drainage pipes Safety Certifications

Drainage pipes are critical components in both residential and commercial plumbing systems. Ensuring their safety and efficiency is paramount, and this is achieved through various certifications and standards. Here are some key safety certifications for drainage pipes:

1. NSF/ANSI Standard 61: This certification, provided by the National Sanitation Foundation (NSF) and the American National Standards Institute (ANSI), ensures that the materials used in the pipes do not leach harmful substances into the water, maintaining safety for potable water applications.

2. ASTM Standards: The American Society for Testing and Materials (ASTM) develops international voluntary consensus standards. ASTM D1785 and ASTM D2729 are commonly referenced standards for polyvinyl chloride (PVC) pipes, focusing on dimensions, material properties, and quality to ensure safe operation.

3. ISO Certifications: The International Organization for Standardization (ISO) offers guidelines such as ISO 9001 and ISO 14001 for quality management and environmental management systems, underscoring the overall reliability and sustainability of the drainage products.

4. UPC/IPC Compliance: The Uniform Plumbing Code (UPC) and International Plumbing Code (IPC) are model codes that drive the performance and safety of plumbing systems. Compliance with these codes indicates that the drainage pipes meet rigorous safety and performance criteria.

5. Local and National Building Codes: Building codes vary by region but typically include specific requirements for drainage pipes to ensure they are designed and installed to prevent leaks, burst pipes, and contamination.

6. Lead-Free Certification: Especially important for potable water systems, lead-free certifications ensure that pipes and fittings contain minimal lead content, adhering to standards such as the Reduction of Lead in Drinking Water Act in the United States.

These certifications collectively ensure that drainage pipes are safe for use, durable, and environmentally friendly, safeguarding both public health and the environment. Always look for these marks of assurance when selecting drainage piping systems for any building project.

List Reference Technical Parameters of “drainage pipes”

Drainage pipes are integral components of plumbing and civil engineering projects, designed to remove excess water and waste efficiently. Here are some key technical parameters to consider:

1. Material Composition: Common materials include Polyvinyl Chloride (PVC), High-Density Polyethylene (HDPE), Cast Iron, and Concrete. The choice affects durability, weight, cost, and chemical resistance.

2. Diameter: Pipe diameters vary based on application, from small residential pipes (around 100mm) to large municipal drainage systems (up to 2000mm or more). Proper sizing ensures efficient flow and prevents blockages.

3. Wall Thickness: Typically determined by the piping schedule or class, wall thickness impacts the pipe’s pressure rating and structural integrity. Thicker walls can handle higher pressures and provide better durability.

4. Pressure Rating: Measured in pounds per square inch (PSI) or bar, the pressure rating indicates the maximum internal pressure the pipe can withstand. It’s critical for applications involving pressurized systems.

5. Flow Rate: Flow rate capacity, usually measured in liters per second (L/s) or gallons per minute (GPM), depends on pipe diameter, slope, and friction losses. Accurate prediction ensures adequate drainage without overflow.

6. Slope/Gradient: A minimal slope is necessary to facilitate gravity-driven flow. Typical gradients range from 1:100 to 1:400, where steeper slopes allow faster water movement.

7. Joint Types: Different joining methods like solvent welding, gasket sealing, and mechanical couplings affect installation time and leak resistance. Each type suits specific installation contexts and material choices.

8. Corrosion Resistance: Depending on the application (e.g., industrial waste), selecting materials resistant to chemical corrosion extends the lifespan of the drainage system.

9. Flexibility: Flexible pipes such as HDPE can absorb ground movements without cracking, essential in areas prone to seismic activity or heavy traffic loads.

10. Installation Depth: Pipes must be installed at appropriate depths to prevent damage from surface loads. The surrounding soil’s type and compaction affect the necessary installation depth.

In consideration of these parameters, selecting the right drainage pipe ensures system efficiency, longevity, and cost-effectiveness.

List Product features of “drainage pipes”

1. Material Variety: Drainage pipes come in a variety of materials such as PVC, HDPE, concrete, and clay, each offering specific advantages like cost-efficiency, durability, and environmental resilience.

2. Durability: Designed to withstand various loads and environmental conditions, drainage pipes are resistant to corrosion, chemicals, and UV radiation, ensuring long-term performance.

3. Diameter and Length Options: Available in multiple diameters and lengths to suit different applications, from residential lawns to large-scale commercial drainage systems.

4. Perforation Options: These pipes can be non-perforated for solid waste transport or perforated for efficient water drainage, preventing waterlogging and soil erosion.

5. Easy Installation: Lightweight materials, convenient joint systems, and flexible design make these pipes easy to install, reducing labor costs and installation time.

6. Smooth Interior Surface: A smooth internal surface minimizes friction, ensuring efficient flow and reducing the risk of clogs.

7. Flexibility: Some drainage pipes, particularly those made of plastic, offer flexibility, making them suitable for uneven terrains and bending around obstacles.

8. Compatibility: Designed to work seamlessly with various fittings, connectors, and other drainage system components, ensuring a coherent and efficient drainage network.

9. Environmental Resilience: Ability to function effectively in diverse environmental conditions, including extreme temperatures and high moisture areas.

10. Load-Bearing Capacity: Different grades are available to withstand various weight loads, from pedestrian areas to heavy traffic zones.

11. Cost-Effective: Long lifespan, minimal maintenance requirements, and easy installation contribute to overall cost savings.

12. Regulatory Compliance: Manufactured to meet national and international standards, ensuring safety and performance across applications.

13. Customization: Can be tailored to specific project requirements, including custom lengths, perforation patterns, and material composition.

14. Leak-proof Design: Advanced sealing mechanisms and joints ensure a leak-proof operation, crucial for preventing soil contamination and ensuring efficient drainage.

List Various Types of “drainage pipes”

Certainly! Here are some common types of drainage pipes:

1. PVC (Polyvinyl Chloride) Pipes:

– Lightweight and easy to install.

– High resistance to chemicals and corrosion.

– Commonly used in residential and commercial drainage applications.

2. CPVC (Chlorinated Polyvinyl Chloride) Pipes:

– Similar to PVC but can withstand higher temperatures.

– Often used in hot water drainage systems.

3. HDPE (High-Density Polyethylene) Pipes:

– Flexible and durable.

– Resistant to chemicals and environmental stress.

– Suitable for both above-ground and underground drainage systems.

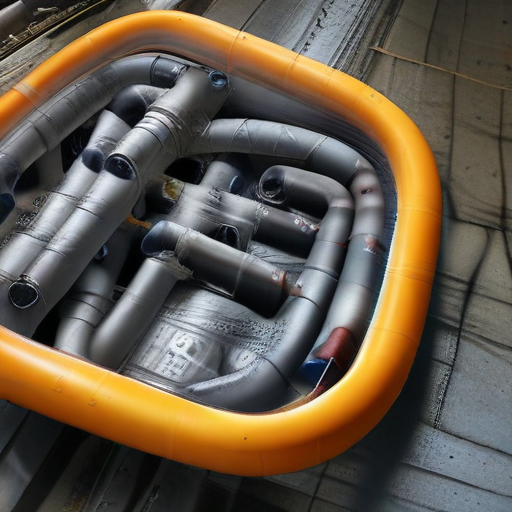

4. Cast Iron Pipes:

– Extremely durable and long-lasting.

– Good for sound attenuation.

– Common in older buildings and municipal applications.

5. Concrete Pipes:

– Very robust and strong.

– Often used in large-scale drainage systems such as stormwater management.

– Heavy and require machinery for installation.

6. Clay Pipes:

– Resistant to chemical corrosion.

– Often used in sewer systems.

– Brittle and heavy, requiring careful handling.

7. Copper Pipes:

– Highly durable and resistant to bacterial growth.

– Used in high-end residential and commercial drainage systems.

– Expensive compared to other options.

8. ABS (Acrylonitrile Butadiene Styrene) Pipes:

– Lightweight and easy to install.

– Good for residential drainage systems.

– Less chemically resistant than PVC.

9. Galvanized Steel Pipes:

– Coated with a layer of zinc to prevent rusting.

– Strong but can corrode over time.

– Often used in industrial applications.

10. Corrugated Plastic Pipes:

– Flexible and easy to install.

– Ideal for landscaping and agricultural drainage.

– Typically used for low-pressure applications.

Each type of drainage pipe has its own set of advantages and specific use cases, so the choice depends on the requirements of the drainage system and the conditions it will be exposed to.

List Application of “drainage pipes”

Drainage pipes are crucial components in various settings to efficiently manage and direct the flow of water and other fluids. Here are some key applications:

1. Residential Drainage:

– Rainwater Management: Drainage pipes are used to channel rainwater from roofs and pavements to prevent pooling and flooding.

– Sewage Systems: They transport wastewater from homes to septic tanks or municipal sewage systems.

2. Commercial and Industrial Use:

– Stormwater Drainage: Commercial buildings use these pipes to handle large volumes of stormwater, preventing waterlogging and structural damage.

– Industrial Wastewater Management: Factories and plants use specialized drainage systems to dispose of industrial effluents safely.

3. Agricultural Applications:

– Field Drainage: Subsurface drainage pipes help in lowering the water table in fields, ensuring crops get the right amount of water.

– Irrigation Systems: They are integral in distributing irrigation water to crops efficiently.

4. Infrastructure:

– Road and Highway Drainage: Drainage pipes along highways and roads prevent water accumulation which can lead to accidents and road damage.

– Railway Drainage Systems: Essential in keeping rail tracks dry and safe by channeling away water.

5. Landscape and Recreational Areas:

– Golf Courses and Parks: Efficient drainage ensures these areas remain usable and attractive, preventing waterlogging.

– Sports Fields: Drainage pipes keep playing fields dry and suitable for activities.

6. Flood Control Systems:

– Developing regions prone to flooding implement large-scale drainage networks to manage excessive rainfall and protect communities.

These applications highlight the versatility and necessity of drainage pipes in managing water and maintaining the integrity of various environments.

List Buyer Types of “drainage pipes”

When it comes to purchasing drainage pipes, various buyer types come into play, each with distinct needs and criteria. Here’s a concise list of the key buyer types for drainage pipes:

1. Construction Companies:

– Residential Builders: Focus on home construction projects, requiring drainage pipes for systems like sewer, stormwater, and wastewater management.

– Commercial Builders: Engage in larger-scale projects such as office buildings, shopping centers, and hotels, needing robust and often larger diameter pipes.

– Infrastructure Contractors: Specialize in public infrastructure projects like highways, bridges, and public utilities, typically requiring high-durability pipes that meet specific regulatory standards.

2. Municipalities and Government Agencies:

– These entities are involved in large-scale, public infrastructure projects like city-wide sewer systems, stormwater management projects, and public works. They often require drainage pipes that adhere to strict regulatory standards and can withstand heavy use and environmental factors.

3. Agricultural Sector:

– Farmers and agricultural businesses use drainage pipes for irrigation systems, field drainage, and managing water flow in agricultural lands. Their needs often include cost-effective solutions that can manage large volumes of water.

4. Industrial Clients:

– Factories and industrial plants needing drainage solutions for onsite water management, including waste disposal and processing water. These pipes must often resist chemicals and high temperatures, depending on the industrial processes involved.

5. Landscaping and Outdoor Construction Firms:

– These businesses focus on smaller-scale outdoor projects such as gardens, parks, golf courses, and other recreational areas. Their requirements typically revolve around managing surface water to prevent flooding and maintain aesthetics and functionality.

6. Individual Homeowners and DIY Enthusiasts:

– Those engaged in personal property improvements, tackling small-scale projects like garden drainage, driveways, and small residential utility projects. These buyers often seek user-friendly, easy-to-install solutions available in smaller quantities.

Understanding the diverse landscape of buyers helps manufacturers, retailers, and suppliers tailor their offerings to meet varying demand profiles effectively.

List “drainage pipes” Project Types for Different Industries

Drainage pipes play a crucial role across various industries, ensuring the effective removal and management of wastewater and other fluids. Below are the key project types involving drainage pipes categorized by industry:

1. Construction and Civil Engineering:

– Urban Stormwater Management: Installation of stormwater drainage systems in city infrastructure to prevent flooding.

– Residential and Commercial Buildings: Integration of drainage systems to manage sewage and rainwater.

– Road and Highway Projects: Roadside drainage and culvert systems to maintain road integrity and safety.

– Land Development: Drainage planning for new subdivisions and industrial parks.

2. Agriculture:

– Irrigation Systems: Implementation of sub-surface drainage pipes for efficient water use in fields.

– Field Drainage: Installation of field drainage systems to prevent waterlogging and enhance crop growth.

– Animal Waste Management: Design and installation of drainage pipes for waste removal in livestock farms.

3. Industrial and Manufacturing:

– Factory Floor Drainage: Systems to handle industrial wastewater and prevent floor flooding.

– Cooling Water Systems: Drainage systems for the removal of excess cooling water in manufacturing plants.

– Waste Treatment Plants: Networks of drainage pipes to carry wastewater to treatment facilities.

4. Mining:

– Pit and Underground Drainage: Installation of drainage systems to manage groundwater and surface water in mining sites.

– Tailings Management: Drainage infrastructure for tailings storage facilities to prevent contamination and manage waste.

5. Municipal and Utilities:

– Sewer Systems: Comprehensive sewer networks to collect and transport wastewater from communities.

– Water Treatment Facilities: Drainage solutions for the disposal of treated water and sludge.

6. Environmental Engineering:

– Wetland Restoration Projects: Installation of drainage pipes to control water levels and promote habitat suitability in restored wetlands.

– Erosion Control: Utilizing drainage systems to protect landscapes from erosion in conservation projects.

These project types illustrate the diverse applications of drainage pipes across industries, each tailored to their specific needs for fluid management and environmental sustainability.

drainage pipes Accessories Upgrades and Custom Manufacturing Options

When it comes to drainage pipes, selecting the right accessories and considering custom manufacturing options can significantly enhance system performance and longevity. Below are various upgrades and options for drainage pipes:

Accessories:

1. Couplings and Fittings: These are essential for joining pipes and allowing for alignment adjustments. High-quality, corrosion-resistant materials are recommended.

2. Filter Fabric: This is used to prevent soil and debris from clogging the drainage pipes, increasing the system’s efficiency and lifespan.

3. Catch Basins and Grates: These components collect and manage surface water, directing it into the drainage system. They are available in various sizes and materials to suit different applications.

4. Vents and Cleanouts: Easy access points for maintenance and cleaning, ensuring the system remains free-flowing and functional.

5. End Caps: These prevent material from entering the pipe system at the endpoints, maintaining the system integrity.

Upgrades:

1. Perforated Pipes: These are particularly useful in areas prone to standing water. They allow water to enter the pipe from multiple points, increasing drainage efficiency.

2. Dual-Layer Pipes: Pipes with an exterior corrugated layer and a smooth interior layer improve flow rates and durability.

3. Anti-Bacterial Coatings: These coatings help reduce microbial growth, extending the life of the pipes.

Custom Manufacturing Options:

1. Material Choice: Depending on application requirements, pipes can be manufactured from various materials such as PVC, HDPE, and cast iron. Each material offers specific advantages regarding durability, flexibility, and resistance to chemicals.

2. Custom Sizing: Tailor-made diameters and lengths to suit unique project requirements, ensuring a perfect fit and straightforward installation.

3. Specialized Designs: Custom designs, including bends, risers, and special inlet/outlet configurations, can address specific site challenges and enhance performance.

4. Reinforced Layers: Additional strength layers can be included for applications involving heavy loads or high pressures.

By carefully selecting the appropriate accessories and considering custom manufacturing options, you can create a drainage system that meets specific needs, ensuring efficiency and reliability.

List Quality Control and The Manufacturing Process of “drainage pipes”

Quality Control of Drainage Pipes

1. Raw Material Inspection:

– Check the quality of raw materials (PVC, HDPE, concrete) to ensure they meet industry standards.

– Verify certificates of compliance from suppliers.

2. Dimensional Accuracy:

– Measure pipe dimensions (diameter, thickness) using precise instruments like calipers and micrometers.

– Ensure conformity to specified tolerances.

3. Visual Inspection:

– Regularly inspect pipes for visual defects such as cracks, holes, or surface irregularities.

– Use automated cameras or manual checks for continuous assessment.

4. Hydrostatic Testing:

– Subject pipes to high-pressure water tests to check for leaks and structural integrity.

– Monitor for consistent pressure maintenance over a set period.

5. Flexibility and Impact Resistance:

– Test piping flexibility under stress and impact resistance to ensure durability.

– Employ standardized test methods such as drop tests or bending tests.

6. Joint and Seal Inspection:

– Assess the quality of joints and seals to ensure leak-proof connections.

– Perform pressure tests on joined sections.

Manufacturing Process of Drainage Pipes

1. Raw Material Preparation:

– Procure and prepare raw materials like PVC, HDPE granules, or concrete.

– Mix and treat materials to desired consistency and composition.

2. Extrusion/ Molding:

– For plastic pipes: use extrusion machines to shape heated plastic through a die to form continuous pipe lengths.

– For concrete pipes: pour concrete into molds and apply vibration to remove air pockets.

3. Cooling and Curing:

– Plastic pipes: pass extruded pipes through a cooling system (water bath or air cooling) to solidify.

– Concrete pipes: allow molded pipes to cure in controlled environments for strength gain.

4. Cutting and Finishing:

– Cut pipes to standardized lengths using precision saws.

– Smooth pipe ends and inspect finishes to ensure smooth connections.

5. Quality Testing:

– Perform all quality control tests as detailed above.

– Address any discrepancies or defects immediately.

6. Marking and Packaging:

– Mark pipes with relevant information (manufacturer, size, specifications).

– Bundle and palletize for safe transportation and storage.

By integrating stringent quality control measures and systematic manufacturing processes, the production of drainage pipes ensures high durability, reliability, and regulatory compliance.

How to use “drainage pipes”

Drainage pipes are essential components in managing water flow to prevent flooding and water damage. Here are steps on how to use them effectively:

1. Plan the System:

– Assessment: Determine areas prone to water accumulation by observing the land during and after rainfall.

– Design: Create a layout that directs water from these areas to a safe discharge point, like a storm drain or water body.

2. Choose Appropriate Pipes:

– Material: Common materials include PVC, corrugated plastic, and clay. PVC is durable and easy to install.

– Size: Ensure the diameter of the pipe matches the volume of water it needs to carry.

3. Excavation:

– Trenching: Dig trenches based on your design, ensuring they have a slight downward slope (usually 1-2% grade) for gravity-driven water flow.

4. Pipe Placement:

– Bedding: Lay a bed of gravel or sand at the bottom of the trench to cushion and support the pipe.

– Installation: Place the pipes in the trench, fitting them together securely. Ensure the slope is consistent.

5. Backfilling:

– Cover Pipes: Add a layer of gravel around and above the pipes to facilitate drainage.

– Final Cover: Use soil to fill the trench, restoring the surface.

6. Outlet Control:

– Discharge Area: Ensure that the end of the drainage system safely exits into a drainage ditch, storm sewer, or designated area to avoid erosion or flooding.

7. Maintenance:

– Inspect Regularly: Check for blockages, especially after heavy rain.

– Clean: Remove debris that may obstruct water flow.

By planning carefully, choosing the right materials, and ensuring proper installation and maintenance, drainage pipes will effectively manage water discharge and protect your property from water damage.

“drainage pipes” Comparative Analysis

Comparative Analysis of Drainage Pipes

Drainage pipes, essential for channeling wastewater and rainwater, come in various types, each with distinct characteristics, advantages, and disadvantages. The primary materials used are PVC (Polyvinyl Chloride), HDPE (High-Density Polyethylene), and concrete.

PVC Pipes:

– Advantages: Lightweight, easy to install, and resistant to corrosion and chemical damage. PVC pipes have smooth interiors, reducing friction and enhancing water flow.

– Disadvantages: Susceptible to UV degradation if exposed to sunlight for extended periods. While durable under normal conditions, they can become brittle in very low temperatures.

HDPE Pipes:

– Advantages: Highly flexible, making them ideal for areas susceptible to ground movement and earthquakes. They are corrosion-resistant and have a high chemical resistance. HDPE pipes are also more durable in extreme temperatures compared to PVC.

– Disadvantages: Installation requires specialized welding equipment, which can increase initial costs. Despite their flexibility, they might sag or deform over time when exposed to high temperatures.

Concrete Pipes:

– Advantages: Exceptional strength and durability, suitable for significant load-bearing environments. They have a long lifespan and can handle high pressures. Concrete pipes are often used for large-scale municipal projects.

– Disadvantages: Heavy and difficult to handle, leading to higher transportation and installation costs. Concrete is susceptible to chemical corrosion from acidic or alkaline environments, requiring protective linings in such cases.

In summary, PVC pipes are preferred for residential and light commercial drainage due to their ease of installation and cost-effectiveness. HDPE pipes are suitable for areas requiring flexibility or exposed to extreme conditions. Concrete pipes are optimal for large-scale infrastructure with heavy loads. Selection depends on specific project requirements, including environmental conditions, budget constraints, and intended application.

“drainage pipes” Warranty and Support

Warranty and Support for Drainage Pipes

At [Company Name], we stand by the quality and durability of our drainage pipes. Our products are backed by a comprehensive warranty and robust customer support to ensure your complete satisfaction.

Warranty Coverage

Our drainage pipes come with a standard [X-year] warranty from the date of purchase. This warranty covers defects in materials and workmanship under normal usage conditions. Should any issues arise, our warranty guarantees repair or replacement at no additional cost. Please retain your original receipt and any installation documentation for warranty claims.

Exclusions

The warranty does not cover damages resulting from improper installation, misuse, natural disasters, or chemical corrosion. Modifications or unauthorized repairs will void the warranty.

How to File a Claim

To file a warranty claim:

1. Contact our customer support via email or phone.

2. Provide proof of purchase, a detailed description of the problem, and photographs if available.

3. Our team will assess the issue and guide you through the next steps.

Customer Support

Our dedicated support team is available [Monday to Friday, 9 AM to 5 PM] to assist you with any inquiries or issues related to your drainage pipes. Whether it’s troubleshooting installation problems or providing maintenance tips, we are here to help.

Maintenance Tips

To extend the lifespan of your drainage pipes:

– Regularly inspect for blockages and clean as needed.

– Avoid disposing of harsh chemicals or large debris through the pipes.

– Follow the installation guidelines provided.

Choose [Company Name] for reliable drainage solutions backed by excellent warranty and support services. For more information, please contact us at [customer service number/email] or visit our website.

List “drainage pipes” FAQ

Drainage Pipes FAQ

1. What materials are commonly used for drainage pipes?

Drainage pipes are typically made from PVC (Polyvinyl Chloride), HDPE (High-Density Polyethylene), cast iron, and sometimes concrete. PVC and HDPE are popular due to their durability, flexibility, and resistance to chemicals.

2. How do I size a drainage pipe?

The size of a drainage pipe depends on the volume of water it needs to carry and the slope of the ground. It’s essential to calculate the flow rate and use sizing charts or consult a professional to determine the appropriate diameter.

3. Can drainage pipes be installed above ground?

Yes, drainage pipes can be installed above ground, but they must be protected from environmental factors such as UV radiation and physical impacts. Above-ground applications are less common and typically temporary.

4. How deep should drainage pipes be buried?

The depth varies based on local building codes, but generally, drainage pipes should be buried at least 18 to 24 inches below the ground surface. In colder climates, pipes should be placed below the frost line to prevent freezing.

5. How do I prevent drainage pipe clogs?

Use strainers or grates to keep debris out, ensure proper grading and slope, and regularly inspect and clean the pipes. Avoid planting trees or shrubs with aggressive root systems nearby.

6. How do I connect drainage pipes?

Use appropriate fittings like couplers, elbows, and tees. Ensure that the connections are secure and watertight using solvent cement for PVC pipes or compression fittings for other types.

7. Can I repair a damaged drainage pipe?

Yes, small cracks or holes can often be repaired using patch kits. For more significant damage, it may be necessary to cut out the affected section and replace it with a new piece of pipe.

8. What is the purpose of perforated drainage pipes?

Perforated pipes are used in drainage systems to allow water to seep into the pipe from the surrounding soil, helping to reduce flooding and manage groundwater levels effectively.

9. How do I maintain drainage pipes?

Routine inspection for clogs, damage, and proper flow is essential. Periodic cleaning using water jets or mechanical methods will help maintain efficiency.

10. Can I install drainage pipes myself, or should I hire a professional?

While simple systems can be DIY projects for those with the necessary skills, complex or large-scale drainage systems typically require professional installation to ensure proper function and compliance with local codes.

Top 10 FAQ with answer about drainage pipes for Buyer Sourcing from China

1. What materials are commonly used for drainage pipes in China?

– Common materials include PVC (Polyvinyl Chloride), HDPE (High-Density Polyethylene), cast iron, and concrete. PVC and HDPE are popular due to their affordability and durability.

2. Are Chinese drainage pipes compliant with international standards?

– Many Chinese manufacturers adhere to international standards such as ASTM, ISO, and EN. It is important to request certifications and verify compliance before purchasing.

3. What is the typical lead time for sourcing drainage pipes from China?

– Lead times can vary depending on order size and customization. Typically, it takes 30-60 days from order placement to delivery.

4. Can Chinese suppliers provide custom sizes and specifications?

– Yes, many suppliers offer customization services according to client specifications, including different diameters, lengths, and material grades.

5. What is the minimum order quantity (MOQ) for drainage pipes from Chinese manufacturers?

– MOQs typically range from 500 to 1,000 meters, but this can vary depending on the supplier and specific product.

6. How is quality control managed for drainage pipes sourced from China?

– Quality control is managed through inspections, testing, and certification. Many manufacturers have in-house QC teams, and third-party inspection services can also be employed.

7. What are the shipping options for drainage pipes from China?

– Drainage pipes can be shipped via sea freight, which is the most common and cost-effective method for bulk goods. Air freight is an option for urgent orders but is more expensive.

8. What are the payment terms when sourcing drainage pipes from China?

– Common payment terms include T/T (Telegraphic Transfer), L/C (Letter of Credit), and sometimes D/P (Document Against Payment). Initial deposits of 30% are typical, with the balance paid before shipment.

9. Are samples available before placing a bulk order?

– Many suppliers offer samples, either free or for a nominal fee, to ensure the product meets your requirements before placing a large order.

10. How does the cost of drainage pipes from China compare to other countries?

– Chinese drainage pipes are often cost-competitive due to lower manufacturing and labor costs. However, it is important to consider shipping costs and potential tariffs.

By keeping these FAQs in mind, buyers can make informed decisions when sourcing drainage pipes from China.