expanded metal grating Safety Certifications

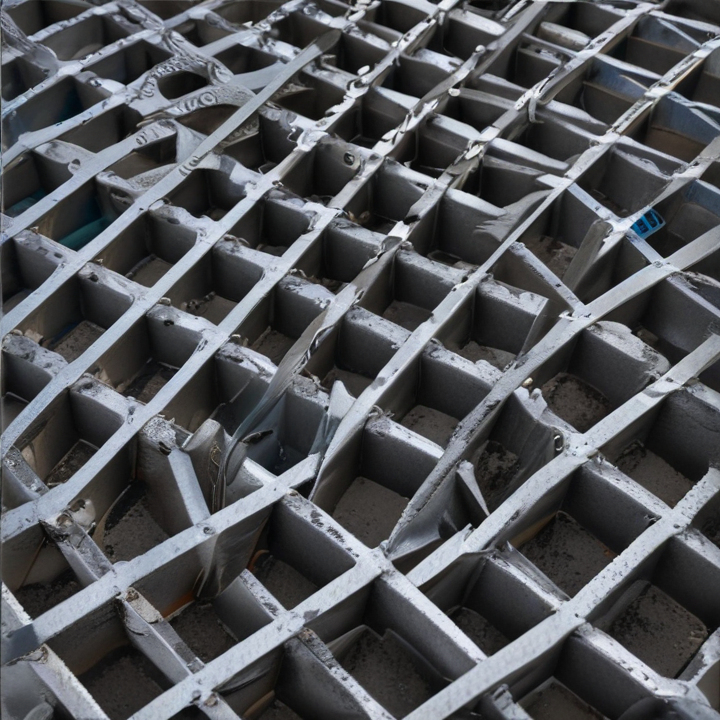

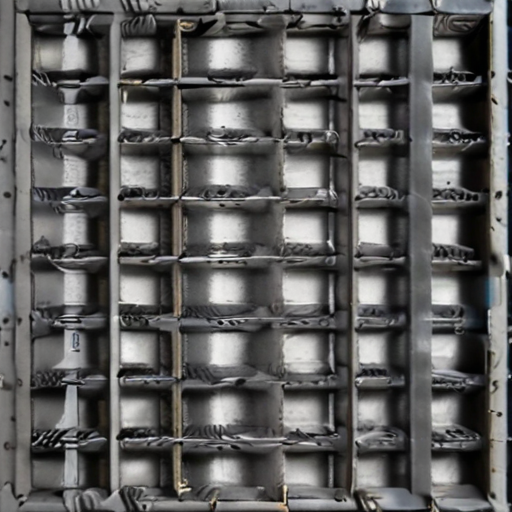

Expanded metal grating is widely used in industrial, construction, and architectural applications for its durability, strength, and versatility. Ensuring safety and compliance with industry standards is critical. Here are some key safety certifications and standards associated with expanded metal grating:

1. ISO 9001: This international standard pertains to quality management systems (QMS). Manufacturers of expanded metal grating often adhere to ISO 9001 to ensure consistent product quality and continual improvements in their processes, which contribute to overall safety and reliability.

2. ANSI/NAAMM MBG 531-09: This standard from the National Association of Architectural Metal Manufacturers (NAAMM) sets guidelines for the materials, fabrication, and installation of metal bar grating, including expanded metal grating. Compliance ensures the grating meets required load-bearing and performance criteria.

3. OSHA Standards: The Occupational Safety and Health Administration (OSHA) provides regulations (e.g., 29 CFR 1910 for general industry, 29 CFR 1926 for construction) that pertain to the safe use of walking-working surfaces. Expanded metal grating used in flooring, walkways, and platforms must comply with these standards to minimize the risk of slips, trips, and falls.

4. ASTM Standards: The American Society for Testing and Materials (ASTM) has various standards related to the material properties and load ratings for metal grating (e.g., ASTM A123/A123M for zinc coatings through hot-dip galvanizing). Compliance with these standards ensures the material’s integrity and suitability for specific uses.

5. RoHS Compliance: The Restriction of Hazardous Substances Directive ensures that expanded metal grating is free from hazardous materials like lead, mercury, or cadmium, which enhances safety, especially in environments where human health is a concern.

Adhering to these and other relevant standards and certifications helps ensure that expanded metal grating is safe, reliable, and fit for purpose in various applications. Regular audits, testing, and improvements in manufacturing processes further bolster compliance and safety.

List Reference Technical Parameters of “expanded metal grating”

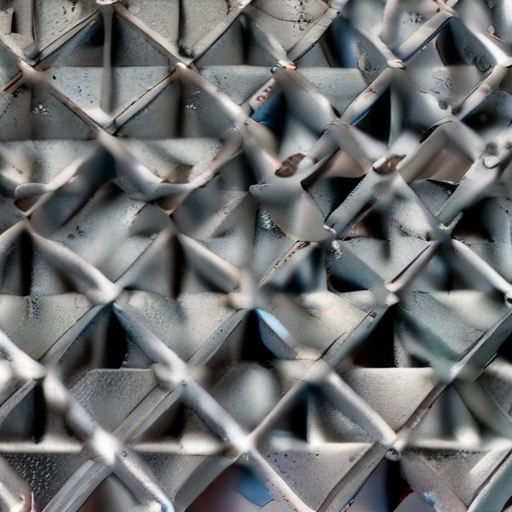

Expanded metal grating consists of a single sheet of metal that is slit and stretched to form a pattern of diamond-shaped openings. Here are some key technical parameters:

1. Material: Typically made from steel, stainless steel, or aluminum. The choice of material affects properties like strength, corrosion resistance, and weight.

2. Thickness: Measured in inches or millimeters, the thickness of the metal sheet before expansion influences the grating’s load-bearing capacity.

3. Strand Width: The width of the individual metal strands that form the pattern. This can vary and impacts the overall strength and weight.

4. Overall Thickness: The total thickness after the metal has been expanded, including any layering effects from the expansion process.

5. Opening Size and Shape: Described by the dimensions of the diamond-shaped openings, typically given in inches or millimeters. The size and shape affect air flow, light passage, and load support.

6. Strand Thickness: The thickness of the metal in the strands forming the expanded mesh.

7. Bond Width: The width of the intersections where strands intersect, contributing to structural integrity.

8. Style Designation: Often represented in codes that specify characteristics like opening size, strand width, and thickness.

9. Weight per Square Foot (or Square Meter): An important consideration for applications where weight impacts overall design, such as in aerospace or architectural use.

10. Open Area Percentage: The ratio of open space to solid metal, impacting airflow, lighting, and visual transparency.

11. Surface Finish: Can be mill finish, painted, or coated for aesthetic purposes or enhanced corrosion resistance.

12. Load Bearing Capacity: Specifications on the maximum weight the grating can support, crucial for structural applications.

13. Compliance and Standards: Must meet specific industry standards and certifications, such as those from ASTM, ISO, or other relevant bodies.

Understanding these parameters helps in selecting the appropriate expanded metal grating for various industrial, architectural, or safety applications.

List Product features of “expanded metal grating”

Expanded metal grating is a versatile and durable material used in a variety of applications. Here are its key product features:

1. High Strength-to-Weight Ratio: Expanded metal grating offers robust strength while remaining lightweight, making it easy to handle and install.

2. Non-Slip Surface: The grating’s surface texture provides excellent traction, reducing the risk of slips and falls, even in wet or oily conditions.

3. Durability: Made from materials like stainless steel, aluminum, or carbon steel, expanded metal grating is resistant to corrosion, wear, and impact.

4. Versatility: Suitable for industrial, commercial, and architectural applications, including flooring, walkways, security enclosures, and decorative facades.

5. Ventilation and Light Passage: The open design allows for air flow and light to pass through, making it ideal for ventilation systems and areas where natural light penetration is beneficial.

6. Low Maintenance: Its robust construction requires minimal upkeep, saving time and costs associated with regular maintenance.

7. Customizable: Available in a range of mesh sizes, thicknesses, and patterns to meet specific project requirements and aesthetic preferences.

8. Cost-Effective: Manufactured from a single piece of material, expanded metal grating eliminates the need for welding or extra fabrication, reducing production and installation costs.

9. Security Features: The material’s strength and design make it difficult to cut or break, providing an added level of security for sensitive areas.

10. Eco-Friendly: Expanded metal grating produces minimal waste during manufacturing and is often made from recycled materials, contributing to sustainability efforts.

11. Enhanced Load Distribution: The grating evenly distributes weight, supporting heavy loads and reducing the risk of structural damage.

12. Easy Custom Fabrication: Can be easily cut, bent, or shaped to fit custom specifications, simplifying the adaptation to various project needs.

These features combined make expanded metal grating a practical and flexible solution for numerous applications.

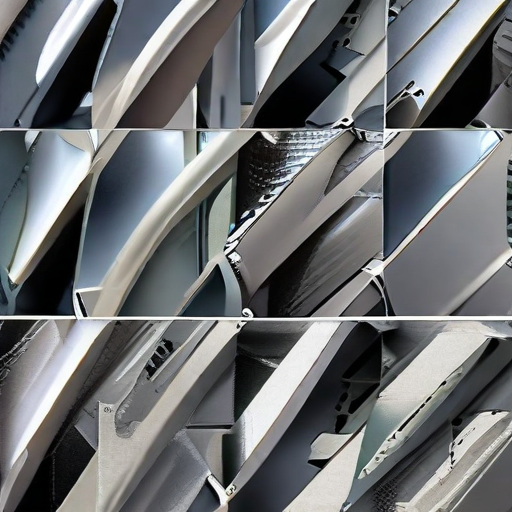

List Various Types of “expanded metal grating”

Expanded metal grating is a versatile material commonly used for flooring, walkways, security fencing, and other structural applications. It is made by cutting and stretching metal sheets to form a diamond or hexagonal pattern. There are several types of expanded metal grating, each catering to different requirements and applications.

1. Standard (or Regular) Expanded Metal: This type features a raised surface due to the stretching process, providing excellent slip resistance. It is used in grating, fencing, and walkways where traction is important.

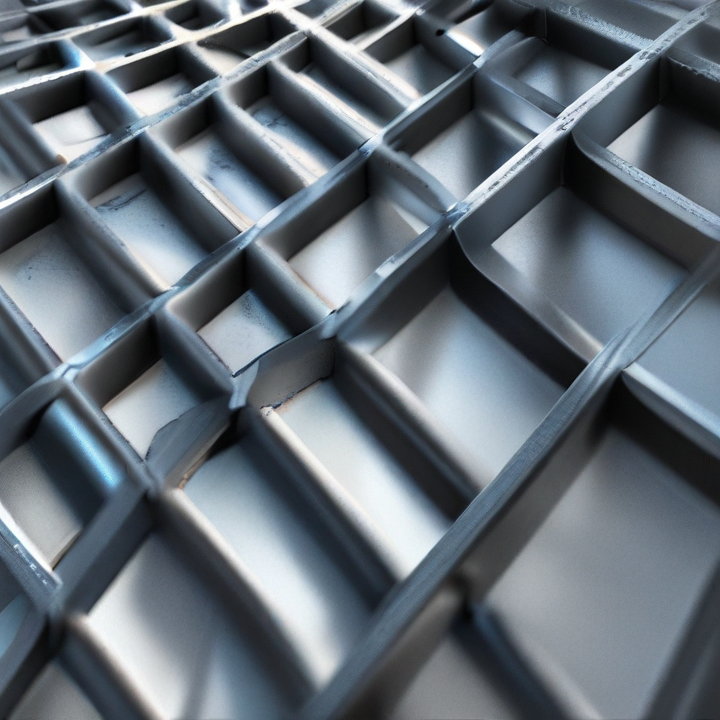

2. Flattened Expanded Metal: After expanding, the material is passed through a cold rolling process to flatten the raised strands. This creates a smoother, more uniform surface, making it suitable for areas where a flat, even surface is needed, such as in shelving and architectural applications.

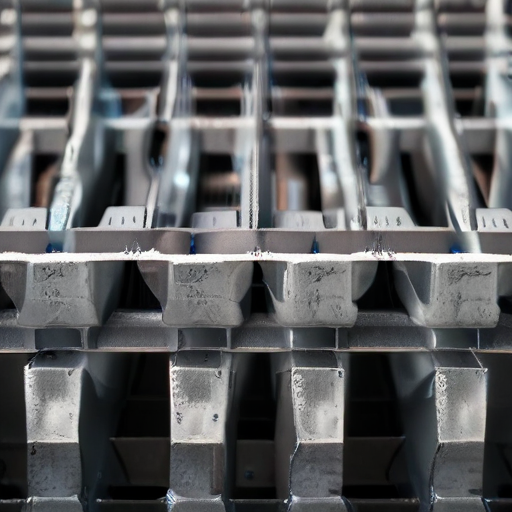

3. Heavy-Duty Expanded Metal: Made from thicker gauges of metal, this type is designed for high-load applications, such as industrial flooring, ramps, and platforms. Its rugged nature ensures durability and longevity under heavy traffic.

4. Micro Expanded Metal: With smaller strand dimensions and openings, micro expanded metal is used in filtration, shielding, and precision equipment protection. Its fine mesh offers strength and air or fluid flow control without sacrificing visibility or ventilation.

5. Decorative Expanded Metal: Designed with aesthetics in mind, decorative expanded metal comes in various patterns and finishes. It is often used in architectural applications, such as facades, partitions, and interior design elements.

6. Grating Types by Material: Expanded metal grating can be made from various materials, including carbon steel, stainless steel, and aluminum. The choice of material depends on the specific requirements for strength, corrosion resistance, and weight.

Each type of expanded metal grating offers unique benefits, making it an adaptable and practical solution for a variety of industrial, commercial, and architectural applications.

List Application of “expanded metal grating”

Expanded metal grating is a versatile material that is formed by slitting and stretching metal sheets to create a mesh pattern. It finds applications across numerous industries due to its strength, lightweight nature, and cost-effectiveness. Here are some key applications:

1. Industrial Flooring and Walkways:

– Provides a non-slip surface, essential for safety in factories and plants.

– Allows for easy drainage and airflow, preventing the accumulation of liquids and debris.

2. Security Fencing and Barriers:

– Used in prisons, military bases, and power plants due to its durability and resistance to cutting.

– Forms protective enclosures around machinery or restricted areas.

3. Architectural Uses:

– Employed in façades, sunscreens, and decorative elements due to its aesthetic appeal.

– Offers a contemporary look for building exteriors and interiors without compromising visibility or airflow.

4. Stair Treads and Ramps:

– Ensures safe and stable footing by providing excellent grip.

– Commonly used in commercial and industrial settings where heavy foot traffic is expected.

5. Shelving and Racking:

– Ideal for storage solutions in warehouses and retail spaces.

– Its open design allows for ventilation and visibility of stored items.

6. Transportation:

– Utilized in the manufacturing of vehicle ramps, walkways, and trailers.

– Provides a lightweight but strong solution for heavy-duty applications.

7. Filtration and Separation:

– Acts as a sturdy support for filtration media in various industries.

– Employed in the oil, gas, and food processing sectors for separation processes.

8. Safety Guards and Grilles:

– Installed over machinery and equipment to protect workers from moving parts.

– Ensures visibility while providing a physical barrier.

9. Agricultural Uses:

– Used for livestock enclosures, feed storage, and ventilation screens in barns.

These applications leverage the durability, flexibility, and low maintenance of expanded metal grating, making it a popular choice across diverse sectors.

List Buyer Types of “expanded metal grating”

Expanded metal grating is a versatile, durable, and cost-effective solution widely used in various industrial and commercial applications. The buyer types for expanded metal grating typically include several key sectors:

1. Construction Companies: These buyers use expanded metal grating for building facades, walkways, stair treads, and fencing due to its strength and lightweight properties.

2. Manufacturing and Industrial Plants: Industries such as automotive, aerospace, and machinery frequently utilize expanded metal grating for flooring, machinery guards, and platforms. Its non-slip surface and ability to handle heavy loads make it ideal for these environments.

3. Oil and Gas Industry: Safety and durability are paramount in this sector. Expanded metal grating is used for offshore platforms, walkways, and safety barriers in refineries and drilling sites.

4. Transportation and Logistics: Railways, shipping docks, and airports use expanded metal grating for platforms, walkways, and even train steps. Its robust construction ensures safety and longevity.

5. Municipalities and Government Agencies: Parks, public buildings, and infrastructure projects require durable and safe materials like expanded metal grating for bridges, covers, and security enclosures.

6. Agricultural Sector: Farmers and agricultural businesses use expanded metal grating for animal enclosures, flooring in barns, and ventilation systems due to its durability and ease of cleaning.

7. Architectural Firms: Designers and architects incorporate expanded metal grating in innovative ways for modern and industrial aesthetics in building facades, staircases, and decorative elements.

8. Retail and Display Companies: Retailers use this material for shelving, racks, and displays. Its strength and versatility allow for creative merchandising solutions.

9. Energy and Utilities: Power plants and utility companies require strong, reliable materials for walkways, screening, and protective barriers in high-traffic and critical areas.

Each buyer type values expanded metal grating for its durability, safety features, structural integrity, and versatility, making it a preferred choice across multiple industries.

List “expanded metal grating” Project Types for Different Industries

Expanded metal grating is a versatile and durable material used in various industries due to its excellent strength-to-weight ratio, non-slip properties, and ease of fabrication. Here’s a list of project types for different industries where expanded metal grating is commonly used:

1. Construction and Architecture

– Walkways and Catwalks: Provides safe, slip-resistant surfaces for pedestrian traffic.

– Facade Cladding: Offers aesthetic appeal and ventilation for building exteriors.

– Stair Treads and Ramps: Enhances safety with non-slip properties and structural integrity.

2. Industrial and Manufacturing

– Work Platforms: Ensures worker safety with durable, non-slip surfaces.

– Machine Guards: Protects operators from moving parts while allowing visibility and airflow.

– Storage Racks and Shelving: Sturdy, ventilated surfaces for heavy-duty storage needs.

3. Transportation

– Railway Steps and Platforms: Safe access points for passengers and maintenance crews.

– Truck Bed Covers: Durable yet lightweight covers that provide security and ventilation for cargo.

– Airport Flooring: Non-slip surfaces in high-traffic areas for passenger safety.

4. Oil and Gas

– Offshore Platforms: Corrosion-resistant surfaces that can withstand harsh marine environments.

– Refinery Walkways: Safe, durable surfaces in hazardous areas.

5. Utilities and Infrastructure

– Bridge Decking: Strong, lightweight material for pedestrian and light vehicle bridges.

– Utility Covers and Grates: Effective drainage in infrastructure projects.

– Cooling Tower Walkways: Non-slip surfaces resistant to environmental elements.

6. Agriculture

– Animal Pens and Enclosures: Provides strength and ventilation for livestock areas.

– Grain Storage: Ventilated flooring for efficient air circulation.

7. Security

– Fencing and Barriers: Strong and secure enclosures for high-security areas.

– Window Guards: Protective, yet allowing airflow and visibility.

8. Marine

– Boat Decking: Slip-resistant surfaces for safety on watercraft.

– Fishing Platforms: Durable and corrosion-resistant for harsh marine conditions.

Each of these project types leverages the strengths of expanded metal grating to meet specific industrial requirements, enhancing safety, durability, and functionality.

expanded metal grating Accessories Upgrades and Custom Manufacturing Options

Expanded metal grating is a versatile material used across numerous industries for applications such as walkways, platforms, and safety barriers. To enhance its functionality and meet specific user requirements, various accessories, upgrades, and custom manufacturing options are available.

Accessories:

1. Fasteners and Clips: Secure grating panels to structures, ensuring stability and safety.

2. Mounting Brackets: Facilitates easy installation and alignment.

3. Skid-Resistant Coatings: Improves safety by reducing the risk of slips and falls.

4. Edge Banding: Enhances aesthetic appeal and reduces the risk of injury from sharp edges.

5. Grating Feet and Stoppers: Provide support and prevent movement.

Upgrades:

1. Galvanization: Adds a layer of zinc to protect against corrosion, extending the life of the grating.

2. Custom Coatings: Options include powder coating and anodizing for enhanced durability and aesthetic appeal.

3. Load Enhancements: Tailor the grating to support heavier loads by altering the mesh size and strand dimensions.

4. Anti-Slip Surface Treatment: Applied directly onto the grating for additional traction.

Custom Manufacturing Options:

1. Tailored Dimensions: Custom cuts to fit specific dimensions and shapes, ensuring a perfect fit for any project.

2. Material Choices: Select from a range of materials, such as aluminum, stainless steel, or carbon steel, depending on the application’s requirements.

3. Special Mesh Patterns: Custom-designed mesh patterns to meet particular aesthetic or functional needs.

4. Integrated Features: Incorporating drains, ramps, or raised edges directly into the grating design.

5. Color Customization: An array of color options to match the project’s branding or visual design needs.

These accessories, upgrades, and custom manufacturing options provide comprehensive solutions, ensuring expanded metal grating meets precise specifications and optimizes performance for varied applications.

List Quality Control and The Manufacturing Process of “expanded metal grating”

Quality Control of Expanded Metal Grating

1. Material Inspection:

– Verify raw materials (usually steel or aluminum) meet specifications.

– Check for any defects or impurities in the base material.

2. Dimensional Accuracy:

– Measure thickness, strand width, and opening size.

– Ensure tolerances align with engineering drawings and industry standards.

3. Coating and Finish:

– Inspect for uniform application of protective coatings (e.g., galvanizing, powder coating).

– Conduct adhesion tests to ensure durability.

4. Load Testing:

– Check load-bearing capacity to confirm it meets performance requirements.

– Assess structural integrity and safety under stress conditions.

5. Visual Inspection:

– Look for surface irregularities, sharp edges, and burrs.

– Ensure consistent pattern and evenness.

6. Compliance Checks:

– Verify compliance with ISO standards or customer specifications.

– Maintain documentation of all tests and inspections for traceability.

7. Final Inspection:

– Conduct a comprehensive review before shipping.

– Ensure packaging protects against damage during transport.

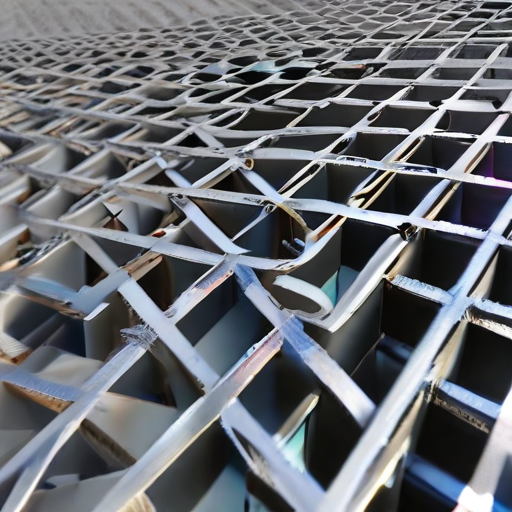

Manufacturing Process of Expanded Metal Grating

1. Material Preparation:

– Select appropriate metal sheets (steel, aluminum, etc.).

– Clean and straighten sheets if necessary.

2. Cutting:

– Use a specialized machine to slit and stretch the metal.

– Create the diamond-shaped pattern of openings.

3. Stretching:

– Simultaneously stretch the metal to desired dimensions.

– Form a one-piece structure without welding, saving material and weight.

4. Flattening (If Required):

– Flatten the expanded metal to achieve a smooth, even surface.

– Ensure uniform thickness and pattern consistency.

5. Shearing:

– Cut expanded metal to specified sizes and shapes.

– Utilize precision cutting tools to maintain dimensional accuracy.

6. Surface Treatment:

– Apply corrosion-resistant coatings (e.g., galvanization, powder coating).

– Enhance durability and aesthetics based on application needs.

7. Final Assembly (If Required):

– Integrate with other components (e.g., framing).

– Ensure proper alignment and secure fittings.

Each phase incorporates continuous quality checks to guarantee product excellence, ensuring the expanded metal grating meets all durability and performance criteria.

How to use “expanded metal grating”

Expanded metal grating is a versatile material made from steel, aluminum, or other metal sheets that are cut and stretched to form diamond-shaped openings. This design provides both strength and ventilation, making it ideal for various applications. Here’s how to use it:

1. Structural Support: Ideal for catwalks, platforms, and stair treads, expanded metal grating offers durability and slip resistance. Secure it to the framework using bolts, clamps, or welds.

2. Safety and Security: Commonly used as enclosures or barriers, it provides visibility while restricting access. Attach the grating to frames or posts using screws, U-bolts, or welding for secure installation.

3. Ventilation and Filtration: Its open design allows for airflow and passage of light. Use it for screens and filters in HVAC systems, or as protective covers for machinery.

4. Decorative Elements: Utilize expanded metal grating in architectural features like facades, sunscreens, or interior design accents. Its textured appearance adds both functionality and visual interest.

5. Fencing and Gates: This sturdy material is suitable for fencing around industrial, commercial, or residential properties. Mount it onto fences or gates using brackets, hinges, and locks.

Installation Tips:

– Measure and Cut: Use appropriate tools (e.g., metal shears or a plasma cutter) to cut the grating to the required size.

– Pre-Drill Holes: If fastening with bolts or screws, pre-drill holes in the grating and the supporting structures.

– Safety Gear: Always wear protective gear such as gloves, goggles, and ear protection when cutting or installing.

Maintenance:

– Regularly inspect for rust or damage, especially in outdoor applications.

– Clean with a wire brush and treat with anti-corrosion coatings as needed.

By following these guidelines, you can effectively incorporate expanded metal grating into your project, ensuring functionality, safety, and aesthetics.

“expanded metal grating” Comparative Analysis

Expanded metal grating is a versatile material widely used in various industrial and commercial applications. This comparative analysis explores its features, advantages, and alternatives, focusing on key aspects such as strength, weight, cost, and durability.

Strength and Durability:

Expanded metal grating is produced by cutting and stretching a metal sheet, typically steel, stainless steel, or aluminum, into a mesh pattern. This process enhances its structural integrity, providing high strength-to-weight ratios. Compared to alternatives like welded wire mesh or perforated metal, expanded metal grating offers superior impact resistance and load-bearing capacity due to its continuous structure without joints or welds.

Weight:

The lightweight nature of expanded metal grating, especially when made from aluminum, makes it an attractive choice for applications requiring easy handling and installation. Heavy-duty grating materials, such as bar grating, provide higher load capacities but at the cost of increased weight and potentially more complex installation requirements.

Cost:

Cost-effectiveness is a significant advantage of expanded metal grating. Its manufacturing process generates minimal waste, making it an economical option. In comparison, bar grating or reinforced concrete grating can be more expensive due to the additional materials and labor involved in their production.

Applications:

Expanded metal grating is used in a variety of applications, including walkways, platforms, security partitions, and ventilation covers. It offers a balance between ventilation, light passage, and security. Alternatives like fiberglass grating are chosen for environments requiring corrosion resistance, while wood or plastic gratings are considered in applications where non-conductivity is essential.

Conclusion:

In summary, expanded metal grating is a cost-effective, strong, and lightweight material suitable for numerous applications. While it excels in overall performance, specific conditions such as corrosive environments or non-conductive requirements might necessitate alternatives like fiberglass or bar grating. Careful consideration of the application requirements will guide the optimal material choice.

“expanded metal grating” Warranty and Support

Warranty and Support for Expanded Metal Grating

When investing in expanded metal grating, ensuring the product’s longevity and reliability is paramount. Most manufacturers offer warranties that typically range from 1 to 5 years, depending on the quality and application. These warranties often cover material defects, manufacturing errors, and premature wear and tear. It’s essential to thoroughly read the warranty terms to understand what is included and any conditions that might void the coverage, such as improper installation or misuse.

Support services are an integral part of the purchase. Reputable suppliers provide comprehensive support that includes technical assistance, installation guidance, and maintenance tips. Many companies have dedicated customer service teams available via phone, email, or chat to answer any questions and resolve issues swiftly. Additionally, some suppliers offer onsite consultations and inspections to ensure the grating is installed correctly and functions as intended.

For ongoing maintenance, many manufacturers supply detailed guidelines to help maximize the lifespan of the grating. This may include cleaning instructions, load capacity limitations, and recommendations for periodic inspections to check for signs of wear or damage.

Choosing a supplier with robust warranty and support services not only protects your investment but also ensures the grating performs efficiently throughout its intended lifespan. Always compare the warranty terms and support options among different manufacturers to find the best combination of product quality and customer care.

In summary, a solid warranty and comprehensive support are critical when purchasing expanded metal grating. They provide peace of mind and confirm that the product you are investing in will meet your long-term operational needs.

List “expanded metal grating” FAQ

Expanded Metal Grating FAQ

1. What is expanded metal grating?

Expanded metal grating is a type of sheet metal that has been cut and stretched to form a regular pattern (often diamond-shaped) of metal mesh-like material. It is used for its strength, durability, and anti-slip properties.

2. What materials are used to make expanded metal grating?

Common materials include mild steel, stainless steel, and aluminum. Each material offers different benefits such as corrosion resistance, strength, and weight.

3. What are the common applications?

Expanded metal grating is used in industrial flooring, walkways, platforms, stair treads, grilles, and security barriers owing to its durability and slip-resistant properties.

4. How is expanded metal grating measured?

Measurements include the type of material, strand thickness, strand width, and the size of the diamond-shaped openings (measured across its shortest dimension).

5. How is it installed?

Grating is typically installed using welding, bolting, or custom brackets, depending on the application and load requirements.

6. Why would I choose expanded over other types of grating?

Expanded metal grating offers a high strength-to-weight ratio, excellent durability, and enhanced slip resistance compared to other types of grating.

7. Is it customizable?

Yes, it can be customized to fit specific shapes, sizes, and patterns to meet unique project requirements.

8. How do you maintain expanded metal grating?

Maintenance involves regular cleaning to remove debris and, if needed, anti-corrosion treatments like painting or galvanizing.

9. Is expanded metal grating safe?

Yes, it’s designed to be slip-resistant and can handle heavy loads, making it safe for high-traffic industrial areas.

10. Where can I buy expanded metal grating?

It can be purchased from industrial suppliers, metal fabrication shops, and online retailers specializing in construction and industrial materials.

This condensed FAQ provides key information about expanded metal grating, serving as a quick reference for understanding its characteristics and uses.

Top 10 FAQ with answer about expanded metal grating for Buyer Sourcing from China

Sure, here are the top 10 frequently asked questions (FAQ) about sourcing expanded metal grating from China, along with concise answers:

1. What is expanded metal grating?

– Expanded metal grating is a type of metal lattice made by cutting and stretching a metal sheet, creating an open grid of diamond-shaped openings. It is used for flooring, walkways, and other applications requiring a durable, non-slip surface.

2. Why source expanded metal grating from China?

– China offers competitive pricing, a vast selection, and large production capacities. Chinese manufacturers have advanced technology and can produce grating to various specifications and standards.

3. What materials are available?

– Common materials include low-carbon steel, stainless steel, aluminum, and galvanized steel. Each material offers different advantages in terms of strength, corrosion resistance, and weight.

4. How to ensure product quality?

– Verify the manufacturer’s certifications (ISO, CE), request samples, conduct factory audits, and check their past performance through references or third-party inspection services.

5. What are the common applications?

– Expanded metal grating is used in industrial flooring, platforms, stair treads, catwalks, fencing, machine guards, and more. Its high strength-to-weight ratio and anti-slip properties make it versatile.

6. Can custom sizes and designs be ordered?

– Yes, many Chinese manufacturers offer customization in terms of size, thickness, strand width, and surface treatment. Provide detailed specifications to the supplier.

7. What is the typical lead time?

– Lead times vary depending on order volume and customization but generally range from 2 to 6 weeks. Communicate with your supplier to get an accurate estimate.

8. What are the shipping options?

– Shipping options include sea freight, air freight, and expedited courier services. Sea freight is most cost-effective for large orders, while air freight is quicker but more expensive.

9. How do I handle import tariffs and duties?

– Check the import regulations and tariffs for expanded metal grating in your country. Work with a customs broker or the supplier to ensure all necessary documentation is in order.

10. What are the payment terms?

– Typical payment terms include T/T (telegraphic transfer), L/C (letter of credit), and sometimes PayPal or Western Union. It’s common to pay a deposit (30-50%) upfront, with the balance due before shipment.

These answers provide a foundational understanding for buyers looking to source expanded metal grating from China.