advantages of injection moulding Safety Certifications

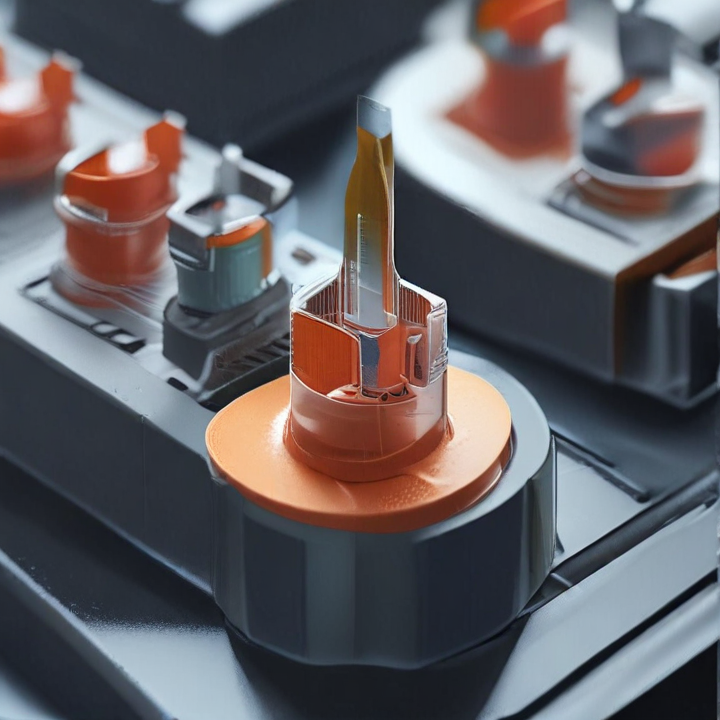

Injection moulding is a highly efficient manufacturing process that offers several advantages, particularly when paired with stringent safety certifications. Understanding these benefits is critical for industries ranging from automotive to healthcare.

1. Efficiency and Precision:

Injection moulding allows for the mass production of complex parts with high precision and repeatability, ensuring consistent quality across large volumes. This minimizes defects and enhances product reliability, a crucial factor for safety-critical applications.

2. Material Versatility:

The process can accommodate a wide range of materials, including thermoplastics, thermosets, and elastomers. This flexibility enables manufacturers to select materials with specific safety properties, such as flame retardance or biocompatibility, depending on the application.

3. Cost-Effectiveness:

Once the initial mold is created, the cost per unit drops significantly, making it economically viable for producing safety-critical components in bulk. Economies of scale further enhance affordability without compromising quality.

4. Design Flexibility:

Advanced injection moulding techniques allow for intricate designs that might be impossible or cost-prohibitive with other methods. This design freedom facilitates the integration of safety features directly into the components, enhancing overall product safety.

5. Reduced Waste:

Injection moulding is a relatively low-waste process, as excess material can often be recycled. This is not only environmentally friendly but also ensures that safety standards are met consistently by maintaining material integrity.

Safety Certifications:

1. ISO 9001:

Adherence to ISO 9001 standards ensures robust quality management systems, fostering continuous improvement and customer satisfaction. This certification is a testament to the manufacturer’s commitment to producing safe, high-quality products.

2. ISO 13485:

For medical devices, ISO 13485 certification specifies stringent requirements for a quality management system. Compliance guarantees that products meet regulatory requirements for safety and performance in healthcare settings.

3. UL Certification:

Underwriters Laboratories (UL) provides safety-related certification, ensuring that moulded components meet rigorous safety standards. Products must undergo comprehensive testing to earn this mark, reflecting their safety and reliability.

In summary, injection moulding combined with top-tier safety certifications offers numerous advantages, including high efficiency, material versatility, cost-effectiveness, and enhanced safety. These factors make it an ideal choice for the production of reliable, high-quality components across various industries.

List Reference Technical Parameters of “advantages of injection moulding”

Injection molding is a widely used manufacturing process that offers numerous technical advantages:

1. High Precision and Consistency: Injection molding allows for the production of complex parts with tight tolerances and excellent surface finishes. This high precision and repeatability are crucial for applications requiring consistent part quality.

2. Material Versatility: The process is compatible with a wide range of thermoplastic and thermosetting polymers, as well as composite materials. This versatility enables the selection of the optimal material for specific mechanical, thermal, and chemical properties.

3. Efficiency and Speed: Injection molding is highly efficient once the mold is created. Cycle times are fast, often ranging from seconds to a few minutes, allowing for high-volume production and quick turnaround times.

4. Design Flexibility: The method supports the creation of intricate geometries and complex structures, including thin walls, undercuts, and threads. This flexibility enables the design of innovative and functional parts that may be difficult to produce with other manufacturing processes.

5. Waste Reduction: Material wastage is minimized as excess plastic can often be recycled and reused in subsequent injection molding cycles. This efficiency contributes to more sustainable manufacturing practices.

6. Strength and Durability: Parts produced through injection molding can be engineered to have high strength and durability by incorporating fillers to enhance material properties or using reinforced materials.

7. Low Labor Costs: The automation intrinsic to injection molding reduces the need for manual intervention, lowering labor costs and minimizing the potential for human error.

8. Cost-effectiveness for Mass Production: While initial mold creation can be expensive, the per-unit cost drops significantly as production volume increases, making injection molding highly cost-effective for large-scale manufacturing.

In summary, injection molding offers high precision, material versatility, efficiency, design flexibility, waste reduction, and cost-effectiveness, making it an ideal choice for mass production of complex parts.

List Product features of “advantages of injection moulding”

Injection moulding is a highly efficient manufacturing process used to produce a wide range of plastic parts. Here are some of the notable advantages:

1. High Efficiency and Speed: Injection moulding allows for rapid production cycles, enabling the manufacturing of large quantities in a short period.

2. Design Flexibility: Complex and intricate designs with tight tolerances can be produced, accommodating various shapes, sizes, and details.

3. Precision and Consistency: This method ensures consistent quality with high precision and repeatability for each product, making it ideal for mass production.

4. Reduced Waste: Injection moulding minimizes material waste owing to its precision and the ability to recycle scrap materials.

5. Wide Material Variety: It supports a broad range of materials, including various plastics and resins, which can be tailored to specific performance requirements.

6. Low Labor Costs: The automated process reduces the need for manual intervention, subsequently lowering labor costs.

7. Enhanced Strength: Fillers can be added to the material to improve strength and durability, making the components robust.

8. Surface Finish and Aesthetics: Injection moulding can produce parts with excellent surface quality and finish, often eliminating the need for additional finishing processes.

9. Cost-Effective for High Volumes: While initial tooling costs can be high, the cost per part becomes very economical when producing in large volumes.

10. Resource Efficiency: Advanced injection moulding techniques allow for the optimization of resources and materials, contributing to sustainable manufacturing.

By leveraging these advantages, injection moulding becomes a versatile and economically viable option for producing high-quality plastic components across various industries.

List Various Types of “advantages of injection moulding”

Injection moulding is a popular manufacturing process with several advantages, offering benefits in various aspects of production and product design. Below are some key advantages:

High Efficiency

Speed and Automation: Injection moulding enables high-volume production runs with rapid cycle times, often incorporating automated processes to increase efficiency and reduce labor costs.

Precision and Consistency

Accuracy: The process ensures precise control over product dimensions, leading to high consistency and minimal variation between units.

Complex Geometry: Capable of producing intricate, detailed parts with complex geometries that would be challenging or impossible to achieve with other manufacturing methods.

Material Versatility

Wide Range of Materials: Accommodates a vast array of thermoplastic and thermoset materials, as well as composites and elastomers, providing flexibility in material selection.

Material Properties: The process allows for the inclusion of additives to enhance material properties such as strength, rigidity, or UV resistance.

Cost-Effectiveness

Low Labor Costs: Automation minimizes manual intervention, reducing labor costs and potential for human error.

Minimal Waste: Efficient use of materials lowers waste, which can also be recycled and reused, contributing to cost savings.

Design Flexibility

Innovative Designs: Injection moulding allows for the design of highly innovative and complex parts, including those with undercuts, threads, and other specialized features.

Surface Finish: Produces superior surface finishes, reducing or eliminating the need for post-production finishing processes.

Strength and Durability

Structural Integrity: The process creates parts with excellent structural integrity, especially when advanced reinforcements such as glass fibres are incorporated into the material.

Scalability

Production Volume: Suitable for both low-volume and high-volume production runs, making it economical even for large-scale projects.

Customization and Versatility

Multi-Material Moulding: Allows for overmoulding and insert moulding, combining different materials or incorporating pre-formed components into a single moulded part.

Color Options: Pigments can be added directly to the material, allowing for a broad palette of color choices without the need for secondary painting or finishing.

Each of these advantages makes injection moulding an attractive option for manufacturers aiming to produce high-quality, cost-effective, and durable components.

List Application of “advantages of injection moulding”

Injection moulding is a versatile manufacturing process widely used in various industries due to its numerous advantages. Here are key applications that benefit from these advantages:

1. Automotive Industry:

– Lightweight Components: Complex geometries and lightweight parts such as bumpers, dashboards, and interior panels are efficiently produced.

– Consistency: High-tolerance parts ensure uniformity and quality across thousands of components.

2. Consumer Electronics:

– Precision: Small and intricate parts such as connectors, casings, and buttons are manufactured with high precision.

– Material Versatility: A wide range of polymers can be used to meet different durability and aesthetic requirements.

3. Medical Devices:

– Sterilizable Materials: Parts made from medical-grade plastics can withstand sterilization processes.

– Complex Designs: Detailed and precise components like syringes, surgical instruments, and housing for medical devices are achievable.

4. Packaging:

– High Volume Production: Efficiently produces large quantities of consistent and high-quality packaging, such as bottle caps and containers.

– Cost-Effectiveness: Economies of scale reduce per-unit costs, making it ideal for disposable packaging.

5. Aerospace:

– Weight Reduction: Produces lightweight components, contributing to fuel efficiency.

– Durability: High-performance polymers can endure extreme conditions.

6. Toy Industry:

– Complex Shapes: Toys with intricate designs and moving parts are easily manufactured.

– Safety: Child-safe materials and designs ensure product safety.

7. Household Goods:

– Detail and Finish: High-quality finishes for items like kitchen utensils, storage containers, and home decor.

– Durability: Produces long-lasting products with excellent material properties.

Injection moulding’s precision, material versatility, and cost-efficiency make it a preferred choice across diverse applications, driving innovation and quality in product manufacturing.

List Buyer Types of “advantages of injection moulding”

Certainly! The advantages of injection moulding can be attractive to several types of buyers, each with unique needs and perspectives. Here’s a breakdown of key buyer types:

1. Manufacturers:

– Advantage: High precision and repeatability.

– Interest: Injection moulding enables manufacturers to produce large volumes of identical parts with tight tolerances, ensuring product consistency and quality.

2. Entrepreneurs/Startups:

– Advantage: Scalability.

– Interest: Injection moulding supports rapid scaling from prototype to mass production, crucial for startups aiming to quickly ramp up production as demand grows.

3. Medical Device Companies:

– Advantage: Sterilizable and biocompatible materials.

– Interest: The ability to use medical-grade plastics that are safe for use in healthcare applications is vital for producing medical devices.

4. Automotive Industry:

– Advantage: Material versatility and strength.

– Interest: Injection moulding allows the production of durable, lightweight components which are often required in automotive applications to improve fuel efficiency and performance.

5. Consumer Goods Companies:

– Advantage: Cost efficiency.

– Interest: Large-scale production leads to economies of scale, reducing the per-unit cost and making injection moulding bottom-line friendly for high-volume consumer goods.

6. Electronics Manufacturers:

– Advantage: Complex geometries and integration.

– Interest: Injection moulding allows for the manufacture of intricate parts and enclosures that can house electronic components, while maintaining high precision.

7. Toy Manufacturers:

– Advantage: Safety and consistency.

– Interest: Consistent quality and compliance with safety standards are key for toys, and injection moulding ensures repeatability in production.

8. Packaging Industry:

– Advantage: Speed and efficiency.

– Interest: High-speed production of packaging materials, such as caps, containers, and lids, meets the fast-paced demands of the packaging industry efficiently.

9. Aerospace Industry:

– Advantage: Lightweight parts with structural integrity.

– Interest: Reducing aircraft weight while maintaining part strength and integrity is crucial, and injection moulding provides the necessary material properties.

By addressing the unique needs of various industries, the advantages of injection moulding make it a versatile and in-demand manufacturing process.

List “advantages of injection moulding” Project Types for Different Industries

Injection moulding is a manufacturing process widely utilized across various industries due to its numerous advantages. Below are some key advantages tailored for different project types:

1. Automotive Industry:

– High Precision: Enables the production of intricate components with tight tolerances such as dashboards, bumpers, and gears.

– Durability and Strength: Produces parts that can withstand mechanical stress and are resistant to high temperatures and chemicals, which are vital for automotive components.

2. Consumer Electronics:

– Complex Designs: Facilitates the creation of complex parts like housings, connectors, and keyboard keys with detailed features and fine structures.

– Volume Production: Offers the capability for high-volume production, maintaining consistent quality and reducing production costs.

3. Medical Industry:

– Biocompatibility: Allows the use of medical-grade plastics to produce biocompatible and sterilizable parts such as syringes, implants, and surgical instruments.

– Precision and Cleanliness: Ensures high precision and cleanliness, meeting stringent regulatory standards.

4. Packaging Industry:

– Efficiency: Ideal for producing lightweight, strong packaging materials like caps, closures, and containers with high-speed cycles.

– Cost-Effectiveness: Reduces material waste and allows for the use of recyclable materials, optimizing cost-efficiency.

5. Aerospace Industry:

– Weight Reduction: Produces lightweight yet robust parts, contributing to fuel efficiency and performance improvements in aerospace applications.

– Material Versatility: Accommodates advanced materials like high-performance polymers, producing components that can endure extreme conditions.

6. Toy Manufacturing:

– Safety and Durability: Ensures the production of safe, durable, and non-toxic toys by using child-friendly plastic materials.

– Detail and Color: Produces finely detailed and vividly colored components, enhancing the aesthetic appeal and functionality of toys.

Injection moulding’s versatility, precision, and efficiency make it integral to various industries, enhancing product quality and manufacturing efficiency across diverse applications.

advantages of injection moulding Accessories Upgrades and Custom Manufacturing Options

Injection molding is a versatile manufacturing process used to produce a wide range of plastic parts and accessories. One of the major advantages is the ability to easily incorporate various upgrades and custom manufacturing options, enhancing functionality, aesthetics, and performance.

Customization:

Injection molding allows manufacturers to customize parts based on specific requirements. This can include tailored shapes, sizes, colors, and material properties. With detailed mold designs, manufacturers can create complex geometries and intricate details that meet precise customer specifications.

Efficiency:

The process can produce large volumes of parts quickly and consistently, making it ideal for high-demand applications. Advanced machinery and automated systems minimize human error, leading to high efficiency and reduced cycle times.

Material Versatility:

A wide range of thermoplastics and other materials can be used, each offering different properties such as flexibility, strength, or chemical resistance. This versatility supports the creation of parts suited for diverse industries, from automotive to healthcare.

Quality and Precision:

Injection molding ensures high precision and repeatability, essential for parts requiring tight tolerances. Modern techniques and quality control systems ensure each part meets stringent quality standards.

Cost-Effectiveness:

While the initial investment in molds can be high, the long-term benefits outweigh the costs. High productivity rates and minimal waste make injection molding a cost-effective solution for large-scale production. Additionally, advanced machinery and software improve cycle time and material usage, further reducing costs.

Upgrades and Integration:

Injection molding machines and molds can be upgraded with new technologies and materials that enhance performance. For example, adding features like robotic automation, real-time monitoring, or multi-material molding can improve efficiency and product quality.

Overall, injection molding is a robust method for producing high-quality, customized parts, benefiting industries with its efficiency, precision, and ability to integrate the latest advancements in manufacturing technology.

List Quality Control and The Manufacturing Process of “advantages of injection moulding”

Quality Control in Injection Moulding:

Quality control in injection moulding involves various stages to ensure that the final products meet the desired specifications and standards. Key elements include:

1. Material Inspection: Checking raw materials for consistency, purity, and compliance with standards.

2. Process Monitoring: Continuous monitoring during the injection process to maintain parameters like temperature, pressure, and cycle time.

3. Dimensional Checks: Using precise measuring tools (like calipers, micrometers) to ensure that the dimensions of moulded parts align with design specifications.

4. Visual Inspection: Identifying surface defects such as scratches, flash, or discoloration.

5. Functional Testing: Ensuring the product performs its intended function under expected use conditions.

6. Automated Inspection: Employing technology like machine vision systems to detect defects or inconsistencies with high accuracy.

Advantages of Injection Moulding:

1. High Precision and Consistency: Injection moulding allows for the production of highly accurate and consistent parts, vital for complex designs and tight tolerances.

2. High Efficiency: Once set up, the injection moulding process is rapid, allowing for high production rates, making it suitable for mass production.

3. Material Versatility: A wide range of materials, including various plastics, elastomers, and thermosets, can be used, enabling diverse applications.

4. Reduced Waste: Excess material from the moulding process can often be recycled, minimizing waste.

5. Cost-Effectiveness: While initial tooling costs can be high, the low per-unit cost for large production runs translates into overall savings.

6. Strength and Stability: Injection-moulded parts can incorporate fillers to enhance strength and stability without significant increases in weight.

7. Complex Geometry: The process supports the production of complex geometries, including intricate and detailed part designs that would be difficult or impossible with other manufacturing methods.

8. Automation Capabilities: The process can be automated to a large extent, reducing labor costs and improving production speed and consistency.

9. Surface Finish Variety: Parts can be produced with various surface finishes directly from the mould, reducing the need for secondary operations.

Injection moulding’s benefits make it a preferred choice for various industries, including automotive, medical, consumer goods, and electronics.

How to use “advantages of injection moulding”

Injection moulding offers numerous advantages, making it a preferred manufacturing process for various industries. Firstly, high efficiency is a notable benefit. The production cycle for injection moulding is typically quick, allowing large volumes of parts to be produced swiftly and consistently.

In addition, precision and accuracy are significant advantages. Injection moulding permits the creation of complex shapes with tight tolerances, ensuring each part is consistent and up to specification. This is particularly essential in sectors like aerospace and medical devices where accuracy is crucial.

Another advantage is the versatility in material use. Injection moulding supports a wide range of materials, from thermoplastics to thermosetting polymers, thus offering flexibility to manufacturers to choose the best material for their application.

Cost-effectiveness is also a major benefit, especially for large-scale production. Despite the high initial costs of mould creation, the overall cost per unit drops significantly when producing in bulk. This makes it economically viable for producing high volumes over time.

Moreover, reduced waste is an important consideration. The process is highly efficient in material use, and any excess material can often be recycled, promoting sustainability.

Lastly, enhanced strength is a key advantage. By using fillers in injection moulding, parts can be made stronger and more robust to meet specific mechanical requirements.

In conclusion, the advantages of injection moulding such as high efficiency, precision, versatility in material use, cost-effectiveness, reduced waste, and enhanced strength, make it an excellent choice for a broad array of manufacturing needs.

“advantages of injection moulding” Comparative Analysis

Advantages of Injection Moulding: Comparative Analysis

Injection moulding stands out as a preferred manufacturing process due to its array of compelling advantages, particularly when contrasted with other methods like 3D printing, CNC machining, and thermoforming.

1. Efficiency and Speed: Injection moulding excels in producing large quantities of parts rapidly. Once the mould is created, the production cycle is remarkably short, often just a few seconds per part. In contrast, 3D printing, though flexible, is considerably slower, making it unsuitable for mass production.

2. Cost-Effectiveness at Scale: While the initial cost for mould creation is high, the per-unit cost decreases substantially with volume. For large production runs, it becomes economically advantageous compared to methods like CNC machining, which incurs higher per-unit costs due to its subtractive nature.

3. Material Versatility: This process supports a wide range of thermoplastics, thermosetting polymers, and even some elastomers, allowing for diverse applications. Thermoforming, on the other hand, is typically limited to thin-walled parts made from specific sheet plastics.

4. Precision and Repeatability: Injection moulding offers high precision, with tight tolerances and excellent repeatability. This level of consistency is harder to achieve with 3D printing, which can suffer from layer alignment issues and variability in finish. CNC machining, while precise, may introduce variability through tool wear and multiple machining steps.

5. Complex Geometries: The method can produce highly complex parts with intricate details, internal structures, and undercuts that would be challenging or impossible with methods like thermoforming or CNC machining.

6. Automated Production: The injection moulding process can be highly automated, reducing labor costs and human error. In comparison, CNC machining may require more manual intervention, and 3D printing often needs post-processing steps.

7. Enhanced Strength: Parts made through injection moulding are generally stronger and more durable because the process ensures proper material compaction. In contrast, 3D-printed objects might have anisotropic properties, making them weaker along certain axes.

In summary, injection moulding’s advantages lie in its speed, cost efficiency at scale, material versatility, precision, capacity for complex geometries, automation potential, and the superior strength of produced parts, rendering it a standout choice for high-volume manufacturing.

“advantages of injection moulding” Warranty and Support

Injection moulding offers numerous advantages, especially when it comes to manufacturing parts on a large scale. One significant advantage is the ability to produce complex shapes with high precision and consistency. This is crucial for industries where exact specifications are paramount, such as automotive, medical, and consumer electronics.

In terms of cost-effectiveness, injection moulding is highly efficient for mass production. Once the initial mould is created, the process allows for the rapid and repeated production of identical parts, significantly reducing the per-unit cost as the volume increases. Additionally, the automation involved in injection moulding reduces labor costs and minimizes human error, contributing further to cost savings.

Material versatility is another strong point. Injection moulding supports a wide range of plastics and even some metals, enabling manufacturers to choose the most suitable material for their specific applications. This ensures that the finished product meets desired mechanical properties, such as strength, flexibility, and heat resistance.

Durability and precision of the moulds are essential to the process, and most manufacturers offer extensive warranty and support services for their moulds. These services can include regular maintenance, repairs, and even replacement of the moulds to ensure uninterrupted production. This not only extends the lifespan of the mould but also ensures consistent product quality over time.

Injection moulding also supports eco-friendliness through the ability to recycle scrap and off-cuts back into the production process. This reduces material waste and promotes sustainable manufacturing practices.

Furthermore, advanced technology such as computer-aided design (CAD) and computer-aided manufacturing (CAM) enhances the injection moulding process, allowing for intricate designs and swift adjustments.

In conclusion, injection moulding offers precision, cost-effectiveness, material versatility, and robust warranty and support services, making it an ideal choice for high-volume manufacturing.

List “advantages of injection moulding” FAQ

FAQs: Advantages of Injection Moulding

Q1: What is injection moulding?

A1: Injection moulding is a manufacturing process used to produce parts by injecting molten material into a mould. Common materials used include plastics, metals, and glass.

Q2: What are the main advantages of injection moulding?

A2: The primary advantages include high efficiency, scalability, excellent part consistency, design flexibility, minimal waste, cost-effectiveness for mass production, and the ability to use multiple materials.

Q3: How does injection moulding achieve high efficiency?

A3: Once the initial setup is complete, the cycle time for producing parts is very short, allowing for rapid production of large quantities.

Q4:How does injection moulding ensure design flexibility?

A4: Complex shapes and detailed features can be easily incorporated into the mould design, enabling the creation of intricate parts.

Q5: Is cost-effectiveness an advantage?

A5: Yes, while the initial setup cost is high, the per-part production cost is low, making it highly cost-effective for high-volume manufacturing.

Q6: How does injection moulding contribute to minimal waste?

A6: Injection moulding generates very little waste because excess material can often be recycled and reused, promoting sustainability.

Q7: Can multiple materials be used in injection moulding?

A7: Yes, multi-material injection moulding allows for the combination of different materials within a single part, enhancing functionality and design.

Q8: Are consistent parts an advantage?

A8: Absolutely. Injection moulding offers excellent part-to-part consistency, crucial for applications where precision and repeatability are vital.

Q9: Does injection moulding support scalability?

A9: Injection moulding is highly scalable, ideal for both small batch production and large-scale manufacturing, adapting easily to changes in production volume.

Q10: How does rapid production benefit industries?

A10: The fast cycle times lead to quick turnaround, significantly benefiting industries that require fast-paced production capabilities.

Each of these advantages makes injection moulding a highly valued process in numerous industries, from automotive to consumer goods.

Top 10 FAQ with answer about advantages of injection moulding for Buyer Sourcing from China

Top 10 FAQ on the Advantages of Injection Molding for Buyer Sourcing from China

#### 1. Why consider injection molding for manufacturing?

Injection molding offers high production efficiency, low labor costs, and the ability to produce complex shapes with high precision. It’s ideal for mass production with consistent quality.

#### 2. What are the benefits of sourcing injection-molded products from China?

China provides cost-effective manufacturing due to lower labor costs and established supply chains. Many Chinese manufacturers have advanced technology and extensive experience, ensuring high-quality production.

#### 3. How does injection molding reduce costs?

Injection molding minimizes waste, reduces labor costs through automation, and allows for large-scale production, significantly lowering per-unit costs.

#### 4. What materials can be used in injection molding?

A wide range of thermoplastics and thermosetting polymers can be used, making it versatile for various industries, including automotive, medical, and consumer goods.

#### 5. How does injection molding ensure product consistency?

Injection molding uses precise molds and automated processes, ensuring that each product is identical to the next, maintaining high quality and reducing defects.

#### 6. Is injection molding environmentally friendly?

Yes, injection molding generates minimal waste, and many materials used are recyclable. Additionally, advancements in technology have made the process increasingly energy-efficient.

#### 7. What is the typical lead time for injection-molded products from China?

Lead times can vary but typically range from 4 to 8 weeks, depending on the complexity of the mold and the production volume.

#### 8. Can custom designs be accommodated in injection molding?

Absolutely. Injection molding is highly flexible and can accommodate complex and customized designs, allowing for tailored solutions.

#### 9. Are Chinese manufacturers compliant with international standards?

Many Chinese manufacturers comply with international standards such as ISO, CE, and FDA, ensuring that products meet global quality and safety requirements.

#### 10. What factors should be considered when choosing a Chinese injection molding supplier?

Consider factors such as the manufacturer’s experience, technology used, compliance with international standards, production capacity, and customer reviews to ensure a reliable partnership.

By understanding these advantages, buyers can make informed decisions when sourcing injection-molded products from China, ensuring high-quality, cost-effective manufacturing solutions.