low bed trailer Safety Certifications

Low bed trailers, used for transporting heavy and oversized loads, must adhere to a variety of safety certifications to ensure operational safety and regulatory compliance. Here are key safety certifications and standards relevant to low bed trailers:

1. FMVSS (Federal Motor Vehicle Safety Standards): In the United States, these standards cover multiple facets, including braking systems, lighting, and coupling connections to ensure the trailer’s safe operation on public roads.

2. ANSI (American National Standards Institute): ANSI sets guidelines for the design, construction, and maintenance of low bed trailers. Compliance ensures trailers meet safety and performance norms.

3. ISO (International Organization for Standardization): Standards such as ISO 1496 and ISO 3874 for freight containers and handling, respectively, are pertinent. ISO certifications help in maintaining global safety and quality standards.

4. ECE Regulations (Economic Commission for Europe): ECE R55, pertaining to coupling devices, and ECE R13, related to braking, are essential for trailers operating in European and other ECE member regions. These regulations facilitate cross-border transport compliance.

5. CSA (Canadian Standards Association) and Transport Canada: Specific to Canada, these standards ensure that trailers meet national safety guidelines, particularly in braking, lighting, and structural integrity.

6. Load Securement Regulations: Both the U.S. and Canada have specific regulations (e.g., FMCSA in the U.S. and NSC Standard 10 in Canada) for securing loads on low bed trailers, critical for preventing cargo shifts that could lead to accidents.

7. OSHA Compliance: Occupational Safety and Health Administration (OSHA) sets forth requirements for the safe operation of equipment used for loading and unloading trailers, ensuring workplace safety.

Meeting these certifications and standards is instrumental for manufacturers and operators not only to comply with legal requirements but also to safeguard both cargo and personnel involved in transportation. Regular inspections, maintenance, and training are pivotal in sustaining adherence to these safety norms.

List Reference Technical Parameters of “low bed trailer”

Low bed trailers, also known as lowboy trailers, are specialized transport vehicles designed to carry heavy, oversized, and tall loads that conventional trailers cannot handle. Below are the key technical parameters that define these trailers:

1. Load Capacity:

– Range: Typically between 20 tons to over 100 tons.

– Use: Often determined by the type of axles, suspension system, and frame strength.

2. Deck Height:

– Range: 18 to 24 inches (450 to 600 mm) from the ground.

– Benefits: Lower center of gravity, making it suitable for transporting tall loads.

3. Length:

– Range: Varies from 40 to 80 feet (12 to 24 meters) overall.

– Note: The length can be adjustable, especially for extendable low bed trailers.

4. Width:

– Standard: 8.5 feet (2.6 meters) to comply with most road regulations.

– Oversized Loads: Can go up to 12 feet (3.7 meters) or more with special permits.

5. Axles:

– Types: Tandem, tridem, or more (multi-axle configurations).

– Load Distribution: Axle capacity ranges from 10 tons to 20 tons per axle.

6. Suspension System:

– Options: Air ride, spring, or hydraulic suspension.

– Function: Impacts load stability and ride quality.

7. Frame Construction:

– Materials: High-strength, low-alloy steel for durability.

– Design: Reinforced to handle heavy and uneven load distribution.

8. Gooseneck Type:

– Fixed or detachable gooseneck options.

– Function: Detachable goosenecks provide easy loading and unloading.

9. Braking System:

– Types: Air brakes are standard, complying with safety regulations.

– Additional: Parking brakes, anti-lock braking systems (ABS).

10. Lighting and Markings:

– Compliance: Meets DOT, CE, or other relevant standards for safe transport.

– Includes: Tail lights, turn signals, and reflectors.

11. Safety Features:

– Tie-down points, ramps, and load securing mechanisms.

– Edge protectors and chains for securing the cargo.

These parameters are crucial for ensuring safe and efficient transportation of heavy and oversized loads. Remember, specifications can vary based on the manufacturer and specific requirements of the transport task.

List Product features of “low bed trailer”

Low Bed Trailer Product Features:

1. Payload Capacity: High payload capacity engineered to haul heavy and oversized machinery, equipment, and loads safely.

2. Deck Height: Low deck height designed to provide a lower center of gravity, ensuring enhanced stability during transport.

3. Gooseneck Design: Detachable gooseneck section allowing for easier loading and unloading of equipment by providing a ramp-like entry point.

4. Axle Configuration: Multi-axle configurations (typically 2-8 axles), providing additional support and weight distribution for heavy loads.

5. Material Construction: Robust construction using high-strength steel or other durable materials to withstand wear and harsh conditions.

6. Hydraulic Systems: Equipped with hydraulic systems for the gooseneck and trailer suspension, improving operational efficiency and ease-of-use.

7. Ramp Options: Various ramp designs (hydraulic, mechanical, folding, or removable) to suit different loading requirements and equipment types.

8. Enhanced Braking System: Advanced braking systems, including air and ABS brakes, to ensure safety and control during transport.

9. Customizable Dimensions: Customizable length, width, and height options to cater to specific needs and regulations.

10. Winch and Tie-Down Points: Integrated winches and multiple tie-down points for secure and versatile load anchoring.

11. Extendable Feature: Some models offer extendable trailers to accommodate longer equipment or loads.

12. Load Capacity Indicators: Load weight indicators or scales to monitor and ensure proper weight limits are maintained.

13. Suspension Options: Multiple suspension types (air, mechanical, leaf spring) to provide smoother ride and shock absorption.

14. Lights and Reflectors: DOT-compliant lighting and reflectors for visibility and safety during night or low-visibility driving conditions.

15. Tool Storage: Integrated tool and accessory storage compartments for convenient access and organization.

16. Rugged Tires: Heavy-duty, high-traction tires suitable for various terrains and weather conditions.

Incorporating these features makes low bed trailers versatile, reliable, and essential for transporting heavy, oversized loads across various industries.

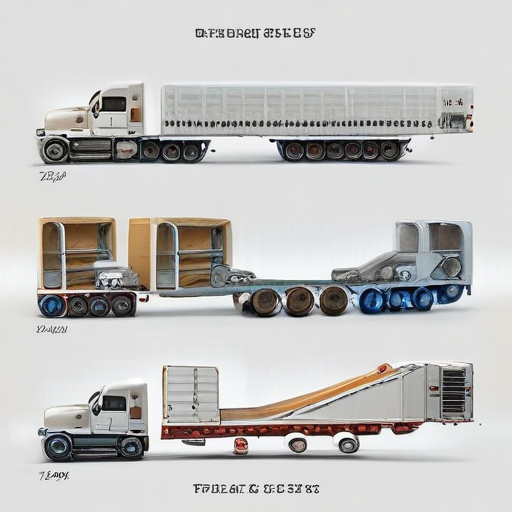

List Various Types of “low bed trailer”

Low bed trailers are specialized vehicles designed for the transportation of heavy, oversized, and tall equipment. They sit close to the ground, ensuring a low center of gravity and increased stability when hauling massive loads. Here are some common types:

1. Fixed-neck Low Bed Trailer:

– Structure: The neck is fixed, making it lighter and simpler.

– Application: Ideal for loads that can be driven, lifted, or rolled onto the trailer.

2. Detachable Gooseneck (RGN) Trailer:

– Structure: The front can be detached, creating a ramp.

– Application: Useful for loading taller machinery that can be driven on.

3. Step Deck Low Bed Trailer (Drop Deck):

– Structure: Features two deck levels, upper and lower decks.

– Application: Handles taller loads without exceeding height limitations.

4. Double-drop Deck Trailer:

– Structure: Features a well in the middle.

– Application: Used for very tall loads, providing extra height clearance.

5. Extendable Low Bed Trailer:

– Structure: The trailer can extend its length.

– Application: Accommodates long equipment and machinery that cannot be disassembled.

6. Perimeter Frame Low Bed Trailer:

– Structure: Designed with a perimeter frame for better load support.

– Application: Suitable for very heavy and wide machinery.

7. Folding Gooseneck Trailer:

– Structure: Features a mechanical or hydraulic gooseneck that folds.

– Application: Simplifies the loading process of equipment with lower ground clearance.

8. Beam Trailer:

– Structure: Consists of two low beams.

– Application: Appropriate for heavy and large-size machinery, offering better load distribution.

Each type offers unique advantages tailored to specific logistical needs, ensuring safe and efficient transportation of heavy and oversized loads across various industries.

List Application of “low bed trailer”

A low bed trailer, also known as a lowboy, is a type of flatbed trailer characterized by its notably low deck height. This feature makes it particularly suitable for transporting heavy and oversized loads. Here are some key applications:

1. Heavy Equipment Transport: Ideal for moving bulky machinery such as excavators, bulldozers, and cranes due to its low ground clearance, which accommodates oversized dimensions and massive weights.

2. Construction Material Hauling: Used to transport heavy construction materials like steel beams, concrete slabs, and other pre-fabricated components that are tough to move with conventional trailers.

3. Wind Turbine Components: Essential for transporting long and heavy wind turbine blades and towers, ensuring safer and easier maneuverability.

4. Mining Equipment Transport: Employed to haul heavy mining machinery and equipment that are typically oversized and weighty, often used in rugged terrains.

5. Agricultural Machinery: Suitable for transporting large agricultural equipment such as combines, tractors, and harvesters from one location to another.

6. Military Equipment Transport: Used for transporting heavy military hardware including tanks, armored vehicles, and artillery, thanks to its ability to handle large and heavy loads securely.

7. Bridge and Infrastructure Components: Facilitates the transport of large structural components for bridges and other infrastructure projects, where traditional trailers might falter due to weight and size constraints.

8. Oil and Gas Industry: Used for moving drilling rigs, pipes, and other heavy equipment to remote sites, where challenging terrains demand robust and reliable transport solutions.

9. Manufacturing Relocation: Assists in the transport of large industrial machinery during factory relocations, ensuring safe and efficient transfer without dismantling the equipment.

10. Specialized Freight: Ideal for hauling various specialized freight that requires enhanced stability and capacity, including large transformers and industrial compressors.

Overall, the low bed trailer’s distinct design facilitates the safe, efficient, and legal transport of oversized and heavy loads across diverse industries.

List Buyer Types of “low bed trailer”

Low bed trailers, also known as lowboy trailers, are critical in the transportation industry for moving heavy, tall, and oversized loads. Various buyers use these specialized trailers across multiple sectors:

1. Construction Companies:

Construction firms frequently purchase low bed trailers to transport heavy machinery, such as excavators, bulldozers, and large cranes, between job sites. The trailer’s low deck height makes it easier to load and unload heavy equipment.

2. Heavy Equipment Manufacturers:

Manufacturers of heavy machinery require low bed trailers to deliver their products to customers. These trailers ensure safe and secure transportation of large, heavy items from factories to end-users.

3. Logistics and Transport Companies:

Firms engaged in logistics and transport services invest in low bed trailers to offer specialized heavy haul services. They cater to industries needing to move oversized loads that standard trailers cannot accommodate.

4. Agricultural Sector:

Farmers and agricultural businesses use low bed trailers to transport large agricultural machinery like combines, tractors, and harvesters. These trailers facilitate the movement of farming equipment across long distances or off-site locations.

5. Mining Industry:

The mining sector often requires heavy-duty low bed trailers to move mining equipment and machinery, such as drills, loaders, and other heavy gear, from one site to another.

6. Renewable Energy Sector:

Companies involved in renewable energy, such as wind and solar energy projects, use low bed trailers to transport large components, including wind turbine blades and massive solar arrays, to installation sites.

7. Military and Defense:

Military organizations utilize low bed trailers for the transport of heavy military vehicles, tanks, and equipment. Secure and stable transportation of such critical machinery is paramount, and low bed trailers provide the necessary support.

8. Public Infrastructure and Utility Companies:

These organizations require low bed trailers for moving infrastructure-related machinery and equipment, like transformers, generators, and large piping for public works projects.

By addressing the needs of these varied sectors, manufacturers and distributors of low bed trailers ensure a broad market for their products.

List “low bed trailer” Project Types for Different Industries

Certainly! Low bed trailers, also known as lowboy trailers, are versatile transportation solutions used across various industries for hauling heavy, oversized, and specialized loads. Here are some project types for different industries:

1. Construction Industry:

– Heavy Machinery Transport: Moving excavators, bulldozers, cranes, and other large construction equipment.

– Building Materials Delivery: Transporting steel beams, precast concrete segments, and other large construction materials.

2. Agriculture Industry:

– Farm Equipment Relocation: Moving tractors, harvesters, ploughs, and other large agricultural machinery.

– Bulk Commodity Transport: Hauling large quantities of bulk commodities like hay bales, silage, and grain storage units.

3. Mining Industry:

– Heavy Duty Equipment Moving: Transporting mining trucks, drills, and other heavy mining equipment.

– Ore and Mineral Loads: Moving large containers of ore, coal, or other mined materials that require robust transport solutions.

4. Renewable Energy Industry:

– Wind Turbine Components: Hauling large components like blades, nacelles, and towers of wind turbines.

– Solar Panel Arrays: Transporting oversized solar panel arrays and mounting structures.

5. Oil and Gas Industry:

– Rig Transport: Moving drilling rigs, pumps, and other large oilfield equipment.

– Pipe Hauling: Transporting long sections of pipe and other pipeline construction materials.

6. Infrastructure Projects:

– Bridge Components: Moving large bridge segments, girders, and other prefabricated infrastructure components.

– Railway Equipment: Transporting railcars, locomotives, and railway maintenance equipment.

7. Manufacturing Industry:

– Factory Equipment: Relocating industrial machinery, presses, and heavy production equipment.

– Oversized Manufactured Goods: Transporting large prefabricated sections of machinery, storage tanks, and other goods.

8. Military and Defense:

– Heavy Armaments Transport: Moving tanks, armored vehicles, and other military machinery.

– Supplies and Equipment: Hauling oversized equipment and supplies to remote or temporary military bases.

Low bed trailers are crucial for these industries, enabling the effective transport of heavy and oversized loads that are essential for various critical projects.

low bed trailer Accessories Upgrades and Custom Manufacturing Options

Low bed trailers are a vital asset for transporting heavy and oversized cargo. Enhancing their functionality and efficiency involves various accessories, upgrades, and custom manufacturing options. Here are some key considerations:

Accessories:

1. Loading Ramps: Essential for ease of loading and unloading equipment.

2. Winches: Aid in pulling heavy items onto the trailer.

3. Toolboxes: Provide secure storage for tools and equipment.

4. Safety Chains and Straps: Ensure that the cargo is securely fastened.

5. Trailer Jacks: Support the trailer during loading and unloading.

Upgrades:

1. Hydraulic Systems: Enhance the ease of operation, especially for adjusting trailer height.

2. Extended Axles: Improve load distribution and stability.

3. Upgraded Suspension: Provides better handling of heavy loads, reducing wear and tear.

4. LED Lighting: Improves visibility and safety.

5. Braking Systems: Enhanced braking capabilities for increased safety during transport.

Custom Manufacturing Options:

1. Specialized Dimensions: Tailored to specific cargo dimensions and weights.

2. Material Choices: Options like high-tensile steel or aluminum for specific needs like weight reduction or increased strength.

3. Detachable Gooseneck: For easy and flexible loading of extremely heavy equipment.

4. Custom Paint and Finishes: To match company branding or for additional protection against the elements.

5. Specialized Axles and Tires: For specific terrain or load requirements.

Conclusion:

Investing in the right accessories, upgrades, and custom manufacturing options can significantly enhance the functionality, safety, and lifespan of low bed trailers. These modifications enable efficient transport, cater to unique transport needs, and ensure the utmost safety during operations.

List Quality Control and The Manufacturing Process of “low bed trailer”

Quality Control of Low Bed Trailers

1. Material Inspection: Begin with stringent inspections of raw materials such as steel, ensuring they meet specified grades and standards for durability.

2. Welding Inspections: Conduct non-destructive testing (NDT) to inspect weld quality, looking for cracks, incomplete fusions, or other defects.

3. Dimensional Checks: Use precision measurement tools to verify that each component adheres to design specifications and tolerances.

4. Load Testing: Simulate load conditions to test structural integrity and performance under stress.

5. Surface Treatment: Inspect cleanliness and application of anti-corrosive coatings or paint to ensure long-term durability.

6. Assembly Verification: Check all assembled parts to confirm they fit together perfectly and function as intended.

7. Electrical Systems Testing: Ensure all lighting and braking systems comply with regulatory standards and function reliably.

8. Final Inspection: Conduct comprehensive reviews of the entire unit to ensure it meets all design and regulatory specifications.

Manufacturing Process of Low Bed Trailers

1. Design and Planning: Engineering teams use CAD software to create detailed models, ensuring compliance with industry standards and specific customer requirements.

2. Material Procurement: Purchase high-quality steel and components, verified against stringent criteria for mechanical properties.

3. Cutting and Shaping: Employ CNC machines for precise cutting and shaping of steel plates and sections.

4. Welding and Assembly: Skilled welders join parts together, followed by an assembly process where components like the frame, axles, and suspension systems are assembled.

5. Surface Preparation: Clean and prepare surfaces through processes like sandblasting to remove impurities for better adhesion of coatings.

6. Coating and Painting: Apply anti-corrosive treatments and paint, ensuring both aesthetic appeal and protection against environmental factors.

7. Installation of Auxiliary Equipment: Attach secondary components such as hydraulic ramps, winches, and electrical systems.

8. Quality Control Testing: Conduct various quality control tests, such as load tests and alignment checks, to ensure the trailer meets all design specifications.

9. Final Assembly and Inspection: Complete final assembly steps and perform a thorough inspection to confirm the trailer is ready for delivery.

10. Delivery Preparation: Prepare trailers for transport by ensuring they are securely packaged and shipped according to the customer’s specifications.

How to use “low bed trailer”

A low bed trailer, also known as a lowboy trailer, is primarily used for transporting heavy or oversized equipment and machinery that exceeds regular height restrictions. Here’s a concise guide on how to use it:

1. Preparation:

– Choose the Right Trailer: Ensure the trailer meets the weight and size requirements of your load.

– Inspect the Trailer: Check tires, brakes, and lights to ensure they are in good working condition.

– Obtain Permits: Depending on the load size and weight, secure necessary transport permits.

2. Loading:

– Positioning: Park the trailer on a flat, stable surface.

– Lower the Trailer: If the trailer has a hydraulic system, lower the deck for easier loading.

– Align the Equipment: Drive or use a crane to position the equipment onto the trailer. Ensure even weight distribution.

– Secure the Load: Use chains, straps, and binders to tightly secure the load. Ensure all fastening points are firm.

3. Transportation:

– Plan Your Route: Avoid low bridges and narrow streets.

– Drive Cautiously: Maintain a moderate speed and take wide turns. Pay attention to height and width clearances.

– Monitor the Load: Make periodic stops to check the stability of the load and the condition of the trailer.

4. Unloading:

– Find a Safe Location: Choose a flat and stable unloading area.

– Stop the Vehicle: Ensure the truck and trailer are completely stationary.

– Unfasten the Load: Carefully remove all chains, straps, and binders.

– Unload: Use appropriate equipment to remove the load safely.

5. Post-Transport:

– Inspect the Trailer: Check for any damage or wear.

– Maintenance: Perform necessary maintenance to keep the trailer in good condition for future use.

By adhering to these steps, you can safely and efficiently use a low bed trailer for transporting heavy and oversized loads.

“low bed trailer” Comparative Analysis

A low bed trailer, also known as a lowboy trailer, offers distinct advantages and limitations when compared to other types of trailers such as flatbed, step deck, and gooseneck trailers. Conducting a comparative analysis between these trailers highlights their respective utility and suitability for various transport needs.

Loading Capacity and Height:

Low bed trailers have a significantly low deck height, which makes them ideal for transporting heavy and oversized machinery that cannot be moved on higher deck trailers due to height restrictions. The low deck height ensures stability and compliance with height regulations during transit, which is a significant advantage over flatbed and step deck trailers.

Versatility and Adaptability:

While low bed trailers excel at hauling heavy and tall loads, they are not as versatile as flatbed or step deck trailers. Flatbed trailers are versatile and frequently used for various types of cargo, including both large and moderately sized loads. Step deck trailers offer a compromise with two deck levels to handle both taller and heavier loads but don’t quite match the low bed trailer’s capacity for the heaviest and tallest loads.

Ease of Loading and Unloading:

Low bed trailers typically require specialized loading equipment such as ramps or cranes due to their lower height and heavy-duty design, whereas flatbed and step deck trailers allow for easier access using forklifts or loading docks. Gooseneck trailers also provide ease of loading due to their design, but they lack the heavy-duty capacity of low bed trailers.

Cost Considerations:

From a cost perspective, low bed trailers are often more expensive both in initial purchase and operational costs due to their specialized construction and usage. Flatbed and step deck trailers present more economical solutions for general freight.

Conclusion:

In summary, low bed trailers are paramount for transporting extremely heavy, tall, and oversized machinery, offering unmatched stability and compliance with height restrictions. However, for versatility, cost-efficiency, and ease of loading, flatbed and step deck trailers present more advantageous options. The choice ultimately depends on specific transportation requirements and budget considerations.

“low bed trailer” Warranty and Support

When purchasing a low bed trailer, understanding the warranty and support options available is essential to ensure long-term reliability and performance. Typically, manufacturers offer varying warranty periods and coverage levels that can include structural components, electrical systems, and other critical parts.

Warranty Coverage

Most reputable manufacturers provide a standard warranty ranging from one to five years. Key aspects covered might include:

– Structural Warranty: Covers issues related to the frame, axles, and suspension.

– Electrical Warranty: Pertains to the trailer’s wiring, lights, and other electrical components.

– Components Warranty: Includes coverage for ancillary parts like hydraulic systems or braking components.

Warranty Conditions

To benefit from the warranty:

1. Regular Maintenance: Adherence to the recommended maintenance schedule is crucial.

2. Proper Usage: Following the manufacturer’s guidelines for load limits and operational use.

Support Services

Comprehensive support services can enhance the ownership experience. Look for manufacturers offering:

– Customer Service: Access to knowledgeable support staff for troubleshooting and queries.

– Spare Parts Availability: Easy access to replacement parts can minimize downtime.

– Authorized Service Centers: Locations equipped to perform repairs under warranty.

Extra Support Options

Some manufacturers may offer additional support services for an added fee, such as:

– Extended Warranties: Option to extend the standard warranty for additional years.

– On-Site Repairs: Technicians who can perform repairs directly at your location.

– Training Programs: Operator training to ensure optimal usage and maintenance.

Conclusion

Choosing a low bed trailer with a robust warranty and comprehensive support services provides peace of mind and ensures your investment remains in optimal condition. Always review the specific terms and conditions of the warranty and support services before finalizing your purchase.

List “low bed trailer” FAQ

Low Bed Trailer FAQ

#### 1. What is a low bed trailer?

A low bed trailer, also known as a lowboy, low-loader, or float, is a type of flatbed trailer with a deck that’s particularly low to the ground. This design allows for the transportation of heavy, tall, and oversized loads that traditional trailers can’t accommodate.

#### 2. What are common uses for a low bed trailer?

Low bed trailers are often used for transporting heavy machinery, construction equipment, prefab structures, and other oversized items. Their low deck height offers a safer and more stable transport solution for heavy loads.

#### 3. How much weight can a low bed trailer carry?

The weight capacity of a low bed trailer typically ranges from 40,000 to 80,000 pounds, but custom trailers can carry over 100,000 pounds. The exact capacity depends on the number of axles and specific design features.

#### 4. What are the legal requirements for using a low bed trailer?

Regulations vary by region, but generally require special permits for oversized loads, adherence to weight limits, and compliance with safety standards. Check local transport authority guidelines for specifics.

#### 5. How do I load and unload a low bed trailer?

Loading and unloading should be done on a flat, stable surface. Use ramps or hydraulic systems to ease the process. Ensure the load is evenly distributed and properly secured to prevent shifting during transport.

#### 6. What types of low bed trailers are available?

Common types include fixed-neck, removable gooseneck (RGN), and folding gooseneck trailers. Each type offers different advantages depending on the load and operational requirements.

#### 7. How do I maintain a low bed trailer?

Regular maintenance involves checking tires, brakes, and lights, ensuring structural integrity, and lubricating moving parts. Consistent inspections can prevent breakdowns and extend the trailer’s lifespan.

#### 8. Where can I buy or rent a low bed trailer?

Low bed trailers can be purchased or rented from specialized trailer manufacturers, heavy equipment dealers, and rental companies. Consider both new and used options based on your budget and specific needs.

This concise FAQ aims to provide a broad overview of common questions regarding low bed trailers. For more detailed information, consult trailer manufacturers or transport experts.

Top 10 FAQ with answer about low bed trailer for Buyer Sourcing from China

Sure, here are the top 10 frequently asked questions (FAQs) about sourcing low bed trailers from China, complete with concise answers:

1. What is a low bed trailer?

– A low bed trailer, also known as a lowboy trailer, is a type of heavy-duty trailer with a low deck height, allowing it to carry tall and heavy loads without exceeding height restrictions.

2. Why source low bed trailers from China?

– China offers competitive pricing, high-quality manufacturing, and a wide variety of options due to its established industrial base and advanced production technologies.

3. What should I consider when choosing a supplier?

– Evaluate the supplier’s manufacturing capabilities, quality certifications (e.g., ISO), industry reputation, customer reviews, and after-sales support.

4. What are the common specifications I should look for?

– Key specifications include load capacity, deck height, number of axles, material composition, and braking systems. Ensure these match your specific needs.

5. How do I assess the quality of a low bed trailer?

– Look for rigorous quality control processes, use of high-strength steel, compliance with international standards, and positive feedback from existing users.

6. What is the typical delivery time for a low bed trailer from China?

– Delivery time generally ranges from 4 to 8 weeks, depending on customization requirements and the production schedule.

7. Is customization available?

– Yes, many Chinese manufacturers offer customized designs tailored to specific loading requirements, dimensions, and operational needs.

8. How can I handle shipping and import regulations?

– Collaborate with the supplier on shipping logistics, and consult with a freight forwarder or customs broker to navigate import regulations and duties.

9. What payment terms are commonly accepted?

– Common payment methods include Telegraphic Transfer (T/T), Letter of Credit (L/C), and sometimes Escrow for added security.

10. What warranty and after-sales support can I expect?

– Reputable suppliers usually offer warranties ranging from 1 to 5 years and provide technical support, spare parts, and maintenance services.

These FAQs aim to address key concerns and provide a solid foundation for those looking to source low bed trailers from China.