hvac rectangular duct Safety Certifications

HVAC rectangular duct systems must adhere to specific safety certifications to ensure the system’s quality, performance, and safety. The key safety certifications often sought after are:

1. UL 181: This certification from Underwriters Laboratories applies to air ducts, air connectors, and various other components used in HVAC systems. It ensures that the materials used are fire-resistant, contributing to the overall safety of the ductwork.

2. SMACNA Standards: The Sheet Metal and Air Conditioning Contractors’ National Association publishes standards for HVAC duct construction and installation. Compliance with these standards ensures that the duct systems are safe, durable, and efficient.

3. ASHRAE Standards: The American Society of Heating, Refrigerating, and Air-Conditioning Engineers provides guidelines that promote energy efficiency and environmental sustainability while ensuring safe operations.

4. NFPA 90A & 90B: The National Fire Protection Association sets fire safety standards for the installation of air conditioning and ventilation systems, including ductwork. These standards are vital for preventing fire hazards within HVAC systems.

5. ICC Building Codes: The International Code Council develops building codes that ensure safety, sustainability, and affordability of structures. Compliance with ICC standards ensures that HVAC systems meet local safety regulations.

6. ISO 9001 Certification: While not specific to safety, ISO 9001 certification ensures that a company maintains high-quality management practices, which often include stringent safety protocols for their products.

Choosing HVAC rectangular ducts that meet these certifications ensures that the system is safe, reliable, and efficient, protecting both the technicians who install them and the occupants of the buildings where they are used. Always verify that the ductwork meets the relevant national and international safety standards to ensure optimal performance and compliance.

List Reference Technical Parameters of “hvac rectangular duct”

Certainly! HVAC (Heating, Ventilation, and Air Conditioning) rectangular ducts have several technical parameters that are essential for their design, installation, and operation. Here are the key reference technical parameters:

1. Dimensions:

– Width (W): The horizontal measurement of the duct.

– Height (H): The vertical measurement of the duct.

– Length (L): The overall distance the duct spans.

2. Material:

– Common materials include galvanized steel, aluminum, and in some cases, plastic or fiberglass.

3. Thickness (Gauge):

– The metal thickness is usually specified by a gauge number, with common gauges being 24, 26, or 28. Thicker metal may be used for larger ducts.

4. Airflow Rate:

– Measured in cubic feet per minute (CFM). Determines the volume of air passing through the duct.

5. Velocity:

– Airflow speed measured in feet per minute (FPM). Ideal velocity ranges from 600 to 900 FPM to avoid noise and friction losses.

6. Pressure Rating:

– Static Pressure: Maximum air pressure within the duct system, typically measured in inches of water column (in. WC).

7. Aspect Ratio:

– Ratio of width to height (W/H). Aspect ratios close to 1 are preferable to reduce resistance and noise.

8. Insulation:

– Types include internal or external liner to minimize heat loss, condensation, and noise.

9. Connection Methods:

– Various joining methods include flange, slip-joint, and welded connections, each having specific design standards.

10. Leakage Class:

– Defined by the allowable air leakage rate, with classes like Class A, B, or C according to standards such as SMACNA or ASHRAE.

11. Fire Ratings:

– Compliance with fire codes, often requiring fire-resistant materials or coatings.

12. Reinforcement:

– Required for maintaining duct shape and integrity against internal pressures, considering factors like stiffeners and brackets.

By keeping these technical parameters in check, engineers ensure that HVAC rectangular ducts perform efficiently, safely, and in alignment with regulatory standards.

List Product features of “hvac rectangular duct”

Certainly! Here are the product features of an HVAC rectangular duct:

1. Material Options:

– Available in galvanized steel, aluminum, or stainless steel for durability and corrosion resistance.

2. Size Variability:

– Customizable sizes and dimensions to fit specific HVAC system requirements.

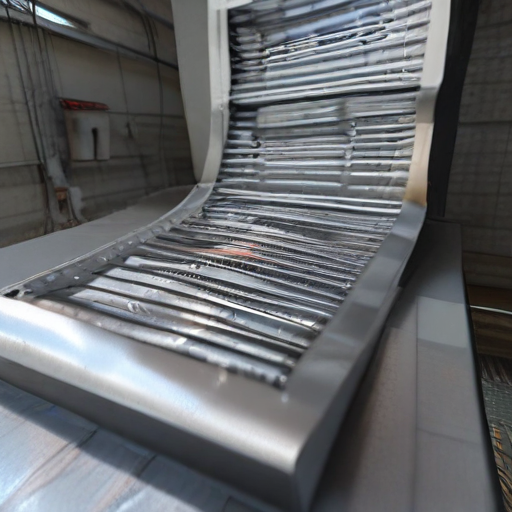

3. Airflow Efficiency:

– Designed for efficient airflow distribution with minimal resistance and noise.

4. Construction Design:

– Typically features a flat and straight design, which minimizes air friction and optimizes space usage.

5. Joint Types:

– Multiple sealing options including slip joints, flange connections, and welded seams to ensure airtight installations.

6. Insulation Compatibility:

– Can be paired with internal or external insulation to improve energy efficiency and control condensation.

7. Accessories Availability:

– Compatible with a wide range of accessories, including dampers, filters, and grills for customized system setups.

8. Compliance:

– Meets or exceeds industry standards, such as SMACNA (Sheet Metal and Air Conditioning Contractors’ National Association) guidelines for construction and performance.

9. Ease of Installation:

– Lightweight yet sturdy, designed for straightforward installation and maintenance, reducing labor costs.

10. Corrosion Resistance:

– Coatings and treatments available to extend duct life and enhance resistance to various environmental conditions.

11. Sound Attenuation:

– Designed to incorporate sound traps and silencers to minimize noise transmission.

12. Thermal Expansion Compatibility:

– Accommodates thermal expansion and contraction without compromising integrity.

13. Pressure Ratings:

– Suitable for varying pressure ratings to handle different system requirements in both residential and commercial applications.

14. Flexibility and Modularity:

– Allows for modular extensions and easy modifications to suit changing HVAC system designs.

15. Aesthetic Options:

– Available in different finishes and coatings to match architectural requirements.

By incorporating these features, HVAC rectangular ducts ensure a reliable, efficient, and customizable solution for diverse airflow management needs.

List Various Types of “hvac rectangular duct”

Here’s a concise overview of various types of HVAC rectangular duct:

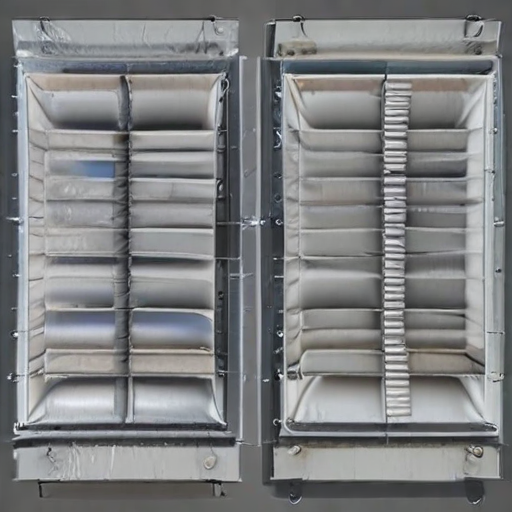

1. Lined Duct:

– Internally Lined: Insulation material is affixed inside the duct walls, reducing noise and thermal transfer.

– Externally Lined: Insulation is placed outside, often wrapped in a protective layer.

2. Double Wall Duct:

– Features a dual-layer construction, with insulation sandwiched between inner and outer sheets, enhancing thermal performance and noise control.

3. Rigid Duct:

– Constructed from materials like galvanized steel or aluminum, providing durability and minimal air leakage.

4. Flexible Duct:

– Though less common in rectangular form, it’s used to navigate around obstacles, often with a metal or plastic framework.

5. High-Efficiency Duct:

– Designed for optimal airflow and minimal resistance, utilizing materials that ensure long-term efficiency and reduced energy consumption.

6. Custom-Built Ducts:

– Tailored to specific project requirements, these ducts can be fabricated in unusual dimensions or configurations to fit unique spaces.

7. Fire-Resistant Duct:

– Made with materials designed to withstand high temperatures, crucial for safety in commercial and industrial applications.

8. Leakage-Resistant Duct:

– Incorporates sealing technologies to prevent air leaks, ensuring efficient operation and reduced energy loss.

These types cater to varied needs, whether it’s for noise reduction, enhanced durability, or specific project requirements.

List Application of “hvac rectangular duct”

HVAC (Heating, Ventilation, and Air Conditioning) rectangular ducts are essential components in a variety of settings, enabling efficient airflow in buildings and industrial spaces. Applications include:

1. Commercial Buildings: Office complexes, shopping malls, and retail stores utilize rectangular ducts for efficient air distribution, ensuring comfort for occupants by maintaining optimal temperature and air quality.

2. Residential Properties: Homes and apartment buildings use rectangular ducts in central HVAC systems to provide consistent heating and cooling, enhancing living conditions.

3. Industrial Facilities: Factories and warehouses depend on these ducts for ventilating large areas, removing contaminants, and maintaining suitable working environments.

4. Healthcare Settings: Hospitals and clinics require stringent air quality controls. Rectangular ducts facilitate efficient air filtration and distribution, essential for patient care and hygiene.

5. Educational Institutions: Schools and universities use HVAC ducts to deliver clean, conditioned air to classrooms, laboratories, and auditoriums, supporting a conducive learning environment.

6. Hospitality Industry: Hotels and restaurants rely on these ducts to create comfortable atmospheres for guests through controlled heating and cooling.

7. Laboratories and Clean Rooms: These facilities need precise air handling to control contamination levels. Rectangular ducts ensure reliable and efficient airflow management.

8. Basement and Crawl Spaces: In residential and commercial buildings, these ducts help manage air quality and temperature in otherwise difficult-to-condition spaces.

9. Theaters and Cinemas: For audience comfort, HVAC systems with rectangular ducts provide well-distributed heating and cooling.

10. Transportation Hubs: Airports, train stations, and bus terminals use rectangular ducts to manage large volumes of air, maintaining a pleasant environment for travelers.

In all these applications, the rectangular shape offers advantages such as ease of installation against walls or ceilings, flexibility in layout, and efficient space utilization, making it a popular choice in diverse HVAC projects.

List Buyer Types of “hvac rectangular duct”

Certainly! There are several types of buyers interested in “HVAC rectangular ducts,” each with specific needs and purposes. Here’s a brief overview:

1. Commercial Contractors:

– Demand: Large volumes for commercial buildings, malls, office spaces, and infrastructure projects.

– Focus: Durability, efficiency, and compliance with building codes and regulations.

2. Residential Contractors:

– Demand: Smaller quantities tailored to individual homes or residential buildings.

– Focus: Cost-effectiveness, space optimization, and ease of installation.

3. Industrial Clients:

– Demand: Heavy-duty ducts for factories, warehouses, and manufacturing plants.

– Focus: Robustness, high-capacity airflow, and resistance to environmental factors like dust and chemicals.

4. HVAC Installers and Technicians:

– Demand: Varied sizes and configurations for renovation, replacement, and repair works.

– Focus: Flexibility, quick availability, and compatibility with existing systems.

5. Building Engineers and Planners:

– Demand: Specifications for new construction and retrofitting projects.

– Focus: Detailed design specifications, energy efficiency, and integration with other building systems.

6. Government and Public Sector:

– Demand: Projects for schools, hospitals, government buildings, and other public facilities.

– Focus: Adherence to stringent regulatory standards and energy efficiency requirements.

7. Wholesale Distributors:

– Demand: Bulk purchases for resale to smaller contractors and retailers.

– Focus: Competitive pricing, consistent quality, and reliable supply chain.

8. Property Management Firms:

– Demand: Regular supplies for maintenance and upgrades across multiple properties.

– Focus: Durability, ease of maintenance, and long-term value.

Each buyer type has distinct needs but shares a common requirement for quality and reliable HVAC rectangular ducts to ensure efficient climate control and ventilation in their respective projects.

List “hvac rectangular duct” Project Types for Different Industries

HVAC Rectangular Duct Project Types for Different Industries

#### 1. Commercial Buildings

– Office Spaces: Ensuring efficient air distribution for large office floors.

– Retail Stores: Facilitating comfortable shopping environments.

– Hospitality: Temperature control in hotels, restaurants, and casinos.

– Medical Facilities: Sterile air conditions in hospitals and clinics.

#### 2. Industrial Facilities

– Manufacturing Plants: Managing temperatures and pollutants in production areas.

– Warehouses: Maintaining climate for storage of temperature-sensitive goods.

– Clean Rooms: Specialized ducts for electronics and pharmaceutical industries.

– Power Plants: Handling ventilation and cooling in high-heat operations.

#### 3. Residential Buildings

– Apartment Complexes: Centralized systems for multi-unit dwellings.

– Single-family Homes: Customized ductwork for individualized air management.

– High-rises: Vertical ducting for efficient air distribution over multiple floors.

#### 4. Educational Institutions

– Schools and Universities: Maintaining optimal learning environments.

– Laboratories: Providing precise temperature and air quality controls.

#### 5. Entertainment and Sports Facilities

– Theaters and Cinemas: Comfortable air distribution in large auditoriums.

– Stadiums: Ventilation in extensive seating and concourse areas.

#### 6. Data Centers

– Server Rooms: High-efficiency cooling solutions to safeguard equipment.

– IT Facilities: Ducts designed for optimal airflow and temperature stability.

#### 7. Public Infrastructure

– Airports: Handling air distribution over large terminal spaces.

– Train Stations: Ventilation in occupied platforms and common areas.

– Municipal Buildings: Ensuring comfort in government offices and public spaces.

#### 8. Historical and Cultural Buildings

– Museums: Climate control to preserve artifacts and artworks.

– Libraries: Ensuring air quality and temperature for preserving books and archives.

Each project type addresses specific industry requirements, focusing on efficient and effective air distribution to maintain comfort, safety, and operational efficiency.

hvac rectangular duct Accessories Upgrades and Custom Manufacturing Options

When upgrading or customizing rectangular HVAC duct systems, several accessories and bespoke manufacturing options can enhance efficiency, performance, and longevity. Here are some critical upgrades and custom manufacturing considerations:

Accessories:

1. Dampers: Control airflow and balance the system with manual or automatic dampers.

2. Insulation: Add external or internal insulation to improve energy efficiency and reduce noise.

3. Flanges and Gaskets: Ensure tight connections and minimize air leaks with high-quality flanges and gaskets.

4. Turning Vanes: Install turning vanes in elbows and offsets to reduce turbulence and improve airflow.

5. Access Doors: Facilitate maintenance and inspection with strategically placed access doors.

6. Fire Dampers: Enhance safety by integrating fire dampers that activate in the event of a fire.

7. Sound Attenuators: Reduce noise levels by incorporating sound attenuation materials or devices.

Custom Manufacturing Options:

1. Material Choices: Select materials like galvanized steel, aluminum, or stainless steel to meet specific durability and environmental requirements.

2. Custom Sizes and Shapes: Bespoke manufacturing enables ducts to fit precisely within unique building layouts, optimizing space and functionality.

3. Coatings and Finishes: Apply custom coatings to resist corrosion, enhance appearance, or meet specific regulatory standards.

4. Prefabrication: Utilize prefabricated sections made to exact specifications to speed up installation and improve site efficiency.

5. Innovative Connectors: Opt for advanced connection systems that simplify assembly and disassembly, such as slide-on flanges or clamp connectors.

6. Aerodynamic Enhancements: Design ducts with smooth interior surfaces and optimized shapes to minimize resistance and improve airflow.

Incorporating these accessories and custom manufacturing options not only enhances the HVAC system’s performance but also prolongs its lifespan and ensures it meets specific building requirements.

List Quality Control and The Manufacturing Process of “hvac rectangular duct”

Quality Control in HVAC Rectangular Duct Production

1. Material Inspection: Examine raw materials (galvanized steel, aluminum) for defects.

2. Dimensional Accuracy: Validate dimensions using precise tools to meet design specifications.

3. Weld Inspection: Ensure robust joint integrity with non-destructive tests.

4. Leakage Tests: Use smoke or pressure tests to detect and rectify leaks.

5. Coating Quality: Check for uniform application of any protective coatings.

6. Final Inspection: Conduct a thorough assessment before dispatch.

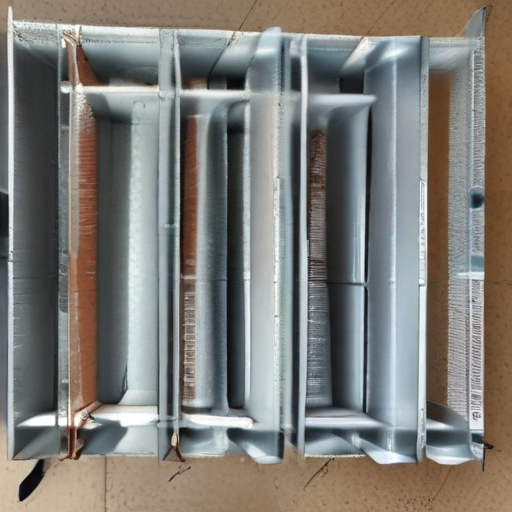

Manufacturing Process of HVAC Rectangular Duct

1. Design and Planning

– Specification Review: Understand the HVAC requirements and design parameters.

– CAD Modelling: Create detailed designs and blueprints.

2. Material Selection and Preparation

– Material Choice: Select appropriate metal sheets.

– Sheet Preparation: Cut the metal sheets to size using shearing machines.

3. Forming and Cutting

– Forming: Use roll formers or brakes to shape the sheets into rectangular ducts.

– Cutting: Trim edges and create necessary openings using plasma cutters or shears.

4. Assembling

– Joining: Use welding, hammering, or locking edges to join sections.

– Sealing: Apply sealants to ensure airtight connections.

5. Coating and Insulation

– Coating: Apply rust-preventive and protective coatings if required.

– Insulation: Install sound and thermal insulation materials as specified.

6. Quality Assurance

– Leak Testing: Perform air leakage tests and rectify any detected issues.

– Final Inspection: Verify dimensions, weld quality, and overall integrity.

7. Packaging and Dispatch

– Packaging: Protect finished ducts using appropriate packaging materials.

– Distribution: Coordinate logistics for timely delivery to the installation site.

This structured approach ensures high-quality HVAC rectangular ducts, meeting both regulatory standards and customer expectations.

How to use “hvac rectangular duct”

Using HVAC rectangular ductwork involves a systematic approach to ensure the efficient distribution of air within a building. Here’s a concise guide:

1. Planning and Design:

– Calculate Load: Determine the heating and cooling loads to size the ducts appropriately. Use HVAC load calculation software for accuracy.

– Duct Sizing: Select the dimensions based on airflow requirements, minimizing pressure loss. Follow the ASHRAE (American Society of Heating, Refrigerating and Air-Conditioning Engineers) guidelines.

– Layout: Design the duct layout to provide uniform air distribution. Plan for minimal bends and turns to reduce friction losses.

– Materials: Choose the right materials (e.g., galvanized steel, aluminum) and insulation to prevent heat loss and condensation.

2. Installation:

– Cutting: Measure and cut the duct sections to the required lengths using tin snips or a power shear.

– Seaming and Joining: Assemble the duct sections using seams (e.g., Pittsburgh seam) and connect them with drive cleats and S-clips.

– Sealing: Seal all joints and seams with mastic or duct tape designed for HVAC use to prevent air leaks.

– Hanging: Support the ducts with metal straps or brackets at regular intervals to keep them secure and reduce vibration.

3. Connection to System:

– Connections: Integrate the ducts with the HVAC system components, such as fans, air handling units, and diffusers.

– Dampers: Install dampers for controlling airflow to different zones or rooms.

– Balancing: After installation, balance the system by adjusting the dampers to ensure even air distribution.

4. Testing and Maintenance:

– Leak Testing: Perform a duct leakage test to identify and seal any leaks.

– Maintenance: Regularly inspect and clean the ducts to maintain efficiency and indoor air quality.

Proper planning, installation, and maintenance are essential for an efficient HVAC system using rectangular ducts.

“hvac rectangular duct” Comparative Analysis

Comparative Analysis of HVAC Rectangular Ducts

Heating, Ventilation, and Air Conditioning (HVAC) systems often use rectangular ducts for air distribution. These ducts are generally compared based on material, efficiency, installation, and maintenance aspects.

Material:

Rectangular ducts are typically made from galvanized steel, aluminum, stainless steel, or fiberglass. Galvanized steel is common due to its durability and cost-effectiveness. Aluminum is lighter and corrosion-resistant but more expensive. Stainless steel offers superior strength and resistance to corrosion but is the most expensive option. Fiberglass ducts provide good thermal insulation but may require additional structural support.

Efficiency:

Efficiency is influenced by duct design and air friction. Rectangular ducts tend to experience higher frictional losses compared to circular ducts due to their larger surface area and potential for turbulent airflow at corners. However, rectangular ducts can be optimized with smooth interior linings and by minimizing sharp bends to reduce energy losses.

Installation:

The installation of rectangular ducts can be more complex than circular ducts. Their shape requires more precise fitting and bracing to prevent sagging or improper sealing at joints. However, rectangular ducts can fit easily within constrained spaces like ceiling cavities and wall chases, offering flexibility in architectural designs.

Maintenance:

Maintenance of rectangular ducts is relatively straightforward due to their flat surfaces, which make cleaning and inspections easier compared to circular ducts. However, repairs can be more labor-intensive and costly if they involve removing and reassembling large sections of ductwork. Proper sealing at joints is critical to prevent air leaks, which can compromise system performance and efficiency.

Conclusion:

Rectangular ducts are a versatile choice for HVAC systems, balancing material options, efficiency, installation ease, and maintenance. While they may face higher frictional losses and installation complexities, their flexibility in fitting within building structures and ease of maintenance can outweigh these considerations. Careful design and regular maintenance can optimize their performance in diverse applications.

“hvac rectangular duct” Warranty and Support

Warranty and Support for HVAC Rectangular Ducts

When investing in HVAC rectangular ducts, it is essential to understand the warranty and support options available. Manufacturers often offer warranties that vary based on the material and construction quality of the ducts. Typically, warranties for HVAC rectangular ducts range from 5 to 10 years, covering defects in materials and workmanship. Some manufacturers may extend these warranties if proper maintenance records are maintained.

To ensure your warranty remains valid, follow the manufacturer’s guidelines on installation, usage, and maintenance. Improper installation or failure to perform regular maintenance can void the warranty. It’s advisable to have your ducts installed by certified professionals to avoid such issues.

Support services play a crucial role in the long-term performance of your HVAC system. Many manufacturers offer technical support for troubleshooting and addressing any issues that arise during usage. This support can include phone consultations, email assistance, and even on-site service calls. Some providers offer annual maintenance contracts to keep your system in optimum condition, which can help prevent unexpected breakdowns and extend the lifespan of your ducts.

Additionally, it is wise to inquire about any extended support packages or premium services that might be available. These packages often include periodic inspections, cleaning, and system tune-ups, providing peace of mind and ensuring your HVAC system operates efficiently.

In summary, thoroughly review warranty conditions and support services when purchasing HVAC rectangular ducts. Ensuring professional installation and adhering to maintenance requirements will help you get the most out of your investment, keeping your system running smoothly for years to come.

List “hvac rectangular duct” FAQ

Certainly! Here are some frequently asked questions (FAQ) about HVAC rectangular ducts:

1. What is an HVAC rectangular duct?

– An HVAC rectangular duct is a component of the heating, ventilation, and air conditioning system, designed to transport air throughout a building. It has a rectangular cross-section, providing an efficient way to move airflow in various directions while fitting within building structures.

2. Why choose rectangular ducts over round ones?

– Rectangular ducts are often selected for their ability to fit within tight spaces, especially between wall studs and ceiling joists. They can also handle high air volumes with lower profile heights, which is crucial for large buildings with spatial constraints.

3. What materials are commonly used for rectangular ducts?

– Common materials include galvanized steel, aluminum, and stainless steel. In some cases, fiberglass or other composite materials may be used for better insulation and noise reduction.

4. How are rectangular ducts sized?

– Sizing involves calculating the airflow requirements (CFM – cubic feet per minute) and the velocity of the air. Using those data points, engineers refer to duct sizing charts or software to determine the optimal duct dimensions for efficient airflow and minimal pressure loss.

5. What are the insulation options?

– Rectangular ducts can be insulated externally or internally with materials like fiberglass insulation, foam boards, or pre-insulated panels. Insulation helps maintain the desired air temperature and reduce noise.

6. How do you maintain rectangular ducts?

– Regular maintenance includes cleaning to remove dust and debris, inspecting for leaks or damage, and ensuring that dampers and other components are functioning correctly.

7. Can rectangular ducts be custom-fabricated?

– Yes, rectangular ducts can be custom-made to fit specific design requirements or to navigate complex building layouts. Custom fabrication ensures that the ductwork efficiently meets the building’s unique needs.

8. What are the advantages of rectangular ducts?

– Their shape allows for versatile installation, often easier to install within confined spaces. They also provide more surface area for insulation, improving thermal efficiency.

By addressing these FAQs, property owners and HVAC professionals can better understand the benefits and requirements of using rectangular ducts in their HVAC systems.

Top 10 FAQ with answer about hvac rectangular duct for Buyer Sourcing from China

Sure, here are the top 10 frequently asked questions and their answers regarding sourcing HVAC rectangular ducts from China:

1. What materials are typically used for HVAC rectangular ducts?

– Chinese manufacturers commonly use galvanized steel, stainless steel, and aluminum. Galvanized steel is the most popular due to its durability and cost-effectiveness.

2. How can I ensure the quality of the ducts?

– Look for manufacturers with ISO 9001 certification. Request samples, check for compliance with international standards like ASHRAE or SMACNA, and consider conducting on-site inspections or hiring third-party QC inspectors.

3. What is the typical lead time for production and delivery?

– Production lead times generally range from 2-6 weeks, depending on the order size and customization requirements. Shipping can take an additional 2-6 weeks, depending on the destination and shipping method.

4. Are there minimum order quantities (MOQs)?

– MOQs vary, but many manufacturers require orders of at least 100-500 square meters. Negotiating with manufacturers for smaller orders is possible, especially for long-term partnerships.

5. Can I get custom sizes and designs?

– Yes, many Chinese manufacturers offer customization to meet specific requirements, including varied sizes, shapes, and additional features such as insulation and coatings.

6. What are the payment terms?

– Standard payment terms include T/T (Telegraphic Transfer) with a common arrangement of 30% deposit and 70% balance upon shipment. L/C (Letter of Credit) is also accepted by some suppliers.

7. How do I handle shipping logistics?

– Manufacturers usually offer FOB (Free on Board) terms, meaning you’ll need to arrange for shipping from the nearest port. Partnering with a reliable freight forwarder can simplify this process.

8. What about after-sales service and warranty?

– Reputable suppliers provide warranties ranging from 1-3 years. Clarify terms for after-sales support, including repair and replacement policies, before finalizing the deal.

9. How can I verify the legitimacy of the supplier?

– Conduct due diligence by checking business licenses, reviewing online reports, and reading customer reviews. Platforms like Alibaba and Made-in-China provide verified supplier status.

10. What are the logistical considerations for importing from China?

– Factor in import duties, customs clearance, and local transport costs. Collaborating with customs brokers and understanding your country’s import regulations ensures smoother logistics.

Keeping these FAQs in mind will help make your sourcing process from China more efficient and reliable.