machining precision Safety Certifications

Machining precision safety certifications are paramount for ensuring the quality and safety of machined products. Here are some key certifications:

1. ISO 9001: This is the international standard for quality management systems (QMS). It ensures that organizations consistently provide products and services that meet customer and regulatory requirements, fostering continuous improvement.

2. ISO 13485: Specifically for medical devices, this certification ensures that the organization has an effective QMS tailored for the design and manufacture of medical devices, emphasizing risk management and sterility.

3. ISO 14001: Focused on environmental management, this certification ensures that companies minimize their environmental footprint, comply with applicable laws, and continually improve their environmental performance.

4. ISO/TS 16949: A critical certification for the automotive sector, it combines ISO 9001 with specific automotive industry requirements, ensuring high quality and systematic manufacturing processes.

5. AS9100: Pertaining to the aerospace industry, this standard integrates ISO 9001 requirements with additional aerospace sector-specific quality requirements, ensuring safety, reliability, and regulatory compliance.

6. NADCAP: The National Aerospace and Defense Contractors Accreditation Program is a global cooperative accreditation program for aerospace engineering, defense, and related industries. It focuses on special processes, ensuring consistent quality and compliance with technical standards.

7. CE Marking: For products sold within the European Economic Area, CE marking signifies that they meet health, safety, and environmental protection standards.

8. OSHA Compliance: Adhering to the Occupational Safety and Health Administration’s regulations ensures a safe and healthy working environment, reducing workplace hazards.

Incorporating these certifications not only assures the precision and quality of machining processes but also reinforces commitment to safety, environmental stewardship, and continuous improvement.

List Reference Technical Parameters of “machining precision”

Machining precision refers to the exactness with which a part is manufactured in accordance with its specified dimensions and tolerances. It encompasses several technical parameters used to measure and ensure the quality of machined parts. Key parameters include:

1. Dimensional Tolerance:

– Defines the allowable variance in a part’s dimensions. Tighter tolerances yield higher precision.

2. Surface Finish:

– Measured in micro-inches or micrometers, it denotes the smoothness of a machined surface. A finer finish signifies higher precision.

3. Geometric Tolerance:

– Specifies permissible deviations from the nominal geometry (e.g., roundness, flatness, straightness, parallelism, perpendicularity).

4. Repeatability:

– The machine’s ability to consistently reproduce the same dimension every time.

5. Positioning Accuracy:

– Refers to the machine’s capability to move to the exact location as specified.

6. Runout:

– Indicates the deviation of a part’s surface as it rotates, affecting concentricity and roundness.

7. Cylindricity:

– Measures the deviation of a cylindrical object from a perfect cylinder.

8. Profile Tolerances:

– Controls the three-dimensional variation in the contour of a surface or feature.

9. Straightness and Flatness:

– Assesses deviations in straight lines and flat surfaces respectively.

10. Angularity:

– The degree to which the angles between surfaces meet design specifications.

11. Thermal Stability:

– The machine’s ability to maintain precision despite temperature changes.

12. Tool Deflection:

– Less deflection maintains higher precision in dimensions and finish.

By controlling these parameters, manufacturers ensure that machined parts meet the required specifications and function as expected in their intended applications.

List Product features of “machining precision”

Sure, here are some key product features of machining precision:

1. High Tolerance Levels:

– Ability to maintain extremely tight tolerances, often within microns, ensuring parts meet exact specifications.

2. Surface Finish Quality:

– Achieves smooth surface finishes, reducing the need for additional surface treatment and ensuring aesthetic and functional quality.

3. Dimensional Accuracy:

– Consistently produces parts with accurate dimensions, critical for parts that must fit with tight assembly requirements.

4. Repeatability:

– Ensures that each part produced is identical, which is crucial for mass production and assembly line applications.

5. Complex Geometries:

– Capable of producing complex shapes and intricate features that may be challenging or impossible with other manufacturing methods.

6. Material Versatility:

– Able to work with a wide range of materials including metals, plastics, composites, and exotic alloys, catering to various industry needs.

7. Speed and Efficiency:

– Advanced machining techniques and equipment maximize production speed without compromising precision, leading to reduced lead times.

8. Automated Control Systems:

– Utilizes computer numerical control (CNC) systems for automated, precise, and efficient operations.

9. Quality Control:

– Incorporates stringent inspection protocols such as Coordinate Measuring Machines (CMM) and laser scanning for verifying precision.

10. Customizability:

– Flexible machining options allow for customization of parts to specific requirements, facilitating a tailored approach to unique challenges.

11. Tool Life and Management:

– Utilizes high-quality, durable tools and incorporates advanced monitoring systems to predict and extend tool life, ensuring consistent machining performance.

12. Adaptability to New Technologies:

– Integrates emerging technologies like 3D printing and AI-driven optimizations to push the boundaries of precision and efficiency.

These features make machining precision essential for industries such as aerospace, automotive, medical device production, and electronics where accuracy, consistency, and quality are paramount.

List Various Types of “machining precision”

Machining precision refers to the degree of accuracy and refinement attained in the manufacturing process. Various types of machining precision cater to different needs and applications. Here are some notable types:

1. Dimensional Precision: Refers to the exactness of dimensions specified in the design. This quality ensures parts fit together as intended, affecting assembly and performance.

2. Geometric Precision: Focuses on the shape and geometrical features of the part like flatness, roundness, and cylindricity. This type ensures parts have the correct form and contour.

3. Positional Precision: Determines the accuracy of the placement of features relative to each other. Essential in assemblies requiring high alignment accuracy.

4. Surface Finish Precision: Pertains to the smoothness of the part’s surface, typically measured in surface roughness (Ra). Important for functional and aesthetic requirements.

5. Tolerance Precision: Encompasses the permissible limits of variation in dimensions. Tighter tolerances mean higher precision and are crucial for high-performance parts.

6. Fit Precision: deals with the exactness of how parts fit together, often categorized as clearance, interference, or transition fits. Critical for moving parts and assemblies.

7. Repeatability Precision: Refers to the ability of the machining process to produce parts with consistent quality over multiple runs. Vital for mass production.

8. Thermal Precision: Accounts for the material’s expansion or contraction due to temperature changes. Important for parts operating in varying thermal conditions.

Each type of precision is crucial in specific applications, from aerospace and automotive to medical devices and consumer electronics. High machining precision enhances performance, reliability, and longevity.

List Application of “machining precision”

Applications of Machining Precision

1. Aerospace Industry: High precision machining is essential for manufacturing components such as turbine blades, engine parts, and airframe components. These parts require tight tolerances to ensure optimal performance and safety in harsh operating environments.

2. Medical Devices: Precision machining is used to produce intricate components for medical instruments, implants, and devices like surgical tools, orthopedic screws, and prosthetic joints. Accuracy is crucial to meet stringent regulatory requirements and ensure patient safety.

3. Automotive Sector: In the production of engine parts, transmission systems, and other critical components, machining precision ensures durability, performance, and fuel efficiency. High precision machining contributes to reducing emissions and improving vehicle lifespan.

4. Semiconductor Industry: Fabrication of semiconductor components, such as silicon wafers and microchips, requires precision machining for the creation of microscale features. Accuracy in machining directly impacts the performance and efficiency of electronic devices.

5. Optics and Photonics: Manufacturing precision lenses, mirrors, and other optical components demands extreme accuracy to ensure proper light manipulation. This is vital for applications in cameras, telescopes, microscopes, and advanced communication systems.

6. Defense and Military: Precision machining is critical for producing weapons, ammunition, and specialized military equipment. Tight tolerances enhance reliability and performance under extreme conditions, which is essential for defense applications.

7. Industrial Machinery: Components for heavy machinery, robotics, and automation systems often require precise machining. High precision ensures the machines operate smoothly, with minimal downtime and maintenance.

8. Energy Sector: Precision machining is necessary for components used in power generation, such as gas turbines, nuclear reactors, and renewable energy systems. Accurate machining contributes to efficiency and safety in energy production and distribution.

9. Consumer Electronics: The production of smartphones, laptops, and other electronic gadgets relies on high precision machining to achieve the miniaturization and integration of complex components.

By ensuring tight tolerances and high accuracy, machining precision is pivotal across various industries, driving advancements and enhancing the performance of critical products and systems.

List Buyer Types of “machining precision”

When it comes to “machining precision,” there are several specialized buyer types that seek high-precision components for their specific needs. These buyers are typically from industries where minute tolerances and exact measurements are crucial for the performance and reliability of their products. Here are the primary buyer types:

1. Aerospace and Defense Companies:

– These buyers require high-precision machining for components such as turbine blades, structural aerospace parts, missile components, and military equipment.

2. Automotive Manufacturers:

– Precision parts are essential for engine components, transmission parts, braking systems, and other critical auto parts that demand tight tolerances and high reliability.

3. Medical Device Manufacturers:

– They require extremely precise machining for creating medical implants, surgical instruments, and diagnostic equipment, where accuracy can be life-critical.

4. Electronics and Semiconductor Companies:

– These buyers need precision machining for components used in electronic devices, microchips, and semiconductor equipment, which require high levels of exactness.

5. Industrial Equipment Manufacturers:

– Companies producing machinery parts, robotics components, and tooling equipment require precision machining to ensure operational efficiency and durability.

6. Energy Sector Firms:

– This includes companies in the oil and gas, renewable energy, and nuclear sectors that need precision-machined parts for turbines, drilling equipment, and other energy-related machinery.

7. Telecommunications Industry:

– Precision parts are used in fiber optic connectors, communication satellites, and various networking hardware where exact specifications are vital for optimal performance.

8. Instrumentation and Controls Companies:

– Manufacturers of scientific instruments, measurement devices, and high-tech control systems rely on precision machining to fabricate accurate and dependable components.

Each of these buyer types demands high-quality, precisely-machined parts suited to their specific industry requirements, ensuring functionality, safety, and performance.

List “machining precision” Project Types for Different Industries

Certainly! Here are various “machining precision” project types across different industries:

1. Aerospace:

– Jet Engine Components: High-precision machining of turbine blades, compressor disks, and fuel nozzles requires minimal tolerances.

– Airframe Parts: Precision machining for fuselage sections, wing components, and landing gear.

2. Automotive:

– Engine Components: Precision machining of cylinders, pistons, and camshafts for optimal engine performance.

– Transmission Systems: Gears, shafts, and housing require tight tolerances for seamless operation.

– Brake Systems: Machining of brake discs and drums to exact specifications.

3. Medical Devices:

– Implants: High-precision machining for orthopedic implants, dental implants, and prosthetics to ensure biocompatibility and fit.

– Surgical Tools: Precision in making instruments like scalpels, forceps, and endoscopic devices.

4. Electronics:

– Semiconductor Equipment: Machining of components used in semiconductor manufacturing equipment, such as etching and deposition machines.

– Printed Circuit Board (PCB): Precision drilling and milling of PCBs for electronic devices.

5. Defense:

– Firearms Components: Machining of barrels, receivers, and other critical parts of guns and rifles for accuracy and durability.

– Ammunition: Precision in casting and machining bullets and cartridges.

6. Energy:

– Turbine Components: Machining parts for gas, steam, and wind turbines, such as blades and rotors, with high precision for efficiency.

– Oil & Gas: Precision-machined components for drilling rigs, pumps, and valves.

7. Robotics:

– Actuators and Servos: High-precision machining for gears, housings, and motor components.

– End Effectors: Custom machining of robotic grippers and tools for various tasks.

8. Watchmaking:

– Micro Mechanical Components: Ultra-precision machining of gears, escapements, and springs for high-end mechanical watches.

9. Space Exploration:

– Satellite Components: Precision machining for structural frames, joining elements, and thermal control systems of satellites.

– Rover Parts: Components machined for Mars rovers and other exploratory vehicles require exact precision for reliable performance in extreme conditions.

Each industry demands specific tolerances and machining techniques to ensure the functionality, safety, and longevity of the products.

machining precision Accessories Upgrades and Custom Manufacturing Options

Machining precision accessories and upgrades play a crucial role in optimizing manufacturing processes, enhancing efficiency, and ensuring product quality. Modern machining centers can significantly benefit from various accessory upgrades and custom manufacturing solutions tailored to specific needs.

Accessory Upgrades:

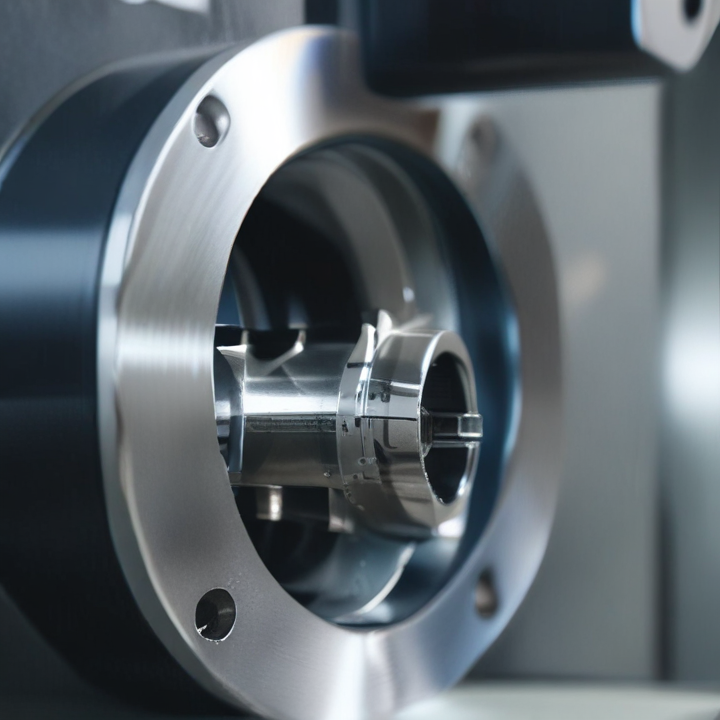

1. Tool Holders and Chucks: Upgrading to high-precision tool holders and chucks can enhance the stability and accuracy of cutting tools, reducing vibrations and improving surface finishes.

2. Boring Heads: Precision boring heads allow for tight tolerance machining, essential for achieving consistent and accurate bore sizes.

3. Coolant Systems: Advanced coolant delivery systems such as high-pressure and through-tool coolant can improve tool life and machining quality by better managing heat and chip removal.

4. Dampened Tools: Utilizing vibration-dampened tooling can minimize chatter and enhance surface finish, crucial for precision applications.

5. Measurement Systems: On-machine probing and laser measurement systems enable real-time adjustments and verification, ensuring parts meet stringent tolerances.

Custom Manufacturing Options:

1. Fixture Design: Custom fixtures are designed to hold workpieces securely in place, ensuring consistent machining and reducing set-up times. This is particularly important for complex or irregularly shaped parts.

2. Specialized Tooling: Custom tooling solutions tailored to specific material properties or unique part geometries can significantly enhance machining efficiency and performance.

3. Automation Integration: Incorporating robotic loading/unloading systems or automated tool changers can streamline production, reduce human error, and increase throughput.

4. Modular Workholding: Solutions like modular vises and clamping systems offer flexibility, allowing quick reconfiguration to accommodate different parts or operations.

5. Software Upgrades: Advanced CAD/CAM software and toolpath optimization algorithms can improve precision machining by optimizing tool movements and reducing cycle times.

Incorporating these precision accessories and custom manufacturing options can drastically enhance machining capabilities, productivity, and product quality, ultimately leading to better end-user satisfaction and higher profitability.

List Quality Control and The Manufacturing Process of “machining precision”

Quality Control and The Manufacturing Process of Machining Precision

Manufacturing Process:

1. Design and Engineering:

– Create detailed CAD models and engineering drawings that meet exact specifications and tolerances.

2. Material Selection:

– Choose appropriate materials based on project needs, ensuring properties like hardness, corrosion resistance, and machinability.

3. Pre-Processing:

– Cut raw materials to manageable sizes using tools like band saws or plasma cutters.

4. Machining:

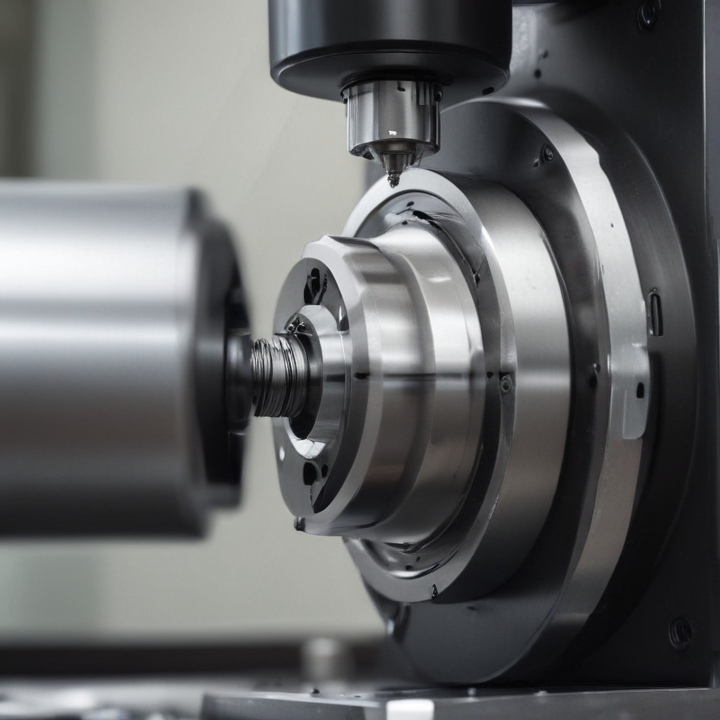

– Perform precise cutting, drilling, milling, and turning using CNC machines. Utilize CAD/CAM software for programming complex geometries.

5. Heat Treatment:

– Apply processes like annealing, quenching, or tempering to achieve desired mechanical properties.

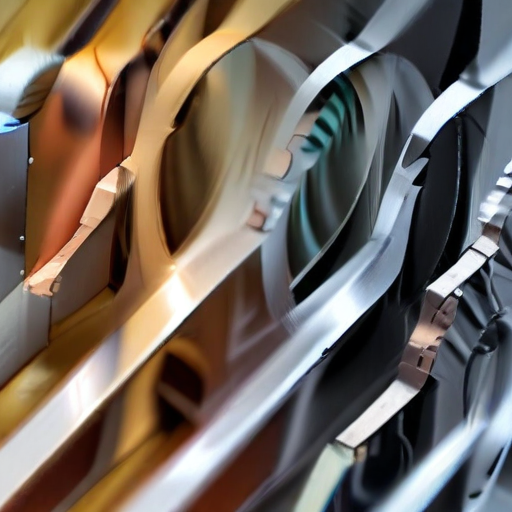

6. Surface Finishing:

– Polish, grind, or apply coatings to achieve the required surface texture and protect from corrosion.

7. Assembly:

– Fit and assemble machined components if creating a more complex final product.

Quality Control:

1. Incoming Inspection:

– Verify raw materials for correct specifications such as grade and dimensions.

2. In-Process Inspection:

– Utilize coordinate measuring machines (CMM), laser scanning, and other tools to verify dimensions and tolerances during production.

3. First Article Inspection:

– Conduct a thorough inspection on the initial piece to ensure it meets all design requirements before full-scale production.

4. Sampling and Statistical Process Control (SPC):

– Use SPC techniques to monitor and control the machining process, ensuring consistency and minimizing defects.

5. Post-Machining Inspection:

– Perform final dimensional checks, surface finish inspection, and hardness tests to verify all specifications are met.

6. Documentation and Traceability:

– Maintain detailed records of inspections and material certificates to ensure traceability throughout the manufacturing cycle.

7. Corrective Actions:

– Implement root cause analysis and corrective actions for any deviations or non-conformances detected.

By meticulously following these steps, machining precision ensures high-quality parts that meet stringent industry standards.

How to use “machining precision”

“Machining precision” refers to the degree of accuracy and exactness with which a machining process can produce a component or part. It is a critical factor for ensuring that parts meet specified tolerances and function correctly in their intended applications. Here are steps on how to use and ensure machining precision effectively:

1. Understand Requirements:

– Clearly define the tolerances and specifications for the part. This includes dimensions, surface finish, and geometric tolerances, typically indicated on engineering drawings.

2. Select Appropriate Equipment:

– Choose machining tools and equipment capable of achieving the required precision. This may involve CNC machines, high-precision lathes, or EDM machines.

3. Material Selection:

– Use materials that are stable and appropriate for the desired precision. Some materials may expand, contract, or deform, impacting precision.

4. Tooling:

– Employ high-quality cutting tools. Regularly inspect and replace them to avoid wear and tear that could affect accuracy.

5. Machine Calibration:

– Regularly calibrate and maintain your machines. Misalignment or wear in machine components can lead to inaccuracies.

6. Process Control:

– Implement process controls such as temperature regulation, vibration dampening, and proper fixturing to minimize external influences that can impact precision.

7. Skill and Training:

– Ensure operators are well-trained and understand the importance of precision. Experienced operators are better equipped to handle nuances in the machining process.

8. Quality Inspection:

– Use precise measurement tools like CMM (Coordinate Measuring Machines), micrometers, and calipers to inspect finished parts. Regular quality checks ensure that parts meet the desired specifications.

By adhering to these guidelines, you can achieve high machining precision, leading to better product performance, reduced waste, and enhanced reputation for quality.

“machining precision” Comparative Analysis

Machining precision is a critical factor in manufacturing, significantly influencing the functionality, performance, and quality of the final product. A comparative analysis of machining precision can be approached by examining various machining processes, materials, and technological advancements.

Traditional Machining vs. CNC Machining:

Traditional machining methods, such as lathe operations and milling, rely heavily on manual control, leading to variability and lower precision. Conventional machines typically achieve tolerances in the range of ±0.05 to ±0.1 mm. In contrast, Computer Numerical Control (CNC) machining offers enhanced precision, consistency, and repeatability. CNC machines often achieve tolerances as tight as ±0.005 mm due to their automated nature and advanced software control, minimizing manual intervention and human error.

Material Considerations:

The type of material being machined plays a significant role in achievable precision. Metals like aluminum and brass are easier to machine precisely due to their relatively softer nature and predictable material properties. Harder materials like steel and titanium require more sophisticated tooling and may result in slightly reduced precision due to increased tool wear and thermal expansion effects. Advanced ceramics and composites present further challenges due to their brittleness and inhomogeneity, often necessitating specialized machining techniques like diamond tooling.

Technological Advancements:

Precision in machining has seen substantial improvements with technological advancements. High-Speed Machining (HSM) enhances cutting efficiency and surface finish, allowing for tighter tolerances. Laser and Electron Beam Machining offer extraordinary precision for extremely small and intricate components, achieving micrometer-level tolerance. Furthermore, advancements in Metrology and Inspection, such as Coordinate Measuring Machines (CMMs) and laser scanning, ensure that the precision achieved is accurately measured and maintained.

Conclusion:

Achieving high machining precision depends on the interplay between the machining method, material characteristics, and technological enhancements. CNC machining represents a significant leap from traditional methods, providing superior precision and consistency. Ongoing advancements in machining technologies and materials science continue to push the boundaries of what is achievable, setting new standards for precision in manufacturing.

By focusing on these elements, manufacturers can better understand the factors that influence precision and make informed decisions to optimize their machining processes.

“machining precision” Warranty and Support

At Machining Precision, we take pride in the quality and durability of our products. Each component is carefully crafted to meet the highest standards, ensuring reliability and exceptional performance. To demonstrate our commitment to excellence, we offer a comprehensive warranty and support package.

Warranty

Duration: Our standard warranty period is one year from the date of purchase.

Coverage: The warranty covers defects in materials and workmanship. If a problem arises due to these issues, Machining Precision will repair or replace the component at no charge.

Exclusions: The warranty does not cover damage resulting from misuse, improper installation, unauthorized modifications, or wear and tear from regular use.

Claim Process: To make a warranty claim, contact our customer service team with your proof of purchase and a detailed description of the issue. We aim to process claims within 5 business days.

Support

Technical Assistance: Our skilled technical support team is available to help with installation, troubleshooting, and maintenance guidance. We offer support through phone, email, and live chat.

Documentation: Comprehensive manuals and troubleshooting guides are available on our website, providing detailed instructions for installation and maintenance.

Training: We provide training sessions for customers who wish to deepen their understanding of machining techniques and best practices.

Replacement Parts: Genuine replacement parts are available for all our products, ensuring you maintain the high performance and longevity of your components.

Customer Portal: Our online customer portal allows you to track orders, download documentation, and submit support tickets, all in one convenient location.

At Machining Precision, your satisfaction is our priority. Our dedicated warranty and support services are designed to give you confidence and peace of mind with every purchase. For any additional inquiries, please contact us directly, and we’ll be more than happy to assist you.

List “machining precision” FAQ

Machining Precision FAQ

#### 1. What is machining precision?

Machining precision refers to the degree of accuracy and closeness to the desired dimensional tolerance in manufacturing processes. It indicates how well a component conforms to specified dimensions.

#### 2. Why is machining precision important?

High precision is crucial for ensuring parts fit together properly, function correctly, and maintain reliability and safety in applications ranging from aerospace to medical devices.

#### 3. What factors affect machining precision?

Several factors impact precision, including:

– Machine tool capability and condition

– Material properties

– Cutting tool quality and wear

– Process parameters (speed, feed, etc.)

– Environmental conditions (temperature, humidity)

– Operator skill level

#### 4. How is machining precision measured?

Precision is often measured using instruments like micrometers, calipers, coordinate measuring machines (CMM), and laser scanners. These tools assess dimensional conformity to specifications.

#### 5. What are common tolerance levels in machining?

Tolerance levels can range from coarse (±0.1 mm) in general manufacturing to extremely fine (±0.001 mm) in high-precision industries. The specific tolerance depends on application requirements.

#### 6. What materials are best for high-precision machining?

Materials with stable properties and high machinability, such as aluminum, certain steels, titanium, and specialized alloys, are preferred for high-precision work.

#### 7. How can I improve machining precision?

Improvement strategies include:

– Regular maintenance of machinery

– Using high-quality, sharp cutting tools

– Optimizing machining parameters

– Controlling environmental factors

– Implementing advanced techniques like CNC machining

#### 8. What role does CNC machining play in precision?

CNC (Computer Numerical Control) machining enhances precision by automating the control of machining tools, reducing human error, and allowing for consistent, repeatable production processes.

#### 9. Can precision machining be cost-effective?

While higher precision often increases costs, the benefits such as reduced assembly errors, lower defect rates, and longer product lifespans can offset the expense.

Conclusion

Machining precision is a critical aspect of manufacturing that ensures products meet stringent dimensional and functional requirements. By understanding and controlling various influencing factors, precision can be improved to meet industry demands.

Top 10 FAQ with answer about machining precision for Buyer Sourcing from China

Top 10 FAQ about Machining Precision for Buyer Sourcing from China

1. What is machining precision?

– Machining precision refers to the degree of exactness to which a part is produced. It measures how closely a machined part adheres to the desired dimensions and tolerances.

2. How do I determine the required precision for my project?

– Determine the tolerances needed for your specific application by considering factors like functionality, fit, form, and cost. Consult with engineers or use industry standards for guidance.

3. What types of machining processes offer high precision in China?

– CNC machining, EDM (Electrical Discharge Machining), and precision grinding are commonly used processes in China for achieving high precision.

4. How can I ensure the Chinese manufacturer meets my precision requirements?

– Request detailed documentation on their machining capabilities, quality control processes, and certifications like ISO 9001. Arrange for material and sample testing before large-scale production.

5. What materials can be used in high-precision machining in China?

– China offers a wide range of materials including aluminum, stainless steel, titanium, brass, plastics, and more. Ensure your supplier has experience with the specific material you need.

6. How does tooling influence machining precision?

– The quality and condition of tooling directly affect machining precision. Verify that the supplier uses high-quality, well-maintained, and appropriately selected tools.

7. What quality control measures should be in place?

– Look for advanced quality control methods like Coordinate Measuring Machines (CMM), in-process inspections, and end-of-line testing. Ensure the supplier implements continuous improvement practices.

8. Can I visit the machining facility in China?

– Yes, visiting the facility for a firsthand inspection is highly recommended. Prepare a checklist to evaluate their equipment, quality control processes, and working conditions.

9. What are typical lead times for high-precision machining projects?

– Lead times vary based on complexity, volume, and the current workload of the manufacturer. Generally, expect lead times ranging from 2 to 8 weeks.

10. How can I handle intellectual property (IP) protection when sourcing from China?

– Use legal tools like non-disclosure agreements (NDAs) and patents. Work with reputable suppliers who have a track record of respecting IP rights and consider consulting local legal experts.

By addressing these FAQs, you can better navigate the complexities of sourcing high-precision machining services from China and ensure successful project outcomes.