flat pack container Safety Certifications

Flat pack containers, widely used for temporary housing, offices, and storage, must adhere to several safety certifications to ensure they meet regulatory standards and provide a secure environment for occupants. The primary certifications to look for include:

1. ISO 9001: Guarantees that the container meets international quality management standards, ensuring consistency and continual improvement in manufacturing processes.

2. ISO 14001: Ensures compliance with environmental management standards, addressing the manufacturing process’s impact on the environment.

3. CE Marking: Indicates compliance with European health, safety, and environmental protection standards. It is mandatory for products sold within the European Economic Area (EEA).

4. EN 1090: Specifies requirements for the execution of steel structures and aluminum structures, ensuring structural integrity and safety during use.

5. UL Certification: For electrical components within the container, the Underwriters Laboratories (UL) certification ensures that electrical systems meet stringent safety standards.

6. CSA Certification: For products used in Canada, the Canadian Standards Association (CSA) certification ensures adherence to national safety standards.

7. ANSI Standards: The American National Standards Institute (ANSI) provides guidelines for safe use and construction, relevant particularly in the United States.

8. Fire Safety: Compliance with local and international fire safety regulations, like NFPA (National Fire Protection Association) standards, is crucial for ensuring fire resistance and safe evacuation routes.

9. Wind and Load Resistance: Certifications for wind and load resistance, such as those based on ASTM standards, ensure containers can withstand various environmental stresses.

By ensuring a flat pack container adheres to these certifications, users can be confident in the product’s structural integrity, safety in use, environmental responsibility, and overall quality.

List Reference Technical Parameters of “flat pack container”

Certainly! Here are the reference technical parameters for a flat pack container:

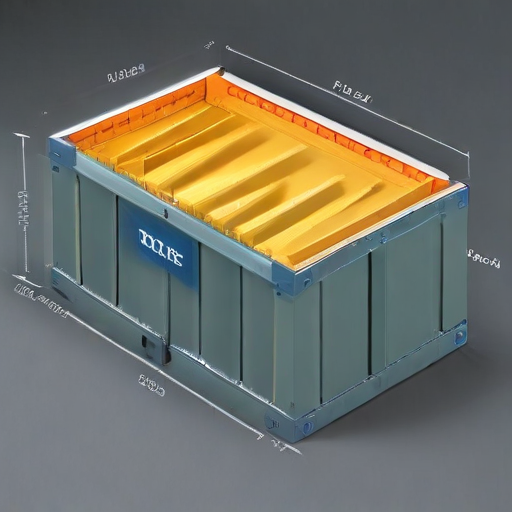

Dimensions and Weight:

– External Dimensions: Typically 6055mm (L) x 2435mm (W) x 2591mm (H) for a 20-foot container.

– Internal Dimensions: Around 5800mm (L) x 2350mm (W) x 2350mm (H) for the same size.

– Weight: Generally, around 1.5 to 2.5 tons, depending on materials and design specifics.

Material:

– Frame: Primarily made from galvanized steel for durability and corrosion resistance.

– Walls: Often consist of insulated steel or composite panels.

– Flooring: Commonly uses marine-grade plywood or steel-reinforced panels.

Insulation:

– Type: Polyurethane or rock wool are commonly used.

– Thickness: Usually in the range of 50mm to 100mm, depending on climate requirements.

Load Bearing Capacity:

– Floor Load Capacity: Generally around 500 kg/m².

– Roof Load Capacity: Around 100 kg/m², suitable for light storage or minimal snow loads.

Assembly Time:

– Time: Generally 4-6 hours with a team of 3-4 people.

Features:

– Doors and Windows: Can be customized; basic units usually come with a standard entry door and a few windows.

– Electrical and Plumbing: Pre-configured setups are often available, customizable based on needs.

– Stackability: Designed to be stackable, with typical configurations allowing stacking up to 3 units high.

Certification:

– ISO Certification: Many flat pack containers adhere to ISO standards for shipping and environmental regulations.

– Fire Safety: Conformance with international fire safety standards (BS, ANSI, etc.).

Optional Add-Ons:

– Climate Control: HVAC systems can be integrated.

– Furniture: Optional built-in furniture, like beds, tables, and shelves.

– Solar Power: Integration for off-grid power solutions.

These parameters provide a comprehensive overview of flat pack containers, suitable for a variety of applications from temporary housing to workspace solutions.

List Product features of “flat pack container”

Flat Pack Containers are innovative construction solutions offering numerous benefits. Here are the key features:

1. Portability: These containers are designed to be dismantled and packed flat, making them highly portable. They can be easily transported via trucks or ships, significantly reducing logistics costs.

2. Ease of Assembly: Flat pack containers can be quickly assembled on-site with minimal tools and labor. This makes them ideal for rapid deployment in remote locations or emergency situations.

3. Durability: Constructed using high-quality, robust materials (such as steel), flat pack containers are exceptionally durable and can withstand harsh environmental conditions.

4. Cost-Effective: The flat pack design optimizes shipping efficiency, leading to lower transportation costs. Additionally, the quick assembly process reduces labor costs.

5. Customization: They can be customized to meet various specifications, including size, layout, and interior fittings. This makes them versatile for different applications like office spaces, living quarters, or storage units.

6. Insulation and Ventilation: Many flat pack containers come with options for thermal insulation and ventilation, ensuring comfort and suitability for diverse climates.

7. Eco-Friendly: The materials used are often recyclable, and due to their reusability, flat pack containers are a sustainable choice for temporary or permanent structures.

8. Security: Equipped with secure locking systems, these containers provide a safe environment for storage or habitation.

9. Modularity: Multiple units can be easily connected or stacked to create larger spaces or multi-story structures, offering flexibility in design.

10. Low Maintenance: The sturdy construction and quality materials used minimize the need for frequent maintenance, ensuring longevity and reliability.

These features make flat pack containers a practical, efficient, and versatile solution for a wide range of applications.

List Various Types of “flat pack container”

Flat pack containers, or collapsible containers, offer versatile solutions for various needs. Here are several types:

1. Standard Flat Pack Containers: These are general-purpose containers, ideal for temporary or permanent storage, workshops, or shelters.

2. Flat Pack Offices: Designed specifically as temporary or semi-permanent office spaces, these come with basic amenities like insulation, wiring for electricity, and sometimes even air conditioning.

3. Accommodation Units: These are tailored for living arrangements, such as emergency housing, dormitories, or remote work sites. They often include bedrooms, bathrooms, and kitchens.

4. Sanitary Units: These include bathrooms, showers, and toilet facilities, useful in campsites, construction sites, and outdoor events.

5. Medical Units: Designed for mobile healthcare services, these containers can be outfitted as clinics, testing centers, or emergency medical stations.

6. Retail Units: These are used for pop-up shops, kiosks, or portable retail spaces. They can be customized with display areas, storage, and lighting.

7. Custom-Built Solutions: Tailored to specific needs, these containers can be modified for diverse applications such as laboratories, classrooms, or exhibition spaces.

8. Storage Solutions: Primarily for storing goods, tools, or equipment, these are robust and can be outfitted with shelves, climate control, and security features.

Each type serves distinct purposes and can be tailored for specific requirements, making flat pack containers a flexible and cost-effective solution.

List Application of “flat pack container”

Flat pack containers, also known as modular or collapsible containers, offer versatile applications across various sectors due to their portability, ease of assembly, and space efficiency. Below are some key applications:

1. Emergency Housing: Ideal for disaster relief situations, flat pack containers can be rapidly deployed and assembled to provide immediate shelter for individuals. They offer a quick solution for housing people displaced by natural calamities like earthquakes, floods, and hurricanes.

2. Temporary Office Spaces: These containers are widely used on construction sites or remote locations, providing temporary offices for project managers, engineers, and teams, ensuring on-site supervision and coordination.

3. Event Venues: For festivals, exhibitions, and trade shows, flat pack containers can be customized to create ticket booths, staging areas, and temporary retail spaces. Their modular nature allows for creative configurations to suit the event’s requirements.

4. Retail Outlets: In urban settings or pop-up markets, flat pack containers serve as temporary or semi-permanent retail spaces for small businesses, allowing for cost-effective and flexible retail operations.

5. Accommodation Units: These containers are frequently used to provide accommodation for workers in isolated or industrial areas such as mining camps or oil rigs, outfitted with necessary amenities to ensure comfort.

6. Storage Solutions: For both residential and commercial purposes, flat pack containers offer secure storage solutions. They can be used to store equipment, tools, documents, or personal belongings.

7. Military Applications: They are used by military forces for barracks, field offices, and even medical units in remote locations, offering durability and ease of transport.

8. Healthcare Facilities: During health crises like pandemics, flat pack containers can be converted into isolation units, testing centers, or small clinics to quickly expand healthcare infrastructure.

In essence, flat pack containers provide a flexible, scalable, and economical solution across diverse applications, making them indispensable in various temporal and spatial contexts.

List Buyer Types of “flat pack container”

Flat pack containers are versatile, modular units that are widely used in various industries due to their ease of transport, assembly, and durable nature. Here are the primary buyer types for flat pack containers:

1. Construction Companies

Construction firms often require temporary site offices, changing rooms, storage units, and accommodations for workers. Flat pack containers offer a practical solution due to their ease of assembly and relocation.

2. Remote and Temporary Housing Providers

Companies specializing in remote housing for workers in mining, oil and gas, and forestry industries use these containers to create livable units in remote locations. Their portability and quick setup are major advantages.

3. Disaster Relief Organizations

In times of natural disasters or humanitarian crises, organizations like the Red Cross or UNHCR purchase flat pack containers for emergency shelters, medical facilities, and storage units for supplies.

4. Educational Institutions

Schools and colleges sometimes need additional space quickly, either for classrooms, administrative offices, or storage. Flat pack containers offer a cost-effective and timely solution.

5. Retail Businesses

Pop-up shops, seasonal sales events, and temporary retail spaces benefit from the flexibility of flat pack containers. They can be easily assembled, customized, and disassembled after the event.

6. Event Management Companies

For music festivals, fairs, and large events, these containers are used for ticket booths, concession stands, merchandise stalls, and even temporary restrooms.

7. Agricultural Sector

Farmers and agribusinesses utilize flat pack containers for storing equipment, fertilizers, seeds, or even as temporary animal shelters, due to their versatility and durability.

8. Government and Military

Both government agencies and military units often require temporary structures that can be quickly deployed and easily transported. Flat pack containers serve as makeshift offices, barracks, medical units, or storage.

9. Hospitality Industry

Hotels and resorts sometimes use these containers to create additional guest rooms, staff accommodation, or temporary facilities during renovations.

10. Individuals and Small Businesses

Entrepreneurs and small business owners might use flat pack containers for creating home offices, studios, or workshops due to their adaptability and affordability.

In summary, flat pack containers appeal to a diverse range of buyers due to their flexibility, cost-effectiveness, and speedy deployment capabilities.

List “flat pack container” Project Types for Different Industries

Flat pack containers are versatile, cost-effective, and easily transportable solutions suitable for various industries. Here are some common project types utilizing flat pack containers across different sectors:

1. Construction

– Site Offices: Portable offices for on-site management.

– Storage Units: Secure storage for tools, materials, and equipment.

– Worker Accommodations: Temporary living quarters for construction workers.

2. Education

– Classrooms: Temporary or permanent educational spaces.

– Libraries: Mobile libraries that can reach remote areas.

– Laboratories: Modular labs for scientific research and education.

3. Healthcare

– Clinics: Field clinics and medical treatment centers.

– Laboratories: Mobile testing and diagnostic labs.

– Isolation Units: Quarantine facilities for infectious diseases.

4. Retail

– Pop-up Shops: Temporary retail spaces for special events or seasonal sales.

– Market Stalls: Portable stalls for farmers’ markets or trade fairs.

– E-Commerce Fulfillment: Storage and distribution centers for online businesses.

5. Hospitality

– Glamping Pods: Luxury camping accommodations.

– Event Spaces: Temporary venues for weddings, festivals, or corporate events.

– Bars & Cafés: Portable dining and drinking establishments.

6. Humanitarian Aid

– Disaster Relief: Emergency shelters for displaced populations.

– Supply Depots: Storage units for relief supplies and equipment.

– Medical Response Units: Mobile medical care facilities in crisis zones.

7. Manufacturing

– Workshops: Portable workspaces for production and assembly.

– Warehouses: Modular storage solutions for raw materials and finished goods.

– Research & Development: Flexible spaces for R&D projects.

8. Residential

– Tiny Homes: Affordable housing solutions.

– Guest Houses: Additional living spaces for guests.

– Student Housing: Cost-effective dormitories for educational institutions.

9. Agriculture

– Farm Offices: Administrative offices for farm management.

– Processing Units: Facilities for processing agricultural products.

– Storage: Secure storage for machinery and produce.

10. Events & Exhibitions

– Exhibition Stands: Display units for trade shows and expos.

– Ticket Booths: Portable ticket counters for events and festivals.

– Concession Stands: Food and beverage stalls for public gatherings.

Flat pack containers offer a flexible and scalable solution, making them ideal for diverse applications across various industries.

flat pack container Accessories Upgrades and Custom Manufacturing Options

Flat pack containers offer a versatile solution for a variety of needs, from storage to living spaces. To maximize their utility, a range of accessories, upgrades, and custom manufacturing options are available.

Accessories:

1. Shelving Units: Modular and adjustable shelving for organized storage.

2. Lighting Kits: Energy-efficient LED lighting for enhanced visibility.

3. Climate Control: Portable air conditioners and heaters to maintain a comfortable environment.

4. Solar Panels: Sustainable energy options for off-grid applications.

5. Security Features: Heavy-duty locks, CCTV systems, and security grills.

6. Furniture Kits: Foldable tables, chairs, and beds for living spaces.

7. Plumbing Fixtures: Portable sinks, showers, and toilets for complete utility facilities.

Upgrades:

1. Insulation: Improved thermal and sound insulation for enhanced comfort.

2. Flooring Options: High-quality vinyl, laminate, or carpeted flooring.

3. Windows and Doors: Additional or upgraded units for better light and access.

4. Partition Walls: Internal walls to create separate rooms or sections.

5. Electrical Wiring: Comprehensive electrical systems for outlets and appliances.

6. Exterior Finishes: Custom paints, claddings, and coatings for aesthetic appeal and durability.

Custom Manufacturing Options:

1. Size and Shape: Tailor-made dimensions to fit specific requirements.

2. Color Schemes: Customizable for branding or personal preference.

3. Multi-Level Units: Stackable containers for vertical expansion.

4. Specialized Interiors: Purpose-built interiors for offices, classrooms, or medical facilities.

5. Mobility Features: Wheels or skids for easy relocation.

6. Advanced Security: Biometric locks, reinforced structures, and secure storage areas.

Flat pack containers can be highly customized to meet specific needs, making them a flexible solution for various applications. Whether you need a simple storage unit or a complex living space, a range of accessories, upgrades, and custom options ensures you get the perfect fit for your requirements.

List Quality Control and The Manufacturing Process of “flat pack container”

Quality Control in Flat Pack Container Manufacturing:

1. Material Inspection: Raw materials such as steel, insulation, and fasteners are inspected for compliance with specifications.

2. Component Testing: Individual parts like panels, frames, and joints undergo rigorous testing for durability, weather resistance, and load capacity.

3. Precision Engineering: Use of CNC machines and automated tools to ensure components have precise dimensions.

4. Assembly Checks: Each assembly stage is scrutinized for accuracy and alignment, ensuring fit and functionality.

5. Weld Quality: Welds are inspected visually and sometimes using non-destructive testing methods like ultrasound.

6. Surface Treatment: Coatings are checked for uniformity, adhesion, and resistance to environmental factors.

7. Compliance Verification: Ensuring that the product meets local and international building codes and standards.

8. Functional Tests: The fully assembled container is tested for doors, windows, electrical systems, and plumbing fittings.

Manufacturing Process of Flat Pack Containers:

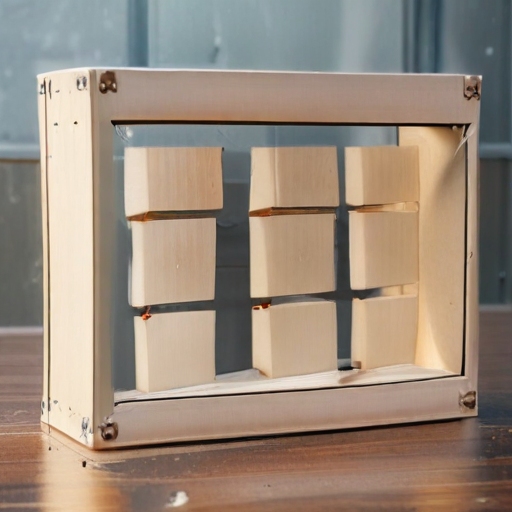

1. Design & Planning: Computer-aided design (CAD) is used to create detailed blueprints. Specifications consider load, insulation, utility layout, and compliance with standards.

2. Material Preparation: High-grade steel is cut into panels and components. Insulating materials and other necessities are prepared.

3. Forming & Cutting: Panels and frames are formed using hydraulic presses and cut to precise dimensions using CNC machines.

4. Welding & Assembly: Frames and panels are welded and assembled using automated robotic arms and skilled manual labor.

5. Surface Treatment: Panels are treated with anti-corrosive coatings and painted.

6. Insulation & Sealing: Insulation material is inserted, and panels are sealed to ensure airtightness.

7. Incorporating Utilities: Electrical wiring, plumbing, and other utilities are integrated.

8. Final Assembly: All components are assembled into the final flat-pack form, ready for shipping.

9. Quality Control: The final product undergoes thorough inspection and testing to ensure it meets all specifications and quality standards.

10. Packaging & Shipping: The flat pack is packed securely for transportation to ensure it reaches its destination without any damage.

These steps ensure that the flat pack containers are manufactured efficiently, meeting both quality and regulatory standards.

How to use “flat pack container”

Using a flat pack container is straightforward and efficient. Here’s a concise guide:

1. Unpacking: Start by carefully opening the flat pack. Check for any assembly instructions provided by the manufacturer. Lay out all components and hardware.

2. Preparation: Ensure you have adequate space for assembly. Gather necessary tools, typically including a screwdriver, hammer, and possibly a wrench. Verify all parts are present and undamaged.

3. Base Assembly: Begin with the base frame. Attach the corner posts to the base panel using the provided screws or bolts. Make sure the base is level and stable.

4. Wall Panels: Attach the side and end panels to the erected frame. Ensure each panel is securely fastened to the posts and base, following the instructions for the proper order and securing method.

5. Roof Installation: Once the walls are in place, position the roof panel. Secure it to the top of the container, ensuring it sits flush and is well-sealed to prevent leaks.

6. Doors and Windows: If your flat pack container includes doors or windows, install these next. Align them properly and secure them using the provided hinges and locks, ensuring they open and close smoothly.

7. Finishing Touches: Double-check all screws, bolts, and joints to ensure everything is tightly secured. If required, seal any gaps with weather-resistant sealant and attach any optional accessories or internal fittings.

8. Inspection: Fully inspect your assembled container to ensure structural integrity and completion of the build.

Remember, always follow the specific manufacturer’s instructions for the best results and safety. The process emphasizes preparation, proper tools, and careful assembly for optimal utilization of your flat pack container.

“flat pack container” Comparative Analysis

Flat pack containers, also known as collapsible or demountable containers, have garnered significant interest as an innovative alternative to traditional shipping and storage solutions.

Advantages:

1. Space-Efficiency: When not in use, flat pack containers can be collapsed to a fraction of their assembled size. This feature significantly reduces storage and return transportation costs.

2. Cost-Effective: The reduced volume during return trips leads to lower freight costs and lower overall operational expenses. Additionally, their modular design generally results in lower manufacturing costs.

3. Easy Assembly: Many flat pack containers are designed for quick and easy assembly, often requiring just basic tools. This can result in reduced labor costs and increased efficiency.

4. Sustainability: Reduced transportation volume contributes to lower carbon emissions, making flat pack containers a more environmentally friendly option.

5. Customization: They can often be tailored to various needs, including unique size requirements, additional insulation, or specific design requisites.

Disadvantages:

1. Durability Concerns: Though modern flat pack containers are designed to be robust, they may not always match the durability and structural integrity of traditional welded containers, especially under extreme conditions.

2. Load Capacity Limitations: They sometimes have lower load capacities compared to traditional containers, limiting their applicability for heavy-duty transportation.

3. Assembly and Disassembly Time: While designed for easy assembly, it still requires time, effort, and potentially skill, which might be a drawback in time-sensitive situations.

4. Initial Investment: The upfront cost for high-quality flat pack containers may be higher than traditional ones, counterbalancing some of the long-term savings.

Comparative Perspective:

Flat pack containers shine in scenarios where space efficiency, cost reduction in return logistics, and flexibility are prioritized. Conversely, traditional containers excel in durability, load capacity, and immediate usability without assembly. The choice between the two largely hinges on specific logistical needs, environmental considerations, and budget constraints. In an era where both sustainability and cost-efficiency are key, flat pack containers offer a compelling proposition for many businesses.

“flat pack container” Warranty and Support

Warranty and Support for Flat Pack Containers

When you invest in a flat pack container, it’s crucial to understand the warranty and support services provided to ensure peace of mind and longevity of your purchase.

Warranty:

Most manufacturers offer a standard warranty period, generally ranging from 1 to 5 years. This warranty typically covers structural integrity and manufacturing defects. Ensure to read the warranty terms carefully to know what is covered and any exclusions. It’s important to maintain regular inspections and proper usage as per the manufacturer’s guidelines to keep the warranty valid.

Support:

Reputable suppliers provide robust customer support services to assist you before, during, and after your purchase. This usually includes:

1. Pre-Purchase Consultation: Expert advice to help you choose the right flat pack container according to your needs. This can include customization options, sizing, and specifications.

2. Delivery and Assembly: Guidance on the delivery process and assembly instructions. Some providers offer professional assembly services to ensure safe and accurate setup.

3. After-Sales Service: Ongoing support to address any issues or queries that arise after purchase. This includes access to customer service via phone, email, or live chat, and prompt resolution of any problems.

4. Replacement Parts: Availability of spare parts and components, which are essential if you need to replace any part of your flat pack container.

5. Maintenance Tips: Detailed instructions on how to maintain your container to extend its lifespan, including recommendations for cleaning, rust prevention, and other care tips.

Before finalizing your purchase, verify the details of the warranty and support services offered. A reliable warranty and comprehensive support are indicators of a trustworthy manufacturer, ensuring your investment is protected over time.

List “flat pack container” FAQ

Flat Pack Container FAQ

1. What is a flat pack container?

A flat pack container is a modular, transportable structure that is delivered in a flat, compact package for easy shipping and assembly. It’s ideal for various uses, including offices, living quarters, storage, or emergency shelters.

2. How is it delivered?

Flat pack containers are shipped as compact flat-packed units, making transportation cost-effective and efficient. They can typically be delivered by truck, ship, or train.

3. How easy is assembly?

Most flat pack containers come with detailed assembly instructions and can be constructed using basic tools. Depending on size and complexity, two to four people can usually assemble a unit within a few hours to a couple of days.

4. What are the components?

A flat pack container generally includes wall panels, a roof, a floor, doors, windows, and all necessary hardware for assembly. Some models also include electrical wiring and insulation.

5. What are the benefits?

– Cost-effective: Lower transportation costs due to compact shipping.

– Flexibility: Easy to transport and relocate.

– Ease of assembly: Can be assembled without specialized skills.

– Scalability: Units can be combined to create larger spaces.

6. Can I customize my flat pack container?

Yes, many suppliers offer customization options, including different sizes, interior layouts, insulation, and additional features like air conditioning, plumbing, and electrical fittings.

7. Are flat pack containers durable?

Flat pack containers are designed for durability, using high-quality materials like galvanized steel and robust insulation to withstand various weather conditions and long-term use.

8. How are flat pack containers insulated?

Insulation options vary by model and supplier, but most include wall and ceiling insulation to ensure thermal efficiency and comfort across different climates.

9. Do I need any permits?

Permit requirements depend on local regulations and the intended use of the container. It’s advisable to check with local authorities to ensure compliance.

By addressing these common queries, a potential user can appreciate the versatility and practicality of flat pack containers for numerous applications.

Top 10 FAQ with answer about flat pack container for Buyer Sourcing from China

1. What is a flat pack container?

– A flat pack container is a type of modular, portable building that is delivered in components and assembled on-site. They are commonly used for storage, offices, or living spaces due to their ease of transport and quick assembly.

2. What are the advantages of sourcing flat pack containers from China?

– China offers competitive pricing, a wide range of suppliers and designs, and a robust supply chain for materials and manufacturing. This combination ensures cost-effectiveness and quality.

3. How can I ensure the quality of the containers from Chinese suppliers?

– Request product samples, verify certifications, conduct factory audits, and check previous client reviews. Engaging a third-party inspection service can further ensure compliance with international standards.

4. What are the typical dimensions of flat pack containers?

– Standard dimensions are often 20 feet or 40 feet in length, with height and width similar to traditional shipping containers. Custom sizes can usually be manufactured on request.

5. What is the typical lead time for manufacturing and delivery?

– Lead times vary but generally range from 4 to 8 weeks, depending on order complexity and volume. Factory schedules and shipping times should be confirmed with the supplier.

6. What kind of customizations are available?

– Customizations can include various finishes, insulation, electrical wiring, plumbing, windows, doors, and interior partitions. Always discuss specific needs with your supplier.

7. How are flat pack containers shipped and assembled?

– Containers are shipped in flat-packed form to optimize space. On-site assembly generally requires a small team and basic tools, with instructions provided by the supplier.

8. What are the shipping costs from China?

– Shipping costs depend on the size of the order, destination, and shipping method (sea or air). It’s advisable to get multiple freight quotes to compare.

9. Are flat pack containers eco-friendly?

– Many flat pack containers are built using recyclable materials and can be repurposed for different uses, contributing to sustainability.

10. What payment terms are generally accepted by suppliers?

– Common payment terms include Telegraphic Transfer (T/T), Letters of Credit (L/C), and sometimes PayPal for smaller transactions. Negotiation is key to agree on mutually beneficial terms.