motorised ball valve Safety Certifications

Motorized ball valves are critical components in numerous industrial and domestic applications, and ensuring their safety and reliability is paramount. To ensure compliance with safety and performance standards, these valves often carry several safety certifications. Here are some prominent certifications to look for:

1. CE Marking: Indicates conformity with health, safety, and environmental protection standards for products sold within the European Economic Area (EEA).

2. UL (Underwriters Laboratories): UL certification ensures that the valve has been rigorously tested for safety issues such as fire hazards, electrical shock, and mechanical dangers.

3. CSA (Canadian Standards Association): Ensures compliance with Canadian safety and performance standards, crucial for products used in North America.

4. NSF (National Sanitation Foundation): Particularly important for valves used in drinking water systems, ensuring they meet health and safety guidelines.

5. FM (Factory Mutual): Indicates that the valve has passed fire protection and other risk management assessments, crucial for hazardous environments.

6. ATEX (ATmosphères EXplosibles): Ensures that the valve is safe for use in explosive atmospheres, a necessity in industries like petrochemicals.

7. ISO (International Organization for Standardization): Certifications like ISO 9001 (Quality Management Systems) and ISO 14001 (Environmental Management Systems) show adherence to international quality and environmental standards.

8. RoHS (Restriction of Hazardous Substances): Ensures that the material used in the valve is free from hazardous substances like lead, mercury, and cadmium.

These certifications not only confirm the motorized ball valve’s compliance with regional and international safety standards but also increase reliability, making them a safer choice for various critical applications. Always verify these certifications before installation to ensure the highest levels of safety and operational efficiency.

List Reference Technical Parameters of “motorised ball valve”

A motorised ball valve is an electromechanical device used for controlling the flow of liquids or gases. Here are some key technical parameters to consider:

1. Valve Size: Typically ranges from 1/4 inch to 6 inches or more, depending on application requirements.

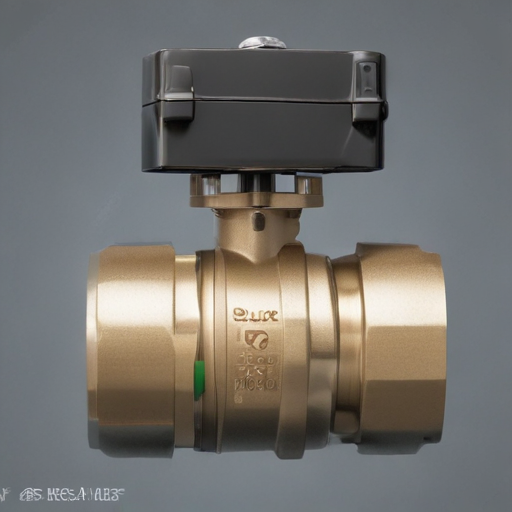

2. Material:

– Body: Common materials include brass, stainless steel, and PVC.

– Ball: Generally made of stainless steel or chrome-plated brass.

3. Connection Type: Options include threaded, flanged, welded, or compression fittings.

4. Actuation Method:

– Electric: Operates on AC or DC voltage (commonly 12V DC, 24V DC, 110V AC, or 230V AC).

– Torque: Specified in Nm (Newton meters), defines the rotational force.

5. Actuation Time: Time required to open or close, typically ranging from a few seconds to several seconds.

6. Control Type:

– On/Off: Simple open/close functionality.

– Modulating: Allows intermediate positions for flow control, often controlled by a 4-20 mA signal or 0-10V DC voltage.

7. Pressure Rating: Maximum operating pressure the valve can handle, usually specified in psi or bar.

8. Flow Capacity: Measured in Cv (flow coefficient), indicating the gallons per minute (GPM) that flow through the valve with a 1 psi pressure drop.

9. Temperature Range: Operating temperature limits, which depend on valve and seal materials.

10. Seals: Common sealing materials include PTFE, EPDM, and Viton, influencing chemical resistance and temperature capacities.

11. Ingress Protection: Rated for dust and water resistance, commonly expressed as IP ratings (e.g., IP67).

12. Certification and Standards: Compliance with industry standards, such as ISO, ANSI, or API.

These parameters help in selecting the appropriate motorised ball valve for specific applications, ensuring performance, reliability, and longevity.

List Product features of “motorised ball valve”

A motorized ball valve is a specialized type of valve used for controlling the flow of liquids and gases in various applications, offering several key features:

1. Automation: Equipped with electric actuators, providing precise and automated control over flow rates without manual intervention.

2. Material Options: Available in a variety of materials, including stainless steel, brass, and PVC, catering to different types of media and environmental conditions.

3. Flow Control: Excellent for precise flow control with a full-bore design, allowing for minimal pressure drop and efficient fluid flow.

4. Durability: Designed for high durability and long service life, featuring robust construction that withstands harsh environments and frequent operation.

5. Easy Installation: Often comes with standardized connection options such as threaded, flanged, or welded ends, making installation straightforward.

6. Low Maintenance: Requires minimal maintenance due to its simple structure and reliable components, reducing downtime and operational costs.

7. Versatile Applications: Used in HVAC systems, water treatment plants, chemical processing, and other industrial applications, demonstrating versatility.

8. Remote Operation: Can be integrated with remote control systems using various communication protocols (e.g., Modbus, BACnet), enabling centralized monitoring and control.

9. Position Feedback: Many models include position sensors or limit switches, providing real-time status updates and ensuring accurate valve positioning.

10. Safety Features: Includes manual override options for emergency operation and failsafe modes that automatically return to a preset position in case of power loss.

11. Energy Efficiency: Typically designed to consume minimal power, contributing to overall energy savings in automated systems.

12. Temperature and Pressure Ratings: Available in models that can handle a wide range of operating temperatures and pressures, suitable for diverse operational requirements.

13. Customization: Customizable configurations for specific needs, including different actuation speeds, voltage options, and control signal types.

These features make motorized ball valves a highly efficient and reliable solution for automated fluid control in various applications.

List Various Types of “motorised ball valve”

Sure! Motorized ball valves are used for controlling fluid flow with precision, using an electric or pneumatic actuator to automate the opening and closing of the valve. Here are various types of motorized ball valves:

1. Electric Motorized Ball Valve:

– On/Off Type: Basic type that allows fully open or fully closed positions.

– Modulating (Proportional): Allows precise control over the valve position for intermediate settings.

– Weatherproof: Designed for outdoor installations.

– Explosion-Proof: Suitable for hazardous environments where explosive gases may be present.

2. Pneumatic Motorized Ball Valve:

– Single-Acting (Spring Return): Returns to a default position when power is lost.

– Double-Acting: Requires air pressure for both opening and closing.

– High-Speed: Suitable for applications requiring rapid opening/closing cycles.

3. Hydraulic Motorized Ball Valve:

– Utilizes hydraulic fluid pressure for operation, often found in heavy industrial applications.

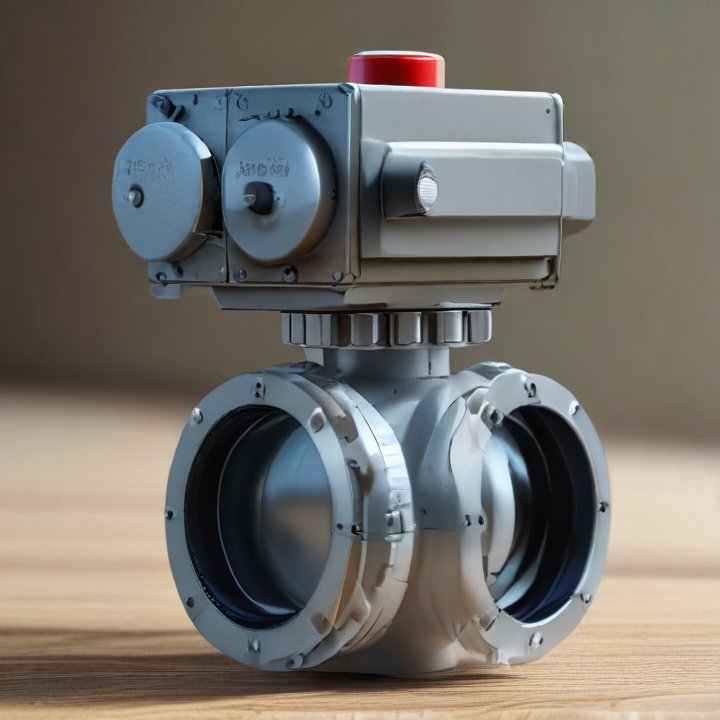

4. Three-Way Motorized Ball Valve:

– L-Port: Allows for one input and diverting the flow to one of two output directions.

– T-Port: Can connect one inlet to two outlets simultaneously or isolate one outlet while connecting the other.

5. Two-Way Motorized Ball Valve:

– Standard configuration with a single inlet and outlet for start/stop flow applications.

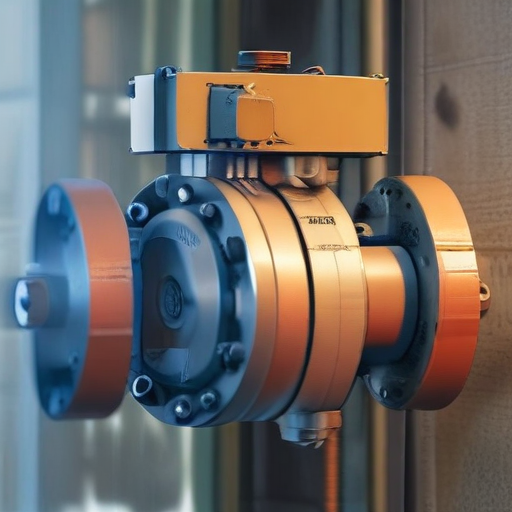

6. Trunnion Mounted Motorized Ball Valve:

– Suitable for high-pressure applications; the ball is supported by trunnions to reduce the torque required for operation.

7. V-Port Motorized Ball Valve:

– Features a V-shaped notch in the ball to provide flow characteristics that are more linear or equal percentage, offering finer control over fluid flow.

These varied types cater to different industries and applications, ranging from simple domestic water systems to complex industrial processes.

List Application of “motorised ball valve”

Motorised ball valves are essential components in a wide range of applications due to their automatic control capabilities and reliability. Here are some key applications:

1. HVAC Systems: Used for controlling the flow of water or steam in heating, ventilation, and air conditioning systems to maintain desired temperatures.

2. Water Treatment Plants: Manage the flow of water and chemicals in purification processes for ensuring clean water supply.

3. Industrial Automation: Employed in manufacturing processes to control the flow of various fluids, from lubricants to coolants, enhancing operational efficiency.

4. Oil and Gas Industry: Essential for the precise control of crude oil, natural gas, and other hydrocarbons in extraction and refining processes.

5. Chemical Processing: Maintain accurate flow control of reactive or hazardous chemicals to ensure safety and process integrity.

6. Food and Beverage Production: Used for the sanitary control of fluids in processing and packaging, ensuring compliance with health regulations.

7. Pharmaceutical Manufacturing: Control the flow of ingredients and solvents during drug production, ensuring precision and sterility.

8. Water Systems in Commercial Buildings: Automated control of water supply in high-rise buildings, including freshwater distribution and sewage management.

9. Irrigation Systems: Efficient water management in agricultural fields by precisely controlling the flow of water to crops.

10. Automotive Industry: Control fluids in various testing and assembly processes to ensure product quality and performance.

11. Home Automation: Integrated into smart home systems for managing water supply, heating, and cooling systems remotely.

These applications demonstrate the versatility and importance of motorised ball valves in ensuring precise control, efficiency, and safety across various industries.

List Buyer Types of “motorised ball valve”

Motorized ball valves are versatile devices used for fluid control in various systems and industries. The primary buyer types for motorized ball valves include:

1. Industrial Manufacturers:

– Oil & Gas: Used in fluid control systems for production, refining, and distribution.

– Chemical Processing: For precise fluid flow regulation in complex chemical processes.

– Water Treatment: Employed in purification systems to control water flow.

2. HVAC (Heating, Ventilation, and Air Conditioning):

– Used to control heating and cooling systems, ensuring optimal climate control in residential, commercial, and industrial buildings.

3. Plumbing and Utilities:

– Municipal water supply systems rely on motorized ball valves for reliable and automated fluid handling and distribution.

4. Pharmaceutical and Biotechnology:

– Ensures sterile and precise control of fluids in manufacturing and research environments.

5. Food and Beverage Industry:

– Facilitates hygienic and controlled fluid flow in production processes, ensuring compliance with safety regulations.

6. Agricultural Sector:

– Utilized in irrigation systems to automate water distribution, enhancing efficiency and conservation efforts.

7. Residential and Commercial Buildings:

– Integrated into smart home systems for automated water shut-off and control, preventing leaks and managing usage.

8. Marine and Shipbuilding:

– Used in various onboard systems to ensure the efficient and reliable operation of critical fluid handling processes.

9. Research and Laboratory Environments:

– Provides precise fluid control necessary for experimental and testing processes requiring high accuracy.

10. Automotive Industry:

– Employed in systems requiring precise fluid control for various automotive manufacturing and testing processes.

Each buyer type relies on the specific attributes of motorized ball valves, such as automation, precision, and reliability, tailored to their unique requirements and applications.

List “motorised ball valve” Project Types for Different Industries

Motorized ball valves find applications across various industries due to their efficiency in regulating fluid flow. Here are project types for different sectors:

1. HVAC (Heating, Ventilation, and Air Conditioning):

– Building Automation Systems: Automating temperature and airflow control.

– Energy Management: Optimizing heating and cooling cycles for energy savings.

2. Water Management:

– Irrigation Systems: Automating water distribution for agriculture.

– Municipal Water Systems: Enhancing control in water treatment plants.

3. Industrial Automation:

– Manufacturing Processes: Precise control of fluids in production lines.

– Chemical Processing: Managing the flow of hazardous chemicals safely.

4. Oil and Gas:

– Pipeline Distribution: Automating remote valve operations for large pipelines.

– Offshore Platforms: Ensuring safety and reliability in fluid transfer.

5. Pharmaceuticals:

– Clean-in-Place (CIP) Systems: Streamlining cleaning processes for production equipment.

– Fluid Transfer Systems: Ensuring precise dosing and mixing of ingredients.

6. Food and Beverage:

– Bottling Plants: Controlling fluid flow in bottling and packaging lines.

– Dairy Processing: Regulating milk and other liquid product flows.

7. Marine Industry:

– Ballast Water Management: Controlling water flow for stability of ships.

– Cargo Management: Automating fluid transfer for various onboard systems.

8. Power Generation:

– Cooling Systems: Automating flow in cooling towers and condensers.

– Wastewater Treatment: Managing effluents in power plants.

9. Renewable Energy:

– Solar Thermal Plants: Controlling heat transfer fluids.

– Biogas Plants: Managing flow in digestion and gas storage systems.

10. Mining:

– Leaching Processes: Efficiently controlling fluid distribution.

– Dust Suppression Systems: Automating water spray systems to minimize dust.

Motorized ball valves provide reliable and precise fluid control, making them integral to modern automation and efficiency in these diverse industrial applications.

motorised ball valve Accessories Upgrades and Custom Manufacturing Options

Motorized ball valves offer precision control for fluid systems and are widely used in various industries. To enhance their functionality and adaptability, several accessories, upgrades, and custom manufacturing options are available:

Accessories:

1. Position Indicators:

– Visual aids to confirm valve status (open/closed).

2. Limit Switches:

– Provide signals for control systems, ensuring accurate positioning.

3. Manual Override:

– Allows manual operation during power loss or system failure.

4. Feedback Systems:

– Transmit real-time valve position to a controller for precise monitoring.

5. Mounting Brackets and Hardware:

– Simplify installation and secure the valve in various orientations.

6. Heaters and Enclosures:

– Protect valves in extreme weather or hazardous environments.

Upgrades:

1. Smart Actuators:

– Incorporate IoT capabilities for remote monitoring and control.

2. Explosion-Proof Actuators:

– Ensure safe operation in flammable environments.

3. Quick-Disconnect Features:

– Facilitate fast and easy maintenance without extensive downtime.

4. Improved Sealing Materials:

– Enhance durability and extend service life in aggressive media.

5. Higher Torque Motors:

– Increase the valve’s ability to handle viscous or high-pressure fluids.

Custom Manufacturing Options:

1. Material Customization:

– Valves and actuators can be made from stainless steel, brass, PVC, etc., suited to specific applications.

2. Valve Size and Configuration:

– Tailored sizes and flow configurations to meet unique system requirements.

3. Bespoke Control Systems:

– Customized electronics and software to fit into existing control frameworks.

4. Special Coatings:

– Apply corrosion-resistant coatings or finishes to extend valve lifespan.

5. Custom Connection Types:

– Adapt threaded, flanged, or welded connections based on specific system needs.

These enhancements not only boost the efficiency and reliability of motorized ball valves but also ensure they meet the exact demands of diverse applications.

List Quality Control and The Manufacturing Process of “motorised ball valve”

Quality Control for Motorized Ball Valves:

1. Incoming Material Inspection: Verify raw materials and components for compliance with specifications using tools like calipers and micrometers.

2. Dimensional Accuracy: Ensure parts meet dimensional criteria through precision measurements.

3. Functionality Testing: Check the motor’s performance, valve operation, and response times.

4. Leak Testing: Conduct pressure and vacuum tests to ensure no leaks in the valve seat or body.

5. Electrical Safety Testing: Validate the proper insulation and electrical functionality of the motor components.

6. Cycle Testing: Operate the valve through numerous cycles to assess durability and performance.

7. Environmental Testing: Examine the valve’s ability to operate under various temperatures, humidity, and exposure conditions.

8. Final Visual Inspection: Inspect for surface defects, proper assembly, and labeling.

Manufacturing Process of Motorized Ball Valve:

1. Design and Engineering: Create detailed specifications and 3D models using CAD software.

2. Material Sourcing: Procure high-quality materials, metals, and electronic components as per design specifications.

3. Machining: Fabricate valve components like the body, ball, and stem using CNC machines for high precision.

4. Surface Treatment: Apply coatings or treatments like polishing and anodization to enhance durability.

5. Sub-assembly: Assemble sub-units like the motor mechanism and electronic control systems.

6. Final Assembly: Integrate the motor with the valve body, secure all components, and ensure proper alignment.

7. Initial Testing: Perform preliminary tests for functionality and compliance with standards.

8. Quality Control: Conduct rigorous quality control and inspection as outlined above.

9. Packaging: Safeguard against damage with appropriate packaging materials.

10. Dispatch: Ship products to distributors or for direct customer use.

This concise yet detailed process and quality control protocol ensure each motorized ball valve is reliable, efficient, and meets industry standards.

How to use “motorised ball valve”

A motorized ball valve is a valve that uses an electric motor to actuate the ball mechanism, enabling the control of fluid flow automatically or remotely. Here’s a concise guide on how to use one:

1. Installation:

– Positioning: Install the valve in the correct orientation. Ensure the arrow on the valve body points in the direction of fluid flow.

– Connection: Connect the valve to the pipe system securely using appropriate fittings, such as flanges or threaded connections.

2. Electrical Wiring:

– Power Supply: Connect the valve’s actuator to a compatible power supply, typically 12V, 24V, or 220V AC/DC, based on the model.

– Control Signal: Integrate the control signal wires if you’re using a control system (e.g., PLC, thermostat). Follow the wiring diagram provided in the manual for proper connections.

3. Operation:

– Manual Override: Some models feature a manual override lever; use this in case of power failure.

– Automatic Operation: Use the control system to send open/close signals to the actuator. The motor will turn the ball 90 degrees to either allow or stop the flow.

4. Testing:

– Initial Test: After installation, apply power and send control signals to ensure the valve opens and closes as intended.

– Leak Check: Inspect for any leaks at joints and connections.

5. Maintenance:

– Regular Inspection: Periodically inspect for wear, corrosion, and proper functioning of the actuator and valve.

– Clean: Ensure the valve and actuator are clean and free from debris.

Remember always to follow the manufacturer’s instructions for specific guidance, as configurations and features can vary between models. Proper use and maintenance ensure efficient and prolonged operation of the motorized ball valve.

“motorised ball valve” Comparative Analysis

Motorized ball valves are pivotal in fluid and gas control, offering automation and precision superior to manual valves. This analysis compares different types of motorized ball valves concerning functionality, construction, and application domains.

Functionality:

– Electrically Actuated Valves:

These use electric actuators for control, offering high precision and the ability to integrate with digital control systems (e.g., Building Management Systems). They are best suited for HVAC, industrial automation, and water treatment systems.

– Pneumatically Actuated Valves:

Here, compressed air drives the actuator. These valves provide fast response times and are ideal for environments where electricity may pose a hazard, such as chemical processing plants.

Construction:

– Two-Way vs. Three-Way Ball Valves:

Two-way valves offer simple open/close control, essential for straightforward flow regulation. Three-way valves, however, can direct flow between two different paths which prove advantageous in more complex piping networks like those in process control industries.

– Materials:

Motorized ball valves come in various materials like stainless steel, brass, and PVC. Stainless steel variants excel in durability and resistance to corrosion, making them perfect for aggressive mediums. Brass is cost-effective, suitable for water systems. PVC valves resist chemicals and are lightweight, apt for light-duty applications.

Applications:

– HVAC Systems:

Electrically actuated valves dominate due to their compatibility with control systems and their ability to provide energy efficiency and precise climate control.

– Industrial Automation:

Pneumatically actuated valves are prevalent due to their reliability, quick actuation, and suitability within hazardous environments.

– Water Treatment:

Electrically actuated, stainless steel or PVC valves are chosen for their resistance to corrosion and ability to handle varying water quality.

In conclusion, the selection of a motorized ball valve depends heavily on the application’s specific requirements regarding automation, material compatibility, and environmental considerations. Electrically actuated valves offer superior integration with modern control systems, while pneumatically actuated valves provide reliability in hazardous conditions. Material choice further refines suitability for the intended application, balancing cost, durability, and resistance to environmental factors.

“motorised ball valve” Warranty and Support

Our motorised ball valve comes with a comprehensive 12-month warranty from the date of purchase. This warranty covers any defects in materials and workmanship under normal use and service. Should you encounter any issues, simply contact our customer support team, and we will address your concerns promptly.

Warranty Services:

1. Repair or Replacement: If your motorised ball valve is found to be defective within the warranty period, we will either repair it or replace it with a new or refurbished unit.

2. Coverage: The warranty covers parts and labor costs for repairs. However, it does not cover damage resulting from misuse, accidents, or unauthorized modifications.

To claim warranty service:

1. Contact our customer support via email or phone with your purchase documentation.

2. Provide a detailed description of the issue and any relevant photographs or videos if possible.

3. Follow the instructions provided by our support team for returning the defective item or receiving service.

Support Services:

Our dedicated support team is available to assist you with any questions or issues you may have. We offer:

1. Technical Assistance: Expert help to troubleshoot and resolve any operational queries.

2. Installation Guidance: Step-by-step instructions and live support to ensure proper installation and setup.

3. Post-Warranty Service: Competitive pricing for repairs and parts after the warranty period has expired.

You can reach our support team through:

– Email: support@motorisedvalves.com

– Phone: 1-800-VALVE-HELP

– Live Chat: Available on our website from 9 AM to 5 PM (Monday to Friday, excluding holidays).

We are committed to ensuring your satisfaction and the optimal performance of your motorised ball valve. Your trust in our product is valuable, and we strive to provide exceptional after-sales support.

List “motorised ball valve” FAQ

Motorised Ball Valve FAQ

1. What is a motorised ball valve?

A motorised ball valve is a type of valve that uses an electric actuator to control the flow of liquids and gases. The valve’s ball, with a hole through the middle, rotates to open, close, or throttle the flow.

2. How do motorised ball valves work?

These valves operate when an electric actuator turns the ball 90 degrees, aligning the hole with the flow direction for an open position, or perpendicular to the flow for a closed position. Throttling is achieved by adjusting the angle.

3. Where are motorised ball valves used?

They are commonly found in HVAC systems, water treatment plants, industrial automation, and irrigation systems due to their reliability and ability to be remotely controlled.

4. What are the advantages of motorised ball valves?

– Automation: They can be controlled automatically via electronic systems.

– Precision: Provide accurate control of flow.

– Durability: Long-lasting with minimal maintenance.

– Efficiency: Offers quick operation with high flow capacity.

5. What are the types of actuators available?

Motorised ball valves may use electric, pneumatic, or hydraulic actuators, with electric being the most common for automated systems.

6. How do I choose the right motorised ball valve?

Consider factors like:

– Size and type: Match the valve to your piping and flow needs.

– Material: Choose materials (stainless steel, brass, PVC) based on the fluid handled.

– Actuation type: Electric, pneumatic, or hydraulic based on the application.

– Voltage: Ensure compatibility with your power supply.

7. How is maintenance performed on motorised ball valves?

Regular maintenance involves inspecting electrical connections, checking for leaks, and ensuring the actuator operates smoothly. Follow the manufacturer’s guidelines for detailed procedures.

8. Can motorised ball valves fail?

Like any mechanical device, they may fail due to wear and tear, electrical issues, or foreign particles. Regular maintenance can mitigate most issues.

By understanding these aspects, you can choose and maintain a motorised ball valve effectively for your specific application needs.

Top 10 FAQ with answer about motorised ball valve for Buyer Sourcing from China

Sure, here are the top 10 Frequently Asked Questions (FAQ) about sourcing motorized ball valves from China, along with succinct answers:

1. What Are the Key Features of Motorized Ball Valves?

– Motorized ball valves typically feature remote operation, precise flow control, and compatibility with various control systems. They come in different materials like brass, stainless steel, and plastic, suitable for various applications.

2. How Do I Evaluate the Quality of Motorized Ball Valves from China?

– Check for ISO certifications and quality management systems. Request sample units and perform third-party quality inspections before bulk purchasing.

3. What are the Common Applications?

– Used in HVAC systems, water treatment, industrial processes, and irrigation systems due to their robust performance and reliability.

4. What Are the Typical Minimum Order Quantities (MOQs)?

– MOQs can vary but typically range from 100 to 500 units depending on the supplier. Always negotiate based on your needs.

5. Are Customizations Available for Specific Applications?

– Yes, many Chinese manufacturers offer customization of components, materials, and control options based on specific requirements.

6. What is the Usual Lead Time for Orders?

– Lead times can vary but generally range from 30 to 60 days. Always clarify lead times upfront to ensure it meets your project timeline.

7. Can I Expect After-Sales Support?

– Reputable suppliers offer after-sales support, including troubleshooting, parts replacement, and technical assistance. Verify this during your supplier selection.

8. What Shipping Methods Are Available?

– Common options include sea freight, air freight, and courier services. Sea freight is cost-effective for large orders, while air freight is faster for urgent needs.

9. How Do I Handle Payment and Incoterms?

– Payment terms often include T/T (Telegraphic Transfer), L/C (Letter of Credit), or PayPal for smaller transactions. Familiarize yourself with Incoterms like FOB (Free on Board) and CIF (Cost, Insurance, and Freight).

10. How Do I Ensure Compliance with International Standards?

– Ensure that the products comply with relevant international standards (e.g., CE, RoHS). Request certification documents and perform compliance checks.

By addressing these common questions, buyers can make more informed decisions when sourcing motorized ball valves from China.