line pumping concrete Safety Certifications

Concrete pumping is a specialized activity that requires adherence to stringent safety standards to ensure the well-being of operators and bystanders. Several certifications and guidelines regulate safety in this field. Here’s a concise overview:

1. American Concrete Pumping Association (ACPA) Certification: This is one of the most recognized certifications in the concrete pumping industry. ACPA offers a comprehensive safety training program that covers proper operation, maintenance, and safety practices. Certified operators must demonstrate their understanding of these protocols to become certified.

2. Occupational Safety and Health Administration (OSHA) Compliance: OSHA provides regulations that must be followed to ensure workplace safety. These regulations cover a wide range of safety aspects, including personal protective equipment (PPE), hazard communication, and job site safety protocols for concrete pumping operations.

3. National Commission for the Certification of Crane Operators (NCCCO): While primarily focused on crane operations, NCCCO certifications can be relevant for operators who handle equipment that may overlap with pumping operations, particularly in terms of load handling and lifting safety.

4. Equipment Manufacturer Training: Many equipment manufacturers offer specific training programs for their machines. This training ensures operators are familiar with the precise safety features and operational guidelines of the equipment they’re using.

5. First Aid and CPR Certification: It’s advisable for operators to have basic first aid and CPR training. This ensures they can respond promptly in case of an emergency on the job site.

6. Environmental Health and Safety (EHS): Companies often have their own EHS programs to further reinforce safety standards. These programs might include routine safety drills, emergency response plans, and continuous education on evolving safety protocols.

Maintaining these certifications and adhering to established safety practices is essential for mitigating risks associated with line pumping concrete operations. By doing so, operators can ensure a safer working environment for everyone involved.

List Reference Technical Parameters of “line pumping concrete”

Line pumping concrete is a crucial technique used in construction where concrete is transported using a series of pipes or hoses to the desired location. The technical parameters influencing line pumping concrete include:

1. Concrete Mix Design:

– Slump: Typically between 100-150mm for optimal flow.

– Aggregate Size: Maximum size usually 20mm to avoid blockages.

– Water-Cement Ratio: Maintained to balance pumpability and strength.

2. Pumping Equipment:

– Pump Type: Usually positive displacement pumps like piston or peristaltic pumps.

– Pumping Pressure: Can range from 50 to 250 bars depending on the distance and height required.

– Flow Rate: Typically between 10 to 80 m³/hr, depending on the pump and project requirements.

3. Pipeline:

– Diameter: Commonly 75mm to 125mm, chosen based on pump capacity and concrete mix.

– Length: Can extend from a few meters up to hundreds of meters with boosters used for long distances.

– Configuration: Straight runs preferred; bends and elbows minimized to reduce pressure losses.

4. Additives and Admixtures:

– Plasticizers/Superplasticizers: Enhance flowability without increasing water content.

– Retarders: Manage setting time, especially for long-distance or high-temperature pumping.

– Air-Entraining Agents: Improve workability and pumpability.

5. Operational Conditions:

– Temperature: Affects the concrete’s workability and setting time.

– Rate of Pumping: Needs to be consistent to prevent segregation or blockages.

6. Safety and Maintenance:

– Regular Inspection: Pipes and joints checked for leaks and potential clogs.

– Clean-Out Procedures: Ensuring no residual build-up post-operations.

Each parameter must be carefully considered to ensure efficient, consistent, and high-quality concrete placement, minimizing risks of segregation, blockages, and ensuring structural integrity.

List Product features of “line pumping concrete”

Line pumping concrete is a construction method that involves using a concrete pump, attached to hoses, to deliver concrete precisely where it is needed on a site. This technique is increasingly popular due to its efficiency and versatility. Here are some key features of line pumping concrete:

1. Precision Placement: The primary advantage of line pumping concrete is the ability to place concrete exactly where it’s needed, even in hard-to-reach areas like high floors, long distances, or confined spaces.

2. Versatility: Line pumps can handle various types of concrete mixes, including high-performance mixes required for specific projects, allowing for a broad range of applications including residential, commercial, and industrial projects.

3. Efficiency: Line pumping is faster and less labor-intensive than traditional methods of moving concrete, such as wheelbarrows or cranes, thus speeding up the construction process and potentially reducing overall project costs.

4. Reduced Labor Costs: By minimizing the need for manual transportation of concrete, line pumping significantly reduces the amount of labor required on-site, leading to lower labor costs.

5. Consistency: Pumps ensure a continuous and consistent flow of concrete, reducing the likelihood of disruptions that can lead to weak spots or inconsistencies in the concrete slab or structure.

6. Accessibility: By using hoses, line pumping can reach areas that are otherwise inaccessible, such as basements, behind existing structures, or through narrow gaps.

7. Cleaner Sites: Using a pump can result in less spillage and waste compared to traditional methods, leading to a cleaner construction site and minimizing the environmental impact.

8. Safety: Reducing the need for manual carrying of heavy concrete reduces the risk of worksite injuries, thereby enhancing overall safety for construction workers.

9. Adaptability: Line pumps can be easily adapted to different sites and conditions, whether for small-scale residential projects or large commercial structures, providing flexibility in planning and execution.

10. Reduced Carbon Footprint: More efficient use of materials and less transportation of concrete can lower the carbon footprint associated with construction activities.

In summary, line pumping concrete offers a myriad of benefits including precision, efficiency, cost reduction, and improved safety, making it an excellent choice for modern construction projects.

List Various Types of “line pumping concrete”

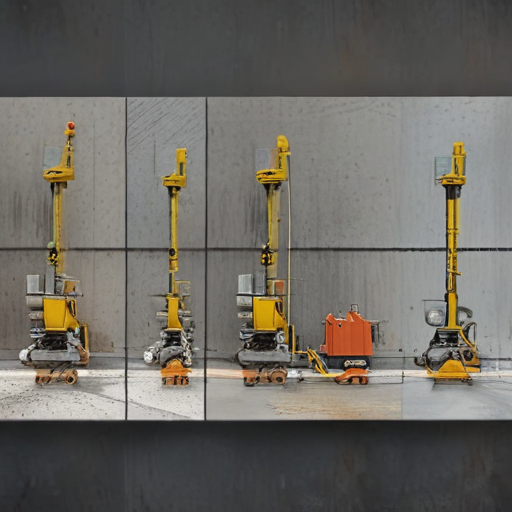

Line pumping concrete involves the use of a line pump (or trailer-mounted pump) to convey concrete through hoses to the pour site. Various types of line pumping concrete can be categorized based on the specific equipment, application, and scale of the project. Here are the primary types:

1. Small Line Pumps:

– Used for residential and small-scale commercial projects.

– Ideal for concrete slabs, patios, driveways, sidewalks, and small-footing works.

– Portable and easy to maneuver within confined spaces.

2. Standard Line Pumps:

– Suitable for medium-scale projects such as low-rise buildings, mid-sized commercial projects, and larger slabs.

– Versatile and can handle a variety of mix designs and aggregates.

3. High-Pressure Line Pumps:

– Designed for high-rise buildings and large commercial or industrial projects.

– Capable of pumping long distances and heights.

– Requires stronger hoses and fittings to withstand high pressure.

4. Truck-Mounted Line Pumps:

– Mounted on a truck for greater mobility.

– Best for large job sites where quick setup and dismantling are required.

– Combines the features of a line pump with the mobility of a truck-mounted unit.

5. Dragline Pumps:

– Ideal for remote or hard-to-reach job sites.

– The hose can be dragged through rough or uneven terrain.

– Suitable for foundations, retaining walls, and difficult access areas.

6. Stationary Line Pumps:

– Fixed in one location, often used in large construction sites.

– Concrete is fed to the pump, and large volumes can be handled continuously.

– Suitable for infrastructure projects like bridges, tunnels, and dams.

These variations each offer unique advantages tailored to the scale and specific requirements of the construction tasks at hand, making line pumping concrete a versatile solution for a wide range of projects.

List Application of “line pumping concrete”

Line pumping concrete refers to the use of a concrete pump with a delivery hose or pipeline, allowing concrete to be transported to precise locations. This technique offers a multitude of applications across various construction scenarios:

1. High-rise Buildings: Essential for conveying concrete vertically to elevated floors, where traditional methods may be impractical or impossible.

2. Foundations and Footings: Facilitates concrete delivery to deep excavations or narrow spaces where manual wheelbarrowing would be difficult and time-consuming.

3. Long-distance Delivery: Ideal for horizontal distances, ensuring concrete reaches areas that are remote or obstructed without compromising quality or consistency.

4. Underwater Construction: Utilized in scenarios such as bridge piers or marine structures, where accurate and controlled placement underwater is crucial.

5. Slabs and Floors: Allows for even and precise pouring of concrete slabs or floors over large areas, significantly enhancing uniformity and reducing labor costs.

6. Tunnels and Subways: Supports underground construction by efficiently delivering concrete in confined or hard-to-reach subterranean locations.

7. Bridges and Flyovers: Facilitates concrete placement at elevated sites and intricate designs, ensuring structural integrity and durability.

8. Residential Construction: Commonly used for pouring driveways, basements, and other home infrastructure needing precise concrete application.

9. Roadwork and Pavements: Provides an efficient method for laying concrete on roads, highways, and pavements, accommodating high volumes and extensive areas.

10. Retaining Walls and Slopes: Assists in forming strong retaining walls and stabilizing slopes with high-quality concrete placement.

11. Architectural Elements: Supports the creation of architectural features requiring precision, such as complex shapes, curves, and specific finishes.

Overall, line pumping concrete enhances efficiency, quality, and safety in construction, making it indispensable for modern building projects.

List Buyer Types of “line pumping concrete”

Line pumping concrete is a versatile service used in various construction projects. Understanding the buyer types can help target marketing efforts more effectively. Here are the primary buyer types for line pumping concrete:

1. Residential Contractors:

– Description: These buyers focus on individual homes and small residential developments.

– Needs: Efficient and cost-effective solutions for foundations, driveways, patios, and small-scale concrete work.

2. Commercial Contractors:

– Description: Companies handling larger commercial buildings like offices, retail spaces, and industrial facilities.

– Needs: Reliable and high-capacity concrete pumping for structural slabs, floors, and complex building projects.

3. Infrastructure Developers:

– Description: Entities involved in large-scale infrastructure projects such as bridges, highways, and public utilities.

– Needs: Precision, reach, and high-volume pumping capabilities to match large-scale and often high-stakes projects.

4. Municipalities and Governments:

– Description: Local, state, or federal agencies responsible for public construction projects.

– Needs: Dependable pumping services that comply with regulatory standards and can handle projects like roads, public buildings, and other civic structures.

5. Utility Companies:

– Description: Organizations that manage utilities, including water, electricity, and telecommunications.

– Needs: Specialized concrete pumping for underground installations, poles, and utility platforms.

6. Renovation Specialists:

– Description: Firms specializing in the renovation and refurbishment of existing structures.

– Needs: Flexible and precise pumping services to navigate existing structures and constraints.

7. Landscaping and Hardscaping Companies:

– Description: Businesses focusing on outdoor improvements such as garden pathways, retaining walls, and decorative concrete features.

– Needs: Precision and adaptability to deliver aesthetically pleasing and durable concrete placements.

Understanding these buyer types allows suppliers of line pumping concrete to tailor their services and marketing strategies to meet the distinct needs and challenges of each category.

List “line pumping concrete” Project Types for Different Industries

Line Pumping Concrete: Project Types for Different Industries

1. Residential Construction

– Foundations: Efficiently pouring concrete for house foundations.

– Driveways and Sidewalks: Ensuring smooth and consistent concrete layers.

– Swimming Pools: Precisely filling complex shapes and designs.

2. Commercial Construction

– Office Buildings: Pouring floors, walls, and structural elements with precision.

– Parking Structures: Facilitating the rapid and uniform layering of concrete over large areas.

– Retail Stores: Building robust flooring and foundational elements.

3. Industrial Construction

– Factories and Warehouses: Laying foundations, floors, and structural elements.

– Power Plants: Placing concrete in complex structures and confined spaces.

– Refineries: Creating durable and chemically resistant infrastructure.

4. Infrastructure and Public Works

– Bridges and Overpasses: Ensuring stability with concrete piers, abutments, and decks.

– Roadways: Laying durable road surfaces and sidewalks.

– Water Treatment Plants: Pouring large volumes of concrete for tanks and other structures.

5. Educational and Healthcare Facilities

– Schools and Universities: Constructing durable and safe facilities.

– Hospitals: Creating reliable foundations and structural elements to support sensitive equipment.

6. Agricultural Projects

– Barns and Silos: Constructing robust storage and livestock structures.

– Irrigation Channels: Ensuring sturdy and leak-proof water channels.

7. Recreational Facilities

– Sports Complexes and Stadiums: Building foundational structures, seating areas, and athletic tracks.

– Parks and Playgrounds: Pouring smooth surfaces for walkways and recreational areas.

8. Specialized Engineering Projects

– Marine Construction: Fabricating piers, docks, and other marine facilities.

– Tunnels and Subways: Employing high-pressure line pumps to place concrete in confined and challenging environments.

Line pumping concrete streamlines the delivery process, making it versatile and invaluable across various industries, contributing to efficient, cost-effective, and high-quality construction projects.

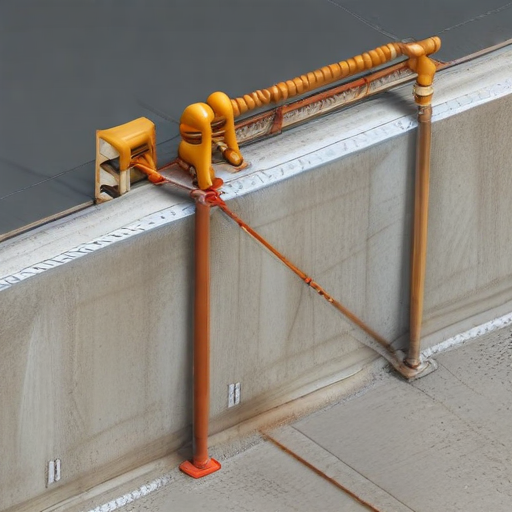

line pumping concrete Accessories Upgrades and Custom Manufacturing Options

Line pumping concrete involves the use of specialized equipment to transport and place concrete in various construction settings. Upgrading accessories and opting for custom manufacturing options can significantly enhance efficiency and performance on the job. Below are some key accessories and customization options available for line pumping concrete systems:

1. High-Pressure Pumps: Upgrading to high-pressure pumps can improve the reach and speed of concrete delivery, making it ideal for large or complex jobs.

2. Durable Hoses: Investing in high-quality, wear-resistant hoses ensures longevity and reduces the risk of breakdowns. Custom lengths and diameters are also available to suit specific project requirements.

3. Remote Controls: Adding remote controls allows operators to handle the equipment from a safe distance, improving job site safety and convenience.

4. Quick-Coupling Systems: These systems facilitate faster and easier connections between hoses and pumping units, minimizing downtime.

5. Grout and Slurry Pumps: Custom-designed to handle different types of materials, these pumps offer versatility in handling various pumping tasks.

6. Pipeline Cleaners: Efficient pipeline cleaning equipment ensures that the hoses remain clog-free, maintaining optimal performance.

7. Custom Hoppers: These can be designed to accommodate varying volumes and types of concrete mixes, ensuring smooth, uninterrupted flow.

8. Wear Parts: High-quality wear-resistant parts such as cutting rings, wear plates, and spectacle glasses can extend the lifespan of the pumping equipment.

9. Boom Attachments: Customizable boom attachments can be added to allow for greater maneuverability and extended reach.

10. Specialized Nozzles: Different nozzle designs can cater to specific application needs, such as spraying or placing concrete in hard-to-reach areas.

Investing in these accessories and custom manufacturing options can lead to increased productivity, reduced downtime, and overall better performance in concrete line pumping operations.

List Quality Control and The Manufacturing Process of “line pumping concrete”

Quality Control and Manufacturing Process of Line Pumping Concrete

#### Manufacturing Process:

1. Material Selection: High-quality raw materials (cement, aggregates, water, and admixtures) are chosen based on project specifications.

2. Batching: Precise measurement of materials using automated batching systems to ensure consistency.

3. Mixing: Combining materials in a concrete mixer for uniform blend. Duration of mixing adheres to standardized protocols.

4. Transport: Concrete is loaded into the line pump’s hopper, ensuring no contamination or segregation.

5. Pumping: Utilizing a hydraulic pump, concrete is transported through a series of pipes and hoses to the desired location. Pump pressure is adjusted based on the distance and height.

6. Placement: Pipes or hoses are positioned to direct concrete where needed. Workers may use vibrators to compact concrete and eliminate air bubbles.

7. Finishing: Surface finishing and leveling are performed to meet project specifications.

8. Curing: Concrete is kept moist for a specified period to achieve the desired strength.

#### Quality Control:

1. Material Testing: Regularly sample and test raw materials for compliance with standards (ASTM, ACI).

2. Batching Accuracy: Ensure the automated batching system is calibrated and functioning correctly.

3. Mix Design Verification: Validate mix design through lab tests to confirm slump, air content, and strength.

4. Pump Maintenance: Regular inspection and maintenance of line pumps to ensure they are clean and operational.

5. Pumping Procedure: Monitor pumping pressure and flow rate to prevent blockages and ensure smooth delivery.

6. On-Site Sampling: Periodic sampling of concrete during placement for slump test and temperature checks.

7. Curing Conditions: Monitor and control environmental conditions to ensure proper curing.

8. Documentation: Maintain detailed records of material tests, mix designs, pump operations, and placement conditions.

#### Summary:

Line pumping concrete involves precise material selection, accurate batching and mixing, efficient transport and pumping, careful placement, and proper curing. Quality control measures include rigorous testing of materials and mix designs, equipment maintenance, on-site sampling, and real-time monitoring to ensure that the final concrete meets the required standards and specifications.

How to use “line pumping concrete”

Line pumping concrete involves the use of a concrete pump and hoses to transport liquid concrete to a desired location. Here’s a concise guide on how to use line pumping effectively:

1. Site Preparation:

– Clear Area: Ensure the area where concrete will be pumped is free of obstructions.

– Ground Preparation: Stabilize the ground to handle the pump’s weight.

2. Set Up the Pump:

– Position the Pump: Place the pump truck or trailer in a location that has easy access to the pour site and a stable ground base.

– Connect Hoses: Attach the required length of hoses, ensuring they are securely connected and laid out to avoid sharp bends or kinks.

3. Ready the Concrete:

– Check Mix: Ensure the concrete mix is pump-friendly, typically with a suitable slump and aggregate size.

– Loading: Load the concrete into the pump’s hopper.

4. Pump Operation:

– Priming: Prime the pump and hoses with a slurry (a mix of water, cement, and sand) to lubricate the system and reduce friction.

– Start Pumping: Begin the pumping process gradually, maintaining a steady flow.

– Monitor Flow: Continuously monitor the concrete flow and pressure.

5. Pumping Process:

– Direct the Hose: Guide the end hose to distribute the concrete evenly to the designated area.

– Adjust Speed: Adjust the pump speed as necessary to control the dispensing rate.

– Communicate: Maintain communication with the team for efficient placement and troubleshooting.

6. Post-Pumping:

– Clean Equipment: Flush the pump and hoses with water immediately after use to prevent concrete from hardening inside.

– Inspect: Check hoses and fittings for any damage or wear.

Safety Tips:

– Wear PPE: Use personal protective equipment such as gloves, goggles, and boots.

– Secure Hoses: Ensure hoses are secured to avoid tripping and other hazards.

– Follow Protocols: Adhere to all safety guidelines and procedures.

This efficient method helps deliver concrete to hard-to-reach places while minimizing labor and improving accuracy.

“line pumping concrete” Comparative Analysis

Line pumping concrete and other concrete delivery methods each have their distinct advantages and challenges, depending on the specifics of a construction project. This comparative analysis will explore the pros and cons of line pumping concrete, and how it stacks up against other concrete delivery techniques such as boom pumping and traditional methods like manual wheelbarrow transport.

Advantages of Line Pumping Concrete:

1. Cost-Effectiveness: Line pumping is generally more affordable than boom pumping, especially for smaller to mid-sized projects or when a high reach is unnecessary.

2. Flexibility: Line pumps can access hard-to-reach areas that boom pumps may not be able to, such as indoor locations or sites with difficult terrain.

3. Lower Set-Up Time: Due to simpler machinery, line pumps usually require less time to set up, making them suitable for projects requiring quick turnaround.

4. Control: Operators have greater control over the flow and placement of concrete, which enhances precision and reduces waste.

Disadvantages of Line Pumping Concrete:

1. Limited Distance: Line pumps are generally less effective for transporting concrete over very long distances without additional equipment.

2. Capacity: They might not be suitable for very large-scale projects that require massive volumes of concrete in short timeframes.

3. Complexity of Hose Arrangement: Setting up long reaches of hose can be cumbersome and time-consuming, requiring careful management to avoid blockages or wear.

Comparison with Boom Pumping:

– Boom Pumping: Boom pumps use a robotic arm to deliver concrete, which is ideal for high-rise buildings and extensive horizontal pours. Although more expensive, they are more efficient for large-scale projects.

Comparison with Manual Methods:

– Manual Transport: Using wheelbarrows or buckets is labor-intensive and time-consuming, suitable only for very small and accessible pours. Line pumping saves on labor and increases efficiency.

Conclusion:

Line pumping concrete bridges the gap between costly large-scale pumping methods and painstaking manual transport, offering a balanced solution for diverse construction needs. It is particularly advantageous for medium-sized projects or complex designs requiring precise concrete placement.

“line pumping concrete” Warranty and Support

Line Pumping Concrete: Warranty and Support

When using line pumping concrete services, ensuring the reliability and longevity of the work is crucial. Our company offers comprehensive warranty and support to provide peace of mind for our clients. Our standard warranty covers any defects in materials and workmanship for a period of one year from the date of service. This includes any issues related to the integrity and durability of the concrete pump line, as well as any associated equipment used during the process.

In the event of any problems arising, we are committed to providing prompt and professional support. Our trained technicians are available to diagnose and address issues efficiently, ensuring minimal disruption to your project. Support requests can be made through our dedicated customer service line or via our online support portal, ensuring you have multiple channels to reach out to us.

We also offer extended warranty options for added protection, which can be tailored to meet the specific needs of your project. These extended warranties provide further coverage beyond the initial one-year period, offering additional assurance and support for larger or long-term projects.

For your convenience, we provide a free initial consultation and site inspection to understand the scope of your project and potential challenges. Our support doesn’t end after the pumping process; we offer ongoing maintenance services to uphold the highest standards of performance and safety.

Choosing our line pumping concrete services means benefiting from our commitment to quality, reliability, and customer satisfaction. With our robust warranty and support systems in place, you can trust that your project will be completed with the utmost care and professionalism. For more details on warranty specifics and support services, please consult our official warranty documentation or contact our customer support team directly.

List “line pumping concrete” FAQ

1. What is line pumping concrete?

– Line pumping concrete involves using a concrete pump to continuously feed concrete through a series of pipes or hoses to the desired location. It’s an efficient method for delivering concrete over long distances or to difficult-to-reach areas.

2. What types of projects are suitable for line pumping?

– Line pumping is ideal for residential and commercial projects, such as foundations, slabs, driveways, sidewalks, and retaining walls. It’s also beneficial for locations with limited access or where a boom pump cannot be used.

3. How does a line pump work?

– A line pump employs a motor to drive a series of pistons within pumping cylinders. As concrete is mixed, it’s fed into the hopper of the pump. The pistons then push the concrete through the piping system to the designated point of discharge.

4. What are the benefits of line pumping concrete?

– Line pumping offers several advantages: precision in placement, speed, ability to access hard-to-reach areas, reduced labor and physical strain, and enhanced quality control by minimizing disruptions in the concrete mix.

5. What are the limitations of line pumping?

– Line pumping can be less effective for very large pours compared to boom pumps. The setup and cleaning of hoses can be labor-intensive and time-consuming. Additionally, movement through long distances may require multiple pumps or relays.

6. What should be considered when setting up a line pump?

– Ensure a clear path for hose placement, secure fittings to avoid leaks, and plan for an adequate supply of concrete to keep the pump running smoothly. Have a thorough understanding of the site layout and the distance to be covered.

7. What kind of maintenance does a line pump require?

– Regular maintenance includes cleaning the pump and hoses after each use, checking for wear and tear on parts, and following the manufacturer’s guidelines for lubrication and parts replacement to ensure ongoing efficiency and reliability.

8. Can line pumps handle all types of concrete mixes?

– While line pumps are versatile, very harsh or chunky mixes might cause blockages. It’s important to coordinate with the concrete supplier to ensure a pump-friendly mix is used.

Top 10 FAQ with answer about line pumping concrete for Buyer Sourcing from China

Here are the top 10 frequently asked questions (FAQ) about sourcing line pumping concrete from China, tailored for buyers:

1. What is line pumping concrete?

Line pumping involves using a series of connected pipes to deliver concrete to specific locations, often for smaller projects or hard-to-reach areas. It’s an effective method for construction sites with obstacles or restricted access.

2. Why source line pumping concrete equipment from China?

China offers competitive pricing, a wide range of products, and advancements in manufacturing technology. Many Chinese suppliers also provide customization options and extensive after-sales service.

3. How do I ensure the quality of the equipment?

Verify the supplier’s credentials, certifications (like ISO), and customer reviews. Requesting sample products and conducting factory audits can also ensure quality. Using third-party inspection services can be beneficial.

4. What specifications should I consider?

Key specifications include pumping capacity (measured in cubic meters per hour), engine power, pipe diameter, operational pressure, and max horizontal and vertical transmission distances. Match these with your project requirements.

5. Is customization available?

Yes, many Chinese manufacturers offer customization to meet specific project needs. You can request modifications in design, capacity, and functionality to better suit your requirements.

6. What is the typical lead time for manufacturing and shipping?

Lead times vary but generally range from 30-60 days depending on the complexity of the equipment and order size. Shipping can take an additional 2-6 weeks based on the destination.

7. What are the payment terms?

Common payment terms include a down payment (20-30%) with the balance due upon completion or before shipping. Letters of Credit (L/C) and Trade Assurance on platforms like Alibaba are also standard.

8. How does the warranty and after-sales service work?

Warranties typically range from 1-2 years covering manufacturing defects. After-sales support includes spare parts, technical assistance, and sometimes on-site service. Verify the terms with the supplier.

9. Are spare parts readily available?

Reputable suppliers maintain an inventory of spare parts. Ensure that you confirm the availability and delivery times during the negotiation process to avoid project delays.

10. What about compliance with local regulations?

Ensure the equipment meets local safety and operational standards. Request detailed technical specifications and compliance documents to avoid legal hurdles and ensure the safe operation of the machinery.

These FAQs provide a comprehensive outlook on sourcing line pumping concrete from China, ensuring informed decision-making and smooth procurement processes.