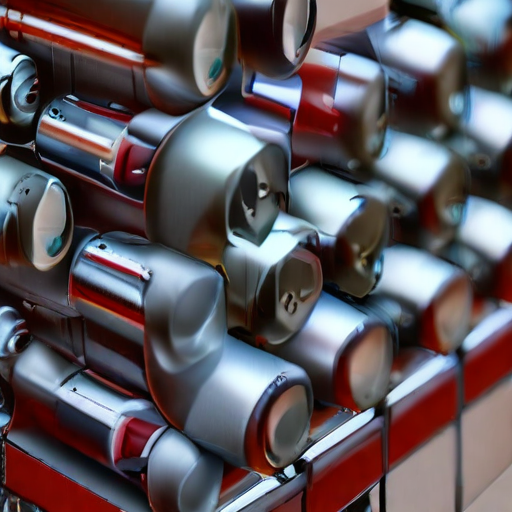

bimba cylinders Safety Certifications

Bimba Manufacturing, a trusted name in pneumatic, hydraulic, and electric actuators, places paramount importance on the safety and quality of its products, including its extensive line of cylinders. To ensure customer confidence and regulatory compliance, Bimba adheres to globally recognized safety and quality standards.

1. ISO 9001:2015 Certification: This international standard specifies requirements for a quality management system (QMS). Bimba’s ISO 9001:2015 certification affirms their commitment to continuous improvement, product quality, and customer satisfaction.

2. CE Marking: Bimba cylinders comply with European Union directives, earning the CE mark. This indicates conformity with health, safety, and environmental protection standards, making them suitable for use in the European Economic Area (EEA).

3. REACH Compliance: By adhering to the Registration, Evaluation, Authorisation, and Restriction of Chemicals (REACH) regulations, Bimba ensures that their products do not have harmful substances beyond the acceptable limits, safeguarding both users and the environment.

4. RoHS Compliance: Bimba cylinders meet the Restriction of Hazardous Substances (RoHS) directive, which restricts the use of specific hazardous materials in electrical and electronic equipment, ensuring safer products for consumers and reduced environmental impact.

5. UL Listing: Some Bimba products may also be Underwriters Laboratories (UL) listed, a certification widely recognized in North America that signifies rigorous testing and adherence to safety standards.

6. CSA Certification: Bimba cylinders may carry the Canadian Standards Association (CSA) mark, indicating compliance with North American safety standards.

By obtaining these certifications, Bimba demonstrates a comprehensive approach to product safety and quality assurance, ensuring that their cylinders are reliable and safe for diverse industrial applications globally.

List Reference Technical Parameters of “bimba cylinders”

Bimba Manufacturing Company, renowned for its pneumatic, hydraulic, and electric actuators, offers a variety of cylinders known for reliability and precision. Here are the reference technical parameters for Bimba cylinders:

1. Bore Size:

– Typically ranges from 9/16″ (1.43 cm) to 8″ (20.32 cm).

2. Stroke Length:

– Customizable, usually from 1/16″ (0.16 cm) to over 100″ (254 cm).

3. Operating Pressure:

– Pneumatic cylinders: generally up to 250 PSI (17.24 bar) for aluminum versions.

– Hydraulic cylinders: can range higher, up to around 3000 PSI (206.84 bar) depending on design.

4. Temperature Range:

– Standard cylinders: from -20°F (-29°C) to 200°F (93°C).

– Special seals available for higher or lower extremes.

5. Mounting Options:

– Various methods including nose, flange, clevis, and trunnion mounts.

6. Materials:

– Cylinder bodies typically made from aluminum or stainless steel.

– Rod materials: usually high-strength steel, sometimes stainless steel for specific applications.

7. Rod Diameter:

– Corresponding to bore size, typically ranging from 7/16″ (1.11 cm) to 1.75″ (4.45 cm).

8. Cushioning:

– Built-in adjustable cushions available to manage end-of-stroke impacts.

9. Seals:

– Variety of seals depending on application, including Buna-N, Viton, and PTFE for high temperature or chemical resistance.

10. Port Sizes:

– Standard sizes include 1/8″, 1/4″, 3/8″, and 1/2″ NPT.

11. Actuation:

– Basic types include single-acting (spring return) and double-acting.

12. Special Features:

– Magnetic pistons for position sensing, custom designs, and configurations for specific industry standards (e.g., cleanroom, food-grade).

13. Compliance:

– Conformance to industry standards, such as ISO, NFPA, or specific customer specifications.

These parameters make Bimba cylinders versatile for automation, manufacturing, robotics, and various industrial applications.

List Product features of “bimba cylinders”

Bimba cylinders are well-regarded in the automation and pneumatics industry for their reliability, versatility, and high performance. Below are some key product features of Bimba cylinders:

1. Variety of Types: Bimba offers a wide range of cylinder types, including single-acting, double-acting, multi-position, and guided cylinders, catering to diverse application needs.

2. Customization Options: Customers can choose from an array of options such as different bore sizes, stroke lengths, mounting styles, and port sizes, allowing for tailored solutions.

3. High Durability: Made from robust materials like stainless steel and aluminum, Bimba cylinders are designed for long-lasting performance in both standard and harsh environments.

4. Compact Design: Their space-efficient design allows for easy integration into tight spaces, making them ideal for complex machinery and equipment.

5. Smooth Operation: Precision engineering ensures smooth and consistent piston movement, reducing wear and tear and increasing cylinder life.

6. Versatile Mounting: Multiple mounting options, including front and rear flange, trunnion, clevis, and side mounts, add to their flexibility in installation.

7. Enhanced Sealing: High-quality seals minimize leakage and enhance performance, making Bimba cylinders suitable for applications requiring high reliability.

8. Temperature & Pressure Range: They are built to operate effectively within a wide range of temperatures and pressures, adaptable to various industrial environments.

9. Low Maintenance: The design focuses on ease of maintenance with accessible parts, contributing to reduced downtime and operational costs.

10. Magnetic Sensing Capabilities: Some models come with magnetic pistons and optional sensors for position monitoring, adding an extra layer of control and precision.

11. Corrosion Resistance: Certain models are specifically designed for corrosive environments, ensuring long-term functionality in demanding conditions.

12. Compliance and Standards: Many Bimba cylinders meet industry standards like ISO, NFPA, and RoHS, ensuring compatibility and safety.

These features collectively make Bimba cylinders a preferred choice for various industrial applications, from manufacturing to automation and beyond.

List Various Types of “bimba cylinders”

Bimba, a leading manufacturer of pneumatic, hydraulic, and electric motion solutions, offers a wide range of cylinders tailored for various applications. Here are some of the primary types of Bimba cylinders:

1. Original Line Cylinders: Known for their durable stainless steel body and consistent performance, these are versatile and widely used in automation and general industrial applications.

2. Flat-II® Cylinders: Designed for compact spaces, these cylinders provide a flat profile which makes them ideal for tight or constrained environments.

3. Twin Bore Cylinders: These cylinders provide increased force in a compact size due to their dual bore design and are often used in small automation systems.

4. Ultran® Rodless Cylinders: With a rodless design, these cylinders are perfect for applications requiring long strokes in a limited space, providing a clean and efficient linear motion.

5. Guided Thrust Cylinders: Featuring an integrated guide mechanism for high side-load capacity and precise linear motion, these are ideal for applications needing controlled and guided movement.

6. Stainless Steel Cylinders: Offering enhanced corrosion resistance, these are suited for harsh environments, such as those in food processing and marine applications.

7. Dura-Matic® Cylinders: These are heavy-duty cylinders designed for demanding applications where increased durability and performance are critical.

8. Position Feedback Cylinders: These cylinders come with built-in feedback systems for precise stroke control and are used in applications requiring position monitoring.

9. Disposable Cylinders: Economical and efficient, these are intended for use in applications where the cylinder is not expected to be serviced or repaired.

10. Rotary Actuators: These are used for applications requiring rotational motion and come in various configurations to meet specific needs.

Each type of Bimba cylinder offers unique features to cater to different industrial requirements, ensuring optimal performance and efficiency for a wide range of applications.

List Application of “bimba cylinders”

Bimba cylinders, renowned for their reliability and versatility, are widely employed across various industries due to their broad range of applications. Here are some key uses:

1. Automation and Robotics

Bimba cylinders are extensively used in automated systems and robots for tasks such as precise positioning, pick-and-place operations, and actuating robotic arms.

2. Material Handling

In warehouses and manufacturing plants, they facilitate activities like conveyor belt sorting, palletizing, and depalletizing by providing linear motion to equipment.

3. Packaging

Bimba cylinders are integral in packaging lines for tasks like sealing, filling, capping, labeling, and box folding, ensuring high speed and accuracy.

4. Medical Devices

In the healthcare sector, they contribute to devices like patient beds, surgical tables, and automated lab equipment, providing reliable and smooth motion.

5. Food and Beverage

These cylinders operate in food processing machinery for tasks such as cutting, slicing, mixing, and filling, often in wash-down environments demanding high hygiene standards.

6. Agriculture

In agricultural equipment, Bimba cylinders are used for automation of feeding systems, livestock handling, and various farming machinery, enhancing efficiency and reducing labor.

7. Aerospace

They are used in aircraft assembly lines and maintenance equipment for functions requiring precision and reliability under tough conditions.

8. Automotive Industry

Bimba cylinders help in automated welding, pressing, painting, and assembly operations, thereby improving production speed and quality.

9. Printing and Paper

In printing presses and paper handling devices, these cylinders assist in operations like cutting, folding, and moving papers, ensuring consistency and speed.

10. Product Testing and Quality Control

In testing setups, they apply controlled movements and forces to test products for durability, compliance, and performance standards.

11. HVAC

Bimba cylinders are used in HVAC systems to operate dampers and valves, ensuring efficient and regulated climate control.

These applications highlight the critical role of Bimba cylinders in enhancing operational efficiency, precision, and automation across various sectors.

List Buyer Types of “bimba cylinders”

Bimba cylinders, known for their reliability and precision in pneumatic and hydraulic applications, attract a diverse range of buyers. Here are the primary buyer types:

1. Manufacturing and Industrial: These sectors utilize Bimba cylinders in automation processes, machinery, and robotics, ensuring efficient and precise movement of components on production lines.

2. Automotive Industry: They are employed in assembly lines and manufacturing equipment, aiding in tasks such as part handling, welding, and painting.

3. Aerospace and Defense: This domain relies on the precision and durability of Bimba cylinders for applications in aircraft manufacturing, testing equipment, and various defense mechanisms.

4. Medical and Pharmaceutical: Here, Bimba cylinders are used in equipment that requires sterile and precise motion control, such as medical devices, packaging machinery, and laboratory automation systems.

5. Food and Beverage: The industry uses Bimba cylinders for their hygienic and precise operations in processing, packaging, and filling machinery, meeting strict sanitary standards.

6. Agriculture: They support various agricultural machinery, including planting equipment, harvesters, and sorting machines, enhancing productivity and reliability.

7. Construction and Heavy Equipment: These buyers implement Bimba cylinders in machinery like excavators, loaders, and cranes, where robust and reliable actuation is crucial.

8. Electronics Manufacturing: Precision in placing components and assembling delicate electronic parts often necessitates the reliability of Bimba cylinders.

9. Packaging Industry: Cylinders are integral in packaging lines for tasks such as sorting, filling, sealing, and labeling, ensuring consistent and efficient operations.

10. Custom Equipment Builders: Engineers and developers of specialized machinery often select Bimba cylinders for tailored automation solutions, benefiting from their customizable options.

In summary, Bimba cylinders cater to a wide spectrum of industries where precision, reliability, and efficiency are vital, offering solutions across various applications from automated production lines to specialized machinery.

List “bimba cylinders” Project Types for Different Industries

Bimba Manufacturing Company, known for its pneumatic and electric actuators, offers a variety of cylinder options tailored to different industries. Below, I’ll summarize some of the key project types and how Bimba cylinders are utilized across various sectors:

1. Manufacturing and Automation:

– Linear Actuators: Used in assembly lines for precise movement and positioning.

– Rotary Actuators: Facilitate rotating components in automated machinery.

– Compact Cylinders: Suitable for space-constrained applications within production equipment.

2. Food and Beverage Processing:

– Stainless Steel Cylinders: Offer corrosion resistance, ideal for washdown environments.

– Hydraulic Cylinders: Provide high force in equipment like food presses.

3. Medical and Pharmaceutical:

– Clean Room Cylinders: Designed for contamination-sensitive environments.

– Miniature Cylinders: Enable precise control in small, delicate devices.

4. Agriculture:

– Heavy-Duty Cylinders: Used in outdoor equipment like plows and harvesters.

– Telescoping Cylinders: Allow extended reach for machinery like sprayers.

5. Transportation:

– Railway Buffers: Absorb shock in rail applications.

– Vehicle Suspension Systems: Enhance ride comfort and stability.

6. Material Handling:

– Guided Cylinders: Ensure precise and repeatable movement, crucial in conveyor systems.

– Rodless Cylinders: Optimize space efficiency in automated storage and retrieval systems.

7. Energy and Utilities:

– Hydraulic Power Units: Operate various utility machinery.

– Pneumatic Cylinders: Control valves in natural gas pipelines and water treatment facilities.

8. Aerospace and Defense:

– Specialty Cylinders: Built to withstand extreme conditions.

– Electromechanical Actuators: Offer precise control for complex aerospace applications.

9. Entertainment and Recreation:

– Animatronic Actuators: Bring life to robotic figures in theme parks.

– Cinema Seating Systems: Provide motion effects in 4D theaters.

These examples illustrate how Bimba’s versatile cylinder offerings can be integrated into diverse industry projects, enhancing functionality and efficiency.

bimba cylinders Accessories Upgrades and Custom Manufacturing Options

Bimba offers a range of accessories, upgrades, and custom manufacturing options to enhance the performance and versatility of their cylinders. Here are some key offerings:

1. Mounting Accessories: Bimba provides various mounting options like flange mounts, clevis mounts, trunnion mounts, and foot mounts to accommodate different installation requirements.

2. Sensors and Switches: For improved control and automation, Bimba cylinders can be equipped with magnetic position sensors and reed switches, enabling precise monitoring of piston positions.

3. Rod End Accessories: Accessories such as rod clevises, rod eyes, and pivot brackets can be added to enhance connectivity with other components in the system.

4. Seals and Lubrication: Bimba offers special seal and lubrication options for extreme temperatures, chemical resistance, and low friction applications to ensure longevity and reliable performance.

5. Guided Cylinder Options: For applications requiring precise linear motion, Bimba provides guided cylinders that minimize side loading and increase accuracy.

6. Adjustable Stroke Options: Stroke adjusters allow for fine-tuning of the cylinder’s stroke length to meet specific application requirements without needing custom-length cylinders.

7. Speed Controls and Flow Controls: These accessories help regulate the speed and flow of the pneumatic system, ensuring smooth and controlled cylinder operation.

8. Custom Cylinders: Bimba offers custom manufacturing solutions tailored to specific applications, including unique sizes, stroke lengths, materials (such as stainless steel for corrosion resistance), and ports configurations.

9. Special Coatings and Finishes: For harsh environments, anti-corrosive coatings and specialty finishes are available to protect the cylinder and extend its operational life.

These accessories and custom options make Bimba cylinders adaptable to a wide range of industrial applications, enhancing efficiency, control, and durability.

List Quality Control and The Manufacturing Process of “bimba cylinders”

Quality Control in Bimba Cylinder Manufacturing

1. Material Inspection: Raw materials such as aluminum, stainless steel, and seals undergo rigorous inspection to ensure they meet specification standards.

2. Precision Machining: Components like the cylinder tube, piston, and rod are machined to precise tolerances using CNC machines. Regular calibration of machines ensures accuracy.

3. Dimensional Checks: After machining, dimensional checks are conducted using micrometers, calipers, and coordinate measuring machines (CMMs).

4. Surface Finish Inspection: The internal cylinder surface is inspected for imperfections that could affect performance and seal longevity.

5. Assembly Testing: Assembled cylinders are tested for alignment, smooth operation, and proper fit of components.

6. Leak Testing: Cylinders are pressurized with air or hydraulic fluid to check for leaks. This involves submerging the cylinder in water or using electronic leak detectors.

7. Performance Testing: Cylinders undergo cycles of extension and retraction to simulate real-world operation. Force output, speed, and response times are measured.

8. Final Inspection: A thorough visual and functional final inspection ensures that each cylinder meets the design specifications and performance criteria before packaging.

Manufacturing Process of Bimba Cylinders

1. Design and Engineering: Detailed designs and engineering drawings are created, specifying materials, dimensions, and tolerances.

2. Material Procurement: High-quality raw materials are sourced based on the design specifications.

3. CNC Machining: The cylinder tube, piston, rod, and other components are precisely machined using CNC machines.

4. Surface Treatment: Components may undergo anodizing, plating, or coating to improve durability and corrosion resistance.

5. Component Assembly: The cylinder is assembled by inserting the piston into the tube, attaching the rod, and fitting seals and end caps.

6. Quality Control Testing: Each assembled cylinder is subjected to rigorous quality control tests as described above.

7. Packaging: After passing all quality tests, the cylinders are carefully packaged to avoid damage during transportation.

By integrating meticulous quality control at each stage of the manufacturing process, Bimba ensures the production of high-performance, reliable cylinders.

How to use “bimba cylinders”

Bimba cylinders are pneumatic actuators commonly used in automation and industrial applications to provide linear motion. Here’s a concise guide on how to use them:

1. Select the Right Cylinder

– Identify Application Requirements: Determine the load, stroke length, speed, and mounting type.

– Choose the Cylinder Type: Bimba offers multiple cylinder types including standard, compact, guided, and rotary models.

2. Installation

– Mounting: Install the cylinder using the appropriate mounts (e.g., front flange, rear clevis). Ensure alignment to avoid side loads.

– Connect Air Lines: Attach the air supply to the inlet ports. Usually, double-acting cylinders have two ports, one for extension and one for retraction.

3. Adjustments

– Cushion Adjustment: If your cylinder has adjustable cushions, set them to control the end-of-stroke damping.

– Flow Controls: Add flow control valves to regulate speed. These can be mounted in-line or at the cylinder ports.

4. Operation

– Control Methods: Use a pneumatic solenoid valve to control the air flow. For double-acting cylinders, a 4-way, 2-position valve is often used.

– Position Sensing: Install magnetic reed switches or sensors if position feedback is needed.

5. Maintenance

– Regular Inspection: Check for air leaks, wear, and proper lubrication.

– Replacement of Worn Parts: Replace seals and worn components as needed.

Safety Considerations

– Pressure Limits: Adhere to the specified pressure ratings to avoid damage.

– Load Capacity: Do not exceed the load capacity to ensure safe operation.

Example Application

To extend the cylinder:

1. Activate the solenoid valve to allow compressed air into the extend port.

2. The piston rod will move in a linear motion, performing the desired task.

To retract:

1. The solenoid valve switches air flow to the retract port.

2. The piston rod moves back to its original position.

Bimba cylinders, when correctly selected and installed, can efficiently handle a variety of pneumatic tasks with precision and reliability.

“bimba cylinders” Comparative Analysis

Bimba Manufacturing, a pioneer in pneumatic actuation, offers a diverse range of cylinders tailored to various industrial applications. This comparative analysis delves into some key offerings in Bimba’s cylinder lineup:

1. Original Line Cylinders:

– Overview: This iconic blue-and-white cylindrical design epitomizes reliability and versatility. Known for its sturdy construction, it is ideal for general-purpose applications.

– Features: Stainless steel body, anodized aluminum heads, and optional cushioning.

– Applications: Automation, packaging, material handling.

2. Flat-1 Cylinders:

– Overview: Characterized by a compact, rectangular shape, Flat-1 Cylinders are optimized for space-constrained environments.

– Features: Low-profile design, lightweight, and available in multiple mounting configurations.

– Applications: Robotics, medical devices, automated gates.

3. EF-II Electric Cylinders:

– Overview: These electrically actuated cylinders provide precise control and positioning.

– Features: Integrated motor, programmable control, and minimal maintenance needs.

– Applications: Precision assembly, stage equipment, automated testing.

4. Ultran RT Rodless Cylinders:

– Overview: Designed to deliver long strokes in a compact form, these cylinders eliminate the need for an extending rod.

– Features: Magnetically coupled carriage, flexible mounting, and high load capacity.

– Applications: Conveyor systems, large-scale automation machinery.

5. Pneu-Turn Rotary Actuators:

– Overview: These actuators provide rotational movement rather than linear.

– Features: Torque output options, adjustable rotation angles, and various size specifications.

– Applications: Assembly systems, packaging, and sorting equipment.

Comparative Insights:

– Adaptability: Original Line offers general versatility, whereas specialized options like Flat-1 and Ultran RT address specific space and motion requirements.

– Control and Precision: EF-II Electric Cylinders excel in applications where precise motion control is crucial.

– Design Considerations: Flat-1’s compact design offers significant advantages in tight spaces, while Ultran RT’s rodless design supports long stroke applications efficiently.

– Applications: The choice largely depends on the specific mechanical, spatial, and control needs, with options available for a broad spectrum of industry requirements.

Bimba’s comprehensive product suite ensures optimal solutions tailored to diverse industrial needs, combining reliability, precision, and innovative engineering.

“bimba cylinders” Warranty and Support

Bimba Manufacturing, a leader in pneumatic, hydraulic, and electric motion solutions, offers a comprehensive warranty and robust support for its range of cylinders. Here are the key points regarding Bimba cylinders’ warranty and support:

Warranty

Bimba provides a standard warranty that covers defects in materials and workmanship for a period of 2 years from the date of shipment. This warranty ensures that if any cylinder fails due to a manufacturing defect within this timeframe, Bimba will repair or replace the defective product at no charge.

Conditions

– The warranty applies only if the cylinder has been used under normal operating conditions.

– It does not cover damage caused by misuse, neglect, alterations, or improper installation.

– Warranty claims must be submitted with proof of purchase and a detailed description of the defect.

Support

Bimba offers extensive support to help customers get the best performance from their cylinders:

#### Technical Support

– Online Resources: Manuals, datasheets, and troubleshooting guides are readily available on the Bimba website.

– Customer Service: Dedicated technical support teams can be reached via phone or email to assist with product selection, installation guidance, and troubleshooting.

#### After-Sales Service

– Repairs: Bimba provides repair services for their cylinders, ensuring they are restored to optimal working conditions.

– Spare Parts: A range of spare parts is available to extend the life of Bimba cylinders and reduce downtime.

– Customization: Bimba offers custom cylinder solutions to meet specific application requirements.

Customer Training

Bimba occasionally conducts training sessions and webinars to educate users on best practices for installation, maintenance, and optimization.

In summary, Bimba’s warranty and support underline their commitment to high-quality products and customer satisfaction, ensuring reliable performance and prolonged service life of their cylinders.

List “bimba cylinders” FAQ

Bimba Cylinders FAQ

1. What are Bimba Cylinders?

Bimba cylinders are pneumatic actuators used to convert compressed air into mechanical motion. They are commonly used in various industrial applications for automation purposes.

2. What types of Bimba cylinders are available?

Bimba offers a wide range of cylinders including:

– Original Line Cylinders

– Stainless Steel Cylinders

– Composite Cylinders

– Rotational Cylinders

– Compact Cylinders

– Specialty Actuators

3. What materials are Bimba cylinders made from?

Materials vary by series but commonly include stainless steel, aluminum, and composite materials, making them suitable for different environments, including those requiring corrosion resistance.

4. Are Bimba cylinders customizable?

Yes, Bimba offers customization options such as stroke length, bore size, mounting configurations, and special seals to tailor cylinders to specific application needs.

5. How do I select the right Bimba cylinder for my application?

Consider factors such as load requirements, operating environment, stroke length, and available space. Bimba provides detailed product specifications and tools like the Bimba configurator to aid in selection.

6. What maintenance is required for Bimba cylinders?

Regular inspection of seals, lubrication, and checking for signs of wear can extend cylinder life. Bimba supplies maintenance kits and guidelines for proper upkeep.

7. Can Bimba cylinders operate in extreme environments?

Yes, certain models are designed for high or low temperatures, harsh chemical environments, and other challenging conditions. Consult the product specifications for details.

8. Where can I purchase Bimba cylinders?

Bimba cylinders can be purchased directly from authorized distributors, through Bimba’s website, or through various industrial supply platforms.

9. Do Bimba cylinders come with a warranty?

Yes, Bimba products typically come with a warranty that covers manufacturing defects. Specific terms can be found in the product’s warranty documentation.

10. Are replacement parts available for Bimba cylinders?

Yes, replacement parts such as seals, rods, and end caps are available to maintain and repair cylinders, ensuring a longer service life.

Top 10 FAQ with answer about bimba cylinders for Buyer Sourcing from China

Certainly! Below are the top 10 Frequently Asked Questions (FAQ) about sourcing Bimba cylinders from China, along with concise answers:

1. What are Bimba cylinders?

Bimba cylinders are high-quality pneumatic actuators known for their durability, reliability, and precision. They are used in various automation and industrial applications.

2. Why source Bimba cylinders from China?

China offers competitive pricing, a wide range of manufacturers, and advancements in manufacturing technology, making it an economical option for sourcing.

3. Are Chinese-made Bimba cylinders genuine?

While many reputable suppliers in China produce high-quality cylinders, ensure you’re dealing with certified and authorized manufacturers or distributors to avoid counterfeit products.

4. How to verify the authenticity of a supplier?

Check certifications like ISO, examine client reviews, request product samples, and use platforms like Alibaba or Made-in-China with verified suppliers to ensure credibility.

5. What should I consider regarding quality control?

Ensure that the supplier has a robust quality control system. Request detailed quality control reports and consider third-party inspections to validate quality before shipping.

6. What are the import duties and taxes?

Import duties and taxes vary by country. Check your local customs regulations for specific rates applicable to pneumatic components imported from China.

7. Can I get customized Bimba cylinders?

Yes, many Chinese manufacturers offer customization options based on specifications such as size, stroke length, mounting options, and materials.

8. What is the typical lead time?

Lead times can vary; it’s generally between 4 to 8 weeks depending on order complexity and production schedules. Confirm with your supplier for accurate timelines.

9. Are there minimum order quantities (MOQ)?

MOQs vary by supplier. Some may offer lower MOQs for standard products, but custom orders might require higher quantities.

10. How to handle logistics and shipping?

Work with a reliable freight forwarder to manage shipping. Ensure the supplier provides proper packaging and documentation to avoid delays at customs.

By addressing these questions, you can make informed decisions and efficiently source Bimba cylinders from China.