is aluminum magnetic Safety Certifications

Aluminum is not considered magnetic under normal circumstances. It is classified as a paramagnetic material, meaning it only exhibits magnetism in the presence of an external magnetic field and loses this magnetism once the external field is removed. Unlike ferromagnetic materials such as iron, cobalt, and nickel, aluminum does not retain any substantial magnetic properties.

Safety certifications for materials and processes involving aluminum ensure that they meet specific standards for health, safety, and environmental performance. Some key safety certifications relevant to aluminum include:

1. ISO 9001: This certification indicates that a company has a quality management system in place, ensuring consistent quality of products and services, including those involving aluminum.

2. ISO 14001: This standard focuses on environmental management systems, ensuring that aluminum production or processing has minimal adverse environmental impacts.

3. OHSAS 18001/ISO 45001: These certifications pertain to occupational health and safety management systems, ensuring that the workplace meets safety standards to protect workers from hazards associated with aluminum processing.

4. ASTM Standards: The American Society for Testing and Materials provides numerous standards specific to aluminum, including its composition, mechanical properties, and permissible limits of impurities.

5. REACH Compliance: Registering under REACH (Registration, Evaluation, Authorisation, and Restriction of Chemicals) ensures that aluminum and its alloys comply with European Union regulations concerning environmental and human health impacts.

6. RoHS Compliance: The Restriction of Hazardous Substances Directive ensures that electrical and electronic products, which may contain aluminum components, do not exceed specified limits for hazardous substances.

These certifications are crucial for ensuring that aluminum use across various industries meets safety, health, and environmental standards.

List Reference Technical Parameters of “is aluminum magnetic”

Aluminum’s magnetic properties can be characterized by evaluating several technical parameters. These include:

1. Magnetic Susceptibility: Aluminum has a small, negative magnetic susceptibility (approximately -1.63 × 10^-5 in SI units), classifying it as a weakly diamagnetic material. Diamagnetic materials create an induced magnetic field in a direction opposite to an applied magnetic field, resulting in a repulsive effect.

2. Permeability: The relative magnetic permeability (μr) of aluminum is very close to 1 (approximately 1.000023). This indicates that its ability to support the formation of a magnetic field is nearly equal to that of free space. Materials with a relative magnetic permeability close to 1 are considered non-magnetic in practical terms.

3. Larmor Precession: In the context of Aluminum, the movement of electrons in its atomic structure causes a small degree of opposition to an external magnetic field, contributing to its diamagnetic behavior. The Larmor frequency quantifies this precession, although it is very low for aluminum.

4. Magnetization (M): Aluminum exhibits no ferromagnetic properties and thus does not retain magnetization in the absence of an applied magnetic field. Its total magnetization is negligible under typical conditions.

5. Resistance to Magnetic Fields: Aluminum does not interact strongly with magnetic fields, meaning it does not exhibit significant attraction or repulsion, nor does it become magnetized in the presence of a magnetic field.

These parameters indicate that aluminum is essentially non-magnetic due to its weak diamagnetic properties. It neither attracts magnets nor gets magnetized, making it an ideal material for applications where minimal magnetic interference is required.

List Product features of “is aluminum magnetic”

When evaluating whether aluminum is magnetic, it’s important to recognize the following features:

1. Non-Magnetic Nature: Pure aluminum is not magnetic under normal conditions. It is classified as a paramagnetic material, which means it has a very weak attraction to magnets that is practically negligible for most practical purposes.

2. Paramagnetism: While aluminum is largely regarded as non-magnetic, in the presence of a strong external magnetic field, it exhibits slight paramagnetic behavior. This weak magnetic attraction is temporary and only present under the influence of an external magnetic field.

3. Impact of Alloying: While pure aluminum is non-magnetic, certain aluminum alloys may exhibit different magnetic properties due to the presence of other elements. For example, adding iron or nickel to aluminum can slightly alter its magnetic characteristics. However, these changes are usually minimal.

4. Induced Eddy Currents: Although aluminum itself is non-magnetic, it can interact with magnetic fields in a dynamic situation. Moving a magnet near an aluminum piece can induce eddy currents within the aluminum, leading to a resistive force that can slow down the movement of the magnet. This is a principle used in some braking systems and other electromagnetic applications.

5. Applications in Technology: Due to its non-magnetic properties, aluminum is widely used in applications where magnetic interference needs to be minimized. This makes it suitable for use in electronics, computer components, and enclosures for magnetic-sensitive devices.

6. Recycling and Magnetism: In the recycling industry, aluminum’s non-magnetic nature is advantageous because it can be easily separated from ferrous materials using magnetic and eddy current separators, enhancing the efficiency of recycling processes.

7. Comparison with Other Metals: In comparison to ferromagnetic materials like iron, cobalt, and nickel, aluminum’s magnetic behavior is negligible and does not exhibit permanent magnetism.

Understanding these features helps clarify why aluminum is typically classified as a non-magnetic material and highlights its diverse applications in various fields due to this property.

List Various Types of “is aluminum magnetic”

Aluminum is generally considered to be non-magnetic under normal circumstances, but there are several nuanced aspects to consider:

1. Fundamental Properties: Pure aluminum is a paramagnetic material, meaning it has a weak attraction to magnetic fields, significantly weaker than ferromagnetic materials like iron, cobalt, and nickel. This effect is so weak that it’s generally not considered magnetic for practical purposes.

2. Magnet Gradients: In strong, especially non-uniform magnetic fields, aluminum can exhibit some magnetic effects due to induced currents (eddy currents) within the metal. These currents can create opposing magnetic fields, causing repulsion.

3. Alloys and Impurities: The magnetic properties can slightly change when aluminum is alloyed with other metals. For instance, some aluminum alloys or impurities may exhibit weak magnetic behavior, but this is typically minimal and not easily noticeable.

4. External Magnetic Fields: Under the influence of very strong magnetic fields, aluminum does demonstrate some level of interaction due to its conductive properties. This is largely because the strong magnetic field can induce eddy currents within the aluminum, which in turn create opposing magnetic fields.

5. Low Temperatures: At extremely low temperatures close to absolute zero, aluminum becomes superconductive. In this state, it can expel magnetic fields (a phenomenon known as the Meissner effect), effectively making it behave in a way that repels magnetic fields.

In summary, while aluminum is not magnetic in the traditional sense like iron, it does interact with magnetic fields in specific conditions. This weak interaction is due primarily to its paramagnetic nature and its conductive properties, making it largely non-magnetic for everyday applications.

List Application of “is aluminum magnetic”

Aluminum, a common and versatile metal, is widely recognized for its non-magnetic properties. Here’s a brief exploration of various applications of this characteristic:

1. Electronics and Electrical Engineering: Aluminum’s non-magnetic nature makes it ideal for use in electronic devices and components where magnetic interference must be minimized. It is often employed in housing and casing for sensitive circuits and devices.

2. Aerospace Industry: Given that aluminum is lightweight and non-magnetic, it is widely used in the aerospace sector for constructing aircraft parts. These properties ensure that the vehicle is light enough for efficient flight and is not affected by magnetic fields in avionic systems.

3. MRI Machines: Magnetic Resonance Imaging (MRI) systems require non-magnetic materials in their construction, especially components in close proximity to the magnetic coil. Aluminum is often used for table structures, supports, and enclosures to avoid any interference with the MRI’s magnetic fields.

4. Shielding and Enclosures: In environments sensitive to magnetic fields, such as medical and laboratory settings, aluminum structures can provide effective enclosures and shielding, preventing external magnetic interference with critical instruments and experiments.

5. Manufacturing and Tooling: Aluminum tools are preferred in certain manufacturing scenarios where magnetic fields could disrupt processes or equipment operation. This includes machining parts that are subjected to magnetic processes or working with magnetic materials.

6. Data Centers and IT Equipment: Magnetic fields can potentially affect the integrity of stored data. Utilizing aluminum components in server racks and enclosures ensures that magnetic disturbances are minimized, protecting sensitive data storage devices.

7. Transportation: Apart from aerospace, aluminum is also used in other vehicles such as trains and cars. Its non-magnetic properties ensure minimal interference with electronic navigation and other electronic systems.

8. Architectural Applications: In buildings where magnetic sensitivity is a concern, such as hospitals or research facilities, aluminum can be used for non-magnetic structural support and fixtures.

These applications illustrate the advantages of aluminum’s non-magnetic properties, proving essential in a diverse range of fields where minimizing magnetic interference is crucial.

List Buyer Types of “is aluminum magnetic”

1. Metallurgists and Material Scientists: Professionals exploring the magnetic properties of aluminum for material research and development. They analyze how aluminum interacts with other magnetic materials and its practical applications in industries.

2. Manufacturers and Engineers: Individuals in sectors like automotive, aerospace, and electronics who need to understand the properties of aluminum for product design, production, and quality assurance. They assess aluminum’s suitability for various applications where non-magnetic materials are preferred.

3. Home Improvement Enthusiasts and Contractors: People involved in DIY projects or professional construction requiring precise material selection. They need to know if aluminum is magnetic for tasks such as metal joining, decoration, or structural support.

4. Recycling Industry Professionals: Workers in recycling centers who sort and process metals. Knowledge of aluminum’s non-magnetic nature helps in separating it from magnetic metals like steel or iron efficiently.

5. Educational Professionals and Students: Teachers, researchers, and learners in fields like physics, chemistry, and engineering. They study aluminum’s properties, including its lack of magnetism, for educational purposes and experiments.

6. Electronics Designers and Technicians: Those designing or repairing electronic devices who need to use non-magnetic materials to avoid magnetic interference with electronic components. Awareness of aluminum’s properties is crucial for product functionality.

7. Artisans and Sculptors: Creators of art pieces and sculptures who work with metals and require non-magnetic materials for specific designs. Understanding aluminum’s characteristics aids in material selection and artistic creation.

8. Collectors and Antiques Dealers: Individuals who need to authenticate metal objects and understand their composition. Knowing that aluminum is non-magnetic helps in distinguishing it from other metals in vintage or collectible items.

List “is aluminum magnetic” Project Types for Different Industries

Certainly! Here’s a concise list of “Is Aluminum Magnetic?” project types tailored for different industries:

1. Education (K-12 and Higher Ed)

– Science Classroom Demonstrations: Simple experiments to test aluminum’s magnetic properties with students.

– Research Papers/Theses: In-depth explorations comparing aluminum’s properties with other materials.

2. Manufacturing

– Quality Control Protocols: Developing guidelines to ensure aluminum parts are properly identified and not mistaken for magnetic materials.

– Industrial Process Optimization: Enhancing processes that require separation of magnetic and non-magnetic metals.

3. Aerospace

– Material Selection Studies: Researching materials for non-magnetic properties in design specifications.

– Component Testing: Assessing aluminum components in environments where magnetic interference must be minimized.

4. Automotive

– Electromagnetic Compatibility Testing: Ensuring aluminum parts do not interfere with vehicle electronics.

– Material Innovation: Exploring new non-magnetic aluminum alloys for different vehicle parts.

5. Electronics

– Shielding Studies: Testing aluminum’s utility in electromagnetic shielding applications.

– PCB Design: Evaluating the use of aluminum in circuit boards to reduce electromagnetic interference.

6. Construction

– Building Material Analysis: Studying aluminum’s suitability in non-magnetic applications within structural design.

– Infrastructure Projects: Evaluating aluminum’s benefits in bridge construction or other large-scale projects where magnetic properties are considered.

7. Utilities (Power, Water, Gas)

– Infrastructure Assessment: Determining the impacts of using aluminum in non-magnetic conduit and piping.

– Equipment Maintenance: Developing maintenance protocols based on the non-magnetic nature of aluminum components.

8. Medical Equipment

– Non-Magnetic Tools: Researching and developing surgical tools that can operate near MRI machines.

– Diagnostic Equipment Design: Evaluating aluminum’s non-magnetic properties for MRI-compatible equipment.

By tailoring projects to industry-specific needs, diverse sectors can derive maximum benefit from understanding aluminum’s magnetic properties.

is aluminum magnetic Accessories Upgrades and Custom Manufacturing Options

Aluminum is not magnetic under normal circumstances. This is due to its atomic structure and the absence of unpaired electrons needed to generate a magnetic field. Aluminum’s weak interaction with magnetic fields makes it ideal for various applications where non-magnetic materials are required.

Accessories and Upgrades:

1. Anodizing: Enhances surface durability, corrosion resistance, and aesthetic appeal. Custom color options are available.

2. Heat Sinks: Aluminum’s excellent thermal conductivity makes it ideal for heat dissipation in electronic devices.

3. Protective Coatings: Options include powder coating and epoxy finishes for additional protection and appearance customization.

4. Machining: Precision machining services can create custom components tailored to specific project requirements.

Custom Manufacturing Options:

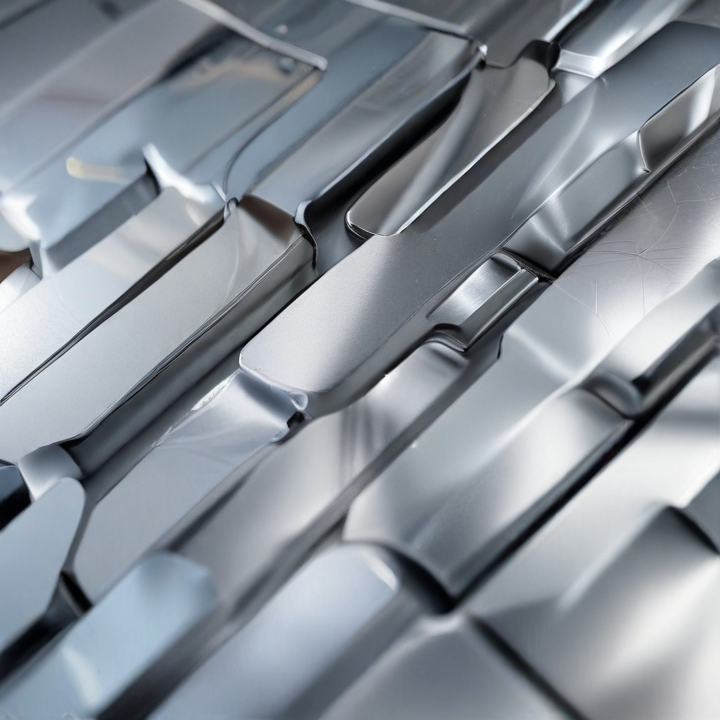

1. Extrusion: Allows the creation of complex cross-sectional profiles for structural, automotive, and aerospace applications.

2. Stamping: Efficient production method for high-volume, precision components.

3. Die Casting: Ideal for creating intricate, lightweight parts with tight tolerances.

4. Welding and Fabrication: Specialized techniques for assembling aluminum parts into larger constructs, essential in construction and transportation industries.

5. CNC Milling and Turning: Enables the production of high-precision aluminum parts, suitable for sectors like medical devices and robotics.

Overall, aluminum’s non-magnetic properties and versatile manufacturing options make it a preferred material in industries ranging from electronics to aerospace.

List Quality Control and The Manufacturing Process of “is aluminum magnetic”

Aluminum is a non-magnetic metal, meaning it does not exhibit magnetism. Below are the quality control aspects and the manufacturing process.

Quality Control:

1. Material Inspection: Raw aluminum is inspected for purity and elemental composition to ensure it meets the required standards.

2. Dimensional Accuracy: Measurements of produced aluminum components are taken to ensure they meet specified dimensions and tolerances.

3. Surface Quality: Visual and microscopic inspections ensure surfaces are free from defects like cracks, dents, and irregularities.

4. Mechanical Testing: Tensile strength, hardness, and ductility tests confirm the aluminum’s mechanical properties.

5. Magnetic Susceptibility Test: Ensure non-magnetic properties meet industry standards, confirming it’s free of magnetic contaminants.

6. Chemical Testing: Verifies the alloy composition to ensure consistency in the final product.

7. Ultrasonic Testing: Detects internal flaws and inconsistencies.

8. Environmental Compliance: Ensures the manufacturing process adheres to environmental regulations.

Manufacturing Process:

1. Bauxite Mining: Aluminum production begins with the extraction of bauxite ore.

2. Bayer Process: Bauxite is refined into alumina (aluminum oxide) via high-temperature chemical treatment.

3. Electrolysis (Hall-Héroult Process): Alumina undergoes electrolytic reduction to produce pure aluminum metal.

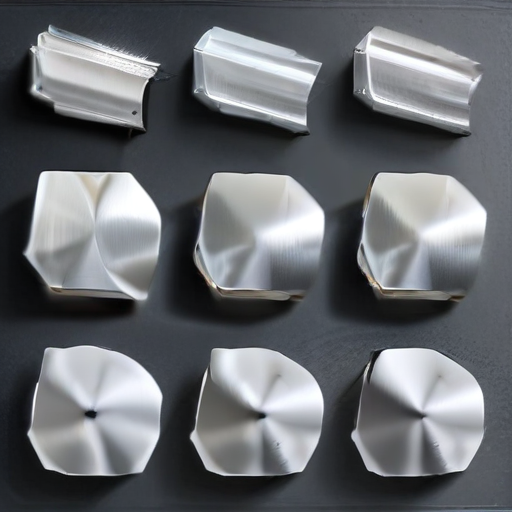

4. Casting: Molten aluminum is poured into molds to form ingots or billets.

5. Rolling/Extrusion: Ingots are further processed into sheets, plates, or extruded shapes by rolling or extrusion.

6. Annealing: Heat treatments are applied to relieve internal stresses and improve ductility.

7. Surface Treatment: Processes like anodizing, painting, or coating improve corrosion resistance and aesthetic properties.

8. Fabrication: Further shaping, machining, or joining components as per final design specifications.

9. Final Inspection: Thorough checks ensure all quality control standards are met before products are shipped.

Understanding these elements ensures that the non-magnetic aluminum produced meets high quality and performance standards.

How to use “is aluminum magnetic”

“Is aluminum magnetic?” is a straightforward question that delves into the properties of aluminum as a material. To understand the answer, it’s crucial to explore the basics of magnetism and how different materials interact with magnetic fields.

Aluminum is classified as a paramagnetic material. This means it is not magnetic in the traditional sense like iron, steel, or cobalt. Unlike ferromagnetic materials, which can retain a magnetic field, aluminum does not exhibit strong magnetic properties. When exposed to a magnetic field, aluminum does experience a very weak attraction, but this effect is so minimal that it is often considered practically non-magnetic.

To illustrate this, consider a simple experiment: When you place a piece of aluminum near a magnet, it will not cling to the magnet the way iron would. However, if you move a strong magnet rapidly past aluminum, an interesting phenomenon occurs due to electromagnetic induction. The moving magnet induces small electrical currents (known as eddy currents) in the aluminum, which creates its own tiny magnetic field opposing the magnet’s motion. This can cause the aluminum to slightly repel the moving magnet, but this is not due to aluminum being magnetic; it’s a result of induced currents and is a temporary effect.

In practical applications, aluminum’s lack of strong magnetic properties makes it ideal for use in environments where magnetism can be problematic. It’s widely used in electronic devices, aviation, and construction industries, where non-magnetic materials are often essential.

In summary, while aluminum is technically paramagnetic due to its very minimal response to magnetic fields, it is commonly considered non-magnetic for most practical purposes.

“is aluminum magnetic” Comparative Analysis

Aluminum is generally considered non-magnetic under normal conditions. This intrinsic characteristic sets it apart from materials with strong magnetic properties like iron, cobalt, and nickel. To understand this more deeply, let’s compare aluminum with these ferromagnetic materials.

Magnetic Susceptibility

– Aluminum: It is classified as paramagnetic, meaning it exhibits a weak attraction to magnetic fields. This property is due to the alignment of its electron spins in the presence of an external magnetic field, though the effect is minimal and disappears once the external influence is removed.

– Iron, Cobalt, Nickel: These are ferromagnetic materials, which exhibit strong magnetic properties. Their electron spins can align in a sustained manner, even after the external magnetic field is removed, forming permanent magnets.

Practical Implications

– In Industries: Aluminum’s non-magnetic nature makes it ideal for applications where magnetic interference is a concern, such as in electronic casings and MRI machines.

– Examples of Magnetic Materials: Ferromagnetic metals are commonly used in making permanent magnets, electric transformers, and magnetic storage media due to their ability to retain magnetic properties.

Temperature Effects

– Aluminum: Remains non-magnetic at room temperature and requires extremely low temperatures (around -273°C) to show significant magnetic properties, which are still quite weak.

– Ferromagnetic Materials: They demonstrate strong magnetic properties at room temperature but may lose these properties (Curie point) at high temperatures unique to each material (e.g., 770°C for iron).

Environmental Interactions

– Aluminum: Its paramagnetic properties mean it doesn’t significantly interact with magnetic fields in everyday environments.

– Ferromagnetic Materials: They interact strongly with magnetic fields, which can be beneficial or problematic depending on the application. For instance, they can cause interference in sensitive electronic devices but are crucial in magnetic applications.

In conclusion, while aluminum exhibits weak paramagnetic behavior, it fundamentally differs from ferromagnetic metals like iron, making it valuable in contexts where non-magnetic properties are essential.

“is aluminum magnetic” Warranty and Support

Aluminum is not magnetic under normal circumstances. This non-ferromagnetic property makes it different from metals like iron, nickel, and cobalt, which are strongly attracted to magnets. Although aluminum can have some weak paramagnetic qualities, meaning it is attracted to very strong magnetic fields, these effects are negligible in everyday conditions.

When it comes to warranty and support for aluminum products, it largely depends on the manufacturer and the type of aluminum product you are purchasing. Here are some general guidelines:

Warranty

1. Duration: Many aluminum products come with a warranty period, which can range from a few months to several years. Always check the warranty duration before making a purchase.

2. Coverage: The warranty might cover defects in materials and workmanship. It often does not cover damage caused by improper installation, misuse, or accidents.

3. Claim Process: Warranties usually require proof of purchase and may involve an inspection process where the manufacturer evaluates the product before approving a claim.

Support

1. Customer Service: Manufacturers often provide customer service via phone, email, or online chat to assist with inquiries about their aluminum products.

2. User Manuals: For complex products, user manuals or installation guides can be incredibly helpful. These are often available on the manufacturer’s website.

3. Replacement Parts: Some manufacturers offer replacement parts or repair services if your aluminum product is damaged or wears out over time.

Tips for Warranty and Support

– Documentation: Keep your purchase receipt and all related documents in a safe place.

– Registration: Some products require you to register for the warranty after purchase. Check if this is a requirement.

– Contact Information: Have the manufacturer’s contact information handy for quick access in case you need assistance.

Always review the warranty and support terms provided by the manufacturer to ensure you understand what is covered and how to make a claim if needed.

List “is aluminum magnetic” FAQ

Is Aluminum Magnetic? – FAQs

1. Is aluminum magnetic?

– No, aluminum is not magnetic. It is classified as a paramagnetic substance, which means it is not attracted to magnets under normal circumstances.

2. What is paramagnetism?

– Paramagnetism refers to materials that are weakly attracted by an external magnetic field and do not retain any magnetization in the absence of an external field. Aluminum falls into this category.

3. Can aluminum be magnetized?

– No, aluminum cannot be magnetized like ferromagnetic materials such as iron, nickel, or cobalt. It does not retain any magnetic properties once an external field is removed.

4. Does aluminum interact with magnetic fields at all?

– While aluminum itself is not magnetic, it can interact with magnetic fields through a phenomenon called electromagnetic induction. When a moving magnetic field interacts with aluminum, eddy currents can be induced, which can create opposing magnetic fields.

5. Can aluminum interfere with magnetic fields?

– Yes, due to eddy currents, aluminum can influence magnetic fields, but it doesn’t attract or repel magnets directly. This property is often used in electromagnetic shielding.

6. Is it true that aluminum is used in electrical applications?

– Yes, because aluminum is a good conductor of electricity and has interactions with electromagnetic fields, it is frequently used in electrical wiring and components despite not being magnetic.

7. Why do some people think aluminum is magnetic?

– Misunderstandings may arise due to aluminum’s use in applications involving magnets, such as in induction cooktops or in electromagnetic shielding. This can create the false impression that aluminum itself is magnetic.

By understanding these FAQs, you can clearly see that aluminum, despite its unique properties and widespread usage, is not magnetic.

Top 10 FAQ with answer about is aluminum magnetic for Buyer Sourcing from China

1. Is aluminum magnetic?

– No, aluminum is not magnetic. It is a paramagnetic material, which means it has a very weak response to magnetic fields and does not retain magnetism.

2. Why is aluminum used in products if it’s not magnetic?

– Aluminum is valued for its lightweight, high strength-to-weight ratio, corrosion resistance, and electrical conductivity, making it suitable for various applications, even if it’s not magnetic.

3. How can I ensure the aluminum sourced from China meets quality standards?

– Work with certified suppliers, request material certificates, and consider third-party quality inspections to ensure the aluminum meets required standards and specifications.

4. Is it possible to get a magnetic alloy containing aluminum?

– Yes, aluminum can be alloyed with other elements like iron or nickel to create materials with magnetic properties, but pure aluminum itself is not magnetic.

5. What certifications should I look for when sourcing aluminum from China?

– Look for ISO 9001 (quality management), ISO 14001 (environmental management), and specific industry certifications like ASTM or EN standards.

6. What are common applications of aluminum in non-magnetic contexts?

– Common applications include aerospace, automotive, construction, electrical conduction, packaging, and consumer electronics, where non-magnetic properties are often advantageous.

7. Can magnets affect aluminum manufacturing or processing?

– No, because aluminum is not magnetic, magnetic fields have minimal impact on its manufacturing or processing.

8. How do I verify the non-magnetic nature of aluminum products from China?

– Conduct tests using a magnet; aluminum will not be attracted. You can also request material composition reports from suppliers.

9. What are the primary benefits of using aluminum in industrial applications?

– The primary benefits include its lightweight, corrosion resistance, excellent thermal and electrical conductivity, and ease of fabrication.

10. Are there any challenges in sourcing aluminum from China?

– Challenges may include ensuring consistent quality, navigating import/export regulations, and dealing with potential communication barriers. Working with reputable suppliers and agents can mitigate these issues.