grua pluma Safety Certifications

Crane boom (gruá pluma) safety certifications are crucial to ensuring the safe operation, reliability, and compliance of lifting equipment. Various certifications and standards exist globally to address these safety concerns, and achieving them often involves rigorous inspection, testing, and maintenance protocols.

1. OSHA (Occupational Safety and Health Administration): OSHA sets forth standards in the United States for the safe operation of cranes and derricks in construction (29 CFR 1926 Subpart CC). Compliance involves meeting specific requirements for design, inspection, and operation.

2. ASME B30.5: The American Society of Mechanical Engineers (ASME) provides guidelines on mobile and locomotive cranes, emphasizing construction, maintenance, inspection, and testing. ASME certifications are highly regarded in the industry.

3. ISO 23813 and ISO 23814: These international standards specify the requirements for the design, materials, manufacturing, and testing of cranes. Adherence ensures globally recognized safety and performance metrics.

4. EN 13000: This European standard applies to mobile cranes, ensuring they meet specific safety requirements during design, testing, and maintenance. It focuses on preventing mechanical and structural failures.

5. API RP 2D: The American Petroleum Institute’s Recommended Practice 2D focuses on the operation and maintenance of offshore cranes but is often referenced for its comprehensive safety guidelines.

6. NCCCO Certification (National Commission for the Certification of Crane Operators): This U.S.-based certification ensures that crane operators are knowledgeable and skilled, reducing the likelihood of accidents.

7. Third-Party Inspections: Regular inspections by certified third parties are often mandated by these standards and regulations. These inspections verify that cranes are maintained and operated correctly.

Acquiring and maintaining these certifications helps to prevent accidents, ensures compliance with legal requirements, and fosters a culture of safety within organizations.

List Reference Technical Parameters of “grua pluma”

A “grua pluma” (commonly known as a jib crane or arm crane) is a type of crane with a horizontal member (jib or boom) that supports a movable hoist. This machinery is typically used in industrial and construction settings for lifting and moving heavy loads. Below are the reference technical parameters for a typical jib crane:

1. Load Capacity: Indicates the maximum weight the crane can handle, often ranging from 0.5 to 20 metric tons.

2. Jib Length: The horizontal reach of the crane, typically between 2 to 10 meters, though longer reaches are available for special applications.

3. Slewing Range: The degree of rotation of the jib around its vertical axis, generally between 180° and 360°, allowing full or partial circular lifting coverage.

4. Hoisting Speed: The speed at which the hoist can lift or lower the load; speeds can vary from 0.5 to 20 meters per minute based on the crane’s design and motor power.

5. Lifting Height: The maximum vertical distance the hoist can travel, ranging from 2 to 10 meters or more depending on the application.

6. Rotation Speed: The speed at which the jib can rotate around its axis, typically measured in degrees per second.

7. Power Supply: Voltage and phase requirements, often 230V/400V, three-phase, to power the hoist and rotational mechanisms.

8. Installation Type: Options include floor-mounted (freestanding), wall-mounted, or column-mounted variants, each suited for different spatial constraints and operational needs.

9. Control System: Can include options such as pendant control, wireless remote control, or integrated automation for precise and safe operations.

10. Material and Construction: Typically constructed from steel with corrosion-resistant coatings to ensure durability in various environments, including indoor and outdoor settings.

11. Safety Features: Incorporates safety mechanisms like overload protection, emergency stop functionality, and end limit switches to enhance operational safety.

Understanding these parameters is vital for selecting the appropriate jib crane to meet specific operational requirements and ensure efficient, safe lifting activities.

List Product features of “grua pluma”

A “grua pluma” (jib crane) is an essential lifting device used in various industrial applications. Here are its prominent features:

1. Versatility: Capable of handling a wide range of loads, from light to heavy-duty materials.

2. Ease of Operation: Simple controls make it user-friendly, reducing the learning curve and enhancing productivity.

3. Rotational Range: Often features a 180 to 360-degree rotational capability, allowing for extensive coverage and flexibility in material handling.

4. Adjustable Boom Length: The boom can often be extended or retracted to accommodate different load sizes and reach requirements.

5. Durability: Constructed from robust materials such as steel, ensuring long-term reliability and resilience against heavy usage and environmental factors.

6. Customization: Can be tailored to specific industry needs, including height, reach, and load capacity adjustments.

7. Compact Design: Space-efficient design, making it suitable for use in confined areas where larger cranes cannot operate.

8. Load Capacity: Capable of lifting a wide range of weights, commonly up to several tons, depending on the model and configuration.

9. Safety Features: Includes safety mechanisms such as overload protection, emergency stop functions, and fail-safe brakes to ensure safe operation.

10. Portability: Some models are designed for easy relocation, equipped with wheels or modular designs for temporary or mobile setups.

11. Electric/Manual Operation: Available in both electric and manual versions, offering flexibility in power sources and operational preferences.

12. Low Maintenance: Designed for minimal upkeep, thus reducing downtime and maintenance costs.

13. Cost-Effective: Provides a value-for-money solution with high efficiency in lifting and moving materials, thereby improving operational efficiency.

14. Wide Application: Suitable for use in various industries such as manufacturing, warehousing, construction, and shipping.

In summary, the “grua pluma” offers a blend of versatility, durability, and efficiency, making it an indispensable tool in material handling and industrial lifting operations.

List Various Types of “grua pluma”

“Grua pluma,” or jib cranes, are versatile and important tools in various industries for lifting and moving loads. Here is a rundown of different types of jib cranes:

1. Wall-Mounted Jib Crane:

– Pivot Wall-Mounted Jib: It’s mounted on a wall or column and can pivot horizontally, usually with a 200° to 180° rotation.

– Fixed Wall-Mounted Jib: Has a fixed, horizontal boom and is mounted on a wall; it doesn’t rotate but can handle heavy loads along its linear path.

2. Floor-Mounted Jib Crane:

– Free-Standing Jib Crane: Supported by a floor-mounted pillar, capable of 360° rotation and can be installed anywhere on the floor with the required foundation.

– Mast-Type Jib Crane: A hybrid between a floor-mounted and ceiling-suspended jib crane. It has a smaller footprint and can rotate up to 360°.

3. Portable Jib Crane:

– Mounted on a portable base with wheels, allowing it to be moved around as needed. Often used for low-capacity lifting tasks in flexible workspaces.

4. Articulating Jib Crane:

– Has an arm with multiple joints, allowing for a combination of two 360° pivots and enabling it to reach around obstacles, providing greater flexibility in confined spaces.

5. Ceiling-Mounted Jib Crane:

– Suspended from the ceiling, making it ideal for areas with limited floor space; can rotate usually up to 200° to 360° depending on design and installation specifics.

6. Foundationless Jib Crane:

– Usually a free-standing jib crane but does not require a costly concrete base, making it easy to install on existing flooring with adequate strength.

Each jib crane type has unique features tailored to specific applications and workspace requirements, making them essential in manufacturing, warehousing, and construction environments.

List Application of “grua pluma”

A “grua pluma,” often referred to as a jib crane, is a type of crane that utilizes a horizontal jib or boom to support a moving hoist. Here are some of its primary applications:

1. Manufacturing and Assembly Lines: Jib cranes are extensively used in manufacturing plants to transport materials and components efficiently across various stages of production.

2. Warehousing: They assist in the lifting and moving of heavy inventory items across different sections of a warehouse, enhancing operational efficiency.

3. Loading and Unloading: At ports and rail yards, jib cranes facilitate the loading and unloading of goods from ships, trucks, and trains, ensuring effective material handling.

4. Automotive Industry: These cranes aid in the installation of heavy vehicle components, such as engines and transmissions, by providing precise and controlled lifting capabilities.

5. Maintenance and Repair: Jib cranes are valuable in maintenance facilities, enabling the safe and effective lifting of heavy equipment and machinery for repairs and servicing.

6. Construction: On construction sites, jib cranes help in hoisting building materials like steel beams and concrete blocks to required heights, enhancing construction efficiency.

7. Workshops: In machine shops and metalworking facilities, they are utilized for handling heavy workpieces, aligning them precisely for machining operations.

8. Aviation: Jib cranes play a crucial role in the aviation industry for lifting aircraft components and assemblies during maintenance and assembly processes.

9. Chemical and Pharmaceutical Plants: These cranes are used to transport heavy drums, containers, and equipment, ensuring safe and efficient material handling in hazardous environments.

10. Energy Sector: Jib cranes are employed in power plants and wind farms for the maintenance and installation of heavy equipment and components.

Their versatility, ease of operation, and capacity to improve workflow make jib cranes indispensable across diverse industries.

List Buyer Types of “grua pluma”

“Grua pluma,” also known as “tower cranes” or simply “cranes,” are essential equipment in construction and various industrial sectors. The buyers of these cranes can be broadly categorized into several types based on their industry and requirements. Below is a concise list of the primary buyer types for “grua pluma”:

1. Construction Companies:

– Large-Scale Construction Firms: These companies frequently require tower cranes for constructing skyscrapers, large commercial complexes, and infrastructural projects. They typically look for durable, high-capacity cranes.

– Residential Construction Firms: Smaller cranes might be more suitable for residential projects, focusing on versatility and ease of use.

2. Rental Companies:

– Equipment Rental Services: These businesses purchase cranes to rent them out to construction companies, making it possible for smaller firms to access the necessary equipment without the high upfront costs.

3. Manufacturing and Industrial Companies:

– Steel and Material Handling Plants: These industries use cranes to handle heavy materials and components within their facilities.

– Shipyards and Ports: Cranes are essential for loading and unloading goods in these settings.

4. Government and Municipalities:

– Public Works Departments: Often need cranes for infrastructure projects like bridges, highways, and public buildings.

– Emergency Services: Some government sectors require cranes for disaster response, such as in the aftermath of earthquakes or floods to clear debris and aid in rescue operations.

5. Specialized Engineering Firms:

– Wind Energy Companies: Firms involved in the installation and maintenance of wind turbines require specialized cranes that can handle the specific demands of lifting heavy and delicate components to significant heights.

– Telecommunication Companies: Responsible for installing and maintaining communication towers.

6. Mining Companies:

– These companies use cranes for lifting heavy equipment and materials in challenging environments.

List “grua pluma” Project Types for Different Industries

“Grua pluma,” or jib cranes in English, serve various functions across several industries due to their versatility and ease of use. Here are some common project types for different industries:

Manufacturing:

– Assembly Line Assistance: Jib cranes can help in the assembly process by transporting parts to different sections.

– Material Handling: Used for lifting and positioning heavy equipment or materials in a factory setting.

Construction:

– Site Preparation: Lifting building materials, tools, and equipment.

– Structural Assembly: Assisting in the placement of beams and other structural components.

Warehousing and Logistics:

– Loading and Unloading: Handling goods onto and off trucks.

– Inventory Management: Moving heavy pallets within a warehouse.

Maritime:

– Shipbuilding: Assisting with the installation of large ship parts.

– Dockyard Operations: Loading and unloading containers and materials from ships.

Automotive:

– Production Lines: Handling engine blocks, body panels, and other components.

– Maintenance Facilities: Lifting heavy parts for installation or removal during vehicle repairs.

Energy Sector:

– Wind Turbines: Installation and maintenance of wind turbine components.

– Oil & Gas: Lifting and moving heavy machinery or materials in refineries and drilling sites.

Mining:

– Material Transport: Moving mined materials for processing.

– Equipment Handling: Lifting and positioning of heavy mining equipment.

Pharmaceuticals and Chemicals:

– Clean Room Applications: Handling sensitive equipment and materials in a controlled environment.

– Chemical Processing: Lifting and moving heavy containers or apparatus.

Aerospace:

– Aircraft Assembly: Assisting in the assembly of various aircraft components.

– Maintenance and Overhaul: Handling large parts or engines during maintenance.

Utility Services:

– Power Plants: Lifting and positioning of heavy machinery or components.

– Water Treatment Facilities: Transporting bulky equipment and materials.

Each industry utilizes jib cranes to improve operational efficiency, safety, and precision, making them invaluable tools for a range of project types.

grua pluma Accessories Upgrades and Custom Manufacturing Options

Crane booms, or grua plumas, can be enhanced with various accessories and custom manufacturing options to optimize functionality, safety, and efficiency. Below are some key upgrades and customizations:

1. Advanced Control Systems:

– Remote Controls: Improve operator safety and precision.

– Automated Systems: For tasks requiring high accuracy.

2. Lifting Attachments:

– Special Hooks: For specific cargo types.

– Jibs: Extend reach and versatility.

– Buckets and Grabs: For material handling.

3. Safety Enhancements:

– Load Monitoring Systems: Prevent overload.

– Anti-collision Systems: For operations in congested areas.

– Stabilizers and Outriggers: Increase stability during heavy lifts.

4. Custom Boom Configurations:

– Telescopic Booms: For various lift heights and loads.

– Articulating Booms: Enhanced maneuverability.

– Boom Extensions: Extend working radius.

5. Material Upgrades:

– High-strength Steel: Enhances durability.

– Corrosion-resistant Materials: For harsh environments.

6. Operational Features:

– Variable Speed Control: Precision in movement.

– Energy-efficient Motors: Reduce operational costs.

– Noise Reduction: For urban or sensitive environments.

7. Rotating and Tilting Platforms:

– 360-degree Rotation: Comprehensive coverage.

– Tilting Mechanisms: For angle-specific tasks.

8. Custom Fabrication:

– Custom-sized Booms: Tailored for specific applications.

– Special Coatings: For protection against environmental factors.

By incorporating these accessories and custom manufacturing options, grua plumas can be tailored to meet a variety of industry-specific requirements, enhancing both operational efficiency and safety.

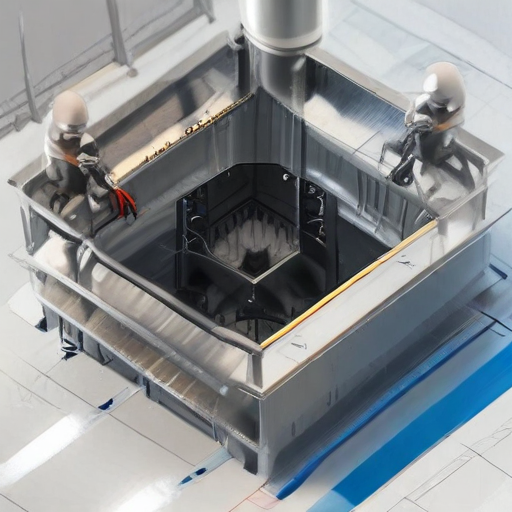

List Quality Control and The Manufacturing Process of “grua pluma”

Quality Control in Grua Pluma Manufacturing

1. Material Inspection: Raw materials, particularly steel, are tested for quality, strength, and durability.

2. Dimensional Accuracy: Precision tools measure components to ensure they meet design specifications.

3. Welding Quality: Welds are inspected using non-destructive testing (NDT) methods such as ultrasonic testing to detect imperfections.

4. Load Testing: Pre-assembly and post-assembly load tests verify the crane can handle its maximum rated capacity.

5. Paint and Coating Inspection: Coatings are examined for uniformity and adhesion to protect against corrosion.

6. Final Inspection: A thorough check of all components and systems (hydraulic, electrical, control systems) is carried out before shipping.

Manufacturing Process of Grua Pluma

1. Design and Engineering: Engineers create detailed plans using CAD software, specifying all dimensions, materials, and parts.

2. Cutting and Shaping: Raw steel plates are cut into required shapes using laser cutting or plasma cutting, followed by machining processes to achieve dimensional accuracy.

3. Forming and Welding: Structural components (e.g., the boom, jib, mast) are formed and assembled using high-precision welding techniques.

4. Machining and Assembly: Machined parts like gears, winches, and bearing assemblies are put together. Hydraulic and electrical systems are integrated.

5. Surface Treatment: Components undergo sandblasting, priming, and painting to protect them from corrosion.

6. Sub-Assembly: Key sections like the boom and rotating device are pre-assembled where controls and hydraulics are calibrated.

7. Final Assembly: All sub-assemblies are brought together. Controlled environments ensure precise fits and alignments.

8. Testing: The assembled crane undergoes rigorous load tests and operational tests to ensure safety and functionality.

9. Packaging and Shipping: The crane is disassembled into transportable sections and prepared for shipping following international safety standards.

Quality control is deeply integrated at each stage to ensure the final product adheres to the highest safety and performance standards.

How to use “grua pluma”

A “grua pluma” (jib crane) is a versatile piece of equipment used primarily for lifting and moving heavy loads within a confined space. Here’s a step-by-step guide to using one safely and efficiently:

1. Inspection:

– Visual Check: Inspect the crane for any signs of wear, damage, or malfunction.

– Operational Check: Test the controls and ensure all safety features, like limit switches and emergency stops, are working.

2. Prepare the Load:

– Weight Calculation: Determine the weight of the load to ensure it’s within the crane’s capacity.

– Secure the Load: Use appropriate lifting devices (slings, straps, hooks) to secure the load. Ensure they are in good condition and correctly attached.

3. Positioning:

– Crane Base: Ensure the base is stable and appropriately anchored.

– Boom Adjustment: Adjust the boom angle and length according to the load’s size and shape.

4. Operation:

– Control Panel Familiarization: Understand and use the crane’s controls for smooth operation.

– Lifting: Raise the load slowly to check stability. Avoid sudden movements.

– Movement: Use the jib to swing the load to the desired location. Keep movements slow and steady to prevent swaying.

5. Placing the Load:

– Lowering: Carefully lower the load to its new position.

– Final Check: Ensure the load is stable and securely placed before detaching the lifting devices.

6. Post-Operation:

– Shutdown: Turn off the crane and secure it in a safe position.

– Maintenance: Perform any necessary maintenance tasks, like lubrication and cleaning.

7. Safety:

– Operators: Only trained and certified personnel should operate the crane.

– Environment: Ensure the work area is clear of obstructions and unauthorized personnel.

By following these steps, you can safely and effectively use a “grua pluma” for your lifting needs.

“grua pluma” Comparative Analysis

A “grúa pluma,” often referred to as a jib crane or tower crane, is a type of machinery extensively used in construction and industrial settings for heavy lifting and material handling operations. This analysis compares its advantages and limitations against alternative lifting devices like mobile cranes and derrick cranes.

Advantages:

1. Height and Reach: Grúas pluma excel in height and reach capabilities, making them ideal for high-rise construction projects. A top-slewing tower crane, for example, can reach greater heights compared to most mobile cranes.

2. Load Capacity: These cranes have substantial load capacities, allowing them to lift very heavy materials. They often have a strong jib, enhancing their ability to lift weights at considerable distances.

3. Fixed Position Stability: Once erected, a grúa pluma offers superior stability and can operate under various weather conditions, which is critical for long-term projects.

4. Efficiency: Being stationary, they can handle repetitive lifting tasks more efficiently than mobile cranes, which require repositioning and setup adjustments.

Limitations:

1. Installation and Dismantling: Grúas pluma require a complex setup and dismantling process, involving substantial time and labor costs compared to mobile cranes, which are easier to transport and erect.

2. Immobility: Unlike mobile cranes, grúas pluma cannot be easily repositioned. This makes them less flexible for projects requiring frequent changes in the crane’s position.

3. Operational Space: These cranes necessitate significant groundwork, including a stable foundation and ample overhead space, which can be a constraint in congested urban areas or sites with restricted space.

4. Cost: The initial cost for purchasing and installing a tower crane can be high. This becomes a considerable investment for short-term projects compared to renting mobile cranes or derrick cranes.

Comparative Summary:

Grúas pluma are unmatched for high-rise construction due to their reach and load capacity but are less flexible and cost-effective for short-term or smaller projects. Mobile cranes offer superior mobility and ease of setup but at the cost of reduced height and load capabilities. Derrick cranes, meanwhile, can provide an alternative with better versatility but may lack the specialized height advantages of a tower crane.

In conclusion, the choice of a grúa pluma versus other crane types depends heavily on the specific requirements of the project, including height, load capacity, duration, and the space available for crane operation.

“grua pluma” Warranty and Support

“Grua Pluma,” a specialized crane often used in construction, offers robust warranty and support services to ensure optimal performance and customer satisfaction. Typically, these cranes come with a manufacturer’s warranty that can range from 1 to 5 years, covering major components such as the boom, hydraulic system, and electronic controls. It is crucial to read the warranty terms carefully, as they often specify regular maintenance requirements and exclude damage from misuse, accidents, or unauthorized modifications.

Support services for the Grua Pluma include 24/7 customer assistance, available through various channels such as phone, email, and sometimes even instant messaging. Many manufacturers also provide online resources like user manuals, troubleshooting guides, and video tutorials to assist operators in resolving common issues.

Routine maintenance is a critical aspect of extending the Grua Pluma’s life and ensuring safety. Most companies offer maintenance packages that include regular inspections, lubrication of moving parts, and replacement of worn-out components. These services can often be bundled with the crane’s purchase for convenience and cost savings.

Additionally, many suppliers have a network of certified technicians who can provide on-site repairs and emergency services. Having qualified professionals handle repairs ensures that the crane remains in compliance with safety and operational standards.

In summary, the Grua Pluma comes with a comprehensive warranty and extensive support services aimed at maximizing uptime and operational efficiency. By leveraging these services, operators can ensure that their equipment remains in peak condition, thereby safeguarding their investment and reducing the risk of unexpected downtime. Always consult with the specific manufacturer or dealer for exact details regarding warranty coverage and support options tailored to your needs.

List “grua pluma” FAQ

Grua Pluma FAQ

1. ¿Qué es una grúa pluma?

Una grúa pluma es un tipo de maquinaria de elevación y transporte, utilizada principalmente en construcciones y fábricas para mover cargas pesadas. Su diseño incluye un brazo horizontal (pluma) para alcance y precisión en el manejo de cargas.

2. ¿Cuáles son las partes principales de una grúa pluma?

– Pluma: brazo horizontal que soporta la carga.

– Columna: soporte vertical que sustenta la pluma.

– Polipasto: dispositivo de elevación para levantar las cargas.

– Base: estructura que proporciona estabilidad a la grúa.

3. ¿Para qué se utiliza una grúa pluma?

Se utiliza para elevar, mover y posicionar cargas pesadas en áreas específicas, como en operaciones de ensamblaje, almacenamiento y mantenimiento.

4. ¿Qué tipos de grúas pluma existen?

– Manual: operada manualmente para levantar y mover cargas más ligeras.

– Motorizada: equipada con motor eléctrico para manipulación de cargas más pesadas.

– Fija: instalada permanentemente en una base fija.

– Móvil: montada sobre ruedas o rieles para movimiento a diferentes áreas.

5. ¿Qué capacidad de carga puede manejar una grúa pluma?

Varía según el diseño y modelo, pero generalmente entre 100 kg y varias toneladas.

6. ¿Qué medidas de seguridad se deben considerar al utilizar una grúa pluma?

– Capacitación adecuada para los operadores.

– Inspección regular de la grúa y sus componentes.

– Uso correcto de los equipos de protección personal (EPP).

– No sobrepasar la capacidad de carga máxima permitida.

– Asegurarse de que el área de operación esté libre de obstáculos.

7. ¿Cuáles son los beneficios de usar una grúa pluma?

Ofrecen precisión en el manejo de cargas, mejoran la eficiencia en las operaciones, reducen el esfuerzo físico y minimizan riesgos de accidentes laborales.

8. ¿Cómo se mantiene una grúa pluma?

Requiere inspecciones periódicas, lubricación de partes móviles, chequeo de sistemas eléctricos y reemplazo de piezas desgastadas según recomendación del fabricante.

Top 10 FAQ with answer about grua pluma for Buyer Sourcing from China

Certainly! Here are the top 10 frequently asked questions about sourcing “grúa pluma” (crane arm or jib crane) from China along with concise answers:

1. What is a grúa pluma?

– A grúa pluma, or jib crane, is a type of crane featuring a horizontal arm (jib or boom) fixed to a wall or floor-mounted pillar. They are commonly used for lifting and moving heavy materials within a range.

2. What are the main types of jib cranes available?

– The primary types are wall-mounted, pillar-mounted, and portable jib cranes. Each type serves different operational needs and space requirements.

3. What are the typical load capacities and spans available?

– Jib cranes range from lightweight models with capacities around 0.5 tons to heavy-duty versions exceeding 10 tons. Spans typically range from 3 to 10 meters.

4. How do I ensure the quality of jib cranes from China?

– Look for ISO-certified manufacturers, request product certifications, and perform factory audits or inspections through a third-party service. Checking customer reviews and testimonials can also be helpful.

5. What is the lead time for manufacturing and delivery?

– Standard lead times range from 4 to 8 weeks, depending on the customization level and order volume. Shipping can take 2 to 6 weeks depending on the destination.

6. Can I customize a jib crane to specific requirements?

– Yes, most manufacturers offer customization options for load capacity, span, height, mounting type, and additional features like motorization and controls.

7. What are the common payment terms?

– Typical payment terms include a 30% advance payment with the balance paid before shipment. Letters of credit (L/C) and escrow services are also commonly used for secure transactions.

8. What are the logistics and shipping options?

– Sea freight is commonly used due to the size and weight of jib cranes. Air freight may be an option for smaller units, though it is significantly more expensive.

9. Are spare parts and after-sales service available?

– Most reputable manufacturers provide spare parts and after-sales service. Ensure the supplier offers a warranty and support agreements, and check the availability of parts.

10. What import regulations should I be aware of?

– Know the import duties, local standards, and certification requirements (such as CE marking for Europe). Working with a local clearing agent can help navigate these regulations efficiently.

These points should help you in making an informed decision when sourcing jib cranes from China.