electric wire rope hoist Safety Certifications

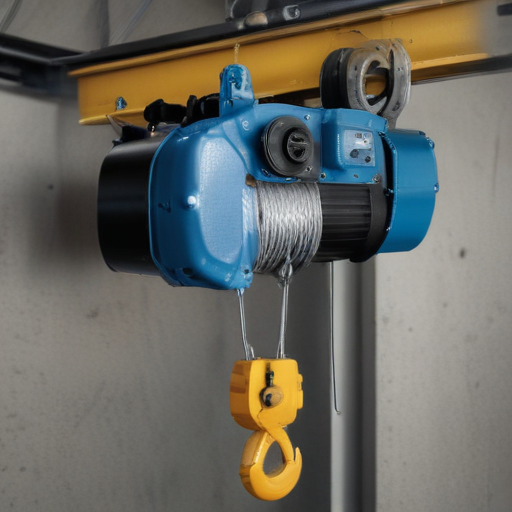

Electric wire rope hoists are essential equipment in various industries, and ensuring their safety and reliability is paramount. Several key safety certifications and standards govern the manufacturing and operation of these devices:

1. CE Certification: This European standard indicates that the hoist complies with EU safety, health, and environmental requirements. It involves rigorous testing and conformity assessments.

2. ISO 9001: This international quality management standard ensures that the hoist manufacturer adheres to strict quality control processes, enhancing product safety and reliability.

3. ASME B30: The American Society of Mechanical Engineers (ASME) B30 standards cover safety standards for various types of hoists, including electric wire rope hoists, ensuring proper design, maintenance, and operation.

4. ANSI/ASME HST-4M: This American National Standards Institute (ANSI) and ASME standard specifically addresses safety guidelines and performance standards for electric wire rope hoists, focusing on design, construction, and testing.

5. UL/CSA Certification: Underwriters Laboratories (UL) and the Canadian Standards Association (CSA) certifications ensure that the hoist’s electrical components comply with North American safety standards.

6. FEM (Fédération Européenne de la Manutention): These standards from the European Federation of Material Handling establish performance criteria for lifting equipment, ensuring reliability and safety.

7. Machinery Directive 2006/42/EC: This EU directive focuses on the safety of machinery, mandating rigorous assessment procedures and conformity marks for lifting equipment.

8. DNV GL Certification: For maritime and offshore applications, this certification ensures that the hoist meets stringent safety and operational requirements.

9. Lloyd’s Register Certification: Provides assurance that the hoist complies with marine and offshore industry standards.

Adherence to these certifications and standards ensures that electric wire rope hoists are safe, reliable, and efficient, minimizing risks to operators and enhancing operational safety. Regular maintenance and inspections, as outlined in these standards, further contribute to safe hoist operation.

List Reference Technical Parameters of “electric wire rope hoist”

Electric wire rope hoists are essential for lifting and transporting heavy loads in industrial settings. Here are key technical parameters that define their performance and usability:

1. Capacity: This indicates the maximum load the hoist can lift, commonly ranging from 500 kg to 50,000 kg.

2. Lifting Speed: Measured in meters per minute (m/min), it describes how fast the load is lifted or lowered. Typical speeds range from 4 to 20 m/min, but variable speed options are available.

3. Lifting Height: The maximum vertical distance the hoist can lift a load, usually between 6 to 50 meters.

4. Motor Power: Denotes the power of the hoist’s motor, generally measured in kilowatts (kW). Standard motor ratings can range from 1 kW to 20 kW or more, depending on the load capacity.

5. Trolley Speed: For hoists with integrated trolleys, this parameter measures the horizontal travel speed, typically between 10 to 30 m/min.

6. Duty Class: Categorizes the hoist’s capability for continuous use. Common classifications include M3, M4, M5, etc., according to FEM standards, indicating the frequency and load conditions.

7. Rope Diameter and Length: Refers to the thickness and length of the wire rope. Thickness varies from 6 mm to 28 mm, tailored to load requirements, while length matches lifting height needs.

8. Power Supply: Specifies the electrical requirements, usually 3-phase, 400V AC.

9. Control Type: Includes pendant control, wireless remote, or fully automated systems, providing various degrees of operational flexibility.

10. Brake System: Ensures safe load handling, incorporating electromagnetic or mechanical brakes.

11. Protection Class: Indicates the hoist’s resistance to dust and water, typically with IP ratings like IP54 or IP65, crucial for different environmental conditions.

12. Safety Features: These include overload protection, emergency stop buttons, and limit switches, ensuring safe operation.

Understanding these parameters assists in selecting the right electric wire rope hoist for specific industrial applications, ensuring efficiency, safety, and reliability.

List Product features of “electric wire rope hoist”

An electric wire rope hoist is an essential piece of equipment commonly used in various industries for lifting and moving heavy loads. The key product features of an electric wire rope hoist include:

1. Load Capacity: Often ranging from 0.5 tons to 50 tons, catering to diverse lifting requirements.

2. Lifting Height: Standard lifting heights can vary from 3 meters to 30 meters, depending on the model and application.

3. Hoist Speed: Dual-speed or variable-speed options are available, ensuring precise and efficient lifting operations.

4. Motor: Equipped with high-performance motors, usually with thermal protection, to prevent overheating and ensure durability.

5. Rope Drum: The grooved rope drum is designed to prevent slippage and provide even winding of the wire rope, ensuring smooth and consistent performance.

6. Wire Rope: High-quality wire rope with superior tensile strength, corrosion resistance, and long service life.

7. Control System: Options include pendant control, remote control, or integrated control systems, allowing flexible operation according to user preferences.

8. Safety Features: Incorporates overload protection, emergency stop buttons, limit switches, and torque limiters to ensure safe operation.

9. Frame Design: Sturdy and compact frame constructed from high-grade materials, ensuring durability and portability.

10. Braking System: Advanced braking systems such as electromagnetic or hydraulic brakes provide reliable and secure load handling.

11. Maintenance: Easy access to internal components and lubrication points ensures simplified maintenance.

12. Versatility: Compatible with a variety of trolleys (manual, electric, or geared) and can be mounted in different configurations (fixed, monorail, or double girder) to suit specific applications.

13. Compliance: Meets international standards and certifications, such as ISO, CE, and ANSI, ensuring reliability and user safety.

14. Energy Efficiency: Modern hoists often feature energy-efficient motors and components to reduce operational costs.

These features make electric wire rope hoists an indispensable tool for manufacturing, construction, warehousing, and other heavy-duty industrial applications.

List Various Types of “electric wire rope hoist”

“Electric wire rope hoists” are essential lifting devices used in various industrial applications for moving heavy loads. Here are some common types:

1. Monorail Hoists: Designed for straight-line lifting tasks. These hoists travel along a single beam or rail, ideal for factories and warehouses.

2. Double Girder Hoists: Used with double girder cranes, these hoists fit between two parallel overhead beams, offering greater hook height and load capacity.

3. Explosion-Proof Hoists: Specially designed for hazardous environments where flammable gases or dust may be present, adhering to strict safety regulations.

4. Low Headroom Hoists: Engineered to maximize lifting height in areas with limited vertical space. They feature a compact design, perfect for tight spaces.

5. Heavy-Duty Hoists: Built for high-capacity lifting tasks, these hoists are robust and durable, capable of handling extremely heavy loads.

6. Foot-Mounted Hoists: These are stationary hoists bolted to the floor or a fixed structure, suitable for specific lifting points where mobility is not required.

7. Trolley Hoists: Equipped with trolleys that allow horizontal movement along a beam or rail, providing greater versatility in load positioning.

8. Variable Speed Hoists: Feature advanced controls for adjusting lifting and lowering speeds, offering precision in handling delicate or critical loads.

9. Portable Hoists: Lightweight and portable, these hoists can be easily transported and set up at various locations, ideal for construction sites.

10. Corrosion-Resistant Hoists: Made from stainless steel or coated with anti-corrosive materials, suitable for use in corrosive environments such as marine or chemical industries.

Each type of electric wire rope hoist is designed to meet specific needs and operational conditions, ensuring efficiency, safety, and reliability in diverse industrial settings.

List Application of “electric wire rope hoist”

Sure! Here are some applications of electric wire rope hoists, presented concisely:

1. Manufacturing Industry: Electric wire rope hoists are utilized for lifting heavy raw materials, machinery, and finished products in factory environments.

2. Warehouse Operations: These hoists are used for stacking and organizing goods in warehouses, improving space utilization and operational efficiency.

3. Construction Sites: Ideal for lifting construction materials like steel beams, concrete blocks, and other heavy objects, ensuring safe and efficient handling.

4. Shipyards: Employed for lifting heavy ship parts, engines, and equipment during shipbuilding and repair processes.

5. Mining Operations: Used for moving and lifting heavy mining equipment and extracted materials, enhancing safety and productivity.

6. Automotive Industry: Helps in lifting and installing heavy car parts like engines and manufacturing equipment.

7. Power Plants: Essential for handling heavy turbines, generators, and other critical components during installation and maintenance.

8. Railways: Used for lifting and positioning heavy railway components, including tracks and carriages.

9. Steel Industry: Utilized for handling heavy steel coils, slabs, and other materials in steel mills.

10. Entertainment and Events: Electric wire rope hoists are used for lifting and securing heavy stage equipment, lighting, and sound systems.

These applications illustrate the versatility of electric wire rope hoists in lifting and handling heavy loads across various industries, contributing to operational safety and efficiency.

List Buyer Types of “electric wire rope hoist”

Certainly, the buyers of electric wire rope hoists come from a variety of sectors. Here’s a concise list of potential buyer types:

1. Manufacturing Facilities: These buyers use hoists for material handling, assembly line operations, and moving heavy components within the plant.

2. Construction Companies: Electric wire rope hoists are crucial for lifting and positioning heavy construction materials such as steel beams, concrete slabs, and other large equipment.

3. Warehousing and Logistics: These buyers use hoists for loading and unloading goods, organizing inventory, and transferring heavy items within the warehouse.

4. Mining and Metallurgy: In these sectors, hoists are used for lifting and transporting heavy mining equipment, minerals, and metal products.

5. Automotive Industry: Car manufacturers and repair shops employ heavy-duty hoists in assembling and repairing vehicles, particularly for lifting engines and large parts.

6. Marine and Shipbuilding: Hoists are utilized for lifting ship components, loading cargo, and handling heavy marine equipment.

7. Power Plants: Both thermal and hydroelectric power plants require hoists for maintenance tasks, such as lifting turbines, generators, and other equipment.

8. Oil and Gas Sector: They use hoists on drilling rigs and for handling heavy components in both offshore and onshore operations.

9. Railroad and Transport: These buyers use hoists for managing heavy rail components and for maintenance tasks in rail depots.

10. Aerospace Industry: Aerospace companies use electric wire rope hoists for assembling large aircraft parts and for maintenance purposes.

11. Professional Rigging Services: These companies offer specialized lifting and moving services using various types of hoists, including electric wire rope versions.

Each type addresses specific needs related to lifting and moving heavy materials, emphasizing efficiency, safety, and reliability.

List “electric wire rope hoist” Project Types for Different Industries

Electric wire rope hoists are versatile lifting devices used across various industries for different applications. Below is a list of project types where electric wire rope hoists play a crucial role:

1. Manufacturing Industry:

– Assembly Lines: Hoisting parts and components into place.

– Material Handling: Moving raw materials and finished products within factories.

2. Construction Industry:

– Building and Infrastructure Projects: Lifting heavy beams, columns, and construction materials.

– Bridge Construction: Hoisting large sections of bridges into place.

3. Mining Industry:

– Underground Mining: Moving ore and other materials from mines.

– Surface Mining: Loading and unloading heavy equipment and mined materials.

4. Oil & Gas Industry:

– Drilling Rigs: Lifting drill pipes and equipment.

– Refineries: Handling large machinery and maintenance tasks.

5. Transportation and Logistics:

– Railway Yards: Lifting rail car sections and bogies.

– Ports and Harbors: Loading and unloading shipping containers and heavy cargo.

6. Automotive Industry:

– Engine Assembly: Hoisting engines and transmissions into vehicles.

– Body Shops: Moving car bodies and heavy parts.

7. Aerospace Industry:

– Aircraft Manufacturing: Lifting plane sections and components.

– Spacecraft Assembly: Handling precision components and assemblies.

8. Power Generation:

– Hydroelectric Plants: Hoisting turbines and generators.

– Nuclear Plants: Handling critical equipment with high precision.

9. Shipbuilding:

– Dry Docks: Lifting ship components during construction and maintenance.

– Outfitting Docks: Installing heavy machinery and fittings on ships.

10. Warehousing and Distribution:

– Storage Yards: Moving heavy goods and materials within warehouses.

– Distribution Centers: Handling large and heavy packages efficiently.

These applications demonstrate the diverse utility of electric wire rope hoists across multiple industries, enhancing efficiency and ensuring safe handling of heavy loads.

electric wire rope hoist Accessories Upgrades and Custom Manufacturing Options

Electric wire rope hoists are indispensable in various industrial applications, and optimizing their performance often involves accessories, upgrades, and custom manufacturing options.

Accessories:

1. Remote Controls: Wireless or tethered remotes offer enhanced operational flexibility and safety.

2. Load Limiters: Protect the hoist and operator by preventing overload.

3. Snatch Blocks: These pulley blocks change the direction of the load, increasing versatility.

4. Trolleys: Motorized or manual trolleys allow lateral movement along the beam.

5. Pendant Controls: Offer an economical and straightforward operation solution.

6. Chain Containers: Keep excess chain neatly stored, reducing hazards and improving efficiency.

7. Safety Latches: Essential for hook safety, preventing accidental load release.

Upgrades:

1. Variable Frequency Drives (VFDs): Offer smooth start/stop functions and better speed control.

2. Anti-Collision Systems: Enhance safety by preventing multiple hoists from colliding.

3. Load Display Units: Show real-time load weight, helping operators manage lifting within safe limits.

4. Anti-Sway Technology: Reduces load swing during lifting, ensuring precision and safety.

5. Enhanced Braking Systems: Improved braking mechanisms for better control and safety.

Custom Manufacturing Options:

1. Specialized Lifting Capacities: Custom-built hoists tailored to specific weight requirements.

2. Non-Standard Height of Lift: Tailor the hoist to meet unique spatial constraints.

3. Corrosion-Resistant Materials: Ideal for harsh environments like marine or chemical industries.

4. Explosion-Proof Design: Suitable for hazardous areas, meeting ATEX or similar standards.

5. Alternate Power Supplies: Custom hoists can be designed for specific power sources, including battery-operated models for remote locations.

6. Custom Cabling and Hook Designs: Adapted to unique lifting requirements, ensuring optimal performance and safety.

Enhancing an electric wire rope hoist with these options can significantly improve operational efficiency, safety, and longevity, making it a valuable asset in industrial settings.

List Quality Control and The Manufacturing Process of “electric wire rope hoist”

Quality Control of Electric Wire Rope Hoist

1. Material Inspection: Ensuring raw materials comply with predefined standards.

2. Component Testing: Electrical and mechanical components are tested for functionality and safety.

3. Dimensional Accuracy: Parts are checked for precision in dimensions to ensure proper assembly.

4. Load Testing: Hoists are tested under load conditions to ensure lifting capacity and safety.

5. Nondestructive Testing: Techniques like ultrasonic or magnetic particle inspection ensure structural integrity.

6. Operational Testing: Complete units undergo functional testing to verify smooth operation, braking, and safety mechanisms.

7. Compliance Checks: Ensuring adherence to industry standards and certifications, such as ISO, CE.

8. Final Inspection: Comprehensive inspection before packaging, including checking documentation and user manuals.

9. Feedback Loop: Customer feedback is analyzed for continuous improvement.

Manufacturing Process of Electric Wire Rope Hoist

1. Design and Engineering: Initial conceptualization, design development, CAD modeling, and simulations.

2. Procurement: Sourcing high-quality raw materials and components based on design specifications.

3. Machining and Fabrication: Machining metal parts using CNC machines, welding, and other fabrication processes.

4. Component Manufacturing: Electrical motors, gears, drums, and other components are produced or assembled.

5. Surface Treatment: Anti-corrosive treatments such as galvanization or powder coating.

6. Assembly: Mechanical parts are assembled, followed by electrical components like control systems.

7. Quality Assurance: Testing individual components and the fully assembled unit as outlined above.

8. Painting and Finishing: Final surface finishing processes, including painting and labeling.

9. Packaging: Safely packaging hoists to prevent damage during transit.

10. Logistics: Managing the storage and transportation to customers.

Through stringent quality control and a step-by-step manufacturing process, electric wire rope hoists are ensured to be reliable, safe, and efficient for industrial use.

How to use “electric wire rope hoist”

An electric wire rope hoist is a lifting device used for material handling in industrial settings. Here’s how to use it safely and effectively:

1. Inspection:

– Pre-Use Check: Inspect the hoist for any damage, wear, or malfunction. Ensure the wire rope is intact and the hook latch functions properly.

– Load Capacity: Verify that the load does not exceed the hoist’s maximum weight capacity.

2. Setup:

– Power Source: Ensure the hoist is connected to a suitable power supply.

– Placement: Position the hoist directly above the load to avoid side loading.

– Hooking: Securely attach the hook to the load’s lifting point. Ensure the hook latch is closed properly.

3. Operation:

– Controls: Familiarize yourself with the control panel, often including up, down, and emergency stop buttons.

– Lifting: Gradually lift the load by pressing the ‘up’ button. Monitor for any unusual noises or movements.

– Lowering: To lower the load, press the ‘down’ button carefully.

– Travel: If your hoist is attached to a trolley, use the controls to move the load horizontally.

4. Safety:

– Load Stability: Avoid sudden or jerky movements to prevent load swinging.

– Stay Clear: Ensure no one is standing under or near the load during lifting operations.

– Emergency Protocols: Be aware of emergency procedures and where the stop button is located.

5. Post-Use:

– Unhook: Once the load is secured in place, carefully unhook the hoist.

– Storage: Store the hoist in a dry, safe place to prevent damage and unauthorized use.

By following these steps, you ensure safe and efficient use of the electric wire rope hoist. Always adhere to the manufacturer’s guidelines and local safety regulations.

“electric wire rope hoist” Comparative Analysis

When comparing electric wire rope hoists, several key factors must be taken into account: lifting capacity, lifting speed, durability, control systems, and cost.

Lifting Capacity: Electric wire rope hoists typically offer various lifting capacities, from a few hundred kilograms to several tons. Higher-end models can handle loads exceeding 50 tons. Brands like Demag, Konecranes, and Street Crane offer robust options with high lifting capacities suitable for industrial applications.

Lifting Speed: Lifting speed is crucial for efficiency. Standard models often provide speeds ranging from 4 to 8 meters per minute, though advanced models can achieve higher speeds. Speed variability through advanced control systems can enhance precision and safety.

Durability: Durability often depends on the construction material and design. Hoists constructed with high-grade steel and advanced corrosion-resistant finishes exhibit superior longevity in harsh environments. Additionally, features like sealed gearboxes and high-quality bearings contribute to durability.

Control Systems: Modern electric wire rope hoists offer sophisticated control systems, including variable frequency drives (VFDs) that provide smooth start-up, adjustable speed, and improved load control. Remote control options increase versatility and safety. Brands like Yale and Stahl distinguish themselves with advanced control technologies.

Cost: Cost varies significantly based on these factors. Basic models may start at a few thousand dollars, while specialized, high-capacity hoists can exceed $50,000. It’s essential to balance cost against the specific needs and operational demands.

Comparing Top Brands:

– Demag: Offers high durability, advanced control systems, and a wide range of capacities. Ideal for heavy-duty industrial applications.

– Konecranes: Known for innovative technology, high safety standards, and large lifting capacities. Suitable for demanding environments.

– Yale: More affordable with reliable performance, suitable for lighter industrial and commercial use.

– Stahl: Excels in precision and control, with excellent durability. Ideal for specialized applications requiring fine handling.

In summary, selecting the right electric wire rope hoist requires a careful consideration of lifting capacity, speed, durability, control systems, and cost. Brands like Demag, Konecranes, Yale, and Stahl offer diverse options catering to various industrial needs.

“electric wire rope hoist” Warranty and Support

Warranty and Support for Electric Wire Rope Hoist

When investing in an electric wire rope hoist, it’s crucial to understand the warranty and support services that accompany the product. Most reputable manufacturers offer a standard warranty that typically spans 1 to 2 years from the date of purchase. This warranty generally covers defects in materials and workmanship, ensuring that the product performs as expected under normal usage conditions.

During the warranty period, should any issue arise, the manufacturer usually provides free repair or replacement of the faulty parts. However, it’s important to note that the warranty might exclude damages resulting from improper use, overloading, unauthorized modifications, or inadequate maintenance. For businesses requiring extended coverage, some manufacturers offer extended warranty options at an additional cost.

Customer support is another vital aspect to consider. Reliable manufacturers offer robust customer support services, including technical assistance via phone, email, or live chat. Many also provide a comprehensive range of resources such as user manuals, maintenance guides, and troubleshooting videos to help users maximize the efficiency and longevity of their hoist.

In addition to remote support, some manufacturers have a network of authorized service centers where expert technicians can perform repairs and maintenance. Regular preventive maintenance, often stipulated in the warranty terms, is recommended to ensure safe and efficient operation.

When purchasing an electric wire rope hoist, always review the warranty and support details closely and keep all related documentation accessible for future reference. A solid warranty and dependable customer support can greatly enhance your investment, offering peace of mind and ensuring minimal disruptions to your operations.

List “electric wire rope hoist” FAQ

Certainly! Here are some frequently asked questions (FAQ) about electric wire rope hoists:

1. What is an electric wire rope hoist?

An electric wire rope hoist is a lifting device that uses a motorized system to lift and move heavy loads via a wire rope that winds on a drum. It is commonly used in industrial and construction settings.

2. What are the typical applications?

Electric wire rope hoists are used in various applications including manufacturing, warehousing, construction, and maintenance operations, especially where lifting heavy objects is frequent and necessary.

3. How much weight can it lift?

The lifting capacity varies depending on the model. They generally range from a few hundred kilograms to several tons. Always refer to the manufacturer’s specifications for exact capacity.

4. How does it differ from a chain hoist?

Wire rope hoists use a wound steel wire rope, providing higher speed and longer lifting distance. Chain hoists use a roller chain and are generally more durable for rugged applications with lesser maintenance needs.

5. What are the benefits of using an electric wire rope hoist?

They offer high lifting speed, greater lifting height, smooth and precise control, and the ability to lift heavy loads efficiently. They also reduce manual labor and increase safety and productivity.

6. What maintenance is required?

Regular inspection and maintenance are crucial. This includes checking the wire rope for wear, inspecting the drum and sheaves, lubricating moving parts, and ensuring the motor and electrical components are functioning properly.

7. Are there safety features?

Yes, most models come with safety features like overload protection, emergency stop buttons, and limit switches to prevent over-travel.

8. Can it be used outdoors?

Some models are designed for outdoor use, but it’s essential to check the IP rating and ensure it is suitable for the specific environmental conditions.

9. How do I select the right hoist for my needs?

Consider factors like load capacity, lifting height, speed, duty cycle, and environmental conditions. Consulting the manufacturer’s guide or a professional can help in making the right choice.

10. What are the power requirements?

Electric wire rope hoists typically require a power supply of 220V or 380V, depending on the model and capacity.

This FAQ should cover the primary concerns and provide a basic understanding of electric wire rope hoists.

Top 10 FAQ with answer about electric wire rope hoist for Buyer Sourcing from China

1. What is an electric wire rope hoist?

An electric wire rope hoist is a lifting device powered by an electric motor that uses a wire rope to lift and move heavy loads. They are commonly used in construction, manufacturing, and warehouses for efficient material handling.

2. Why source an electric wire rope hoist from China?

China is a leading manufacturer of lifting equipment, offering competitive prices without compromising on quality. The extensive range of products, availability of customization, and advancements in technology make China a favorable sourcing destination.

3. What are the key specifications to consider?

Critical specifications include load capacity, lifting speed, lifting height, power source, and control type. Understanding your application requirements will help you select the most suitable hoist.

4. What certifications should the hoist have?

Ensure the hoist complies with international standards such as ISO, CE, and ANSI. These certifications guarantee safety, quality, and reliability.

5. How do I assess the quality of the hoist?

Check for material quality, engineering design, and manufacturing processes. Request product samples and certifications. Read reviews and possibly conduct factory audits.

6. What are the common payment terms?

Payment terms may include a 30% advance payment and 70% balance before shipment. However, terms can vary, so negotiate based on your relationship with the supplier and order volume.

7. How can I handle shipping and logistics?

Suppliers typically offer FOB (Free on Board) or CIF (Cost, Insurance, and Freight) terms. Engage a reliable freight forwarder or use the supplier’s logistics service for streamlined handling.

8. What after-sales support should I expect?

Expect warranty services, availability of spare parts, and technical support. Clearly discuss after-sales terms and service agreements with the supplier.

9. How long is the manufacturing lead time?

Lead time can range from a few weeks to a couple of months, depending on the complexity and customization of the hoist. Verify the lead time at the order’s outset to avoid delays.

10. What should I look for in a supplier?

Look for suppliers with a good reputation, excellent customer service, and a proven track record in exporting. Check credentials, certifications, and client feedback to make an informed choice.

These FAQs provide a concise overview to help you make an informed decision when sourcing an electric wire rope hoist from China.