing?

– PEX: More resistant to bursting in freezing conditions due to its flexibility.

7. Can PEX be used for both hot and cold water lines?

– Yes, PEX is suitable for both hot and cold water applications.

8. Which type has a longer lifespan?

– Copper: Can last over 50 years under ideal conditions.

– PEX: Typically has a lifespan of 40-50 years, but it can vary depending on water quality.

9. Is it difficult to switch from copper to PEX?

– No, transition fittings make it relatively straightforward to switch from copper to PEX.

10. Which is more environmentally friendly?

– PEX: Produces less waste during installation and requires less energy to produce.

– Copper: 100% recyclable, which offsets its initial environmental cost to some extent.

Top 10 FAQ with answer about pex vs copper piping for Buyer Sourcing from China

Certainly! Here are the top 10 frequently asked questions (FAQ) with answers for prospective buyers sourcing PEX vs. Copper piping from China:

1. What are the main differences between PEX and Copper piping?

– PEX (cross-linked polyethylene) is a flexible plastic material, while Copper is a rigid metal.

2. Which one is more cost-effective?

– PEX tends to be more cost-effective in terms of both material and installation costs compared to Copper.

3. What’s the durability like for PEX and Copper?

– PEX is resistant to scale and chlorine, doesn’t corrode or develop pinholes, and typically lasts 25-50 years. Copper pipes are durable and can last even longer, over 50 years, but can corrode over time.

4. How does the ease of installation compare between PEX and Copper?

– PEX is more straightforward to install due to its flexibility, reducing the need for fittings and joints. Copper requires soldering and rigid installation.

5. How does the performance in different temperatures compare?

– PEX can withstand a range of temperatures and is freeze-resistant. Copper is also suitable for various temperatures but can burst in severely cold conditions.

6. Are there any health concerns associated with PEX or Copper?

– Both materials are generally considered safe; however, some concerns have been raised about chemicals leaching from PEX. Copper doesn’t have these concerns but may be affected by water pH levels.

7. Which one is more environmentally friendly?

– Copper is a natural resource and can be recycled, making it more eco-friendly. PEX is a type of plastic, less ideal environmentally, but it’s highly efficient in production and use.

8. How do PEX and Copper react to water quality?

– PEX is resistant to acidic water and scaling. Copper can be affected by acidic or alkaline water, causing corrosion over time.

9. Are PEX and Copper suitable for all types of plumbing systems?

– Both are versatile but PEX is more suitable for retrofits and installations needing flexibility. Copper is ideal for new builds and exposed piping due to its rigidity and appearance.

10. Can I source PEX and Copper piping from China?

– Yes, China is a significant supplier of both PEX and Copper piping. Ensure to check certifications, comply with safety standards, and vet suppliers for quality assurance.

These FAQs help buyers weigh the pros and cons of each material and make informed decisions when sourcing from China.