dental models Safety Certifications

Dental models are essential tools in the field of dentistry, used for diagnostic, educational, and therapeutic purposes. Ensuring the safety and quality of these models is paramount, and several certifications and regulations exist to standardize the materials and manufacturing processes involved.

ISO Certifications

The International Organization for Standardization (ISO) offers various certifications relevant to dental models. ISO 13485, for instance, specifies requirements for a quality management system where an organization needs to demonstrate its ability to provide medical devices and related services that consistently meet customer and applicable regulatory requirements. ISO 10993-1 outlines the evaluation and testing requirements for the biological safety of medical devices, ensuring that materials used are biocompatible and safe for patient contact.

FDA Regulations

In the United States, the Food and Drug Administration (FDA) regulates dental models under the Medical Device Classification system. Depending on their intended use, dental models may fall under Class I, II, or III devices, each with increasing levels of oversight. Manufacturers must adhere to FDA’s Quality System Regulations (QSR), which outline good manufacturing practices (GMP) that ensure products are safe and effective for use.

CE Marking

In the European Union, dental models must comply with the Medical Device Regulation (MDR 2017/745). A CE mark indicates conformity with health, safety, and environmental protection standards for products sold within the European Economic Area (EEA). Manufacturers must provide thorough documentation including a clinical evaluation and a risk management plan to gain CE certification.

Other Certifications

Additional certifications, such as those from the Occupational Safety and Health Administration (OSHA) and specific industry certifications like ISO 9001 for quality management or UL for safety, may also be relevant depending on the specific type of dental model and its use-case scenario.

In summary, dental models must meet stringent safety and quality standards verified by certifications such as ISO 13485, FDA regulations, and CE marking, ensuring they are safe and effective for clinical use.

List Reference Technical Parameters of “dental models”

Dental models, essential tools in modern dentistry, represent the oral cavity, including teeth and surrounding tissues. Accurate and detailed, these models assist dentists in diagnosis, treatment planning, and patient education. Key technical parameters of dental models include:

1. Material Composition:

– Gypsum Products: Typically Type III (dental stone), Type IV (high-strength stone), or Type V (die stone) based on hardness and accuracy.

– Resin: Photopolymer resins used in 3D printing for high precision.

– Acrylic: Often used for durable models.

2. Dimensional Accuracy:

– Tolerance: Ensuring minimal deviations, typically within 0.05 mm for precise simulations.

– Surface Detail Quality: Capturing fine anatomical details.

3. Resolution:

– Layer Thickness: In 3D printing, commonly ranging from 20-100 microns.

– XY Resolution: Horizontal precision, contributing to overall model fidelity.

4. Mechanical Properties:

– Hardness: Varies by material but crucial for manipulation and durability.

– Compressive Strength: Particularly important for gypsum-based models to withstand operational forces.

5. Stability and Shrinkage:

– Dimensional Stability: Ensures model accuracy over time.

– Linear Shrinkage: Minimal in high-quality materials, influencing fit and function.

6. Color:

– Color Contrast: Aids in distinguishing anatomical features, typically white for gypsum, varied hues for resins.

7. Surface Finish:

– Smoothness: Impacts the ease of use and overall accuracy.

– Texture: High-definition to mimic real oral surfaces.

8. Compatibility:

– Interoperability: Syncing with various dental software and hardware tools for enhanced diagnostic and therapeutic purposes.

9. Application Specifics:

– Orthodontics: Models require higher precision for bracket and aligner planning.

– Prosthodontics: Focused on fine detail for restorative work.

Understanding these technical parameters ensures the creation of functional, reliable, and high-fidelity dental models, thereby improving clinical outcomes and patient care in dentistry.

List Product features of “dental models”

Dental models, essential tools in the field of dentistry, attract attention for their range of features designed to facilitate various dental procedures, education, and patient care. Below are the key features of dental models:

1. High Precision: Dental models often boast exceptional accuracy, reflecting intricate anatomical details of teeth and gums, which is crucial for diagnosis, treatment planning, and simulation of dental procedures.

2. Material Quality: Typically made from durable materials like acrylic resin, plaster, or advanced plastics, ensuring longevity and resistance to wear and tear through repetitive use.

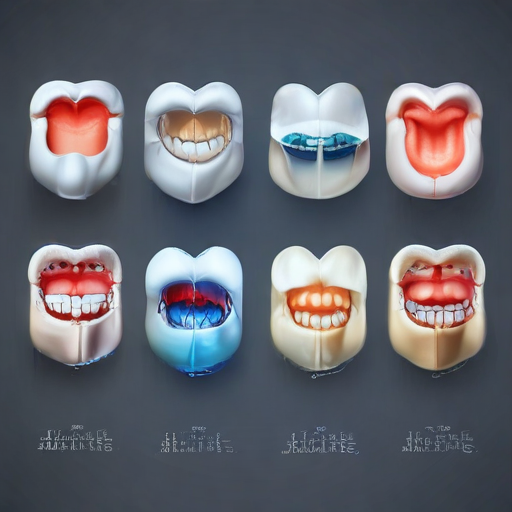

3. Variety: Available in multiple forms such as typodonts, orthodontic models, implant models, and pathology models, catering to diverse specialties within dentistry.

4. Realistic Appearance: Many models exhibit lifelike textures and colors, aiding in realistic practice scenarios and enhancing understanding for both practitioners and patients.

5. Articulation: Some dental models feature articulating jaws, enabling simulation of bite and occlusion, critical for orthodontics and restorative procedures.

6. Customizability: Custom dental models can be created based on individual patient scans, providing personalized tools for accurate treatment planning and patient-specific solutions.

7. Educational Utility: Widely used in educational settings, helping students and trainees to practice and master various dental techniques and procedures before treating actual patients.

8. Patient Communication: Act as visual aids during patient consultations, making it easier to explain conditions, procedures, and expected outcomes, thereby improving patient understanding and consent.

9. Diagnostic Support: Played a significant role in diagnostic processes, particularly in the study and design of prosthetics, orthodontic appliances, and surgical guides.

10. Portability: Most dental models are lightweight and portable, facilitating easy transport between dental operatories, classrooms, or patient locations as needed.

11. Cost-Effective: Provides a cost-efficient means for continuous practice and demonstration without consuming disposable materials or occupying chair time with patients.

Such comprehensive features make dental models indispensable in both clinical and educational settings, significantly contributing to the advancement and precision of dental care and treatment outcomes.

List Various Types of “dental models”

Dental models are essential tools in dentistry, aiding in diagnostics, treatment planning, and patient education. Various types of dental models include:

1. Study Models: These are detailed replicas of a patient’s teeth and gums made from materials like dental stone or plaster. Primarily used for diagnosing and treatment planning, they help in visualizing the dental arches and identifying malocclusions.

2. Orthodontic Models: Specifically designed for orthodontic purposes, these models assist in planning braces, retainers, and other orthodontic appliances. They provide a precise representation of the teeth before, during, and after orthodontic treatment.

3. Diagnostic Wax-Up Models: These are created by adding wax to a base model to simulate the desired outcome of a dental treatment, such as crowns, bridges, or veneers. They help dentists and patients visualize the final results before actual treatment begins.

4. Implant Models: These include simulations of dental implants within the model, providing a realistic representation of implant placement and helping in precise surgical planning.

5. 3D Printed Models: Utilizing digital scans and 3D printing technology, these models offer high precision and can be quickly produced. They are used for a variety of applications, including surgical guides and orthodontic appliances.

6. Training Models: Designed for educational purposes, these models help dental students practice procedures like extractions, fillings, and root canals. They typically feature a range of dental conditions for comprehensive skills development.

7. Anatomical Models: These provide a detailed representation of dental and oral anatomy, often used in educational settings to teach students about the structures of the mouth and teeth.

8. Functional Orthopedic Models: Used in the treatment of jaw disorders, these models simulate the function of the temporomandibular joint (TMJ) and are handy for diagnosing and planning treatments for TMJ disorders.

Each type of dental model has unique features tailored to specific diagnostic, educational, and treatment needs in dental practice.

List Application of “dental models”

Dental models, or dental casts, are essential tools in the field of dentistry, aiding in various diagnostic, treatment planning, and educational activities. Here are key applications:

1. Diagnosis and Treatment Planning:

– Orthodontics: Dental models help analyze occlusion, determine the necessity and strategy for braces or other corrective devices.

– Prosthodontics: They assist in the design and fit of crowns, bridges, dentures, and implants.

– Surgical Planning: Surgeons use models to plan complex oral surgeries, including jaw realignments and reconstructive procedures.

2. Patient Communication and Education:

– Visual Aids: Models help explain dental conditions and potential treatments to patients, enhancing their understanding and consent.

– Demonstration: They are used to demonstrate oral hygiene techniques, like brushing and flossing.

3. Fabrication of Dental Appliances:

– Custom Appliances: Accurate models ensure proper fitting of night guards, retainers, and other personalized dental devices.

– Temporary Restorations: Models are used to create temporary crowns or bridges while permanent solutions are being prepared.

4. Training and Education:

– Dental Students: Models provide a realistic medium for students to practice examination, diagnostic, and treatment skills.

– Continued Education: Practicing dentists use models for advanced training in new techniques and technologies.

5. Research and Innovations:

– Material Testing: New dental materials and products are often tested on models before clinical application.

– Technique Development: Innovative dental techniques are refined and validated using realistic dental models.

6. Legal and Forensic Applications:

– Case Documentation: Dental models serve as crucial evidence in legal cases involving dental malpractice.

– Forensic Investigation: Models assist in identifying deceased individuals based on dental records.

Dental models are thus indispensable across various facets of dentistry, enhancing precision, education, and patient care.

List Buyer Types of “dental models”

When it comes to dental models, several distinct buyer types emerge, each with unique needs and purposes. Below, we explore the primary categories of buyers:

1. Dental Professionals: This includes dentists, orthodontists, periodontists, and prosthodontists who use dental models for patient education, treatment planning, and procedural practice. These professionals often seek high-fidelity, detailed models to illustrate various dental conditions, anatomical structures, and treatment options.

2. Dental Laboratories: These facilities produce dental restorations like crowns, bridges, and dentures. They employ dental models to ensure accurate fabrication and fitting of these prosthetics. Precision and durability are key criteria for the models used in labs.

3. Dental Students and Institutions: Educational institutions, dental schools, and students require dental models for teaching and learning purposes. These models help visualize oral anatomy, diagnose conditions, and practice clinical skills. Typically, these models are affordable, durable, and versatile.

4. Dental Equipment Manufacturers: Companies that create dental implants, orthodontic appliances, and other dental products use models for research, development, and demonstration. They need highly accurate models that replicate real anatomical conditions for testing and showcasing their products.

5. Patients and General Public: Occasionally, patients or interested individuals purchase dental models for personal education, perhaps to understand a specific condition or upcoming treatment better. These models are generally simpler and designed for layperson understanding.

6. Veterinary Dentists: Veterinarians specializing in dental care for animals also use dental models to study and plan treatments for various species. These models are typically designed to replicate the unique anatomical differences between human and animal teeth.

Each buyer type prioritizes different aspects such as accuracy, durability, cost-effectiveness, or educational value. Understanding these distinctions helps suppliers tailor their products to better serve the diverse needs of the market.

List “dental models” Project Types for Different Industries

Dental models are essential tools utilized across various industries for diverse applications. Here are some of the key project types and their associated industries:

1. Dental Industry:

– Educational Training Models: Demonstration tools for dental students to practice procedures.

– Orthodontic Models: Used for planning and simulating orthodontic treatments.

– Procedural Models: To practice complex procedures like implants and root canals.

2. Healthcare Technology:

– 3D Printed Dental Models: Utilized for advanced, customizable treatment planning.

– Simulation Models for Device Testing: Testing new dental instruments and devices.

– Dental Software Development: Models to design and test dental simulation software.

3. Medical Research:

– Biocompatibility Testing: Models for testing new dental materials.

– Anatomical Studies: Detailed models for studying dental anatomy and pathology.

– Biomechanical Analysis: Testing the impact of stresses and strains on dental structures.

4. Manufacturing:

– Product Prototyping: Developing prototypes for dental tools and appliances.

– Quality Assurance: Ensuring consistency and quality in the production of dental implements.

– Material Testing: Evaluating dental materials like resins and ceramics.

5. Consumer Goods:

– Teeth Whitening Products: Models to test and showcase the effectiveness of whitening products.

– Dental Care Products: Demonstrating the use of toothbrushes, dental floss, and other care items.

– Custom Mouthguards: Creating precise fit models for sports or medical use.

6. Insurance:

– Claim Validation: Using models to assess and validate dental claims.

– Risk Assessment: Evaluating the likelihood of dental issues in policyholders.

7. Forensics:

– Identification: Dental models for forensic identification purposes.

– Bite Mark Analysis: Analyzing bite marks for criminal investigations.

Each of these industries utilizes dental models differently, highlighting their versatility and crucial role in advancing dental science and improving patient care.

dental models Accessories Upgrades and Custom Manufacturing Options

Dental models play a crucial role in diagnosis, treatment planning, and patient education in dentistry. To enhance their functionality and precision, various accessories, upgrades, and custom manufacturing options are available.

Accessories:

1. Articulators: These devices mimic jaw movements, allowing for the accurate assessment and adjustment of occlusions.

2. Intricate Anatomic Components: Occlusal pads, gingival masks, and simulated tooth and bone structures enhance realism.

3. Base Plates and Mounting Plates: Designed for stability and ease of use, they provide a secure foundation for dental models.

4. Model Trays and Cases: Ensures organized and safe storage of dental models, protecting them from damage.

Upgrades:

1. Digital Integration: Incorporating CAD/CAM technology allows for precise modeling and replication. Digital scanning and printing can significantly enhance the accuracy and detail of dental models.

2. High-Resolution 3D Printing: Upgrading to advanced printers capable of fine-detail printing improves the quality and detail of dental models.

3. Smart Materials: Using materials that simulate natural tooth and gum textures can offer a more realistic practice experience.

4. Customizable Software: Upgraded software options enable better design and simulation features, facilitating complex dental procedures.

Custom Manufacturing Options:

1. Tailored Anatomical Models: Custom models based on patient-specific scans provide a highly accurate representation of individual oral anatomy.

2. Orthodontic Study Models: Customized models specifically designed for orthodontic applications, enabling precise bracket placement and alignment adjustments.

3. Implant Planning Models: These models are tailored for implant procedures, offering specialized features such as removable gingival simulators and drill guides.

4. Training Phantom Heads: Custom-designed to mimic various patient scenarios, these models are invaluable for surgical training and educational purposes.

In conclusion, the combination of essential accessories, state-of-the-art upgrades, and bespoke manufacturing options ensures dental models remain indispensable tools in modern dentistry, continually enhancing both clinical outcomes and educational experiences.

List Quality Control and The Manufacturing Process of “dental models”

Quality Control and Manufacturing Process of Dental Models

Manufacturing Process:

1. Initial Consultation: The dentist takes an impression of the patient’s teeth using alginate or a digital scanner.

2. Impression Creation: For traditional methods, the alginate impression is poured with dental stone or plaster to create a physical model. For digital methods, 3D scans are sent to software for model design.

3. Model Design: The digital or physical impression is used to design the dental model. If digital, CAD software helps in fine-tuning the model.

4. Material Selection: Choose appropriate materials such as resin, stone, or plaster based on the requirements of accuracy and durability.

5. Model Production: For physical models, plaster or stone is poured into the mold. For digital models, 3D printing technology (e.g., SLA, DLP) or milling techniques are used.

6. Post-Processing: Printed or cast models are cleaned, cured, or trimmed to remove any unnecessary material and ensure a smooth finish.

Quality Control:

1. Material Inspection: Check batches of plaster, stone, or resin to ensure they meet required specs for hardness, reliability, and safety.

2. Accuracy Verification: Compare the produced model against the original impression or digital scan. For digital models, software can measure deviations and ensure precision.

3. Surface Quality Check: Inspect models for surface defects such as bubbles, rough edges, or incomplete sections.

4. Dimensional Integrity: Use calipers or digital measuring tools to verify that the tooth dimensions and overall geometry match the patient’s original impressions.

5. Strength Testing: Subject samples of the material to stress tests to verify their durability and suitability for dental applications.

6. Audits and Calibration: Regularly audit the machinery and tools used in both digital and physical model creation to maintain consistent accuracy and performance.

By maintaining stringent quality control throughout the manufacturing process, dental models can achieve high accuracy, durability, and reliability, which are essential for effective dental treatments.

How to use “dental models”

Dental models are essential tools in dentistry, used for diagnosis, treatment planning, and education. Here’s a concise guide on how to use dental models effectively:

1. Diagnosis and Treatment Planning:

– Impressions: Start by taking accurate impressions of the patient’s teeth and gums using alginate or silicone materials.

– Cast Models: Pour dental stone or plaster into the impressions to create precise cast models.

– Examination: Use these models to examine the bite, tooth alignment, and occlusion. Identify any abnormalities or issues that need addressing.

2. Patient Education:

– Visual Aid: Show the dental model to the patient to explain their oral condition clearly. This visual representation helps patients understand complex dental concepts.

– Demonstrate Procedures: Use the model to demonstrate proposed treatments like restorations, braces, or implants. This aids in informed decision-making.

3. Orthodontic Planning:

– Alignment Assessment: Assess the alignment and spacing of teeth. Dental models help in planning the placement of braces or other orthodontic appliances.

– Progress Tracking: Periodically take new models to track progress and make necessary adjustments in the treatment.

4. Prosthodontics:

– Fabrication: Use dental models to fabricate crowns, bridges, dentures, and other prosthetic devices. Ensure they fit well and function properly by testing on the model before finalizing.

5. Surgical Planning:

– Implant Placement: Plan the exact placement of dental implants using models to ensure precise and successful outcomes.

– Surgical Guides: Create custom surgical guides to aid in accurate implant placement based on the model.

6. Training and Research:

– Skill Development: Practice various dental procedures on models to enhance skills without risk to patients.

– Study and Research: Use models for educational purposes, case studies, and research to advance dental knowledge.

Maintenance:

– Storage: Store models in a safe, dry place to prevent damage or deformation.

– Labeling: Properly label each model with patient details for easy identification and reference.

Using dental models effectively enhances diagnostic accuracy, patient communication, treatment planning, and overall dental care.

“dental models” Comparative Analysis

Dental models are essential tools in orthodontics, prosthodontics, and general dentistry for diagnostic, treatment planning, and educational purposes. They are traditionally categorized into gypsum, digital, and 3D printed models.

Gypsum Models: These are the most conventional and widely recognized. Made from dental stone, they offer high accuracy and are cost-effective. Dentists can easily manipulate these models for various procedures. However, they are fragile, susceptible to wear and tear, and require physical storage space, which can be cumbersome.

Digital Models: These are created using intraoral scanners and specialized software. Digital models offer several advantages, including enhanced precision, ease of storage, and seamless integration with other digital dental tools. They allow for quick modifications and simulate treatment outcomes efficiently. The downside includes high initial costs and the need for technical proficiency to operate the software and equipment.

3D Printed Models: Bridging the gap between physical and digital, these models are printed using various materials like resin or plastic. They offer the tactile benefits of gypsum models along with the precision and modifiability of digital ones. 3D printed models are durable and can be produced rapidly. However, the cost of 3D printers and materials, as well as ongoing maintenance, can be substantial. Additionally, the quality of the print can vary depending on the printer used.

In comparative terms, gypsum models excel in simplicity and low cost, digital models lead in precision and storage efficiency, and 3D printed models combine physical and digital benefits, albeit at a higher operational cost. The choice between these models largely depends on the specific needs of the dental practice, budget, and desired outcomes.

“dental models” Warranty and Support

Our dental models come with a comprehensive one-year warranty, ensuring that you receive a product free from manufacturing defects. Should any issues arise due to workmanship or materials within this period, we will repair or replace the item at no extra cost. Please note that the warranty does not cover damages resulting from misuse, mishandling, or unauthorized alterations.

To initiate a warranty claim, contact our customer support team with your proof of purchase and a detailed description of the issue. Our team will guide you through the claim process, ensuring minimal disruption to your practice.

Beyond the warranty period, we offer robust support services to help you maintain and maximize the lifespan of your dental models. Our dedicated support team is available via phone, email, and live chat to assist with any technical or usage queries. Additionally, we provide a range of resources, including user manuals, troubleshooting guides, and instructional videos, available on our website.

For professional assistance, we offer maintenance and repair services at competitive rates. These services are designed to keep your dental models in optimal condition, minimizing downtime and ensuring they remain reliable tools in your practice.

We are committed to ensuring your complete satisfaction with our dental models and support services. For any inquiries or assistance, please don’t hesitate to contact us. Our goal is to provide you with the highest quality products and support to enhance your practice’s efficiency and patient care.

List “dental models” FAQ

Dental Models FAQ

1. What are dental models?

Dental models are replicas of a patient’s teeth and gums used by dental professionals for diagnosis, treatment planning, and patient education. They are typically made from materials like plaster, stone, or digital compositions via 3D printing.

2. How are dental models created?

Traditionally, dental impressions using alginate or silicone materials are taken to cast a model. Alternatively, digital models can be created using intraoral scanners.

3. What are the advantages of digital dental models?

Digital models offer higher accuracy, easier storage, and enhanced manipulation for simulations. They facilitate efficient communication between dental professionals and laboratories.

4. How accurate are dental models?

High-quality dental models, whether traditional or digital, are generally accurate enough for most dental applications, including orthodontics, prosthodontics, and surgical planning.

5. How are dental models used in orthodontics?

Orthodontists use dental models to diagnose alignment issues, plan treatment strategies, and monitor progress throughout orthodontic procedures.

6. Can dental models help in restorative dentistry?

Yes, they play a crucial role in fabricating crowns, bridges, dentures, and other restorative devices by providing a precise representation of the patient’s oral anatomy.

7. Are dental models reusable?

Traditional models are not reusable once destroyed or altered. However, digital models can be stored indefinitely and reprinted or modified as needed.

8. How do dental models assist in patient communication?

They serve as educational tools to visually explain issues, proposed treatments, and expected outcomes, thereby improving patient understanding and acceptance of treatment plans.

9. What is the difference between a diagnostic and a study model?

A diagnostic model is used to analyze existing conditions, while a study model allows detailed examination and planning of future treatments.

10. What are the limitations of dental models?

Traditional models can be prone to errors due to material shrinkage or inaccuracies in impression-taking, whereas digital models require high initial investment in technology and training.

Top 10 FAQ with answer about dental models for Buyer Sourcing from China

1. What are dental models used for?

Dental models are used for diagnostic purposes, creating treatment plans, patient education, and fabricating dental prosthetics such as crowns, bridges, dentures, and orthodontic appliances.

2. What materials are commonly used in dental models?

Dental models are typically made from plaster, stone, or resin. Advanced models may use CAD/CAM technology with materials like PMMA, zirconia, or polymers.

3. What types of dental models can be sourced from China?

China manufactures a variety of dental models, including diagnostic models, teaching and training models, orthodontic models, implant models, and simulation models for practice.

4. How do I ensure the quality of dental models from China?

Verify the suppliers’ certifications such as ISO, CE, and FDA. Request samples and assess reviews or feedback from other buyers. Quality inspections by third-party agencies can also be valuable.

5. What is the usual lead time for bulk orders?

Lead times can vary based on the supplier and the complexity of the order, but typically range from 2 to 6 weeks. Always confirm this with your supplier upfront.

6. Are customization options available?

Yes, many Chinese suppliers offer customization based on dental laboratories’ or educational institutions’ specific needs, including custom shapes, sizes, and materials.

7. What about intellectual property protection?

Choose a reputed supplier with strict IP protection measures. Work with legal professionals to secure agreements that safeguard your designs and innovations.

8. What are the shipping options?

Suppliers usually offer multiple shipping options including air freight, sea freight, and express delivery. The choice depends on the budget and urgency of the order.

9. How is pricing determined?

Pricing depends on the material, complexity, quantity, and customization requirements of the dental models. Getting quotes from multiple suppliers can help in making cost-effective decisions.

10. Any tips for building a strong supplier relationship?

Communicate clearly, provide detailed specifications, place regular orders, and give prompt feedback. Building a relationship based on trust and mutual benefit fosters better business outcomes.