cummins piston Safety Certifications

Cummins pistons are integral components of the company’s engines, which are renowned for their reliability, durability, and performance. Ensuring the safety and compliance of these pistons involves adhering to several rigorous certification and regulatory standards.

1. ISO/TS 16949 Certification: Cummins adheres to the ISO/TS 16949 standard, which is specifically designed for the automotive sector. This certification focuses on quality management and continuous improvement, crucial for ensuring the manufacturing of high-quality and safe pistons.

2. ISO 9001 Certification: This is a more generalized standard for quality management systems, ensuring that Cummins’ manufacturing processes consistently meet customer and regulatory requirements.

3. IATF 16949 Certification: A global automotive sector-specific quality management system standard that provides for continual improvement, emphasizing defect prevention and reduction of variation and waste in the supply chain.

4. SAE Standards Compliance: Cummins pistons are designed and manufactured in compliance with the Society of Automotive Engineers (SAE) standards. This ensures that the materials and design meet the high safety and performance benchmarks required in the automotive industry.

5. Environmental and Safety Regulations Compliance: Cummins also adheres to environmental and occupational health and safety standards, such as ISO 14001 and ISO 45001. These certifications ensure that manufacturing processes are responsibly managed with minimal environmental impact and that workplace conditions are safe for employees.

6. Third-Party Testing and Verification: Cummins pistons undergo rigorous third-party testing and verification to ensure they meet or exceed industry safety standards. These independent tests help validate the safety and reliability of the pistons under various operating conditions.

By adhering to these certifications and standards, Cummins ensures that its pistons not only deliver high performance but also comply with stringent safety and regulatory requirements, providing peace of mind to their customers globally.

List Reference Technical Parameters of “cummins piston”

The technical parameters of a Cummins piston, designed for robustness and efficiency, vary by engine model and purpose. Key reference technical parameters include:

1. Material Composition:

– Typically made of high-strength aluminum alloys or cast iron to withstand high pressure and temperature.

2. Diameter/Bore:

– The diameter range varies by engine model, commonly between 80mm to 150mm for different engines like ISX, QSB, or 6BT.

3. Piston Pin Diameter:

– This is critical for matching the connecting rod. Sizes range typically from 25mm to 60mm.

4. Compression Height:

– This is the distance from the center of the piston pin to the top of the piston. It can vary from 30mm to 70mm, depending on the engine design.

5. Top Land Height:

– The distance from the flat top of the piston to the top ring groove can range from 6mm to 12mm.

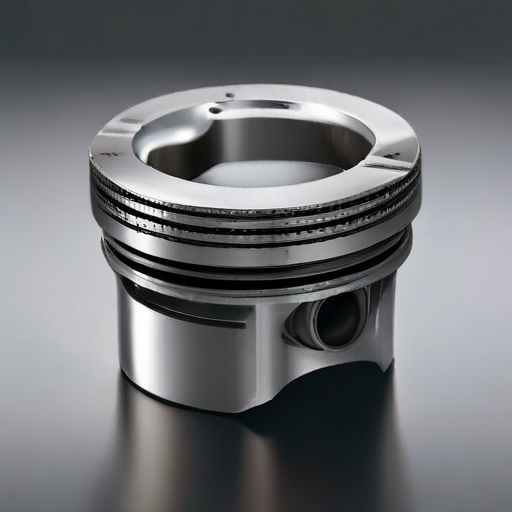

6. Ring Grooves:

– There are generally three ring grooves; the thickness of these grooves typically ranges from 2mm to 5mm.

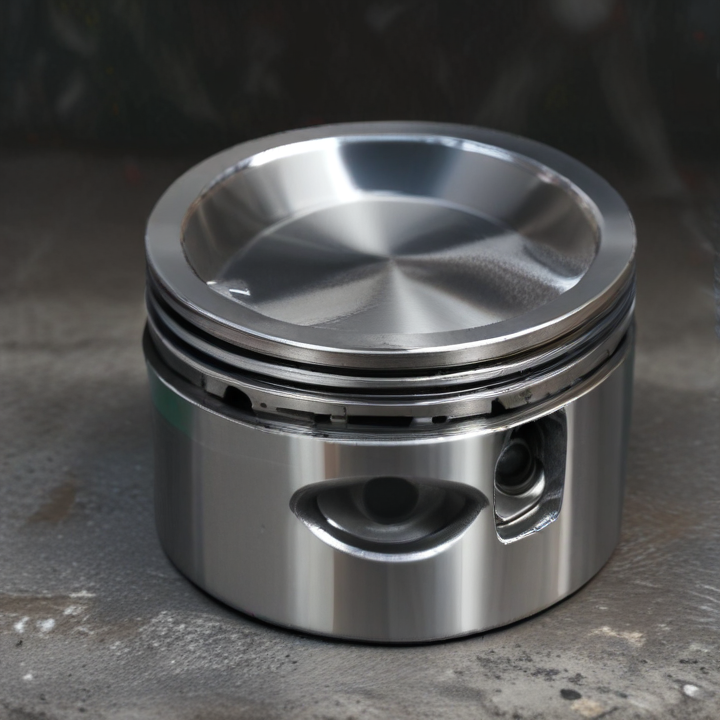

7. Crown Shape:

– The piston crown can be flat, domed, or recessed to optimize combustion efficiency.

8. Thermal Expansion Coefficient:

– A crucial material property that ensures the piston maintains a proper seal and minimizes wear under varying thermal conditions.

9. Weight:

– Varies by design, generally between 500g to over 2kg, ensuring a balance between strength and minimizing reciprocating mass.

10. Coatings:

– Thermal barrier coatings and lubricants might be applied to improve heat resistance and wear characteristics.

11. Stress Tolerances:

– Designed to withstand pressures exceeding 150 bar and temperatures up to 350°C, based on the engine application.

These parameters ensure that Cummins pistons deliver performance, durability, and efficiency in various applications, from light-duty to heavy-duty engines. Exact specifications depend on the specific engine model and intended operational conditions.

List Product features of “cummins piston”

Cummins pistons are integral components in the performance and reliability of Cummins engines. Here are some key product features:

1. Durable Construction: Engineered from high-strength alloys to ensure durability and long service life under high-pressure conditions.

2. Precision Machining: Manufactured with tight tolerances and high precision to ensure optimal fit and performance within the engine cylinder.

3. Thermal Control: Designed to manage and dissipate heat efficiently, preventing overheating and thermal fatigue.

4. Optimized Geometry: Features like complex bowl shapes and crown designs are optimized to enhance combustion efficiency and reduce emissions.

5. Surface Coatings: Advanced coatings on the piston skirts reduce friction and wear, contributing to smoother engine operation and extended lifespan.

6. Lightweight Design: Constructed to be lightweight, which helps to improve fuel efficiency and reduce overall engine weight.

7. Resistance to Corrosion: Materials and coatings resist corrosion, increasing the component’s resistance to harsh operating environments.

8. Compatibility: Designed to fit seamlessly with other Cummins engine components, ensuring compatibility and ease of maintenance.

9. Performance-Enhancing Features: Some models include features such as cooling channels or oil galleries to further enhancing engine performance.

10. OEM Quality: Meets or exceeds original equipment manufacturer (OEM) specifications, ensuring reliable performance and warranty compliance.

11. Versatility: Available for a wide range of Cummins engines, covering various applications from on-highway to industrial and marine.

12. Reduced Noise and Vibration: Engineered to minimize noise and vibrations, contributing to a quieter and smoother engine operation.

These features make Cummins pistons a dependable choice for maintaining the performance and longevity of Cummins engines.

List Various Types of “cummins piston”

Cummins pistons are vital components in their engines, designed to meet diverse operational requirements. Here are various types of Cummins pistons:

1. Aluminum Pistons: Commonly used in light-duty diesel engines; offer a good balance of strength and weight, leading to efficient performance and fuel economy.

2. Steel Pistons: Used in high-performance and heavy-duty applications; provide superior strength and durability under extreme conditions, ensuring long engine life.

3. Forged Pistons: Manufactured by forging, these pistons offer enhanced structural integrity, making them suitable for high-stress environments.

4. Cast Pistons: Made by casting, typically found in lower-cost and general-purpose applications. They offer reasonable performance and cost efficiency.

5. Hypereutectic Pistons: Cast using a high silicon content alloy, these pistons are used in high-performance applications due to their high thermal stability and wear resistance.

6. Coated Pistons: Feature specialized coatings like ceramic or graphite to reduce friction, improve heat resistance, and enhance overall performance.

7. Floating Piston Pins: Pistons designed with floating wrist pins to reduce stress on connecting rods and improve operation smoothness.

8. Articulated Pistons: Feature a design where the skirt is separate from the crown, offering benefits in heat management and reduced friction.

9. Monotherm Pistons: Made entirely from forged steel, ensuring extreme durability and reliability in heavy-duty engines.

10. Composite Pistons: Utilize a combination of materials and advanced manufacturing techniques to optimize weight, strength, and thermal properties for specific engine requirements.

Choosing the right type of piston depends on the specific engine application, operational requirements, and performance expectations. Cummins ensures each piston type meets stringent quality and performance standards for robust and reliable engine operation.

List Application of “cummins piston”

Cummins pistons are integral components of the internal combustion engines manufactured by Cummins Inc., a global leader in power solutions. These pistons are designed to endure high temperatures and pressures and are critical for various applications across different industries:

1. Automotive Industry: In commercial vehicles like trucks and buses, Cummins pistons are used to ensure reliable performance, efficiency, and durability in engines, contributing to reduced emissions and improved fuel economy.

2. Industrial Equipment: Cummins pistons are widely used in industrial machinery such as construction and mining equipment. Their robust design helps in handling heavy loads and operating under rugged conditions.

3. Agricultural Machinery: In tractors and other farm equipment, Cummins pistons support efficient engine operation, enabling farmers to perform tasks like plowing, harvesting, and irrigation effectively.

4. Marine Applications: They are used in marine engines for boats and ships, providing the necessary power and reliability required for maritime operations.

5. Power Generation: In diesel and natural gas generators, Cummins pistons help in converting fuel into mechanical energy, ensuring a consistent power supply for residential, commercial, and industrial purposes.

6. Railway Systems: Cummins pistons are utilized in locomotives, offering the high power output necessary for transporting goods and passengers across long distances.

7. Oil and Gas Industry: In this sector, Cummins pistons are employed in compression and power generation systems, aiding in the extraction and processing of oil and gas.

Overall, Cummins pistons are vital for the efficient operation of engines across a diverse range of applications, contributing significantly to performance, reliability, and longevity.

List Buyer Types of “cummins piston”

When looking into the buyer types for “Cummins piston,” various categories of buyers come to mind. Here’s a comprehensive list:

1. Original Equipment Manufacturers (OEMs):

– Companies producing engines or machinery that incorporate Cummins engines often need pistons as critical components during the assembly process.

2. Fleet Operators:

– Companies running large fleets of trucks, buses, construction equipment, or marine vessels typically seek Cummins pistons for maintenance, repair, and overhaul (MRO) purposes to ensure operational efficiency.

3. Independent Repair Shops:

– Auto repair shops and service centers working on diesel engines may stock and utilize Cummins pistons for repair and rebuild services offered to their customers.

4. Individual Vehicle Owners:

– Owners of personal or commercial vehicles powered by Cummins engines may purchase pistons for DIY repairs or to supply to a mechanic for engine rebuilding.

5. Distributors and Wholesalers:

– Businesses specializing in diesel engine parts often buy Cummins pistons in bulk and resell them to smaller retailers, repair shops, and end-users.

6. Performance Enthusiasts:

– Individuals and companies involved in tuning and upgrading engines for high performance, including racing and heavy-duty applications, may seek specialized Cummins pistons for enhanced engine capabilities.

7. Agricultural Sector:

– Farmers and agricultural businesses with machinery powered by Cummins engines are frequent buyers, ensuring their equipment remains functional during critical farming periods.

8. Industrial Machinery Operators:

– Industries utilizing heavy machinery, such as mining, oil, and gas, often require a steady supply of Cummins pistons to maintain their equipment’s reliability and performance.

9. Educational and Training Institutions:

– Schools and vocational training centers focused on automotive and diesel engine repair programs may purchase Cummins pistons for instructional purposes, training the next generation of mechanics and technicians.

10. Government and Military:

– Agencies with fleets of vehicles or machinery may also be in the market for Cummins pistons to maintain their operational readiness.

Each buyer type has specific needs and motivations, ranging from maintaining operational efficiency to pursuing high-performance upgrades.

List “cummins piston” Project Types for Different Industries

Cummins pistons are integral components in various engines across multiple industries. The project types where Cummins pistons are used include:

1. Automotive Industry:

– Passenger Vehicles: Engine rebuilding and performance upgrades.

– Commercial Vehicles: Fleet maintenance and engine overhauls for trucks and buses.

2. Construction Industry:

– Heavy Machinery: Piston replacements in excavators, bulldozers, and cranes for enhanced durability.

– Equipment Refurbishment: Restoring older construction equipment to extend service life.

3. Agricultural Sector:

– Tractors: Engine overhauls to improve power and efficiency.

– Harvesters: Regular maintenance and piston upgrades to ensure reliability during peak seasons.

4. Marine Industry:

– Commercial Shipping: Engine rebuilds and maintenance for cargo ships and tankers.

– Pleasure Craft: Performance tuning for yachts and speedboats.

5. Power Generation:

– Industrial Generators: Rebuilding diesel generators to ensure uninterrupted power supply.

– Backup Power Systems: Piston replacements in emergency standby generators.

6. Mining Industry:

– Mining Equipment: Reconditioning engines in drill rigs, loaders, and haul trucks.

– Underground Machinery: Ensuring engine reliability in harsh, subterranean environments.

7. Railway Sector:

– Locomotives: Overhauling locomotive engines for freight and passenger trains.

– Rail Maintenance Equipment: Ensuring the efficiency of track maintenance machinery.

8. Oil & Gas Industry:

– Drilling Rigs: Engine servicing for onshore and offshore drilling activities.

– Pump Equipment: Maintaining engines in pumps used for oil extraction and transport.

These project types highlight the versatility and essential role of Cummins pistons in maintaining the efficiency and reliability of engines across various sectors.

cummins piston Accessories Upgrades and Custom Manufacturing Options

Cummins piston accessories and upgrades can significantly enhance engine performance, longevity, and efficiency. Key options include:

1. High-Performance Pistons: Upgraded materials like forged aluminum or steel provide superior strength and endurance, essential for high-power applications.

2. Ceramic Coatings: Adding ceramic coatings to pistons can improve heat dissipation, reduce friction, and enhance overall engine efficiency. This upgrade is particularly beneficial in high-temperature environments.

3. Piston Rings: Opt for advanced multi-piece or gapless piston rings to improve sealing, reduce oil consumption, and boost compression. These rings can withstand higher pressures and temperatures compared to standard rings.

4. Custom Piston Skirts: Skirt coatings can diminish wear and friction between the piston and cylinder wall, leading to better longevity and smoother operation.

5. Lightweight Pistons: By choosing lightweight designs, you can reduce reciprocating mass, helping to increase engine responsiveness and potentially improving fuel efficiency.

6. Enhanced Cooling Options: Cooling channels or oil squirters can be integrated for advanced thermal management, crucial for heavy-duty or high-performance engines.

7. Custom Sizes and Shapes: Tailor pistons to your specific needs with custom diameters, pin locations, and dome shapes. Precision manufacturing ensures compatibility with specialized applications and performance targets.

8. Cryogenic Treatment: This process strengthens the piston material at a molecular level, enhancing durability and resistance to wear and fatigue.

To achieve these upgrades, several custom manufacturing options are available:

– Precision CNC Machining: Ensures exact tolerances and high-quality finishes.

– 3D Printing: For rapid prototyping and complex geometries.

– Specialized Forging: Customizable forging processes can produce pistons tailored to exact specifications, offering superior mechanical properties.

By leveraging these accessories and custom manufacturing options, Cummins engine performance can be significantly optimized for a variety of demanding applications.

List Quality Control and The Manufacturing Process of “cummins piston”

Quality Control of Cummins Pistons

1. Material Inspection: Raw materials are inspected for chemical composition and mechanical properties to ensure they meet specified standards.

2. Dimensional Verification: Precision measuring tools such as calipers and coordinate measuring machines (CMM) verify dimensional accuracy.

3. Surface Finish Checks: Surface roughness is measured using profilometers to ensure appropriate finish parameters.

4. Non-Destructive Testing (NDT): Techniques like ultrasonic testing or radiography detect internal flaws without damaging the piston.

5. Hardness Testing: Indentation hardness tests (e.g., Rockwell or Brinell) ensure appropriate material strength.

6. Metallurgical Analysis: Microstructural analysis checks for proper grain structure and phase distribution using microscopes.

7. Functional Testing: Pistons undergo various functional tests, including thermal expansion and cyclic loading tests.

8. Visual Inspection: Manual inspection for surface defects, including scratches, burrs, and irregularities.

Manufacturing Process of Cummins Pistons

1. Design and Prototyping:

– Engineers use CAD software to design pistons based on engine specifications.

– Prototypes are created using 3D printing or CNC machining for initial validation.

2. Material Preparation:

– Selected alloys, usually aluminum or steel, are prepared and melted in furnaces.

3. Casting or Forging:

– Pistons are typically made through precision casting or forging to shape the raw material.

– Forging enhances strength by aligning grain structures.

4. Machining:

– CNC machines are used for detailed machining, ensuring precise dimensions and fitting.

– Key features like piston rings, skirts, and pinholes are machined to specification.

5. Heat Treatment:

– Pistons undergo heat treatment to improve mechanical properties such as hardness and fatigue resistance.

6. Surface Treatment:

– Surface treatments like anodizing or coating are applied to improve wear resistance and lubrication properties.

7. Final Inspection:

– Each piston undergoes comprehensive quality control checks before packing and shipping.

By maintaining rigorous quality control standards and following a meticulous manufacturing process, Cummins ensures their pistons meet high-performance standards and reliability requirements.

How to use “cummins piston”

Using a Cummins piston involves several steps, primarily related to the installation and maintenance in an engine. Here’s a concise guide:

Installation

1. Preparation:

– Ensure you have the correct piston model for your Cummins engine.

– Gather all necessary tools: torque wrench, ring compressor, piston ring installer, etc.

2. Clean and Inspect:

– Clean the engine cylinder and check for any damage.

– Inspect the new piston for any manufacturing defects.

3. Install Piston Rings:

– Use a piston ring installer to fit the rings onto the piston.

– Stagger the ring gaps according to the manufacturer’s specifications.

4. Lubrication:

– Apply engine oil to the piston, rings, and cylinder wall to reduce friction.

5. Position the Piston:

– Insert the piston into a ring compressor.

– Guide the piston into the cylinder, ensuring the arrow on the piston crown points towards the engine’s front.

6. Install the Connecting Rod:

– Attach the connecting rod to the crankshaft.

– Torque the rod bolts to the manufacturer’s specifications.

Maintenance

1. Regular Inspection:

– Periodically inspect the piston during routine engine maintenance.

– Check for wear, scoring, or damage.

2. Cleaning:

– Occasionally, remove carbon deposits from the piston crown using a brush and suitable solvent.

3. Lubrication:

– Ensure the engine has adequate and clean oil to maintain piston and cylinder lubrication.

Tips

1. Refer to Manual:

– Always follow the Cummins engine service manual for specific torque settings and procedures.

2. Use Quality Parts:

– Use genuine Cummins parts to ensure compatibility and longevity.

3. Seek Professional Help:

– If unsure, consult a professional mechanic specializing in Cummins engines.

Proper installation and maintenance of Cummins pistons are vital for engine performance and longevity. Always adhere to the detailed guidelines provided by Cummins to achieve the best results.

“cummins piston” Comparative Analysis

Cummins, a global leader in the design and manufacturing of diesel and alternative fuel engines, produces various types of pistons tailored to meet the specifications of their diverse engine range. A comparative analysis of Cummins pistons reveals the key differences in materials, design, and performance suited for different engine applications.

Materials:

Cummins utilizes high-grade materials like aluminum and steel in their pistons. For heavy-duty applications, steel pistons are preferred due to their superior strength and thermal resistance. Aluminum pistons are lighter, thus enhancing fuel efficiency, but they might not withstand the high stress environments as effectively as steel.

Design:

The design of Cummins pistons varies across different engine models. For instance, the pistons in the ISX15 engine are designed with a larger diameter and advanced cooling features to manage the higher temperatures associated with heavy-duty trucking. On the other hand, smaller engines like the B6.7 use pistons designed for efficiency, balancing strength and lightweight properties.

Performance:

Steel pistons, as seen in heavy-duty Cummins engines like the X15, can endure higher pressures and temperatures, translating to reliability and longer service intervals. Aluminum pistons, used in medium-duty engines like the 6BT, contribute towards lower engine weight, increasing efficiency and reducing emissions. The choice depends on the engine’s operational requirements—whether the priority is endurance under high stress or optimizing fuel consumption.

In summary, Cummins pistons are engineered to meet the specific demands of different applications, balancing factors like material properties, design complexity, and performance objectives. Heavy-duty engines benefit from steel pistons due to their robustness, while aluminum pistons suit applications where weight and efficiency are critical. This versatility ensures that Cummins engines remain reliable and efficient across a wide array of industrial and commercial uses.

“cummins piston” Warranty and Support

Cummins extends a robust warranty and support system for its pistons, ensuring that customers receive maximum reliability and performance. Each piston, integral to the engine’s operation, is covered under Cummins’ comprehensive warranty program which typically spans a significant duration of either miles or operating hours, depending on the specific model and application.

The warranty covers defects in material and workmanship under normal use and service, giving customers peace of mind. For detailed terms, conditions, and duration, users are advised to refer to the warranty documentation specific to their engine model or contact Cummins directly.

In addition to the warranty, Cummins offers extensive support services. Authorized Cummins service centers, strategically located worldwide, provide expert repairs and maintenance. These centers employ certified technicians adept at diagnosing and resolving issues with genuine Cummins parts, ensuring longevity and optimal performance of the pistons.

Cummins also offers a suite of online resources and customer service options. Through the official Cummins website, customers can access technical documents, service manuals, and maintenance tips. Furthermore, the online portal allows users to register their engines, track warranty status, and access support.

For real-time assistance, Cummins provides a customer service hotline. This helpline connects users with knowledgeable representatives capable of answering technical queries, directing to local service centers, and guiding through troubleshooting processes.

In summary, Cummins stands behind its pistons with a substantial warranty and multi-faceted support, ensuring users worldwide can maintain their engines with confidence, efficiency, and expert assistance.

List “cummins piston” FAQ

Certainly! Below are some frequently asked questions (FAQs) about Cummins pistons:

Cummins Piston FAQ

1. What are Cummins pistons made of?

Cummins pistons are typically made from high-quality aluminum or steel alloys to ensure strength, durability, and efficient heat dissipation.

2. How often should Cummins pistons be replaced?

The replacement interval for Cummins pistons depends on usage and maintenance practices. Regular inspections and following the manufacturer’s guidelines are essential for determining when a replacement is necessary.

3. What are common signs of piston wear or damage?

Signs include excessive oil consumption, white or blue exhaust smoke, knocking sounds from the engine, decreased performance, and difficulty starting the engine.

4. Can Cummins pistons be re-used?

Pistons can sometimes be re-used if they are in good condition and meet specific tolerances after inspection. However, if there is significant wear or damage, replacement is recommended.

5. How do I ensure proper piston installation in a Cummins engine?

Follow the manufacturer’s manual carefully. Proper lubrication, correct orientation, and ensuring the correct ring gap and clearance measurements are crucial for installation.

6. What are the benefits of using OEM Cummins pistons?

OEM (Original Equipment Manufacturer) Cummins pistons ensure compatibility, reliability, and performance, as they are designed and tested to meet Cummins’ standards.

7. Are there aftermarket options for Cummins pistons?

Yes, there are aftermarket options available, but it is essential to choose reputable brands and ensure they meet the required specifications and standards.

8. What role do piston rings play?

Piston rings seal the combustion chamber, regulate oil consumption, and help dissipate heat. Inspect and replace them along with the pistons if needed.

9. Can piston upgrades improve engine performance?

Performance pistons designed for higher compression ratios and better durability can improve engine performance, but they should be chosen based on specific engine requirements.

10. Where can I purchase genuine Cummins pistons?

Genuine Cummins pistons can be purchased through authorized Cummins dealerships, service centers, and reputable automotive parts retailers.

By maintaining and properly servicing Cummins pistons, you ensure the longevity and efficiency of your engine. Always consult a professional mechanic or refer to the Cummins service manual for specific guidance.

Top 10 FAQ with answer about cummins piston for Buyer Sourcing from China

1. What are the key factors to consider when sourcing Cummins pistons from China?

– Quality standards, supplier reputation, certification (ISO, QS), material specifications, lead time, and post-sale support are crucial.

2. How can I verify the quality of Cummins pistons from Chinese suppliers?

– Request quality certification, conduct factory audits, obtain product samples, and read customer reviews and testimonials.

3. What are the payment terms typically offered by Chinese suppliers for Cummins pistons?

– Common terms include T/T (Telegraphic Transfer), L/C (Letter of Credit), and sometimes Western Union. Initial transactions often require 30% deposit and 70% upon shipping.

4. Are the pistons manufactured in China compatible with all Cummins engine models?

– Verify part numbers and specifications with the supplier to ensure compatibility. Many suppliers can provide a cross-reference list for specific Cummins models.

5. What is the minimum order quantity (MOQ) when sourcing from China?

– MOQs can vary, but they generally range from 50 to 100 units. Some suppliers may offer flexibility for initial sample orders.

6. How long does it take to manufacture and deliver Cummins pistons from China?

– Production typically takes 4-6 weeks, and shipping can take an additional 2-4 weeks, depending on the method (air or sea).

7. What shipping methods are available for Cummins pistons from China?

– Common methods include air freight (faster but more expensive), sea freight (more economical for large quantities), and express couriers like DHL and FedEx for smaller orders.

8. Can Chinese suppliers provide customization for Cummins pistons?

– Yes, many suppliers offer customization services, including specific coatings, material grades, and design modifications based on your requirements.

9. What kind of warranty do Chinese suppliers offer for Cummins pistons?

– Warranties typically range from 6 months to 1 year. It’s essential to discuss and agree on warranty terms before finalizing the purchase.

10. How do I handle after-sales service and support for Cummins pistons sourced from China?

– Opt for suppliers who offer reliable after-sales support, including technical assistance, returns, and replacements. Ensure clear communication channels are established.