hydro pneumatic cylinder Safety Certifications

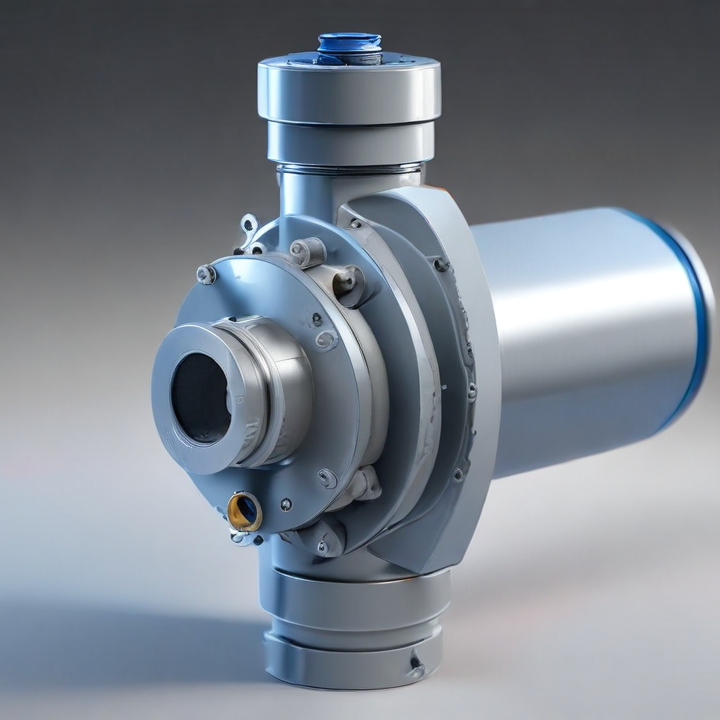

Hydro pneumatic cylinders, which combine the principles of hydraulics and pneumatics, are used in various industrial applications for their powerful force and precise control. Ensuring their safe operation is vital, and this is where safety certifications come into play. Key certifications for hydro pneumatic cylinders include:

1. CE Marking (European Conformity):

– Indicates compliance with EU safety, health, and environmental requirements.

– Required for machinery and pressure equipment within the European Economic Area.

2. ISO Certifications:

– ISO 9001: Ensures quality management systems are in place, enhancing product reliability and safety.

– ISO 4414: Specific for pneumatic fluid power systems, focusing on safety requirements.

3. ANSI/BFPA Certifications (American National Standards Institute/British Fluid Power Association):

– Ensure compliance with standards relevant to fluid power systems, including safety and performance metrics.

4. CSA (Canadian Standards Association):

– Certifies compliance with Canadian safety regulations, crucial for products used in Canada.

5. UL (Underwriters Laboratories):

– Ensures products meet rigorous safety testing and standards, particularly for electrical and fire safety.

6. ROHS (Restriction of Hazardous Substances):

– Ensures that products do not contain harmful substances, contributing to environmental safety.

When selecting hydro pneumatic cylinders, verifying these certifications helps ensure the product meets stringent safety and quality standards, reducing the risk of operational failures and ensuring compliance with regional regulations.

In summary, CE, ISO, ANSI/BFPA, CSA, UL, and ROHS certifications provide a robust framework for the safe and reliable use of hydro pneumatic cylinders, ensuring they meet the necessary health, safety, and environmental criteria.

List Reference Technical Parameters of “hydro pneumatic cylinder”

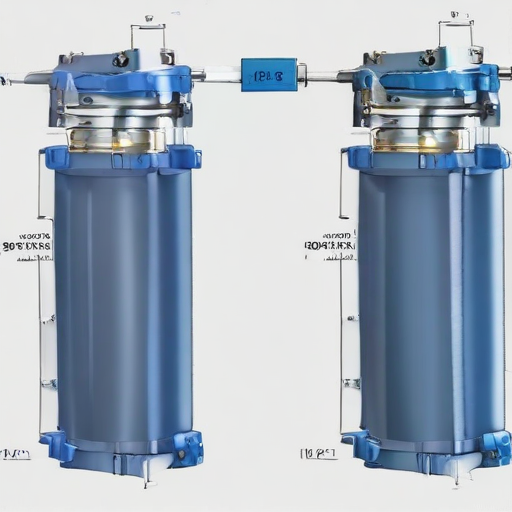

A hydro-pneumatic cylinder combines hydraulic and pneumatic technologies to achieve precision and power in various industrial applications. Below are key technical parameters typically associated with such cylinders:

1. Pressure Rating: A crucial specification, often denoted in bar or psi. It indicates the maximum hydraulic and pneumatic pressures the cylinder can safely handle. Typical pressure ratings might range from 100 to 400 bar for hydraulic components and 6 to 10 bar for pneumatic components.

2. Bore Size: The internal diameter of the cylinder, usually measured in millimeters or inches. Common bore sizes range from 25 mm to over 300 mm, affecting the force output.

3. Stroke Length: The maximum distance the piston rod can travel, generally listed in millimeters or inches. Standard stroke lengths can vary from 50 mm to more than 1000 mm.

4. Load Capacity: The maximum force the cylinder can exert, calculated based on the bore size and operating pressure. It’s often listed in Newtons (N) or pounds-force (lbf).

5. Rod Diameter: The diameter of the piston rod, which influences the cylinder’s structural integrity and load capacity. Common diameters range from 10 mm to 70 mm or more.

6. Velocity: The operating speed of the cylinder rod, often indicated in mm/s or in/s. It depends on both hydraulic and pneumatic components, typically ranging from 50 to 300 mm/s.

7. Temperature Range: The operating temperature limits, which can affect seal materials and overall performance. Typical ranges might be from -20°C to 80°C (-4°F to 176°F).

8. Mounting Options: Various configurations like flange, trunnion, or clevis, providing flexibility for installation.

9. Fluid Type: Specifications for compatible hydraulic fluids and compressed air quality, ensuring efficient operation and longevity.

10. Cycle Life: A measure of durability, often given in millions of cycles, depending on usage and maintenance.

Understanding these parameters helps in selecting the appropriate hydro-pneumatic cylinder for specific applications, ensuring optimal performance and reliability.

List Product features of “hydro pneumatic cylinder”

Hydro Pneumatic Cylinder: Key Product Features

1. Combined Action:

– Leverages both hydraulic and pneumatic principles.

– Provides the high force of hydraulics with the rapid action of pneumatics.

2. High Force Output:

– Capable of achieving very high force outputs due to hydraulic pressure.

– Ideal for heavy-duty applications requiring significant force.

3. Speed and Flexibility:

– Offers faster operational speeds compared to purely hydraulic systems.

– Adjustable speed to cater to different applications and requirements.

4. Compact Design:

– Integrates both hydraulic and pneumatic systems in a single, compact unit.

– Saves space and reduces installation complexity.

5. Energy Efficiency:

– Utilizes compressed air for rapid movements and oil for the power stroke.

– Enhances energy efficiency by reducing the overall need for hydraulic power during the entire cycle.

6. Versatility:

– Suitable for pressing, clamping, lifting, and other industrial operations.

– Adaptable to various environments and tasks due to its dual operation mode.

7. Durability and Reliability:

– Built to withstand rigorous industrial environments.

– Ensures consistent performance under high-stress conditions.

8. Ease of Maintenance:

– Simplified maintenance procedures.

– Fewer moving parts compared to pure hydraulic systems, leading to reduced wear and tear.

9. Safety Features:

– Includes integrated safety mechanisms to protect against overpressure and system failures.

– Enhances operational safety by delivering controlled force.

10. Customizable Options:

– Available in various sizes, force capacities, and configurations.

– Customizable to meet specific industrial or application requirements.

Overall, hydro pneumatic cylinders offer a robust and efficient solution by combining the strengths of hydraulic and pneumatic systems, thereby delivering high force and rapid action in a compact, versatile, and reliable unit.

List Various Types of “hydro pneumatic cylinder”

Hydro pneumatic cylinders combine the principles of hydraulics and pneumatics, providing high force and precise control. Here are several types, categorized by their distinctive features and applications:

1. Standard Hydro Pneumatic Cylinders:

– Single and Double Acting: Single-acting cylinders use pneumatic force in one direction and a spring return, while double-acting cylinders use pneumatic force in both directions for better control.

2. Telescopic Hydro Pneumatic Cylinders:

– Feature multiple stages that extend sequentially, allowing for a longer stroke in a compact design. They are ideal for applications with limited space.

3. Rotary Actuated Hydro Pneumatic Cylinders:

– Combine linear motion with rotary motion, useful in applications requiring rotation with linear extension, such as in robotic arms or complex tooling machinery.

4. Proportional Control Hydro Pneumatic Cylinders:

– Equipped with sensors and control valves to provide variable output, precise positioning, and adaptable force control, useful in automation systems.

5. Locking Hydro Pneumatic Cylinders:

– These include mechanisms to lock the piston in place, ensuring it maintains position under load. They are often used in safety-critical applications.

6. High-Speed Hydro Pneumatic Cylinders:

– Designed for rapid cycling and high-speed operations, beneficial in fast-paced manufacturing and packaging processes.

7. Press Cylinders:

– Specifically designed for press applications, offering high force and accuracy. They are common in metal forming, punching, and pressing operations.

8. Custom/Bespoke Hydro Pneumatic Cylinders:

– Tailored to unique application requirements, these cylinders are engineered to meet specific force, stroke, and installation specifications.

Each type of hydro pneumatic cylinder is designed to meet specific industry needs, providing a blend of speed, force, and control. They are widely used in manufacturing, robotics, automotive, aerospace, and various other industries requiring efficient and reliable linear motion solutions.

List Application of “hydro pneumatic cylinder”

Hydro pneumatic cylinders, which combine the features of both pneumatic and hydraulic systems, are used in various industrial applications due to their high force capabilities, precision control, and efficiency. Below are key applications:

1. Pressing and Stamping Operations: Used extensively in manufacturing for pressing, forming, and stamping metal sheets, providing high force and precise control.

2. Clamping and Holding: Employed in fixtures and jigs in machining processes to securely hold workpieces without deformation.

3. Injection Molding: Utilized in plastic injection molding machines for generating the required force to close the mold and sustain it during the injection process.

4. Material Handling: Implemented in robotic arms and automated guided vehicles (AGVs) for lifting, pushing, and positioning heavy objects accurately.

5. Punching and Blanking: Ideal for continuous high-speed punching and blanking processes due to their rapid cycling capabilities and sustained force.

6. Automobile Assembly Lines: Integrated into car manufacturing lines for operations like riveting, clinching, and pressing parts together.

7. Packaging Equipment: Used in packaging machinery for sealing, cutting, and forming packages with high precision and speed.

8. Shock Absorption and Damping: Employed in machinery that requires controlled deceleration and absorption of shock loads, enhancing equipment longevity and performance.

9. Die Casting Machines: Utilized to provide the necessary force for clamping and holding dies in die-casting processes.

10. Testing and Measuring Equipment: Used in material testing machines for applying controlled forces during tensile, compression, and fatigue testing.

These applications demonstrate the versatility and efficiency of hydro pneumatic cylinders in enhancing productivity and precision across various industrial sectors.

List Buyer Types of “hydro pneumatic cylinder”

Hydro pneumatic cylinders are specialized devices employed in various industrial applications due to their versatility and efficiency. The key buyer types for hydro pneumatic cylinders include:

1. Manufacturers: These include automotive, aerospace, and heavy machinery manufacturers who require precise and powerful motion control for assembly lines, robotic systems, and other automation processes.

2. Construction Companies: Construction firms use these cylinders in equipment like excavators, loaders, and cranes, where reliability and strength are critical for lifting and moving heavy materials.

3. Mining Industry: Mining operations utilize hydro pneumatic cylinders for heavy-duty machinery involved in drilling, hauling, and excavating, ensuring efficient and robust performance under harsh conditions.

4. Agricultural Sector: Farmers and agricultural enterprises deploy these cylinders in machinery such as tractors, harvesters, and other equipment to achieve efficient mechanization and automation of farming processes.

5. Renewable Energy: Wind and solar power installations use hydro pneumatic cylinders for positioning and adjusting panels and turbines, facilitating optimal energy capture and operational efficiency.

6. Railway and Transportation: Companies in this sector utilize these cylinders for applications in train and freight systems, particularly in braking and suspension systems, to enhance safety and performance.

7. Marine Industry: Marine applications, including ships and offshore platforms, employ hydro pneumatic cylinders for various functions like hatch covers, lifting systems, and stabilizers.

8. Defense and Military: Defense contractors and military services use these cylinders in vehicles, aircraft, and artillery systems where durability and precision are crucial under extreme conditions.

9. Utilities and Infrastructure: Municipalities and utility companies use these cylinders in infrastructure projects for tasks like lifting floodgates, operating waste management machinery, and other heavy-duty utilities work.

10. Custom Machinery Builders: Companies that design and build custom machinery for niche applications often require hydro pneumatic cylinders due to their capacity for tailored and specific performance needs.

These buyer types leverage the advantages of hydro pneumatic cylinders, which include high force-to-size ratio, reliability, and versatility, to meet the demands of their respective fields.

List “hydro pneumatic cylinder” Project Types for Different Industries

Hydro pneumatic cylinders, a fusion of hydraulic and pneumatic technologies, find versatile applications across various industries. Here’s a brief overview of project types across different sectors:

Automotive

1. Stamping Presses: Used to provide force for metal shaping in the production of car body parts.

2. Suspension Systems: For the precise control of damping forces and ride comfort.

3. Assembly Line Robotics: Enhancing automation and efficiency in vehicle production.

Aerospace

1. Landing Gear Systems: For smooth retraction and extension during takeoff and landing.

2. Hydraulic Brakes: Improving control and response in braking systems.

3. Actuation Systems: For flight control surfaces like flaps and ailerons.

Manufacturing

1. Material Handling: Used in conveyor systems and automated cranes for efficient material transport.

2. Pressing and Forming Machines: Ideal for applications requiring high force but with controlled motion.

3. Injection Molding: Facilitating the operation of molds for producing plastic components.

Construction

1. Earthmoving Equipment: Enhancing the functionality of machines like excavators and loaders.

2. Concrete Pumping: Precisely controlling the delivery of concrete in construction projects.

3. Formwork Systems: Ensuring accurate and reliable movement for formwork operations.

Energy

1. Wind Turbines: For pitch control systems that optimize blade angles for maximum efficiency.

2. Oil & Gas Extraction: Used in wellhead control systems for enhanced safety and precision.

3. Solar Trackers: Enabling solar panels to follow the sun’s movement for optimal energy capture.

Medical

1. Patient Lifting Systems: Ensuring smooth and safe operation in lifting and positioning patients.

2. Surgical Robots: Providing precise control for minimally invasive surgeries.

3. Rehabilitation Equipment: Facilitating controlled and adjustable motion for various rehabilitation exercises.

Packaging

1. Filling Machines: Accurate control in the filling process for liquids and granules.

2. Sealing Systems: Ensuring reliability and consistency in packaging seals.

3. Carton Formers: Efficiently shaping and assembling packaging cartons.

These examples highlight the extensive and varied applications of hydro pneumatic cylinders, showcasing their adaptability and efficiency across different industrial fields.

hydro pneumatic cylinder Accessories Upgrades and Custom Manufacturing Options

Hydropneumatic cylinders are widely utilized in various industrial applications due to their unique combination of hydraulic and pneumatic technologies, providing efficient and controlled movement. Upgrading and customizing these cylinders can significantly enhance their performance and longevity.

Accessories:

1. Sensors and Switches: Incorporate proximity sensors, position sensors, or reed switches to precisely monitor and control cylinder position and motion.

2. Mounting Kits: Specialized mounting brackets and pivot kits ensure secure and flexible installation in diverse setups.

3. End-of-Stroke Cushions: Install cushioning pads or hydraulic shock absorbers to minimize impact and noise at the end of the stroke, enhancing cylinder life.

4. Hydraulic Accumulators: These can be used to ensure consistent pressure and smoother operation, especially in fluctuating load scenarios.

5. Pressure Gauges and Regulators: To monitor and adjust the pressure within the cylinder for optimal performance and safety.

Upgrades:

1. Sealing Systems: Use advanced sealing technologies, such as Viton or Teflon seals, to improve resistance to extreme temperatures and aggressive media.

2. Enhanced Materials: Upgrade to corrosion-resistant materials like stainless steel or hard-anodized aluminum for better durability in harsh environments.

3. Modular Components: Implement modular designs to facilitate easier maintenance and replacements, reducing downtimes.

4. Integrated Feedback Systems: Integrate electronic feedback systems like LVDTs (Linear Variable Differential Transformers) for precise position control and monitoring.

Custom Manufacturing Options:

1. Specialized Bore and Stroke Sizes: Custom bore diameters and stroke lengths tailored to meet the specific needs of your application.

2. Non-Standard Mounts: Customized mounting options such as flange mounts, clevis mounts, or trunnion mounts to suit unique installation requirements.

3. Multiple Bore Cylinders: Design multiple bore configurations to provide varying force outputs within the same cylinder envelope.

4. Custom Coatings: Apply proprietary coatings for improved wear resistance and performance in specific environmental conditions.

Balancing the right mix of accessories, upgrades, and custom manufacturing options can elevate the performance and reliability of hydropneumatic cylinders to meet demanding industrial needs efficiently.

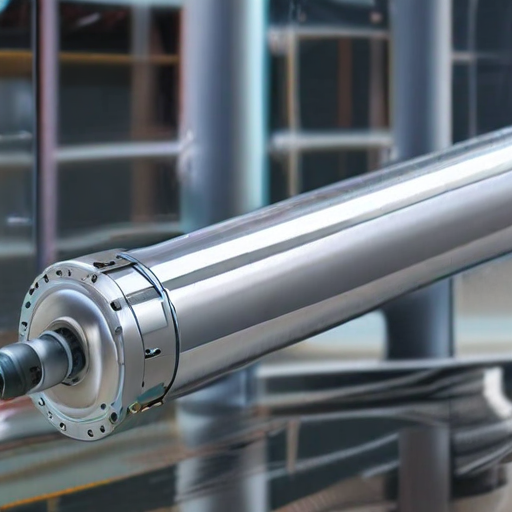

List Quality Control and The Manufacturing Process of “hydro pneumatic cylinder”

Quality Control in Hydro-Pneumatic Cylinder Manufacturing

1. Material Inspection: Verify raw materials using standard certifications and sample testing to ensure they meet specifications.

2. Precision Machining: Use CNC machines for accurate component shaping. Inspect dimensions with calipers and micrometers.

3. Surface Treatment: Ensure coatings and heat treatments are uniform and adhere to design requirements. Perform adhesion and hardness tests.

4. Component Assembly: Assemble components in a clean environment to avoid contamination. Validate assembly through fit and functional tests.

5. Leak Testing: Conduct hydrostatic and pneumatic tests to ensure the cylinder is free from leaks.

6. Performance Testing: Simulate operational conditions to confirm performance metrics like pressure ratings and cycle times.

7. Final Inspection: Verify all aspects, from dimensions to performance, adhere to design specifications. Document findings in quality reports.

Manufacturing Process of Hydro-Pneumatic Cylinder

1. Design & Engineering: Define specifications and create detailed CAD models. Run simulations to predict performance under various conditions.

2. Material Procurement: Source high-quality metals and composites. Ensure materials are certified to meet industry standards.

3. Machining: Use CNC milling and turning to create precise components like the cylinder barrel, piston, and rod.

4. Surface Treatment: Apply treatments such as anodizing, plating, or painting to improve durability and performance.

5. Assembly: Carefully assemble machined and treated components. Include seals, valves, and gaskets to ensure airtight performance.

6. Quality Testing: Perform rigorous testing, including leak, pressure, and cycle tests to ensure reliability.

7. Packaging & Shipping: Protect finished cylinders with appropriate packaging. Label for identification and traceability before dispatch.

By integrating stringent quality control measures, the manufacturing process ensures hydro-pneumatic cylinders meet high standards of performance and durability.

How to use “hydro pneumatic cylinder”

A hydro pneumatic cylinder integrates both hydraulic and pneumatic technologies to provide a versatile actuation solution. Here’s a concise guide on how to use it:

1. Installation:

– Mounting: Securely mount the cylinder using brackets or flanges designed to handle its force and movement.

– Connections: Attach hydraulic and pneumatic lines according to manufacturer specifications. Ensure airtight and leak-free connections.

2. Setup:

– Hydraulic System: Connect to a hydraulic power unit. Adjust pressure settings to match the cylinder’s requirements.

– Pneumatic System: Integrate with an air compressor system. Regulate air pressure using control valves.

3. Operation:

– Initial Stroke (Pneumatic): The pneumatic section initiates the movement. When air pressure is applied, the piston moves, performing rapid movements with minimal force.

– Switch to Hydraulic: For higher force requirements, the system switches to hydraulic power during the work stroke phase. The hydraulic fluid exerts pressure, enabling high-force applications like clamping or pressing.

4. Control:

– Valves and Sensors: Use directional control valves to manage flow direction. Sensors can be integrated for precise positioning and monitoring.

– Automation: PLCs (Programmable Logic Controllers) or other automation systems can optimize the operation sequence.

5. Maintenance:

– Routine Checks: Regularly inspect the cylinder for leaks, wear, and proper functioning. Ensure seals and gaskets are in good condition.

– Fluid Levels: Maintain appropriate hydraulic fluid levels and ensure the pneumatic supply is clean and dry to prevent contamination.

Using a hydro pneumatic cylinder effectively combines the speed of pneumatic systems with the power of hydraulics, suitable for various industrial applications requiring dynamic control and high force.

“hydro pneumatic cylinder” Comparative Analysis

A hydro-pneumatic cylinder combines the operational benefits of both hydraulic and pneumatic systems. These hybrid cylinders utilize compressed air to provide rapid movements and hydraulic fluid to ensure precise control, durability, and the ability to sustain significant loads.

1. Performance:

– *Hydraulic*: Offers high force and precise control but can be slow and involves complex systems.

– *Pneumatic*: Fast and straightforward but generally limited to lower forces and less precision.

– *Hydro-Pneumatic*: Achieves a balance by providing speed and high force with better control, making them suitable for applications requiring both quick and powerful actuations.

2. Efficiency:

– *Hydraulic*: Higher energy consumption due to continuous fluid pressurization.

– *Pneumatic*: Energetically efficient but requires large air compressors for power.

– *Hydro-Pneumatic*: More efficient than purely hydraulic systems; it combines the power of hydraulics with the speed of pneumatics, reducing the need for constant pressurization.

3. Maintenance and Costs:

– *Hydraulic*: Costly due to complex systems requiring regular maintenance.

– *Pneumatic*: Lower maintenance but can be costly in environments requiring high force due to compressor needs.

– *Hydro-Pneumatic*: Generally offers lower life-cycle costs by minimizing complexity and reducing the need for continuous maintenance.

4. Application Areas:

– *Hydraulic*: Heavy-duty applications in construction, mining, and heavy manufacturing.

– *Pneumatic*: Light to medium-duty applications in automation, packaging, and material handling.

– *Hydro-Pneumatic*: Ideal for applications that demand both rapid movement and substantial force, such as automotive manufacturing, metal stamping, and assembly lines.

In summary, hydro-pneumatic cylinders provide a versatile solution by bridging the gap between the high force and control of hydraulics and the speed and simplicity of pneumatics. This makes them suitable for a wide range of industrial applications where performance, efficiency, and cost are critical considerations.

“hydro pneumatic cylinder” Warranty and Support

Warranty and Support for Hydro Pneumatic Cylinders

When purchasing a hydro pneumatic cylinder, it’s crucial to understand the warranty and support policies to ensure long-term performance and reliability. Our hydro pneumatic cylinders come with a comprehensive warranty of 2 years from the date of purchase. This warranty covers any defects in materials or workmanship, ensuring you receive a product that meets high-quality standards.

Warranty Coverage:

1. Material Defects: Any flaws in the materials used in manufacturing the cylinder are fully covered.

2. Workmanship: Any defect due to faulty workmanship is included in the warranty.

3. Replacement and Repairs: If a defect is found, the product will be repaired or replaced at no extra cost.

Exclusions:

1. Normal Wear and Tear: Regular wear and tear, which occurs under normal operating conditions, are not covered.

2. Misuse and Abuse: Damage resulting from misuse, abuse, improper installation, or unauthorized modification will void the warranty.

3. Unauthorized Repairs: Any unauthorized repair attempts will also void the warranty.

Support Services:

1. Technical Support: We offer 24/7 technical support to assist with installation, troubleshooting, and maintenance queries. Our expert technicians are just a call away to provide you with timely solutions.

2. Installation Guides and Manuals: Detailed installation guides and operational manuals are available to help you set up and maintain your hydro pneumatic cylinder correctly.

3. Training Programs: We provide optional training programs to ensure your team can operate and service the cylinders proficiently.

Our commitment to quality and customer satisfaction is reflected in our robust warranty and support services. In case of any issues, our dedicated support team is always ready to assist you, ensuring minimal downtime and maximum efficiency.

For full details, please refer to the warranty documentation provided with your product or visit our website.

List “hydro pneumatic cylinder” FAQ

Hydro Pneumatic Cylinder FAQ

1. What is a hydro pneumatic cylinder?

– A hydro pneumatic cylinder combines hydraulic and pneumatic technologies to deliver high force and controlled motion within a compact design. It uses air pressure to initiate movement and hydraulic fluid to control the speed and force.

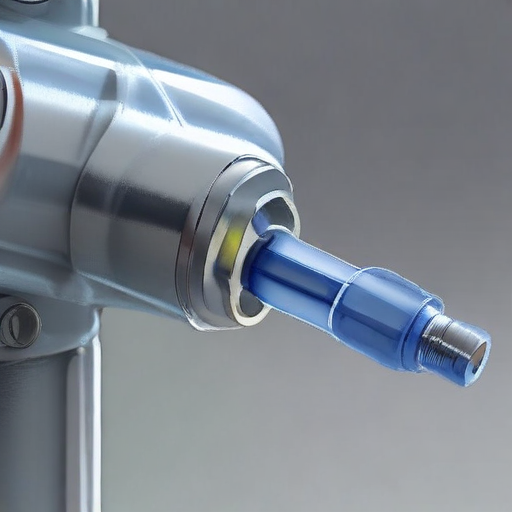

2. What are the main components of a hydro pneumatic cylinder?

– The primary components include a pneumatic cylinder, a hydraulic cylinder, pressure valves, seals, and a reservoir.

3. How does a hydro pneumatic cylinder work?

– Pneumatic pressure initiates the movement of the piston, while hydraulic fluid provides additional force and allows for precise control of motion and speed.

4. What are the advantages of using a hydro pneumatic cylinder?

– They offer high force output, precise control, reduced energy consumption, compact size, and versatility in various applications.

5. What industries commonly use hydro pneumatic cylinders?

– Industries such as automotive, manufacturing, aerospace, and heavy machinery frequently employ these cylinders for tasks requiring high force and precision.

6. What applications are hydro pneumatic cylinders suitable for?

– They are ideal for metal forming, punching, riveting, clamping, and other high-force, controlled-motion applications.

7. How do I select the right hydro pneumatic cylinder for my application?

– Key considerations include the required force, stroke length, operating pressure, speed, and environmental conditions.

8. What maintenance is required for hydro pneumatic cylinders?

– Regular inspection for leaks, lubrication of moving parts, replacement of worn seals, and monitoring of hydraulic fluid levels helps maintain optimal performance.

9. What are common issues with hydro pneumatic cylinders, and how can they be resolved?

– Issues like leaks, reduced force output, and erratic movement can often be traced to worn seals, contaminants in the hydraulic fluid, or improper pressure settings. Routine maintenance and timely component replacement generally address these problems.

10. Are hydro pneumatic cylinders customizable?

– Yes, manufacturers can customize cylinders to meet specific application requirements, including different sizes, force capacities, and configurations.

This concise FAQ addresses key points about hydro pneumatic cylinders, providing essential information for prospective users and industry professionals.

Top 10 FAQ with answer about hydro pneumatic cylinder for Buyer Sourcing from China

Certainly! Here are the top 10 frequently asked questions (FAQ) about sourcing hydro pneumatic cylinders from China, along with concise answers:

1. What is a hydro pneumatic cylinder?

A hydro pneumatic cylinder combines the principles of hydraulics and pneumatics, using compressed air and hydraulic oil to produce high force with precision and control.

2. Why source hydro pneumatic cylinders from China?

China offers competitive pricing, a vast range of manufacturers, advanced production technologies, and significant expertise in industrial components, making it a cost-effective sourcing destination.

3. How to determine the quality of a Chinese manufacturer?

Verify certifications (e.g., ISO 9001), request product samples, check the company’s production facilities (via virtual or physical tours), and consult reviews or third-party inspection services.

4. What is the typical lead time for these cylinders?

Lead times can vary but generally range from 4-8 weeks depending on customization levels, order quantity, and production schedules.

5. What are the customization options available?

Cylinders can be customized in terms of size, stroke length, material (e.g., stainless steel, aluminum), mounting options, and additional features like sensors and seals.

6. Are there common standards or certifications these cylinders comply with?

Many manufacturers adhere to international standards like ISO and CE. Ensure compliance to meet your regional and industry-specific requirements.

7. What are the typical payment terms when sourcing from China?

Common terms include a small deposit (20-30%) upfront and the balance paid before shipment. Payment methods may include T/T (Telegraphic Transfer), L/C (Letter of Credit), or even Trade Assurance via platforms like Alibaba.

8. How to handle shipping and logistics?

Your supplier can often assist with logistics. Options include FOB (Free On Board), CIF (Cost, Insurance, and Freight), or DDP (Delivered Duty Paid). Utilize freight forwarders for smooth logistics management.

9. What is the procedure for handling quality issues or returns?

Agree on a detailed quality assurance process upfront, which includes return policies and warranty terms. Many manufacturers offer warranties ranging from 12 to 24 months.

10. Can I visit the factory before placing an order?

Yes, most manufacturers welcome potential buyers to visit their facilities. This is highly recommended for larger or long-term orders to ensure quality and establish a strong business relationship.

These FAQs should provide a solid foundation for sourcing hydro pneumatic cylinders from China, ensuring you make informed decisions and achieve successful transactions.