class 1 duct Safety Certifications

Class 1 ducts are those designed for low-pressure HVAC (Heating, Ventilation, and Air Conditioning) applications typically used in residential and light commercial settings. Ensuring their safety is paramount to avoid hazards like fire, toxic smoke, and system inefficiencies. Here are key safety certifications related to Class 1 ducts:

1. UL 181 Certification:

– Purpose: UL 181 standard covers the safety of air ducts, air connectors, air duct materials, and air connectors for use in air distribution systems.

– Requirements: It includes tests for flame spread, smoke generation, and puncture resistance.

– Mark: Ducts meeting UL 181 standards bear the UL mark as a sign of compliance.

2. NFPA Standards:

– NFPA 90A and 90B: The National Fire Protection Association (NFPA) outlines standards for the installation of air conditioning and ventilating systems. NFPA 90A is for commercial buildings, while NFPA 90B is for residential.

– Focus: They emphasize minimizing fire and smoke hazards associated with central heating and air-conditioning systems.

3. ASHRAE Standards:

– ASHRAE 62.2: Developed by the American Society of Heating, Refrigerating, and Air-Conditioning Engineers, this standard ensures acceptable indoor air quality in residential buildings.

– Relevance: Proper ductwork is essential for compliance to maintain air quality and safety.

4. SMACNA Guidelines:

– The Sheet Metal and Air Conditioning Contractors National Association (SMACNA) manuals provide guidance on the construction standards and installation practices for HVAC ductwork, emphasizing on structural and operational safety.

5. ICC Codes:

– International Mechanical Code (IMC) and International Residential Code (IRC): These codes are integral to ensuring that HVAC designs meet specific safety and performance standards.

– Inclusion: They cover aspects from duct design to materials used, ensuring comprehensive safety measures.

Compliance with these certifications and codes ensures that Class 1 ducts meet high safety standards, providing reliability and peace of mind for both installers and users.

List Reference Technical Parameters of “class 1 duct”

Class 1 duct refers to a category of air ducts used in HVAC systems that meet stringent fire resistance and smoke production criteria. Below are the key technical parameters for Class 1 ducts:

1. Fire Safety Ratings:

– Flame Spread Index: Must be 25 or less, per ASTM E84 or UL 723 standards.

– Smoke Developed Index: Must not exceed 50, according to ASTM E84 or UL 723.

2. Material Composition:

– Typically made of non-combustible materials such as galvanized steel, aluminum, or specific types of fire-rated fiberglass.

3. Thickness:

– Duct Material Thickness: Ranges from 24-gauge (0.0239 inches) for smaller ducts to 18-gauge (0.0478 inches) for larger ducts.

4. Insulation:

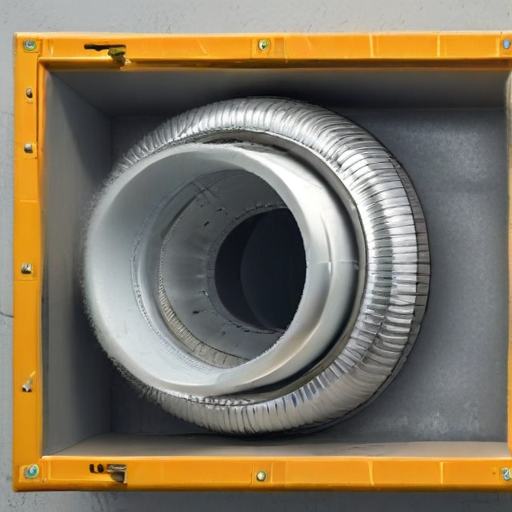

– Fire-rated Insulation: Often wrapped in fire-resistant materials or coatings. Insulation may also comply with UL 181 for fiberglass ducts.

5. Sealing:

– Sealant: Use fire-rated duct sealants that comply with SMACNA (Sheet Metal and Air Conditioning Contractors’ National Association) standards.

6. Installation and Support:

– Support Spacing: Must follow specific guidelines to ensure stability under fire conditions. E.g., 4 feet for horizontal ducts.

– Hangers and Supports: Made from non-combustible materials, following SMACNA guidelines.

7. Pressure Ratings:

– Operating Pressure: Typically designed to handle pressures up to 2 inches of water gauge (WG) for lower pressure class ducts, and up to 10 inches WG for high-pressure systems.

8. Leakage Standards:

– Leakage Class: Must comply with permissible leakage rates often cited in ASHRAE standards.

9. Temperature Ratings:

– Operational Temperature: Designed to withstand operational temperatures up to specific ratings, which are generally higher than typical operating conditions.

10. Compliance:

– Must meet local and national building codes, including NFPA (National Fire Protection Association) standards.

These parameters ensure that Class 1 ducts provide high performance while maintaining safety and compliance in critical environments.

List Product features of “class 1 duct”

Class 1 duct is a specialized type of air duct used in HVAC (Heating, Ventilation, and Air Conditioning) systems that meets stringent safety and performance standards. Here are some of its key features:

1. Fire Resistance: Class 1 duct is designed to resist fire and is often tested to meet the highest fire safety standards. This includes having a low flame spread index and smoke developed index.

2. Durability: Made from high-quality materials such as galvanized steel, aluminum, or fiberglass, Class 1 ducts are robust and long-lasting, suitable for both residential and commercial applications.

3. Thermal Insulation: These ducts often come with insulation that minimizes heat loss or gain, enhancing energy efficiency and maintaining consistent air temperatures.

4. Air Quality: The materials used in Class 1 ducts are designed to resist mold, mildew, and bacterial growth, thereby ensuring better indoor air quality.

5. Sound Attenuation: Class 1 ducts often include features that reduce noise generated by the HVAC system, contributing to a quieter indoor environment.

6. Low Leakage: High sealing performance ensures minimal air leakage, which improves the system’s efficiency and reduces energy costs.

7. Ease of Installation: Designed for easy handling and installation, which can save time and labor costs for contractors.

8. Corrosion Resistance: Generally made from materials that are resistant to corrosion, making them suitable for a variety of environments.

9. Compliance: Meets or exceeds the standards set by organizations such as the National Fire Protection Association (NFPA) and Underwriters Laboratories (UL), ensuring reliability and safety.

10. Versatility: Available in various shapes and sizes, Class 1 ducts can be custom-made to fit specific design requirements.

These features make Class 1 ducts an excellent choice for applications requiring stringent safety, durability, and performance standards.

List Various Types of “class 1 duct”

Class 1 ducts, typically used in heating, ventilation, and air conditioning (HVAC) systems, are designed to meet specific safety standards regarding fire resistance and low smoke production under UL 181 and NFPA 90A. Here are various types of Class 1 ducts:

1. Flexible Ducts (Flex Ducts): These are made from a combination of plastic and metal, providing flexibility for installation in tight spaces. They are also insulated to minimize heat loss.

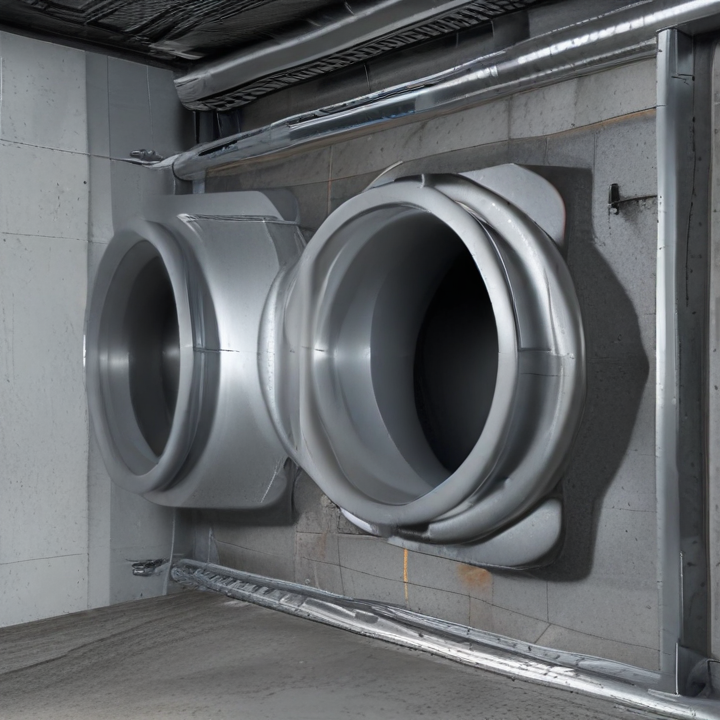

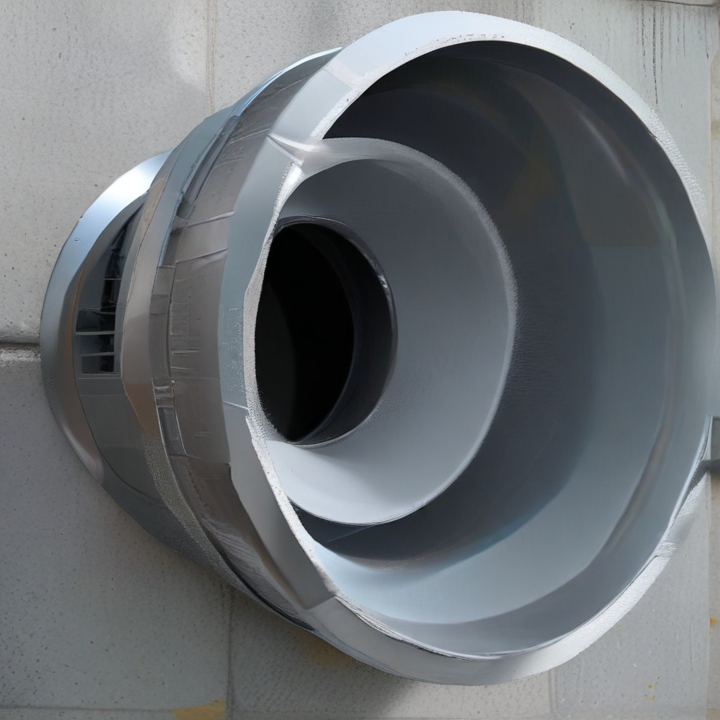

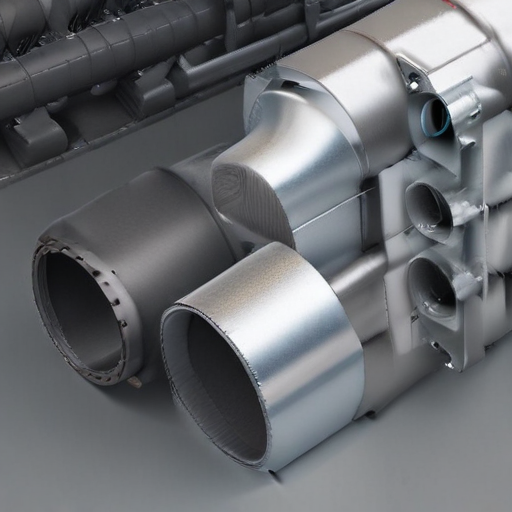

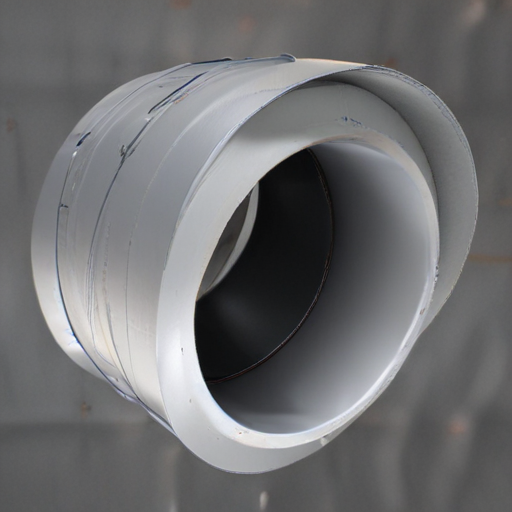

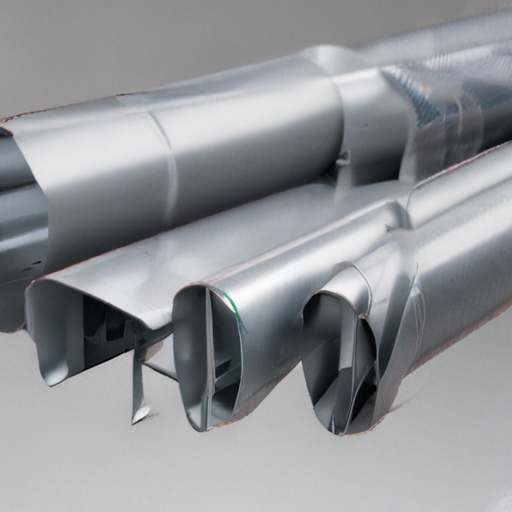

2. Sheet Metal Ducts: Commonly constructed from galvanized steel or aluminum, these ducts are durable and suitable for high-pressure applications. They are less flexible but provide excellent fire resistance.

3. Fiberglass Duct Board: Made from rigid fiberglass panels, these ducts offer good thermal insulation and noise control. They are typically used in residential and commercial applications.

4. Fabric Air Ducts: These are made from special textiles and are often used in food processing facilities, laboratories, and other environments where frequent cleaning and sanitation are required.

5. Spiral Ducts: These round ducts are constructed from sheet metal and are known for their strength and reliable performance in high-velocity systems. They are also aesthetically pleasing and often used in exposed ductwork designs.

Each type serves specific applications but complies with Class 1 requirements for fire safety and smoke production, making them favorable in ensuring a safe HVAC environment.

List Application of “class 1 duct”

Class 1 ductwork is a classification based on the fire and smoke characteristics of the materials used in the construction of the duct system. It’s designed to meet stringent fire safety standards and has applications in various settings where fire resistance and low smoke emission are critical. Below are notable applications of Class 1 duct:

1. Commercial Buildings:

– Offices: Provides safe air distribution systems complying with building codes.

– Shopping Malls: Essential for large areas requiring stringent fire protection.

2. Hospitals and Healthcare Facilities:

– Normative Spaces: Ensures air quality and fire safety in high-risk environments like operating rooms and intensive care units.

– Corridors and Lobbies: Important for evacuation routes, preventing smoke spread.

3. Educational Institutions:

– Schools and Universities: Fire-resistant ducts are crucial for high-occupancy buildings to protect students and faculty.

4. Residential Complexes:

– High-rise Apartments: Offers a safer HVAC system in densely populated residential areas.

5. Public Assembly Areas:

– Stadiums and Theaters: Ensures the safety of large crowds during emergencies by preventing smoke propagation through air ducts.

6. Industrial Facilities:

– Manufacturing Plants: Provides fire resilience in environments where hazardous materials may be present.

– Data Centers: Ensures protection of sensitive electronic equipment from fire damage and smoke.

7. Transportation Hubs:

– Airports and Train Stations: Enhances fire safety in high-traffic environments with complex duct networks.

8. Hotels:

– Ensures occupant safety and compliance with fire safety regulations, offering peace of mind to guests.

9. Government Buildings:

– Courthouses and Administrative Buildings: Safeguards critical infrastructure and public records.

10. Correctional Facilities:

– Essential for maintaining the safety of inmates and staff in secure environments.

In summary, Class 1 ductwork is integral to the safety and efficiency of air distribution systems in various environments, especially those with high occupancy and strict fire safety requirements.

List Buyer Types of “class 1 duct”

“Class 1 duct” refers to a category of HVAC (Heating, Ventilation, and Air Conditioning) ductwork that meets certain fire safety standards, specifically related to flame spread and smoke production. Understanding the various buyer types can help in targeting and meeting their specific requirements. Here are the main buyer types:

1. HVAC Contractors

HVAC contractors are primary buyers of Class 1 ducts. They install, maintain, and repair HVAC systems in residential, commercial, and industrial buildings. They need ductwork that complies with safety standards to ensure compliance with building codes and to provide safe, efficient systems for their clients.

2. Commercial Building Owners

Owners and managers of commercial properties, such as office buildings, shopping malls, and hotels, often procure Class 1 ductwork for HVAC systems to ensure occupant safety and adherence to fire safety regulations. They require durable and compliant ducting to maintain the integrity of their buildings.

3. Residential Developers

Developers of residential complexes, from single-family homes to large apartment buildings, purchase Class 1 ducts to meet building codes and enhance the safety of their projects. They focus on providing secure and comfortable living environments for homebuyers.

4. Industrial Facility Managers

Managers of industrial facilities such as factories, manufacturing plants, and warehouses require robust HVAC systems that utilize Class 1 ducts to manage air quality and temperature control effectively, reducing the risk of fire and ensuring the safety of their personnel and equipment.

5. Mechanical Engineers and Consultants

Mechanical engineers and HVAC consultants who design and recommend HVAC systems for various projects often specify Class 1 ducts in their plans to ensure safety and code compliance. They influence purchasing decisions by setting the technical requirements for the project.

6. Government and Institutional Buyers

Government buildings, universities, and hospitals also need HVAC systems designed with Class 1 ductwork to meet stringent fire and safety codes, ensuring the safety of large, often vulnerable populations.

By understanding the specific needs and standards required by these different buyer types, suppliers and manufacturers can tailor their offerings to meet market demands more effectively.

List “class 1 duct” Project Types for Different Industries

“Class 1 duct” projects typically refer to ductwork systems conforming to specific high-standard building codes and safety regulations, ensuring low leakage, efficient energy use, and high fire resistance. Here are some project types by industry:

1. Commercial Buildings:

– Office Complexes: Utilize Class 1 duct systems for effective HVAC to ensure a comfortable working environment and compliance with indoor air quality standards.

– Retail Spaces: Integrate in shopping malls, department stores, and supermarkets to manage the climate control efficiently and improve customer experience.

– Hotels: Essential for maintaining optimal conditions and air quality in guest rooms, lobbies, and recreational areas.

2. Healthcare Facilities:

– Hospitals and Clinics: Critical for maintaining sterile conditions in operating rooms, patient wards, and laboratories to minimize airborne contaminants.

– Pharmaceutical Manufacturing: Ensures cleanroom environments meet stringent air quality standards necessary for drug formulation and production.

3. Educational Institutions:

– Schools and Universities: Provides reliable air quality and temperature control in classrooms, laboratories, and administrative offices to foster a conducive learning environment.

– Libraries: Manages air circulation to protect books and sensitive materials from humidity and temperature fluctuations.

4. Industrial Applications:

– Factories and Warehouses: Facilitates the removal of pollutants, dust, and harmful particles, ensuring a safe working environment and protecting machinery.

– Cleanrooms: Used in semiconductor manufacturing, biotechnology, and other high-tech industries where precision environmental controls are essential.

5. Residential Complexes:

– High-rise Apartments and Condominiums: Ensures efficient heating and cooling, enhancing comfort and improving air quality for residents.

6. Public Institutions:

– Government Buildings: Ensures a controlled environment in municipal offices, courthouses, and other civic facilities for both employees and visitors.

– Museums and Art Galleries: Critical for preserving artworks and historical artifacts by controlling temperature and humidity levels.

Each project type benefits from using Class 1 duct systems, which uphold the stringent standards necessary for efficient, safe, and environmentally friendly HVAC solutions.

class 1 duct Accessories Upgrades and Custom Manufacturing Options

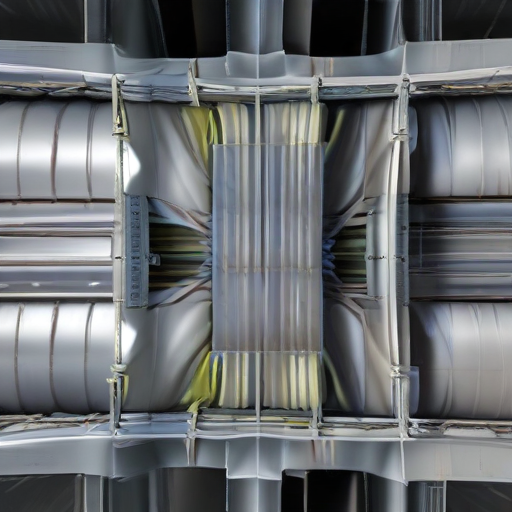

Class 1 duct systems are critical components in HVAC installations, focusing on air distribution, energy efficiency, and air quality. Accessories and upgrades, along with custom manufacturing options, can enhance the performance and reliability of these systems.

Accessories:

1. Dampers: Essential for regulating airflow, dampers can be manual or motorized. They help in maintaining desired air pressure and temperature.

2. Insulation: Adding insulation reduces thermal loss and acoustic noise. Options include fiberglass wrap or foam-based products.

3. Filters: High-efficiency particulate air (HEPA) filters improve indoor air quality by trapping fine particles.

4. Grilles and Registers: These control airflow entry and exit, available in various designs to match interiors.

5. Vibration Isolators: Installed to minimize noise and mechanical vibrations, enhancing comfort.

Upgrades:

1. Smart Controls: Integrating automated systems with digital thermostats for precise climate control and energy savings.

2. UV Lights: Kill pathogens and bacteria, improving air quality, especially beneficial in medical or high-traffic environments.

3. Energy Recovery Ventilators (ERVs): Optimize energy efficiency by exchanging indoor air with outdoor air, maintaining temperature and humidity levels.

4. Zoning Systems: Allow different areas to be heated or cooled independently, increasing comfort and efficiency.

Custom Manufacturing Options:

Custom manufacturing allows for duct systems to be tailored to specific building layouts or requirements. This can include:

1. Bespoke Sizing: Customized dimensions and shapes to fit unique architectural spaces.

2. Material Choices: Options range from galvanized steel, aluminum, to more specialized composites or coatings for corrosion resistance.

3. Advanced Finishing: Powder coating or painting options for aesthetic or functional purposes.

4. Custom Grilles and Diffusers: Designed to match interior decor while meeting specific airflow requirements.

Investing in the right accessories, upgrades, and customizations can significantly improve the efficiency, lifespan, and performance of Class 1 duct systems. These enhancements not only foster a more comfortable and healthy environment but also contribute to energy savings and operational efficiency.

List Quality Control and The Manufacturing Process of “class 1 duct”

Quality Control and The Manufacturing Process of “Class 1 Duct”

Quality Control:

1. Material Inspection:

– Verify the quality of materials such as galvanized steel or aluminum to ensure compliance with industry standards.

– Inspect for defects like rust, dents, or surface irregularities.

2. Dimensional Inspection:

– Measure dimensions to ensure adherence to specified tolerances.

– Use calipers, micrometers, and other precision tools.

3. Welding and Sealing Checks:

– Inspect welds for completeness and consistency.

– Perform leak tests to ensure airtight seals, often using smoke or pressure tests.

4. Coating and Finish Verification:

– Assess coatings for even application and durability.

– Check for proper curing of coatings.

5. Performance Testing:

– Conduct tests for airflow efficiency and noise levels.

– Ensure duct meets or exceeds thermal and acoustical insulation requirements.

6. Documentation and Traceability:

– Maintain records of inspections, tests, and material certifications.

– Traceability to ensure any defects can be traced back to their source.

Manufacturing Process:

1. Design and Planning:

– Create detailed design specifications, including dimensions and material type.

– Develop production plan and schedule.

2. Material Preparation:

– Cut raw materials to the required sizes using shears or laser cutting machines.

– Prepare and shape components using bending and forming machines.

3. Assembly:

– Join components via welding, flanging, or mechanical fastening.

– Align and fit parts precisely to ensure tight joints.

4. Welding and Sealing:

– Use techniques like MIG or TIG welding for joining metal parts.

– Apply sealants or gaskets to ensure airtight connections.

5. Insulation and Coating:

– Apply thermal and acoustic insulation where required.

– Coat the exterior with corrosion-resistant materials.

6. Final Assembly and Inspection:

– Perform a comprehensive inspection of the finished product.

– Assemble duct sections as per design, checking for fit and finish.

7. Packaging and Shipping:

– Package ducts to prevent damage during transport.

– Label and document according to standards for easy identification.

By adhering to these quality control checks and following a meticulous manufacturing process, the integrity, and performance of Class 1 ducts are ensured, meeting stringent HVAC industry standards.

How to use “class 1 duct”

A “class 1 duct” typically refers to a type of air duct that meets specific safety and performance standards, often related to fire resistance and smoke production. Class 1 ducts are commonly used in HVAC (Heating, Ventilation, and Air Conditioning) systems in commercial, industrial, and residential buildings to ensure safe air distribution.

Here’s a basic guide to using class 1 ducts:

1. Planning:

– Assess the building layout and HVAC requirements.

– Consult local building codes and standards to ensure compliance.

2. Selection:

– Choose the appropriate size and type of class 1 duct. These ducts are often made of materials like galvanized steel or special coatings that resist fire and limit smoke production.

– Verify the manufacturer’s specifications match the building’s needs.

3. Installation:

– Follow the manufacturer’s guidelines for installation. This includes securing the ducts properly, using the right type of fasteners and supports.

– Ensure joints and seams are sealed to prevent air leakage and maintain system efficiency.

4. Insulation:

– Depending on the application, class 1 ducts may require additional insulation. Use fire-resistant materials to match the duct’s classification and enhance energy efficiency.

5. Testing and Maintenance:

– Test the HVAC system after installation to check for air leaks, proper airflow, and overall system performance.

– Schedule regular inspections and maintenance to ensure the ducts remain in good condition and comply with safety standards.

6. Safety:

– Ensure that all personnel involved in the installation are aware of the safety protocols related to working with class 1 materials.

– Maintain clearances from other building components, especially those that could compromise the duct’s fire-resistant properties.

By following these steps, you can ensure that class 1 ducts are used effectively and safely in any HVAC system.

“class 1 duct” Comparative Analysis

Class 1 ducts are a type of air duct material regulated by the National Fire Protection Association (NFPA) and are characterized by their high resistance to fire and smoke spread. This classification is crucial in commercial and residential HVAC systems to ensure safety and compliance with building codes.

Key Characteristics:

1. Fire Resistance: Class 1 ducts are designed to resist fire penetration and prevent the spread of flames.

2. Smoke Production: These ducts produce minimal smoke in case of fire, reducing the risk of smoke inhalation.

3. Application: Commonly used in high-risk areas such as hospitals, schools, and commercial buildings where fire safety is paramount.

Comparative Analysis:

1. Material:

– Class 1 ducts are typically made from robust materials like metal, which can withstand high temperatures without degrading.

– In contrast, lower-class ducts may use materials like fiberglass or other composites that may not offer the same level of fire resistance.

2. Cost:

– Due to their enhanced safety features, Class 1 ducts can be more expensive.

– This is offset by the benefits of increased safety and compliance with stringent building codes.

3. Installation:

– Class 1 ducts often require specific installation procedures to maintain their fire-resistant properties, potentially increasing labor costs.

– However, their installation is justified in buildings where safety and code compliance are critical.

4. Performance:

– These ducts maintain structural integrity under fire conditions, ensuring the HVAC system remains functional for a longer period during an emergency.

– Lower-class ducts may deteriorate faster, leading to quicker system failure.

5. Regulatory Compliance:

– Class 1 ducts meet rigorous NFPA standards, making them suitable for buildings that need the highest fire safety ratings.

– Other duct classes might not satisfy these strict regulations, limiting their applicability in certain scenarios.

In summary, while Class 1 ducts come with higher material and installation costs, their unparalleled fire resistance and compliance with safety regulations make them indispensable for critical environments.

“class 1 duct” Warranty and Support

Class 1 Duct Warranty and Support

—

#### Warranty

The Class 1 Duct comes with a comprehensive warranty designed to ensure peace of mind and reliability. Our standard warranty period is 5 years from the date of purchase, covering any manufacturing defects in materials or workmanship. During this time, any defective product will be repaired or replaced at no cost to you. Warranty claims require proof of purchase and are subject to approval upon inspection. Note that the warranty does not cover damage caused by misuse, improper installation, or unauthorized modifications.

#### Support

We are dedicated to providing unparalleled support to our customers. Our technical support team is available 24/7 to assist with any inquiries or issues you may have. Whether you need help with installation, operation, or troubleshooting, our experts are just a phone call or email away.

Additionally, our online resources include detailed manuals, FAQs, and instructional videos to guide you through common procedures and questions. For more complex concerns, you can schedule a virtual consultation with our specialists, who will offer personalized assistance to ensure optimal performance of your Class 1 Duct system.

#### Contact Information

– Phone: 1-800-123-4567 (Toll-Free)

– Email: support@class1duct.com

– Website: www.class1duct.com/support

For any warranty claims or support inquiries, please contact us using the information above. We aim to respond to all requests within 24 hours, ensuring that your concerns are addressed promptly and effectively.

By choosing Class 1 Duct, you are investing in a product backed by a reliable warranty and an experienced support team dedicated to your satisfaction.

List “class 1 duct” FAQ

Class 1 Duct FAQ

1. What is a Class 1 duct?

– A Class 1 duct is a type of air distribution ductwork that meets specific fire and smoke safety standards. It is made from materials that have low flame spread and smoke development ratings, typically defined by testing standards like ASTM E84.

2. What materials are used in Class 1 ducts?

– Common materials include galvanized steel, aluminum, or specialized fire-retardant fabrics. These materials are treated or constructed to resist the spread of flames and produce minimal smoke.

3. Where are Class 1 ducts typically used?

– They are often used in commercial buildings, hospitals, schools, and other public spaces where stringent fire safety standards are required. They can also be used in residential settings to enhance safety.

4. Why is Class 1 duct important?

– Using Class 1 duct materials helps to prevent the rapid spread of fire through air systems, providing critical time for evacuation and firefighting efforts. This enhances overall building safety.

5. How is Class 1 status verified?

– Class 1 status is verified through standardized tests, such as ASTM E84 (Standard Test Method for Surface Burning Characteristics of Building Materials), which measure flame spread and smoke development.

6. What maintenance is required for Class 1 ducts?

– Regular inspections and cleaning are necessary to ensure that fire-retardant properties are not compromised by buildup of dust, debris, or damage. Maintenance should follow guidelines provided by the manufacturer and local fire codes.

7. Can Class 1 ducts be used in existing buildings?

– Yes, they can be retrofitted into existing buildings, although it may require modification of the current HVAC system. Consulting a professional is recommended for compliance with fire safety regulations.

8. Are there any limitations to using Class 1 ducts?

– While highly effective in reducing fire risk, they may be more expensive than standard ductwork. Additionally, proper installation is crucial to maintain their fire-retardant properties.

By choosing Class 1 ducts, building owners enhance fire safety and comply with legal standards, thereby safeguarding occupants and property.

Top 10 FAQ with answer about class 1 duct for Buyer Sourcing from China

Sure, here are the top 10 frequently asked questions (FAQ) about sourcing Class 1 duct from China, along with their answers:

1. What is Class 1 Duct?

– Class 1 duct refers to ductwork classified for its flame spread and smoke developed properties, ensuring higher fire resistance and safety standards.

2. Is the Quality from China Reliable?

– Yes, provided you source from certified and reputable manufacturers. Look for certifications like ISO, UL 181, and other relevant international standards.

3. What Certifications Should I Look For?

– Ensure the manufacturer holds certifications like ISO 9001, UL 181, and other national fire safety standards pertinent to Class 1 ductwork.

4. How Do I Verify the Manufacturer’s Credentials?

– Request copies of certifications, customer references, and perform a background check. Third-party inspections and audits can also be arranged.

5. What Are the Common Materials Used?

– Common materials include galvanized steel, aluminum, and sometimes fiberglass. Ensure materials comply with Class 1 fire-resistance standards.

6. What is the Lead Time for Production?

– Lead times vary depending on the manufacturer and order size, usually between 4 to 8 weeks. Confirm the timeline in advance.

7. How Can I Ensure Consistent Quality?

– Implement strict quality control measures, conduct factory visits, and employ third-party inspection services to monitor production.

8. What are the Shipping Options?

– Common shipping methods include sea freight, air freight for urgent orders, and railway for some regions. Confirm the shipping method based on your timeline and budget.

9. What are the Payment Terms?

– Typical payment terms are T/T (Telegraphic Transfer) with a 30% deposit before production and 70% balance before shipment. Alternative terms like L/C (Letter of Credit) might also be available.

10. Are There Language Barriers in Communication?

– While English is commonly used in international trade, some nuances might be lost. Using clear, concise communication and confirming all details rigorously will help mitigate any misunderstandings.

By addressing these questions, buyers can make informed decisions and successfully source high-quality Class 1 duct from China.