dental suction unit Safety Certifications

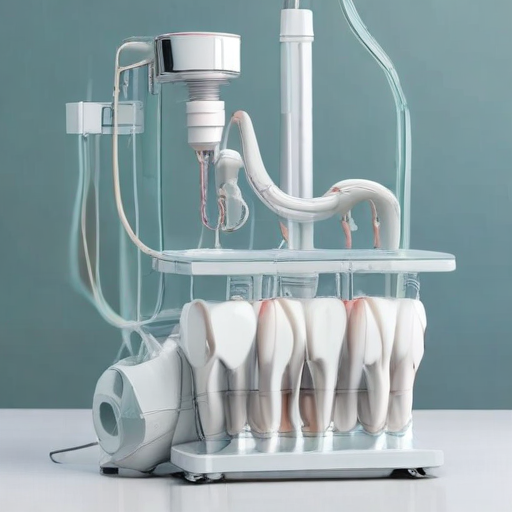

Dental suction units, essential for maintaining a clean and safe oral environment, must adhere to several safety certifications to ensure their effective and safe operation. These certifications affirm that the equipment meets stringent safety, performance, and quality standards. Key safety certifications for dental suction units include:

1. FDA (Food and Drug Administration): In the United States, dental suction units need approval from the FDA, ensuring they meet health and safety regulations for medical devices.

2. CE Marking (Conformité Européenne): Required in the European Economic Area, CE marking indicates that the dental suction unit complies with essential health, safety, and environmental protection standards within the region.

3. ISO (International Organization for Standardization) Certifications:

– ISO 9001: This certification attests to a quality management system that consistently provides products meeting customer and regulatory requirements.

– ISO 13485: Specifically for medical devices, this standard ensures that the dental suction unit meets comprehensive quality management requirements.

– ISO 9001: Certification for effective environmental management systems, ensuring environmentally responsible production and operational processes.

4. UL Certification (Underwriters Laboratories): In North America, UL certification indicates that the dental suction unit has been tested for safety and meets national safety standards.

5. CSA (Canadian Standards Association): Similar to UL, CSA certification ensures that the dental suction unit meets the safety standards specific to Canada.

6. ETL (Intertek): An alternative to UL and CSA, ETL certification also signifies that the equipment complies with North America’s safety standards.

Ensuring compliance with these safety certifications is crucial for dental professionals to guarantee safe, reliable, and efficient operation. These certifications not only safeguard patients and practitioners but also enhance the overall trust and reliability in dental care services.

List Reference Technical Parameters of “dental suction unit”

Sure, here are the reference technical parameters for a dental suction unit:

1. Flow Rate:

– Measurement: Liters per minute (L/min) or cubic meters per hour (m³/h)

– Standard: 300-600 L/min (depending on unit size)

2. Vacuum Pressure:

– Measurement: Kilopascals (kPa) or inches of mercury (inHg)

– Standard: 10-30 kPa or 100-200 mmHg

3. Motor Power:

– Measurement: Watts (W) or horsepower (HP)

– Standard: 300-700 W or 0.4-1 HP

4. Noise Level:

– Measurement: Decibels (dB)

– Standard: 50-70 dB

5. Tank Capacity:

– Measurement: Liters (L)

– Standard: 1-3 L

6. Filtration System:

– Includes: Primary filters, HEPA filters

– Efficiency: HEPA filters ≥ 99.97% for particles ≥ 0.3 microns

7. Air-Water Separation:

– Measurement: Efficiency rating or specific technology (e.g., cyclone separator)

– Standard: High efficiency (specifics depend on manufacturer)

8. Tubing Length and Diameter:

– Length: 1-3 meters (m)

– Diameter: 6-12 millimeters (mm)

9. Drainage System:

– Type: Manual or automatic

– Features: Anti-backflow devices

10. Power Supply:

– Voltage: 110V/220V

– Frequency: 50Hz/60Hz

11. Dimensions and Weight:

– Measurement: Centimeters (cm) or inches (in)

– Standard Dimensions: 40 x 30 x 60 cm (L x W x H)

– Weight: 10-30 kilograms (kg)

12. Safety Standards:

– Compliance: CE, FDA, ISO

– Protection: Electrical safety (IP rating)

These parameters are critical for ensuring that the dental suction unit operates effectively and safely, meeting the requirements of dental practices. Specific models may vary, so it is essential to consult the manufacturer’s specifications for precise details.

List Product features of “dental suction unit”

A dental suction unit is an essential device in any dental clinic, providing critical functionality to ensure a clean and hygienic environment during dental procedures. Here are some key features of a dental suction unit:

1. High Suction Power: Efficiently removes saliva, blood, and other debris from the patient’s mouth, ensuring a clear working area for the dentist.

2. Low Noise Operation: Designed to operate quietly to maintain a calm and stress-free environment for both patients and dental practitioners.

3. Adjustable Suction Levels: Allows customizable suction pressure to suit different dental procedures and patient comfort levels.

4. Compact and Portable Design: Typically lightweight and easy to move, making it suitable for clinics with limited space and for use in multiple treatment rooms.

5. Ergonomic Handpieces: Equipped with user-friendly handpieces that are easy to maneuver, providing better control and precision during procedures.

6. Anti-retraction Valves: Prevents backflow of fluids, thereby minimizing the risk of cross-contamination and infection.

7. Easy Maintenance: Features accessible components that can be quickly cleaned and maintained to ensure consistent performance and hygiene.

8. High-capacity Waste Container: Comes with a sufficiently large waste container to collect debris, reducing the frequency of emptying and thus enhancing workflow efficiency.

9. Replaceable Filters: Equipped with replaceable filters to trap fine particles and ensure clean operating conditions, protecting both patients and equipment.

10. Reliable Durability: Constructed from high-quality materials to ensure long-lasting performance and withstand regular use in a busy dental environment.

11. Compatibility: Designed to integrate seamlessly with other dental equipment and systems for a cohesive operational setup.

12. Safety Features: Includes safety mechanisms such as automatic shut-off in case of system overload or component failure to protect both the operator and the unit.

13. Warranty and Support: Often comes with a warranty and access to customer support services to assist with any operational issues or repairs needed.

These features collectively enhance the functionality, reliability, and efficiency of dental suction units, making them indispensable in modern dental practices.

List Various Types of “dental suction unit”

Certainly! Dental suction units are vital for maintaining a clear field of operation, controlling infection, and removing oral fluids during dental procedures. They come in various types, each serving distinct purposes:

1. High-Volume Evacuators (HVE)

– Usage: Primarily used during major dental procedures such as oral surgeries or extensive cleanings.

– Features: Provides strong suction to quickly remove large volumes of debris, saliva, and liquid from the mouth.

2. Low-Volume Suction (Saliva Ejectors)

– Usage: Commonly used in routine dental cleanings and minimally invasive procedures.

– Features: Offers gentler suction, ideal for continuous fluids removal without causing discomfort.

3. Portable Dental Suction Units

– Usage: Ideal for mobile dentistry or clinics with spatial constraints.

– Features: Lightweight, compact, and typically battery-operated or built with rechargeable units.

4. Centralized Dental Suction Systems

– Usage: Used in larger dental practices with multiple operatories.

– Features: A centralized system that connects several dental chairs to one powerful vacuum system.

5. Dry Dental Suction Units

– Usage: Suited for practices aiming to reduce water usage.

– Features: Utilizes air to create suction, eliminating the need for cooling water, resulting in eco-friendliness and reduced running costs.

6. Wet Dental Suction Units

– Usage: Commonly used in clinics where continuous, high-volume suction is required.

– Features: Employs water to cool the pump, providing continuous, reliable suction.

7. Noise-Reduced Suction Units

– Usage: Designed for practices prioritizing a quieter environment.

– Features: Incorporates noise-reducing technologies to minimize acoustic disturbances during procedures.

Selecting the right dental suction unit depends on the specific needs of the practice, including the type of procedures performed, mobility requirements, and environmental considerations. Each type offers distinct advantages to ensure efficient and effective dental care.

List Application of “dental suction unit”

A dental suction unit is an essential tool in modern dentistry, with diverse applications critical for both patient comfort and procedural efficiency. Here are some primary uses:

1. Saliva Management: Dental suction units are crucial in keeping the operative field dry by continuously removing saliva. This allows dentists to work with better visibility and precision.

2. Blood and Debris Removal: During procedures like tooth extractions, root canals, or gum surgeries, these units remove blood, tissue fragments, and dental debris, maintaining a clean area and reducing the risk of infection.

3. Aerosol and Droplet Mitigation: Suction units help in minimizing aerosol and droplet spread, which is particularly important for infection control, especially highlighted during the COVID-19 pandemic.

4. Patient Comfort: By keeping the mouth clear of excess fluids, dental suction units ensure that patients remain more comfortable and can avoid the unpleasant sensation of choking or gagging.

5. Enhanced Visibility and Precision: A clear operative field allows better visibility, aiding in more precise dental work, whether it involves restorations, fillings, or cosmetic procedures.

6. Dry Working Conditions for Materials: Many dental materials, such as composite resins, require dry conditions for optimal bonding and setting. Suction units help achieve these conditions.

7. Emergency Situations: In emergency scenarios like managing excessive bleeding or preventing aspiration of foreign objects, dental suction units are vital.

8. Orthodontic Procedures: For procedures like bracket application and adjustment, maintaining a dry field is imperative for adhesive effectiveness, which suction units facilitate.

9. Endodontics: During root canal treatments, keeping the canal dry and free from saliva and blood enhances procedural success and patient outcomes.

10. Periodontics: During periodontal treatments and surgeries, suction units are essential for removing blood and maintaining visibility.

In essence, dental suction units play a pivotal role in ensuring cleanliness, visibility, patient comfort, and overall procedure efficiency in dental practices.

List Buyer Types of “dental suction unit”

Certainly! Here are the primary buyer types for a “dental suction unit”:

1. Dental Clinics: General and specialized dental practices require dental suction units for routine procedures such as cleanings, fillings, and surgeries.

2. Dental Hospitals: Larger healthcare facilities that offer specialized and complex dental treatments often invest in high-capacity suction units to cater to multiple patients simultaneously.

3. Orthodontic Practices: Specialists in orthodontics need suction units for various treatments, including braces adjustments and other oral appliance fittings, ensuring a clean and dry working environment.

4. Oral and Maxillofacial Surgeons: These surgeons perform intricate dental surgeries, requiring powerful suction units to manage fluids effectively during procedures.

5. Pediatric Dentists: Dental suction units in pediatric settings must often be quieter and less intimidating for young patients. These buyers prioritize units that cater to the unique needs of children.

6. Veterinary Dental Clinics: Veterinary practices that offer dental care for pets also invest in specialized dental suction units designed for animals.

7. Dental Schools and Training Centers: Institutions that provide dental education and training invest in multiple suction units for student practice and clinical demonstrations.

8. Public Health Clinics: These clinics, often offering community-based dental services, require reliable and cost-effective suction units to serve a wide patient demographic.

9. Mobile Dental Units: Services that provide dental care in remote or underserved areas need portable and durable suction units that can operate efficiently in various environments.

10. Dental Equipment Distributors and Retailers: Businesses that sell dental equipment purchase suction units to resell to the above demographics. They focus on a range of options to meet different buyer needs.

List “dental suction unit” Project Types for Different Industries

Sure, here are some project types involving dental suction units across different industries:

Healthcare Industry

1. Dental Clinics Setup and Renovation:

– Installation of advanced dental suction units to improve patient care.

– Retrofit older clinics with energy-efficient and quieter suction systems.

2. Hospital Dental Departments:

– Integrating centralized suction systems in new hospital wings.

– Upgrading existing systems for better infection control and efficiency.

Manufacturing Industry

1. Production of Dental Suction Units:

– Development of lightweight, portable suction units.

– Design and manufacture of eco-friendly, high-efficiency units.

2. Quality Assurance Projects:

– Implementation of rigorous testing processes to ensure product reliability.

– Compliance with international safety and hygiene standards.

Research and Development

1. Innovative Technologies:

– Exploring new materials for quieter operation and greater suction power.

– Developing AI-integrated suction units that adjust suction levels based on real-time needs.

2. Pilot Projects:

– Collaboration with dental professionals to test new prototypes.

– Gathering data for continuous improvement and refinement.

Education and Training

1. Dental School Programs:

– Equipping training labs with the latest suction technology.

– Offering hands-on workshops on maintenance and troubleshooting.

2. Online Training Modules:

– Development of digital resources for efficient use and care of dental suction units.

– Certification courses for dental technicians on suction unit installation and repair.

Sales and Marketing

1. Market Research:

– Identifying market needs and trends for targeted product development.

– Conducting surveys and focus groups to refine product features.

2. Promotional Campaigns:

– Launching new dental suction units with educational events and webinars.

– Showcasing products at dental conferences and trade shows.

Environmental Impact

1. Sustainability Projects:

– Researching and implementing sustainable materials in production.

– Developing recycling programs for outdated suction units.

2. Energy Efficiency Upgrades:

– Retrofitting existing units with energy-saving technologies.

– Educating dental practices on reducing energy consumption.

These project types illustrate the diverse applications and developmental possibilities for dental suction units across various industries.

dental suction unit Accessories Upgrades and Custom Manufacturing Options

Upgrading and customizing dental suction units can significantly enhance their efficiency, functionality, and hygiene. Various accessories and custom manufacturing options are available to meet the specific needs of dental practices.

Accessories:

1. High-Efficiency Filters: Upgrade to HEPA or ULPA filters for enhanced infection control by trapping airborne contaminants more effectively.

2. Ergonomic Handles and Nozzles: Improve user comfort with ergonomically designed handles and nozzles that reduce strain during prolonged procedures.

3. Silencers: Add silencers to reduce operational noise, creating a more patient-friendly environment.

4. Disposable Suction Tips: Offer better hygiene and reduce cross-contamination risks by using single-use, disposable tips.

5. Collection Jars and Separators: Integrate amalgam separators and large-capacity collection jars for better waste management and compliance with environmental regulations.

6. Adjustable Pressure Settings: Incorporate adjustable suction pressure settings for more precise control during different dental procedures.

7. Anti-Backflow Valves: Ensure better infection control by preventing contaminated material from flowing back into the system.

Custom Manufacturing Options:

1. Compact Designs: Opt for custom-sized units to fit the spatial constraints of various dental office layouts.

2. Portability Enhancements: Add wheels or handle options for easy movement between treatment rooms.

3. Material Customization: Utilize high-quality, durable materials like stainless steel or advanced polymers to enhance longevity.

4. Integration with Dental Chairs: Customize units to seamlessly integrate with specific dental chair models and existing equipment setups.

5. Advanced Control Panels: Develop touch-screen control panels or wireless remote controls for more intuitive operation.

6. Color and Branding: Customize colors and add logo branding to match the aesthetic of the dental practice.

7. Enhanced Suction Capability: Tailor suction power to meet the demands of high-volume dental practices or specialized procedures.

Investing in these accessories and custom manufacturing options can lead to improved operational efficiency, patient comfort, and overall dental care quality.

List Quality Control and The Manufacturing Process of “dental suction unit”

Quality Control of Dental Suction Unit:

1. Raw Material Inspection:

* Verify materials for compliance with specifications.

* Test for durability, non-toxicity, and biocompatibility.

2. In-Process Checks:

* Continuous monitoring during assembly to detect defects early.

* Calibration of instruments used in production.

3. Performance Testing:

* Check suction power and efficiency.

* Test noise levels to ensure minimal disruption.

4. Electrical Safety:

* Conduct electrical safety tests to ensure compliance with standards.

* Inspect all electrical connections and components.

5. Final Inspection:

* Visual check for physical defects.

* Ensure all parts are correctly assembled and secured.

6. Sterilization Validation:

* Test for the unit’s ability to withstand sterilization processes.

* Ensure no degradation or malfunction post-sterilization.

7. Documentation:

* Maintain detailed records of inspections and tests.

* Traceability of all components and processes.

Manufacturing Process of Dental Suction Unit:

1. Design and Engineering:

* Create detailed designs and specifications.

* Develop prototypes for initial testing and feedback.

2. Material Sourcing:

* Procure raw materials and components like motors, filters, and tubing.

* Ensure all materials meet regulatory and safety standards.

3. Component Fabrication:

* Manufacture components using precise machining and forming processes.

* Use CNC machines for accuracy.

4. Assembly:

* Assemble individual components following strict guidelines.

* Integrate motors, control systems, and suction mechanisms.

5. Electrical Integration:

* Install and wire electrical components.

* Ensure proper insulation and shielding.

6. Testing and Calibration:

* Perform rigorous testing of the assembled unit for functionality and safety.

* Calibrate settings according to specifications.

7. Quality Control Checks:

* Conduct thorough inspections and tests as outlined in the quality control protocols.

* Address and rectify any issues immediately.

8. Packaging and Sterilization:

* Pack the units in sterile, tamper-proof packaging.

* Label and include necessary documentation and user manuals.

9. Distribution:

* Ship the final products to distributors or directly to dental practices.

* Ensure compliance with transportation and storage conditions.

How to use “dental suction unit”

Using a dental suction unit effectively is crucial for maintaining a clear and dry workspace during dental procedures. Here are the steps to operate a dental suction unit:

1. Preparation:

– Ensure the dental suction unit is clean and sterilized.

– Verify that all parts are correctly assembled and functioning.

– Check the suction levels and adjust according to the specific procedure.

2. Positioning:

– Seat the patient comfortably and adjust the chair to an ergonomic position.

– Position the suction tip or hose close to the area being worked on but not obstructing the view or access.

3. Operation:

– Turn on the suction unit to the appropriate power setting.

– Use the suction tip to remove saliva, blood, and debris from the patient’s mouth.

– Continuously move the suction tip around the treatment area to keep it clear.

4. Techniques:

– High-volume (HVE): Use high-volume suction for procedures generating significant debris, like drilling and extractions. Position it adjacent to the treated tooth for optimal efficiency.

– Low-volume (saliva ejector): Utilize low-volume units for routine cleaning or minor procedures. Place it at the corner of the mouth to manage saliva buildup.

5. Maintenance:

– Regularly clean and disinfect the suction tips and hoses.

– Perform scheduled maintenance checks to ensure the unit functions smoothly.

6. Safety:

– Be mindful of not causing discomfort to the patient.

– Use gentle suction and avoid prolonged contact with soft tissues to prevent injuries.

By following these steps, you can efficiently manage oral fluids and debris, ensuring a smoother workflow and better patient care.

“dental suction unit” Comparative Analysis

Dental suction units are essential tools in dental practices, crucial for maintaining a clean and dry oral environment during procedures. Here is a comparative analysis of two common types: high-volume evacuators (HVE) and saliva ejectors.

High-Volume Evacuators (HVE)

– Suction Power: HVEs have substantial suction power, capable of removing large volumes of fluids, debris, and aerosols. This makes them ideal for a wide range of dental procedures including surgeries and restorations.

– Infection Control: The strong suction provided by HVEs significantly reduces the risk of aerosol contamination, thus enhancing infection control.

– Patient Comfort: Although efficient, the high suction power can sometimes be uncomfortable for patients due to the noise and the sensation caused by strong vacuum pressure.

– Efficiency: HVEs are time-efficient, quickly clearing the operative field, which can contribute to shorter procedure times.

Saliva Ejectors

– Suction Power: Saliva ejectors offer mild suction, designed primarily to remove saliva and excess fluid from the mouth. They are not equipped to handle large debris.

– Use Case: These units are suitable for less intensive procedures, such as preventive care and minor restorative work.

– Patient Comfort: Saliva ejectors are generally more comfortable for patients due to their gentle suction. They are quieter and less intrusive than HVEs.

– Infection Control: While helpful, saliva ejectors are less effective in minimizing aerosol spread compared to HVEs. This could pose a higher risk in procedures producing significant aerosols.

Summary

In summary, high-volume evacuators are superior for procedures requiring rigorous suction and improved infection control but may sacrifice some patient comfort. They are essential in high-stakes, debris-intensive treatments. Conversely, saliva ejectors provide gentle suction suitable for less intensive tasks, ensuring more patient comfort at the expense of lower efficiency and aerosol control. Practices must select the appropriate unit based on the nature of the procedure, patient needs, and infection control priorities.

“dental suction unit” Warranty and Support

Warranty and Support for Dental Suction Unit

The dental suction unit is covered under a comprehensive warranty designed to provide peace of mind and ensure optimal performance. The standard warranty period is typically one year from the date of purchase, which covers any defects in materials or workmanship. During this period, any malfunctioning parts will be repaired or replaced free of charge. To initiate a warranty claim, customers must provide proof of purchase and may need to return the unit to an authorized service center.

Extended warranty options are often available, offering coverage beyond the initial period for an additional fee. This may include regular maintenance checks, replacement parts, and even emergency service visits as needed. Customers are encouraged to register their unit immediately after purchase to activate the warranty and receive updates on maintenance tips and product recalls.

Support services for the dental suction unit are robust, ensuring that both technical and operational issues are promptly addressed. A dedicated customer service hotline operates during regular business hours, providing immediate assistance. Additionally, an online support portal is available 24/7, featuring a comprehensive FAQ section, troubleshooting guides, and instructional videos. For more complex issues, live chat or email support can connect you with experienced technicians who can provide detailed assistance or schedule on-site service visits.

Routine maintenance programs are highly recommended and may be part of the extended warranty package. These programs include regular inspections, cleaning, and replacement of consumable items to ensure the unit operates at peak efficiency.

Additional training resources, such as user manuals and video tutorials, are readily available to ensure that dental professionals can operate the unit safely and effectively.

By combining a comprehensive warranty and robust support services, customers can rely on their dental suction unit to perform consistently and efficiently.

List “dental suction unit” FAQ

Dental Suction Unit FAQs

1. What is a dental suction unit?

A dental suction unit is a device used in dental procedures to remove saliva, blood, debris, and other fluids from the patient’s mouth, ensuring a clear working area for the dentist.

2. Why is a dental suction unit important?

It helps maintain a clean and dry oral environment, enhances visibility for the dentist, and improves patient comfort during procedures.

3. How does a dental suction unit work?

The unit generates a vacuum that draws fluids through a suction tip or hose, which are then collected in a container for easy disposal.

4. Are there different types of dental suction units?

Yes, there are two main types: high-volume evacuation (HVE) systems for larger debris and fluids, and saliva ejectors for lighter tasks like removing saliva.

5. Can dental suction units handle biohazardous waste?

Yes, most units are designed to safely handle biohazardous waste, but proper disposal protocols must be followed.

6. How often should the dental suction unit be maintained?

Routine maintenance, including cleaning and filter changes, should be performed daily. Consult the manufacturer’s guidelines for specific maintenance schedules.

7. Are dental suction units noisy?

Noise levels can vary by model, but many modern units are designed to operate quietly to enhance patient comfort.

8. Can dental suction units be used with all patients?

While generally safe for most patients, special considerations may be needed for those with certain medical conditions. Always consult patient history and medical advice.

9. How do I choose the right dental suction unit?

Consider factors like the type of procedures you perform, suction power, noise level, ease of maintenance, and budget.

10. Is training required to operate a dental suction unit?

Basic training is usually necessary to ensure safe and effective use, covering operation, maintenance, and emergency procedures.

11. Can dental suction units be sterilized?

Parts that come into contact with the mouth often need to be sterilized or use disposable components. Check the manufacturer’s guidelines for specific cleaning instructions.

Maintaining and properly using a dental suction unit is crucial for effective dental care and patient safety.

Top 10 FAQ with answer about dental suction unit for Buyer Sourcing from China

1. What is a dental suction unit?

A dental suction unit is a device used in dental practices to remove saliva, blood, debris, and other fluids from a patient’s mouth during procedures.

2. Why source dental suction units from China?

China offers competitive pricing, a wide range of options, rapid innovation, and numerous manufacturers with a global reputation for quality and reliability.

3. What standards should I ensure the unit meets?

Ensure the unit complies with international standards like ISO 13485, CE (Europe), and FDA (USA) to guarantee safety and performance.

4. How do I verify the credibility of suppliers?

Verify through platforms like Alibaba with manufacturer certifications, customer reviews, and by requesting samples. Visiting the factory or using third-party inspection services also helps.

5. What types of dental suction units are available?

There are mainly two types: high-volume evacuators (HVE) and saliva ejectors. HVE units remove larger amounts of debris rapidly, while saliva ejectors handle smaller volumes.

6. What should be considered regarding power and maintenance?

Check power requirements compatible with your country and inquire about maintenance frequency, ease of servicing, and availability of spare parts.

7. What is the typical lead time for orders?

Lead times vary; however, expect 2-4 weeks for standard units. Custom orders or larger quantities might take longer.

8. Are there options for customization?

Many manufacturers offer customization regarding branding, specification adjustments, and features. Discuss specific needs with the supplier.

9. What are the common payment terms?

Payment terms commonly include T/T (Telegraphic Transfer), L/C (Letter of Credit), PayPal, or Western Union. Negotiate favorable terms while ensuring security for both parties.

10. How is shipping and logistics handled?

Suppliers often handle shipping and logistics through arranged freight forwarders. Ensure insurance and track are included. Consider CIF (Cost, Insurance, and Freight) or FOB (Free on Board) terms for clarity in responsibilities.

Sourcing dental suction units from China can offer great benefits if navigated thoughtfully with a clear understanding of the process.