12v hydraulic pump Safety Certifications

When selecting a 12V hydraulic pump, paying attention to safety certifications is crucial to ensure reliable and safe operation. Here are some widely recognized safety certifications to look for:

1. CE Marking (Conformité Européenne):

– Indicates conformity with health, safety, and environmental protection standards for products sold within the European Economic Area (EEA).

– Ensures compliance with relevant EU directives and regulations.

2. UL Certification (Underwriters Laboratories):

– Commonly used in the United States.

– Ensures adherence to rigorous safety standards to mitigate risks of fire, electrical shock, and mechanical hazards.

3. CSA Certification (Canadian Standards Association):

– Recognized in Canada and often accepted in the U.S.

– Signals compliance with Canadian safety standards and quality requirements.

4. ISO 9001 (International Organization for Standardization):

– Focuses on quality management systems and processes.

– Though not a direct safety certification, it ensures the manufacturer’s production processes meet international quality standards.

5. RoHS Compliance (Restriction of Hazardous Substances):

– Ensures that the pump does not contain harmful substances like lead, mercury, and cadmium.

– Important for environmental safety and reducing health risks.

6. ATEX Certification (ATmosphères EXplosibles):

– Necessary for equipment used in explosive environments.

– Indicates the pump is safe for operation in hazardous locations prone to explosions.

7. IP Rating (Ingress Protection):

– Indicates the level of protection against dust and water.

– For hydraulic pumps, a higher IP rating (e.g., IP65) ensures better protection in rugged environments.

8. Machinery Directive (2006/42/EC):

– Applies to machinery sold within the EEA.

– Ensures safety and performance standards are met to protect users and operators.

When choosing a 12V hydraulic pump, verifying these certifications ensures compliance with safety and quality standards, reducing the risk of accidents, malfunctions, and non-compliance with local regulations. Always consult manufacturer documentation or reach out to the supplier for detailed certification information.

List Reference Technical Parameters of “12v hydraulic pump”

Sure, below are the key reference technical parameters for a 12V hydraulic pump:

1. Voltage: 12 V DC

– Operates on a 12-volt direct current power supply, suitable for automotive, marine, and other mobile applications.

2. Motor Power: Varied (commonly between 0.5 kW to 3 kW)

– Motor power determines the capability of the pump to handle different loads and applications.

3. Flow Rate: Typically 1-10 liters per minute (L/min)

– Indicates the volume of hydraulic fluid the pump can move per minute, essential for gauging the pump’s efficiency and suitability for various tasks.

4. Maximum Pressure: 1500 – 3000 PSI (often around 2000 PSI)

– The highest pressure the pump can generate, critical for applications requiring high-force exertion.

5. Reservoir Capacity: 1 – 10 gallons

– The size of the hydraulic fluid tank, which affects the duration and capacity of the operation without needing a refill.

6. Port Sizes: Commonly 1/4″ to 1/2″ NPT

– Refers to the dimensions of the inlet and outlet ports, which need to be compatible with the hydraulic system’s plumbing.

7. Duty Cycle: Intermittent (e.g., 20 minutes on, 40 minutes off)

– Defines the operational duration the pump can handle without overheating, crucial for longevity and safety.

8. Weight: 10 – 50 lbs

– The weight of the pump, which impacts portability and ease of installation.

9. Dimensions: Variable (e.g., 10” x 8” x 7”)

– Specific to the model, affecting how the pump can be integrated into different systems.

10. Material: Housing typically made of aluminum or steel

– Ensures durability and longevity, especially in demanding environments.

11. Certifications: CE, ISO, RoHS (depending on the manufacturer)

– Compliance with international standards ensuring quality and safety.

These parameters are essential for selecting a 12V hydraulic pump that aligns with specific application requirements, ensuring optimal performance and reliability.

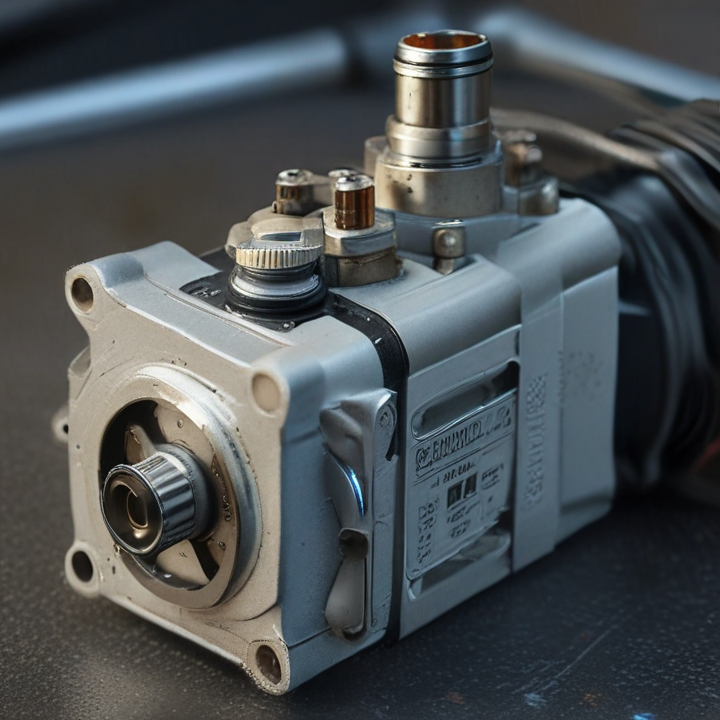

List Product features of “12v hydraulic pump”

1. Voltage Compatibility: Designed for 12V systems, making it ideal for automotive and other low-voltage applications.

2. Durable Construction: Built with high-quality materials to withstand harsh environments and prolonged use.

3. Compact Design: Features a small and efficient form factor for easy installation in tight spaces.

4. High-Pressure Output: Capable of generating substantial hydraulic pressure, suitable for lifting, pushing, and other heavy-duty tasks.

5. Integral Reservoir: Includes a built-in fluid reservoir to simplify the hydraulic system setup.

6. Overpressure Protection: Equipped with an overpressure valve to prevent damage to the pump and connected components.

7. Remote Operation: Some models offer remote control capabilities for easier and safer operation.

8. High Performance: Provides consistent and reliable hydraulic power across various applications.

9. Easy Maintenance: Designed for straightforward maintenance with easily accessible components.

10. Versatile Applications: Suitable for use in a variety of applications, including truck bed lifts, dump trailers, agricultural equipment, and more.

11. Thermal Protection: Features thermal protection to prevent overheating during extended periods of operation.

12. Energy-Efficient: Engineered to maximize power efficiency, reducing battery drain during operation.

13. Corrosion-Resistant: Coated or constructed with materials that resist rust and corrosion, enhancing longevity in outdoor or moist environments.

14. Quick Connectors: Equipped with quick-connect hydraulic outlets for fast and easy setup and removal.

15. Noise Reduction: Designed to operate quietly, minimizing noise pollution during use.

16. Safety Features: Includes features like emergency shut-off and automatic resets for enhanced operational safety.

17. User-Friendly Interface: Many models come with an intuitive control interface for simplified operation.

These features make a 12V hydraulic pump a reliable, versatile, and efficient solution for various hydraulic applications, ensuring robust performance and ease of use.

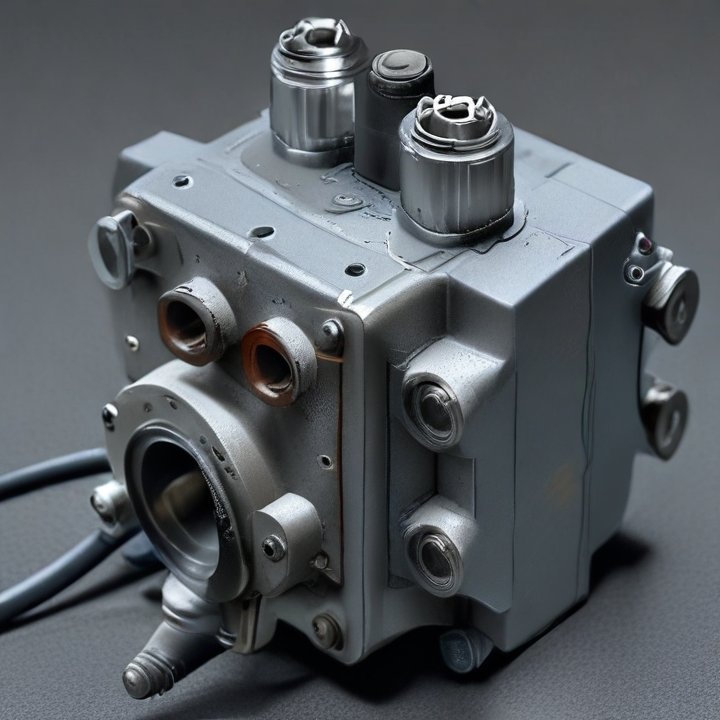

List Various Types of “12v hydraulic pump”

Sure, here’s a concise list of various types of 12V hydraulic pumps:

1. Gear Pumps

– External Gear Pumps: Utilized for high-pressure applications, featuring two gears that create flow by meshing together.

– Internal Gear Pumps: Known for smooth operation and typically used in applications requiring steady flow.

2. Piston Pumps

– Axial Piston Pumps: Common for applications needing high pressure and efficiency, using several pistons in a circular array.

– Radial Piston Pumps: Feature pistons arranged radially, suitable for high-pressure requirements with low noise.

3. Vane Pumps

– Known for offering a consistent flow with low noise levels, suitable for medium-pressure applications.

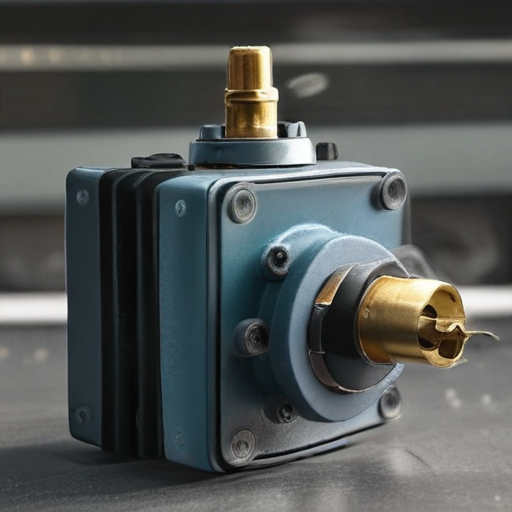

4. Hydraulic Power Units (HPU)

– A compact unit combining a 12V motor, hydraulic pump, hydraulic valve, and reservoir. Used for mobile equipment and small-scale applications.

5. Multifunctional Pumps

– Double-acting Pumps: Provide hydraulic power in both extending and retracting motions.

– Single-acting Pumps: Provide hydraulic power in one direction, generally used with spring-loaded or gravity-return mechanisms.

6. Mini Hydraulic Pumps

– Smaller units designed for light-duty applications such as lifting tailgates, RV leveling systems, and snow plows.

7. High-Flow Hydraulic Pumps

– Designed to deliver higher flow rates, suitable for systems requiring more hydraulic fluid movement.

These types of 12V hydraulic pumps are used across various industries, including automotive, agricultural, industrial, and recreational applications, due to their versatility and convenience in mobile and remote operations.

List Application of “12v hydraulic pump”

A 12v hydraulic pump is a versatile and portable power unit that can be applied in various fields, owing to its capability to convert electrical energy into hydraulic power. Here are some key applications:

1. Automotive Industry: In tow trucks, 12v hydraulic pumps are used for operating winches and towing mechanisms, ensuring efficient vehicle recovery and transport. They’re also used in RV leveling systems and truck bed lift systems, providing stability and convenience.

2. Agriculture: Farmers utilize these pumps in machinery like sprayers, seeders, and tractors for tasks such as lifting, steering, and implementing various agricultural attachments. This enhances productivity and operational efficiency.

3. Construction Equipment: Compact and portable construction machinery such as mini-excavators, dump trailers, and compactors rely on 12v hydraulic pumps for performing tasks like lifting, digging, and compressing. They ensure precise and powerful operations in limited spaces.

4. Marine Applications: Boats and yachts use 12v hydraulic pumps for steering systems, anchor handling, and operating winches for sails. They provide reliable and efficient hydraulic power in marine environments.

5. Material Handling: Forklifts, pallet jacks, and other material handling equipment use these pumps for lifting and moving heavy loads. They ensure smooth and controlled movements, enhancing workplace safety and efficiency.

6. Off-Road and Recreational Vehicles: These pumps power the hydraulic systems in off-road vehicles, enabling functionalities like suspension adjustments and four-wheel drive engagement, which enhances vehicular performance in rugged terrains.

7. Emergency and Rescue Operations: Hydraulic rescue tools such as cutters, spreaders, and rams use 12v hydraulic pumps for operations like extricating victims from vehicles. They offer rapid response and precise control crucial in rescue scenarios.

In summary, 12v hydraulic pumps are essential in various domains for their reliability, portability, and efficiency in converting electrical power into hydraulic energy for versatile applications.

List Buyer Types of “12v hydraulic pump”

When it comes to purchasing a 12v hydraulic pump, the buyer landscape is diverse, encompassing various industries and applications. Below is a breakdown of the key buyer types:

1. Automotive Enthusiasts and Mechanics:

– These buyers use 12v hydraulic pumps for tasks such as lifting vehicles, powering hydraulic jacks, and operating hydraulic presses. They’re particularly useful for off-road vehicles and in custom automotive projects where portability and compact power are required.

2. Agricultural Sector:

– Farmers and agricultural businesses utilize these pumps to run various types of farm equipment, including hydraulic lifts, loaders, and sprayers. The 12v system is particularly advantageous in remote locations where access to mains electricity is limited.

3. Construction and Heavy Equipment Operators:

– In construction, 12v hydraulic pumps are employed to power small machinery such as mini excavators, dump trailers, and other hydraulic tools. The portability and power efficiency are ideal for on-site operations.

4. Marine and Boating:

– Boat owners and marine professionals purchase these pumps to power anchor winches, hydraulic steering systems, and other onboard hydraulic equipment. The 12v power system integrates well with marine electrical setups.

5. Emergency and Rescue Services:

– Firefighters, EMTs, and rescue teams leverage 12v hydraulic pumps for hydraulic rescue tools like the jaws of life. These pumps provide quick and reliable power in critical situations.

6. Manufacturing and Industrial Applications:

– In small manufacturing setups and workshops, these pumps are useful for powering presses, clamps, and other hydraulic tools. They offer a mobile and flexible solution for various applications.

7. DIY and Hobbyists:

– Individuals engaging in DIY projects, custom builds, and home improvement tasks may opt for 12v hydraulic pumps for their versatility and ease of integration into various mechanical systems.

8. OEM (Original Equipment Manufacturers):

– Companies that produce machinery or vehicles requiring hydraulic systems often integrate 12v hydraulic pumps into their designs, providing a reliable power source for their products.

In summary, the buyer types for 12v hydraulic pumps span across automotive, agriculture, construction, marine, emergency services, manufacturing, DIY enthusiasts, and OEMs, highlighting the broad utility and application of these hydraulic systems.

List “12v hydraulic pump” Project Types for Different Industries

Sure, here are different project types utilizing a 12V hydraulic pump across various industries, condensed into a brief format:

1. Automotive:

– Custom Off-Road Vehicles: Hydraulic lifts for suspension systems.

– Towing Equipment: Operating winches and lift gates.

– Convertible and Tonneau Covers: Powering the movement mechanisms for convenience.

2. Agriculture:

– Tractor Attachments: Operating front loaders, plows, and other attachments.

– Irrigation Systems: Controlling water distribution mechanisms.

– Livestock Handling Equipment: Hydraulic gates and chutes for livestock management.

3. Marine:

– Boat Steering Systems: Enhancing ease of steering for small to medium-sized boats.

– Anchor Winches: Facilitating the deployment and retrieval of anchors.

– Deck Equipment: Operating cranes and winches for loading and unloading.

4. Construction:

– Heavy Machinery: Supporting small-scale equipment like mini-diggers and skid-steer loaders.

– Scissor Lifts: Elevating platforms for workers safely.

– Remote-Controlled Vehicles: Enhancing control for demo and unmanned applications.

5. Industrial Equipment:

– Compact Hydraulic Presses: Enabling efficient pressing in confined spaces.

– Robotic Arms: Facilitating precise movement in assembly lines.

– Hydraulic Jacks: Providing powerful lifting capabilities in compact forms.

6. Recreational Vehicles (RVs):

– Leveling Systems: Ensuring the camper or RV is properly leveled.

– Slide-Out Rooms: Smooth operation of expanding living spaces.

– Lifts and Hoists: Assisting in storage solutions and accessibility options.

## 7. Renewable Energy:

– Wind Turbine Maintenance: Hydraulic systems in maintenance equipment.

– Solar Panel Orientation: Adjusting panels for maximum solar intake.

– Hydraulic Generators: Small-scale renewable hydraulic energy solutions.

8. Emergency and Utility Services:

– Rescue Equipment: Powering jaws of life and other rescue tools.

– Utility Trucks: Enhancing functionalities like bucket lifts.

– Mobile Clinics: Operating medical equipment in field operations.

Each industry leverages the portability, power, and flexibility of 12V hydraulic pumps to optimize performance and efficiency in their specialized applications.

12v hydraulic pump Accessories Upgrades and Custom Manufacturing Options

When optimizing a 12V hydraulic pump, a range of accessories, upgrades, and custom manufacturing options can significantly enhance its performance, durability, and suitability for specific applications. Below are some key considerations:

Accessories:

1. Pressure Gauges: Allows for monitoring system pressure, ensuring safe and efficient operation.

2. Heat Exchangers: Helps maintain optimal oil temperature, preventing overheating and extending pump life.

3. Filters: Keeps the hydraulic fluid clean, reducing wear and tear on internal components.

4. Mounting Brackets: Securely mount the pump to various surfaces, increasing stability and reducing vibrations.

5. Remote Controls: Enables convenient operation from a distance, enhancing user flexibility and safety.

Upgrades:

1. Variable Speed Controllers: Adjust the pump’s speed to match the load requirements, improving efficiency and reducing energy consumption.

2. Higher Capacity Batteries: Offers longer operation times for off-grid or remote applications.

3. Improved Seals and Gaskets: Use of advanced materials for better resistance to wear, chemicals, and extreme temperatures.

4. Enhanced Motor Options: Opt for brushless motors for better efficiency, longer life, and reduced maintenance.

5. Noise Dampening: Incorporate silencers or soundproofing materials to reduce operational noise, making the pump more suitable for residential or quiet environments.

Custom Manufacturing Options:

1. Customized Flow Rates and Pressure Settings: Tailor the pump’s specifications to suit unique application needs, such as robotics, automotive, or agricultural uses.

2. Material Selection: Choose specialized materials like stainless steel or aluminum for parts to meet specific requirements for weight, corrosion resistance, or environmental conditions.

3. Design Modifications: Incorporate features like compact design for space-constrained applications or modular designs for easier maintenance and part replacement.

4. Special Ports and Connections: Customize inlet/outlet ports and electrical connections to integrate seamlessly with existing systems.

5. Branded Customization: Personalize pumps with logos or color schemes for brand alignment or identification purposes.

Careful selection and integration of these accessories and upgrades can transform a standard 12V hydraulic pump into a high-performance, custom-tailored tool for various demanding applications.

List Quality Control and The Manufacturing Process of “12v hydraulic pump”

Quality Control of 12V Hydraulic Pump

1. Raw Material Inspection: Ensure that the materials used, such as metals for the housing and seals, meet specifications.

2. Dimensional Accuracy: Measure critical dimensions of components using precise instruments.

3. Leakage Testing: Subject the pump to pressure tests to detect leaks in the housing and seals.

4. Performance Testing: Check the flow rate, pressure output, and operational efficiency.

5. Electrical Testing: Test the motor windings and connections for continuity and resistance.

6. Noise and Vibration Analysis: Ensure the pump operates within acceptable noise and vibration levels.

7. Final Inspection: Visual and functional checks before packaging to ensure the pump meets all quality standards.

Manufacturing Process of 12V Hydraulic Pump

1. Design and Prototyping: Engineers design and create a prototype, often using CAD software and initial 3D printing.

2. Material Selection and Procurement: Purchase raw materials such as aluminum, steel, rubber, and electronic components based on specifications.

3. Component Manufacturing:

– Housing: Machined from metal blocks to precise tolerances.

– Seals and Valves: Molded from rubber or plastic.

– Motor Assembly: Winding and assembling the 12V electric motor.

4. Component Assembly:

– Housing Assembly: Install seals, connect the motor to the pump mechanism, and assemble the housing.

– Internal Components: Install valves, pistons, and other internal components.

5. Testing and Calibration: Conduct pressure and performance testing to ensure functionality and efficiency.

6. Surface Treatment: Apply coatings or paint to prevent corrosion and enhance appearance.

7. Quality Control: Perform a series of rigorous tests (as detailed in the Quality Control section).

8. Packaging and Shipping: Finally, the pumps are carefully packaged to prevent damage during shipping and then dispatched to distributors or customers.

By adhering to these quality control measures and manufacturing steps, a reliable and efficient 12V hydraulic pump can be produced.

How to use “12v hydraulic pump”

Using a 12V hydraulic pump involves a few essential steps to ensure safe and efficient operation. Below are the concise instructions:

Materials Needed:

– 12V hydraulic pump

– Hydraulic fluid

– Battery or 12V power source

– Hydraulic hoses and fittings

– Control switch or relay (if applicable)

– Hydraulic cylinder or motor (load mechanism)

Steps:

1. Assembly:

– Ensure all components are compatible.

– Connect the hydraulic hoses to the pump’s inlet and outlet fittings securely.

– Attach the other ends of the hoses to your hydraulic cylinder or motor.

2. Electrical Connection:

– Connect the pump’s electrical terminals to a 12V power source like a car battery or dedicated 12V supply.

– Use appropriate connectors and wiring, along with a fuse to prevent electrical overloads.

– Incorporate a control switch or relay to manage the pump’s operation.

3. Filling with Hydraulic Fluid:

– Open the reservoir on the pump and fill it with the recommended hydraulic fluid.

– Ensure the fluid level is within the required range.

4. Priming the Pump:

– Prime the pump by running it briefly without load to allow hydraulic fluid to fill the internal components and hoses.

– Check for air bubbles and ensure complete priming to avoid cavitation.

5. Operation:

– Activate the control switch or relay to start the pump.

– The hydraulic pump should begin moving the fluid through the hoses, powering the connected load (hydraulic cylinder/motor).

– Monitor the system for leaks and verify smooth operation.

6. Maintenance:

– Regularly check fluid levels and top up as needed.

– Inspect hoses and fittings for wear or damage.

– Maintain a clean environment around the hydraulic pump to avoid contamination.

Safety Tips:

– Always use gloves and eye protection when handling hydraulic fluid.

– Disconnect the power source before performing any maintenance.

– Keep the operating environment dry and clean to prevent electrical hazards.

Following these steps will ensure your 12V hydraulic pump operates smoothly and efficiently.

“12v hydraulic pump” Comparative Analysis

When comparing 12V hydraulic pumps, several critical factors should be considered: performance specifications, efficiency, durability, and application suitability.

Performance Specifications:

1. Flow Rate: Typically measured in gallons per minute (GPM) or liters per minute (LPM), a higher flow rate can translate to faster operation. Pumps range from 1 GPM to 4 GPM.

2. Pressure Rating: Measured in pounds per square inch (PSI), standard ratings fall between 1500 and 3000 PSI. Higher PSI handles more demanding tasks but requires more robust systems.

Efficiency:

1. Energy Consumption: Efficiency rates differ; some models may draw more amperage, impacting energy usage. Look for pumps with lower amp draw for extended battery life.

2. Technology: Modern pumps may incorporate brushless motors, enhancing efficiency and reducing wear, compared to traditional brushed motors.

Durability:

1. Construction Materials: High-quality pumps use materials like stainless steel or aluminum for resistance to corrosion and wear.

2. Design: Sealed pumps prevent contamination, while thermal protectors guard against overheating, extending the pump’s lifespan.

Application Suitability:

1. Portability: Compact and lightweight models are ideal for mobile applications, such as vehicle recovery or portable hydraulic systems.

2. Fixed Applications: Larger, more robust pumps cater to industrial or construction equipment that demands consistent, high-power output.

Brand Comparisons:

1. Premium Brands: Brands like Parker and Enerpac often offer higher-end models with advanced features and higher reliability but at a premium cost.

2. Mid-Range Options: Brands like VEVOR and Mophorn offer a good balance of performance and cost, suitable for general applications without the high price tag.

3. Budget Brands: Cheaper options might suffice for infrequent or less demanding uses but can lack durability and after-sales support.

Conclusion:

Selecting a 12V hydraulic pump involves balancing performance, efficiency, durability, and specific needs. Premium brands provide reliability for demanding tasks, while mid-range options offer cost-effective solutions for general use. Comparing specifications and brand reputation can help find the best tool for your needs.

“12v hydraulic pump” Warranty and Support

When considering the purchase of a 12V hydraulic pump, paying close attention to the warranty and support options can significantly impact your long-term satisfaction and overall user experience.

Warranty: Most reputable manufacturers offer a warranty ranging from one to three years for 12V hydraulic pumps. This warranty typically covers defects in materials and workmanship. It’s crucial to read the warranty conditions closely to understand what is included. For instance, some warranties might not cover damage caused by improper installation, misuse, or lack of maintenance. Additionally, some warranties may require the registration of the product shortly after purchase to be valid.

Support: Customer support is essential when dealing with complex machinery such as hydraulic pumps. Look for manufacturers that offer multiple channels for customer support, including phone, email, and live chat. A detailed user manual and troubleshooting guide should also be provided. Reputable companies often have an online resource center filled with FAQs, instructional videos, and technical documents. It’s beneficial if the manufacturer provides access to professional technicians who can offer advice on installation, troubleshooting, and maintenance.

Spare Parts and Service Centers: Accessibility to spare parts and authorized service centers can be a significant factor. Ensure that the manufacturer has an extensive network of service centers and the availability of replacement parts. This can mitigate downtime and prolong the life of your hydraulic pump.

In summary, a comprehensive warranty and robust customer support are crucial when investing in a 12V hydraulic pump. Opt for manufacturers known for high-quality products and responsive customer service to ensure that you are covered in the event of any issues. Always read the fine print of the warranty and understand the support structure in place. This proactive approach will provide peace of mind and a smoother ownership experience.

List “12v hydraulic pump” FAQ

12V Hydraulic Pump FAQ

1. What is a 12V hydraulic pump?

A 12V hydraulic pump is a type of pump that uses a 12-volt DC power source to create hydraulic pressure, used to operate a variety of equipment like lifts, trailers, and other mobile machinery.

2. Where is a 12V hydraulic pump commonly used?

It is commonly used in mobile applications, including truck bed lifts, dump trailers, RV leveling systems, snowplows, and other machinery requiring hydraulic power on the go.

3. How does a 12V hydraulic pump work?

It converts electrical energy from a 12V battery into mechanical force by moving hydraulic fluid through the pump, creating pressure that operates hydraulic cylinders and motors.

4. What are the advantages of using a 12V hydraulic pump?

– Portability: Powered by 12V batteries, making it suitable for mobile operations.

– Ease of Installation: Typically more straightforward to install compared to higher voltage systems.

– Versatility: Suitable for a wide variety of applications.

5. How do you power a 12V hydraulic pump?

It is typically connected to a 12V DC battery, like those in vehicles, making it convenient for mobile and remote applications.

6. What maintenance is required for a 12V hydraulic pump?

Regular checks and maintenance for hydraulic fluid levels, inspecting hoses and fittings for leaks, and ensuring the electrical connections are clean and secure. Also, periodic replacement of the hydraulic fluid and filters is needed.

7. How much fluid can a 12V hydraulic pump handle?

This varies based on the specific model and design but typically ranges from 1 to 10 gallons per minute (GPM).

8. Are 12V hydraulic pumps compatible with all hydraulic systems?

Not necessarily; you must confirm compatibility with the hydraulic specifications (pressure ratings, flow requirements) of your specific equipment.

9. What safety precautions should be taken?

Ensure the system is depressurized before maintenance, use proper PPE, and follow manufacturer guidelines to prevent accidental injuries.

10. Can I use a standard car battery to power my 12V hydraulic pump?

Yes, as long as the battery provides sufficient current and is in good condition, it can power the pump effectively.

Top 10 FAQ with answer about 12v hydraulic pump for Buyer Sourcing from China

Certainly! Here are the top 10 frequently asked questions (FAQ) about sourcing a 12V hydraulic pump from China, complete with concise answers:

1. What are the key factors to consider when sourcing a 12V hydraulic pump from China?

– Quality certifications (ISO, CE)

– Supplier reputation and experience

– Product specifications and compatibility

– Warranty and after-sales service

– Minimum order quantity (MOQ)

2. How can I verify the reliability of a Chinese supplier?

– Check customer reviews and testimonials

– Request product samples

– Verify business licenses and certifications

– Conduct factory audits or virtual tours

3. What is the typical lead time for delivery?

– Standard lead time is typically 3-6 weeks, depending on order volume and customization requirements.

4. Can the 12V hydraulic pump be customized to specific requirements?

– Yes, many suppliers offer customization options for flow rate, pressure, mounting configurations, and electrical connectors.

5. What is the average price range for a 12V hydraulic pump from China?

– Prices can range from $50 to $300 per unit based on specifications, order quantity, and customization.

6. What payment terms are typically accepted?

– Common payment terms include T/T (Telegraphic Transfer), L/C (Letter of Credit), and PayPal. A 30% deposit with the balance paid before shipping is standard.

7. How do I ensure the quality of the hydraulic pump before shipment?

– Request pre-shipment inspection reports

– Conduct third-party quality inspections

– Ask for detailed product testing records.

8. What shipping options are available?

– Sea freight, air freight, and express courier (DHL, FedEx, UPS). Sea freight is often the most cost-effective for bulk orders.

9. Are there import duties or taxes to consider?

– Yes, import duties and taxes depend on your country’s regulations. Check the HS code for the specific hydraulic pump to estimate duties.

10. What kind of after-sales support can I expect?

– Look for suppliers offering warranties (typically 1-2 years), technical support, and availability of spare parts.

By considering these FAQs, you can make a more informed decision when sourcing 12V hydraulic pumps from China, ensuring a reliable supply and high-quality product.