types of rope Safety Certifications

Rope safety certifications ensure that ropes meet established standards for quality, performance, and safety across various applications. Here are some key types:

1. CE (Conformité Européenne) Marking:

– Indicates compliance with European safety, health, and environmental protection requirements.

– Common for ropes used in climbing, rescue, and industrial applications.

2. UIAA (International Climbing and Mountaineering Federation):

– Certifies ropes for climbing and mountaineering.

– Focuses on dynamic performance, fall ratings, and safety margins.

3. NFPA (National Fire Protection Association):

– Specific to fire and rescue operations.

– Ropes are categorized based on general use, technical use, and escape purposes.

4. EN (European Norm) Certifications:

– EN 892: Dynamic mountaineering ropes.

– EN 1891: Low stretch ropes for industrial and rescue applications.

– Conforms to stringent European safety standards.

5. ANSI (American National Standards Institute):

– Addresses workplace safety and performance for ropes used in industrial settings.

– ANSI/ASSE Z359.15: Standard for rope access and work positioning systems.

6. CSA (Canadian Standards Association):

– Standards for ropes used in workplace safety, particularly in fall protection systems.

7. ISO (International Organization for Standardization):

– ISO 2307: Specifies dimensions, mechanical properties, and test methods for different types of ropes.

– Applies globally, ensuring consistent and reliable quality.

Each certification has specific criteria and testing protocols to ensure the ropes can endure the rigors of their intended use. Always check for relevant certifications to ensure maximum safety and compliance for any rope-related activity.

List Reference Technical Parameters of “types of rope”

Certainly! Here are key technical parameters for various types of rope:

Natural Fiber Ropes:

1. Manila Rope:

– Strength: High tensile strength; approx. 600 lbs for 1/2″ diameter.

– Stretch: Moderate stretch after initial use.

– Abrasion Resistance: Good abrasion resistance.

– Weather Resistance: Resistant to UV but susceptible to rot and mildew.

– Use Cases: Maritime operations, landscaping, decoration.

2. Cotton Rope:

– Strength: Lower tensile strength; approx. 300 lbs for 1/2″ diameter.

– Stretch: Low stretch.

– Abrasion Resistance: Moderate.

– Weather Resistance: Susceptible to rot and mildew, poor UV resistance.

– Use Cases: Crafts, hammocks, lightweight applications.

Synthetic Fiber Ropes:

1. Nylon Rope:

– Strength: Very high tensile strength; approx. 3,500 lbs for 1/2″ diameter.

– Stretch: High stretch (elongation up to 40%).

– Abrasion Resistance: Excellent.

– Weather Resistance: UV resistant, resistant to rot and mildew.

– Use Cases: Dock lines, climbing, towing.

2. Polypropylene Rope:

– Strength: Moderate tensile strength; approx. 2,700 lbs for 1/2″ diameter.

– Stretch: Low to moderate stretch.

– Abrasion Resistance: Good.

– Weather Resistance: Excellent resistance to rot, mildew, and most chemicals; UV degradation over time.

– Use Cases: Marine applications, general utility, water sports.

3. Polyester Rope:

– Strength: High tensile strength; approx. 3,000 lbs for 1/2″ diameter.

– Stretch: Low stretch (5-15% elongation).

– Abrasion Resistance: Excellent.

– Weather Resistance: Excellent UV resistance, resistant to rot and mildew.

– Use Cases: Marine applications, rigging, sailing.

4. Dyneema Rope:

– Strength: Extremely high tensile strength; approx. 8,500 lbs for 1/2″ diameter.

– Stretch: Very low stretch.

– Abrasion Resistance: Excellent but can be cut by sharp edges.

– Weather Resistance: Superb UV resistance, resistant to chemicals, rot, and mildew.

– Use Cases: High-performance sailing, climbing, military applications.

Specialty Ropes:

1. Kevlar Rope:

– Strength: Exceptional tensile strength; superior to steel wire rope weight-for-weight.

– Stretch: Very low stretch.

– Abrasion Resistance: Excellent.

– Weather Resistance: Fire-resistant, good chemical, and UV resistance.

– Use Cases: High-stress situations, rescue operations, industrial applications.

Each type of rope has distinct properties suited to specific applications. Selecting the right rope involves considering factors such as tensile strength, stretch, abrasion, and weather resistance.

List Product features of “types of rope”

When considering different types of rope, it’s crucial to understand that each variety has unique features tailored for specific applications. Here are some common rope types and their distinct features:

1. Nylon Rope:

– Strength and Durability: High tensile strength makes it suitable for heavy-duty tasks.

– Elasticity: Excellent stretch recovery, ideal for absorbing shock loads.

– Weather Resistance: Good UV and chemical resistance, performs well in wet conditions.

2. Polypropylene Rope:

– Lightweight: Floats on water, making it perfect for marine applications.

– Chemical Resistance: Resists acids, alkalis, and most solvents.

– Cost-Effective: Generally cheaper than other synthetic ropes.

3. Polyester Rope:

– Low Stretch: Retains shape under load, great for rigging and sports applications.

– UV Resistance: High resistance to ultraviolet light, making it suitable for outdoor use.

– Durability: Resistant to abrasion and rot.

4. Manila Rope:

– Natural Fiber: Made from abaca plant fibers, eco-friendly.

– Grip: Offers excellent grip, often used in decorative and landscaping applications.

– Aesthetic Appeal: Rustic look, commonly used for decorative purposes.

5. Kevlar Rope:

– High Strength: Superior tensile strength, often used in high-stress environments.

– Heat Resistance: Can withstand extreme temperatures.

– Lightweight: Strong yet lightweight, ideal for aerospace and military use.

6. Dyneema Rope:

– Ultra-High Strength: Pound-for-pound stronger than steel.

– Lightweight: Easy to handle, popular in marine and climbing applications.

– Low Stretch: Minimal elongation, holds load securely.

7. Cotton Rope:

– Soft Texture: Gentle on hands, used in pet toys and decorative projects.

– Absorptive: Excellent water absorption, making it less slippery when wet.

– Biodegradable: Environmentally friendly as it degrades naturally.

Each type of rope offers specific advantages tailored to particular environments and uses. The selection depends on the intended application, considering factors such as strength, elasticity, resistance to elements, weight, and cost.

List Various Types of “types of rope”

Certainly! Here’s a concise list of various types of rope, categorized by material and specific application:

Natural Fiber Ropes

1. Manila Rope

– Made from abacá plant fibers

– Strong, flexible, durable

2. Cotton Rope

– Soft, easily dyed

– Popular for crafts and indoor use

3. Hemp Rope

– Made from natural hemp fibers

– Eco-friendly, strong, and resistant to UV rays

4. Jute Rope

– Made from jute plant fibers

– Biodegradable, often used in gardening

Synthetic Fiber Ropes

1. Nylon Rope

– Highly elastic and durable

– Resistant to abrasion and chemicals

2. Polyester Rope

– Low stretch, high strength

– Resilient to UV rays and wear

3. Polypropylene Rope

– Lightweight, floats on water

– Chemical-resistant and economical

4. Kevlar Rope

– Extremely strong and heat-resistant

– Used in high-stress applications like climbing

Specialized Ropes

1. Climbing Rope

– Typically nylon, kernmantle design

– Dynamic or static variants

2. Paracord (Parachute Cord)

– Lightweight, versatile, strong

– Used in survival gear and bracelets

3. Battle Rope

– Heavy-duty, typically polyester or nylon

– Used for fitness and strength training

4. Sailing Rope (Marine Rope)

– Often polyester or polypropylene

– Resistant to saltwater and UV exposure

5. Wire Rope

– Made from steel or stainless steel strands

– Extremely strong, used in lifting and rigging

Decorative and Craft Ropes

1. Macramé Rope

– Soft, usually cotton or synthetic

– Used in weaving and crafts

2. Bakers Twine

– Cotton or cotton blend, often red and white

– Decorative, used in baking and packaging

Each type of rope has its own unique properties and is chosen based on its intended use, whether for durability, flexibility, resistance to elements, or aesthetic appeal.

List Application of “types of rope”

Ropes are versatile tools used across various industries and applications. Their utility depends on their type, material composition, and specific properties. Here’s an overview of different types of ropes and their applications:

1. Nylon Rope

– Applications: Climbing, Boating, Safety Lines

– Features: High strength, elasticity, good shock absorption, and resistance to UV, chemicals, and rot.

2. Polypropylene Rope

– Applications: Marine, Pool Lanes, Flags, Barrier Ropes

– Features: Lightweight, floats on water, resistant to mold and mildew, and economical.

3. Polyester Rope

– Applications: Sailing, Rigging, Outdoor Use

– Features: Durable, UV resistant, low stretch, and strong against abrasion.

4. Manila Rope

– Applications: Twine, Landscaping, Decorative Uses

– Features: Natural fiber, good grip, biodegradable, and resistant to saltwater.

5. Hemp Rope

– Applications: Agriculture, Gardening, Craft Projects

– Features: Environmentally-friendly, durable, and flexible.

6. Cotton Rope

– Applications: Pet Toys, Macramé, Decorative

– Features: Soft, flexible, and ideal for indoor use.

7. Kevlar Rope

– Applications: Industrial, Aerospace, Safety Equipment

– Features: Extremely strong, heat-resistant, and low stretch.

8. Dyneema Rope

– Applications: Fishing, Climbing, High-Performance Sports

– Features: High strength-to-weight ratio, floats on water, and minimal stretch.

9. Wire Rope

– Applications: Construction, Lifting, Heavy-Duty Industry

– Features: Very strong, durable, and resistant to corrosion (especially stainless steel variants).

10. Sisal Rope

– Applications: Agricultural, Packing, Craft

– Features: Natural fiber, affordable, and biodegradable.

Each type of rope is specifically designed to meet the unique demands of its intended application, ensuring safety, efficiency, and durability across various settings.

List Buyer Types of “types of rope”

Certainly! When it comes to types of rope, there are various buyer types, each with specific needs and preferences. Here’s a concise overview of the primary buyer types:

1. Outdoor Enthusiasts and Adventurers:

– Climbers, Hikers, and Campers seek durable, lightweight ropes, often opting for dynamic climbing ropes, paracord, or reflective guy lines for tents.

2. Marine and Boating Enthusiasts:

– Boaters and Sailors require ropes like polyester, nylon, or polypropylene that resist water, UV rays, and abrasion. They are keen on mooring lines and anchor ropes.

3. Industrial and Construction Workers:

– Construction Workers and Engineers look for high-strength, heavy-duty ropes such as wire rope, manila, or polypropylene for lifting, rigging, and securement purposes.

4. Arborists and Landscape Professionals:

– Arborists need strong, flexible ropes such as arborist climbing ropes and rigging ropes designed to handle repeated stress and support heavy loads while maintaining flexibility.

5. Outdoor Event Organizers and Decorators:

– Event Planners and Outdoor Decorators seek visually appealing and dependable ropes for decorations, stage setups, and securing structures, often choosing natural fibers like jute or synthetic varieties with aesthetic finishes.

6. Emergency Services and Rescue Teams:

– First Responders favor ropes that guarantee reliability under pressure, leaning towards static ropes, kernmantle ropes, and escape ropes used in rescue and safety operations.

7. Farmers and Ranchers:

– Agricultural Workers require ropes for a multitude of tasks such as securing loads, constructing fences, or handling livestock, often using sisal, manila, or soft poly ropes.

8. DIY Enthusiasts and Hobbyists:

– Crafters and Home DIY Enthusiasts look for versatile and easy-to-handle ropes like natural cotton ropes, thin paracord, and multi-purpose utility ropes for various home projects and crafts.

Each buyer type prioritizes specific features and materials in their rope purchases, ensuring the ropes meet their particular demands and applications.

List “types of rope” Project Types for Different Industries

Certainly! Different industries rely on various types of ropes designed for specific applications. Here’s a concise look at the types of ropes used across various sectors:

1. Construction:

– Nylon Rope: Known for strength and elasticity, ideal for lifting and rigging.

– Polypropylene Rope: Lightweight, floatable, and resistant to chemicals; used for temporary netting and barrier ropes.

2. Maritime:

– Manila Rope: Traditional natural fiber rope used for mooring and anchoring.

– Polyester Rope: Highly resistant to UV rays and abrasion, used for sails, rigging, and dock lines.

3. Climbing and Adventure Sports:

– Dynamic Rope: Designed to stretch under load, minimizing impact force during falls.

– Static Rope: Minimal stretch, used for caving, rappelling, and rescue operations.

4. Theatre and Entertainment:

– Cotton Rope: Soft texture, ideal for aesthetic purposes like stage rigging and prop creation.

– Kevlar Rope: Strong and heat-resistant, used for special effects and pyrotechnics.

5. Agriculture:

– Sisal Rope: Biodegradable, used for bundling hay and tying crops.

– Hemp Rope: Durable and eco-friendly, used for fencing and general-purpose farm tasks.

6. Industrial and Manufacturing:

– Wire Rope: Made of metal strands, crucial for hoisting, elevator cables, and cranes.

– Kevlar Rope: Extremely strong and heat-resistant, used in heavy-duty industrial applications.

7. Fishing:

– Dacron Rope: Durable and lightweight, used for lines and nets.

– Tarred Twine: Weather-resistant, used for lobster pots and other marine traps.

8. Firefighting and Rescue:

– Technora Rope: High heat resistance, used for escape ropes and rescue operations.

– Aramid Fiber Rope (e.g., Nomex): Flame-retardant, used in critical rescue scenarios.

Each rope type is tailored to meet specific needs, ensuring safety, efficiency, and effectiveness across various applications.

types of rope Accessories Upgrades and Custom Manufacturing Options

Rope accessories, upgrades, and custom manufacturing options enhance the functionality, durability, and aesthetics of ropes. Below are some commonly available options:

1. Thimbles and Eyes

– Thimbles: Metal or plastic inserts to protect rope eyes from wear and deformation.

– Spliced Eyes: Professionally woven loops for secure attachments.

2. End Terminations

– Whipping: Prevents unraveling by wrapping the rope’s end with twine.

– Heat Sealing: Melts the rope fibers to prevent fraying.

– Crimping: Uses metal fittings to securely bind the rope ends.

– Knots and Braids: Customized according to specific needs for strength and functionality.

3. Protective Coatings and Treatments

– UV Protection: Extends the lifespan by guarding against sun damage.

– Waterproofing: Makes ropes water-resistant for marine or outdoor use.

– Abrasion Resistance: Enhances durability with specialized coatings.

4. Hardware Attachments

– Carabiners: Spring-loaded clips for quick and secure connections.

– Snap Hooks: Similar to carabiners but often easier to use with one hand.

– Cleats and Shackles: Provide secure anchor points for ropes.

5. Customization Options

– Color Coding: Custom color selections for easy identification and aesthetics.

– Reflective Materials: Embedded for visibility in low-light conditions.

– Elastic Properties: Integration of elastic materials for stretchability.

– Custom Lengths and Diameters: Tailored to specific requirements for different applications.

6. Specialized Manufacturing Techniques

– Double-Braiding: Increases strength and reduces stretch.

– Dynamic and Static Rope: Tailored for climbing, rescue operations, or general use.

– Load-Rated Ropes: Certified for specific weight-bearing capacities.

These accessories and customizations ensure that the ropes meet unique needs, providing safety, efficiency, and convenience across various applications such as marine, industrial, and recreational use.

List Quality Control and The Manufacturing Process of “types of rope”

Quality Control in Rope Manufacturing

1. Raw Material Inspection: Assess quality of fibers (natural or synthetic) for uniformity, tensile strength, and resistance to environmental factors.

2. Pre-production Testing: Samples tested for breaking strength, elongation, abrasion resistance, and UV stability.

3. In-process Monitoring: Continuous inspection during manufacturing to check for consistency in diameter, twist, and braiding.

4. Post-production Testing: Finished ropes undergo rigorous testing for tensile strength, impact resistance, and durability. Non-destructive testing methods are used as well.

5. Certification and Compliance: Ensure ropes meet industry standards like ISO, ANSI, or others pertinent to their application.

6. Documentation and Traceability: Maintain detailed records of material sources, production batches, and test results for traceability.

Manufacturing Process of Types of Rope

1. Material Selection: Choose suitable fibers (e.g., nylon, polyester, polypropylene, manila, sisal) based on rope type and application.

2. Fiber Preparation: Clean, align, and straighten natural fibers; for synthetic fibers, extrude into filaments or threads.

3. Twisting or Braiding:

– Twisted Rope: Fibers are twisted into yarns, then multiple yarns are twisted together in the opposite direction to form strands. These strands are then twisted together to make the rope.

– Braided Rope: Fibers are braided using specialized machines that interweave multiple yarns. Common types include single braid, double braid, and hollow braid.

4. Heat Setting (Synthetic Ropes): Post-braiding/twisting, ropes are often heat-treated to stabilize structure and set properties like stretch resistance.

5. Splicing and Finishing: Ends are spliced or whipped to prevent fraying. Additional treatments like coating for UV resistance or waterproofing can be applied.

6. Quality Testing and Packaging: Final ropes are subjected to quality controls and tests to confirm they meet specifications. Post testing, ropes are cut to length, coiled, and packaged for distribution.

By integrating stringent quality control at every stage and using precise manufacturing techniques, diverse types of ropes are produced to meet specific demands across various industries.

How to use “types of rope”

Ropes come in various types, each suited for specific applications. Here’s a brief guide on how to use several common types:

1. Nylon Rope:

– Uses: Climbing, towing, and ship docking.

– Benefits: High tensile strength, elasticity, and resistance to UV rays, chemicals, and abrasion.

– Tips: Ideal for heavy-duty tasks requiring flexibility and durability.

2. Polypropylene Rope:

– Uses: Water sports, fishing, and temporary outdoor use.

– Benefits: Floats on water, resistant to mildew, and relatively inexpensive.

– Tips: Avoid prolonged UV exposure as it degrades over time.

3. Polyester Rope:

– Uses: Sailing, rigging, and outdoor climbing.

– Benefits: Low stretch, high strength, and excellent UV and abrasion resistance.

– Tips: Excellent for load-bearing activities requiring stable performance.

4. Cotton Rope:

– Uses: Decorative projects, pet toys, and craftwork.

– Benefits: Soft, natural, and easy to handle.

– Tips: Best for indoor use; susceptible to rot and mildew if used in wet conditions.

5. Manila Rope:

– Uses: Landscaping, obstacle courses, and classic rigging.

– Benefits: Durable, biodegradable, and has a traditional appearance.

– Tips: Soak in water before use to prevent shrinking; store in a dry place to avoid mildew.

6. Kevlar Rope:

– Uses: Safety lines, aerospace, and military applications.

– Benefits: Extremely strong, high heat resistance.

– Tips: Not as elastic; best for situations requiring high tension without stretch.

7. Dyneema/Spectra Rope:

– Uses: High-performance marine, climbing, and industrial lifting.

– Benefits: Very light, floats in water, with incredibly high strength-to-weight ratio.

– Tips: Avoid sharp bends which can weaken the fibers.

Choose the appropriate type of rope based on the specific demands of your project to ensure safety and efficiency.

“types of rope” Comparative Analysis

Ropes are essential tools in various industries, recreational activities, and everyday tasks. They come in several types, each with unique properties suited for specific applications. Here’s a comparative analysis of some common types:

1. Nylon Rope:

– Strength and Durability: High tensile strength and excellent abrasion resistance.

– Flexibility: Very flexible, making it easy to handle.

– Water Resistance: Absorbs water which can lead to decreased strength and increased weight when wet.

– Applications: Climbing, towing, and general industrial use.

2. Polypropylene Rope:

– Strength and Durability: Moderate strength with good resistance to rot, mildew, and most chemicals.

– Flexibility: Less flexible than nylon and more susceptible to abrasion damage.

– Water Resistance: Excellent water resistance and buoyancy.

– Applications: Marine use, lifelines, and water sports.

3. Polyester Rope:

– Strength and Durability: Slightly less strong than nylon but with superior resistance to abrasion and UV rays.

– Flexibility: Flexible and easy to handle, similar to nylon.

– Water Resistance: Low water absorption, maintaining strength and flexibility when wet.

– Applications: Sailing, rigging, and outdoor use.

4. Manila Rope:

– Strength and Durability: Natural fiber with good strength but prone to rot and deteriorates faster with prolonged exposure to elements.

– Flexibility: Fairly flexible but stiffer than synthetic ropes.

– Water Resistance: Poor; absorbs water leading to rot and decay.

– Applications: Decorative purposes, landscaping, and some historical and traditional uses.

5. Dyneema®/Spectra® Rope:

– Strength and Durability: Extremely high tensile strength, stronger than steel by weight.

– Flexibility: Lightweight and highly flexible.

– Water Resistance: Excellent water resistance; does not absorb water.

– Applications: High-performance sailing, climbing gear, and extreme sports.

Conclusion: Selection of rope type hinges on specific needs such as strength, flexibility, durability, and environmental resistance. Nylon and polyester ropes are versatile, catering to a wide array of applications, whereas manila rope is more traditional and suited for specific aesthetic or natural requirements. High-tech ropes like Dyneema® are preferred in scenarios demanding exceptional strength and minimal weight.

“types of rope” Warranty and Support

When purchasing different types of rope, particularly for specialized uses, it’s crucial to consider the warranty and support provided by the manufacturer or seller. Understanding these aspects can significantly impact both the longevity and effectiveness of the rope for your intended application.

Warranty

1. Coverage Duration: Warranties typically range from a few months to several years. Ensure you understand the length of coverage for your specific rope type, whether it’s natural fiber rope (like cotton or Manila) or synthetic rope (like nylon, polyester, or polypropylene).

2. Inclusions and Exclusions: Most warranties cover defects in materials and workmanship but could exclude damages from improper use, wear and tear, or exposure to harsh environmental conditions. Check if the warranty covers UV resistance or rot resistance for natural fibers.

3. Claim Process: Understand the process for claiming a warranty. This often involves providing proof of purchase and, in some cases, returning the defective product for evaluation.

Support

1. Customer Service: Reliable manufacturers offer robust customer support to assist with product selection, usage recommendations, and troubleshooting. Look for companies with knowledgeable representatives who can advise on the best rope type for your specific tasks, whether that’s climbing, marine applications, or general utility.

2. Documentation: Quality ropes often come with detailed documentation, including specifications, safety information, and maintenance instructions. This can be crucial for ensuring proper usage and extending the rope’s service life.

3. Online Resources: Many reputable manufacturers provide online tutorials, FAQs, and forums to help customers understand product capabilities and limitations. Utilizing these resources can enhance your product experience and extend its usability.

By prioritizing both warranty and support, you can safeguard your investment in any type of rope, ensuring it meets your needs effectively and reliably for the long term.

List “types of rope” FAQ

Types of Rope FAQ

#### 1. What are the basic types of rope?

– Natural Fiber Rope: Made from plant fibers like cotton, sisal, hemp, and manila.

– Synthetic Fiber Rope: Made from man-made materials like nylon, polyester, polypropylene, and Kevlar.

– Wire Rope: Constructed from metal wires, usually steel, twisted together.

#### 2. What are the characteristics of natural fiber ropes?

– Cotton: Soft, flexible, and biodegradable; commonly used in crafts.

– Sisal: Strong and durable; resistant to sunlight but susceptible to rot if wet.

– Hemp: Very strong and environmentally friendly; used in gardening and marine applications.

– Manila: Made from abaca fiber; very strong and resistant to sunlight but deteriorates in moist conditions.

#### 3. How do synthetic ropes differ from natural fiber ropes?

– Nylon: Very strong, elastic, and resistant to abrasion; used in climbing and towing.

– Polyester: Strong, low-stretch, UV-resistant; ideal for marine and industrial uses.

– Polypropylene: Lightweight, floats on water, and resistant to chemicals; used in water sports and for general utility.

– Kevlar: Extremely strong and heat-resistant; used in high-stress applications like safety lines and rescue operations.

#### 4. What are the uses of wire ropes?

– Typically used in heavy lifting, construction, elevators, and cable car systems due to their strength and durability.

#### 5. How do you choose the right type of rope?

– Application: Consider what you’ll be using the rope for (e.g., climbing, boating, general utility).

– Strength: Determine the load capacity you need.

– Environmental Conditions: Think about exposure to elements like water, sunlight, and chemicals.

– Flexibility: Some applications require flexible ropes, while others need rigid ones.

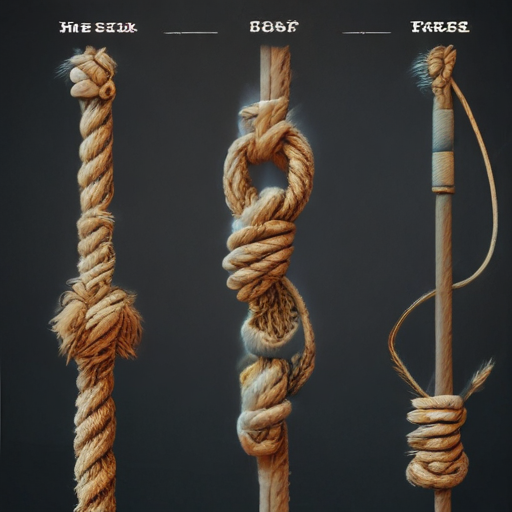

#### 6. What’s the difference between twisted and braided ropes?

– Twisted Rope: Made by twisting fibers or yarns together; more flexible but may untwist under load.

– Braided Rope: Made by braiding multiple strands; smoother and less likely to unravel.

Understanding these basic types of ropes and their characteristics helps in choosing the right rope for specific needs and ensures safety and effectiveness in various applications.

Top 10 FAQ with answer about types of rope for Buyer Sourcing from China

Certainly! Here are the top 10 frequently asked questions (FAQ) about sourcing types of rope from China, with concise answers:

1. What types of ropes are commonly available from Chinese manufacturers?

– Answer: Chinese manufacturers offer a variety of ropes including nylon, polyester, polypropylene, jute, sisal, manila, dacron, cotton, and UHMWPE (Ultra-High-Molecular-Weight Polyethylene) ropes.

2. How can I ensure the quality of ropes sourced from China?

– Answer: Opt for suppliers certified with ISO standards and request product samples. Conduct third-party inspections and ask for quality assurance documentation.

3. Are Chinese ropes compliant with international standards?

– Answer: Many Chinese manufacturers comply with international standards like ASTM, ISO, and CE. Verifying certifications and requesting compliance documentation is recommended.

4. What is the minimum order quantity (MOQ) for ropes?

– Answer: MOQs vary; they generally start from 500 to 1,000 meters, but some suppliers may be flexible, especially for first-time orders or long-term partnerships.

5. Can I get customized ropes from Chinese suppliers?

– Answer: Yes, customization in terms of size, color, material, and branding (logos, labels) is often available. Discuss specific requirements with the supplier.

6. What are the typical lead times for orders from China?

– Answer: Lead times can range from 15 to 45 days, depending on the complexity and quantity of the order. Confirm specifics with the supplier.

7. What are the shipping options and costs?

– Answer: Options include sea freight, air freight, and express courier services. Shipping costs depend on volume, weight, and delivery speed. Request quotes from suppliers.

8. Are there any import duties or taxes applicable?

– Answer: Import duties and taxes vary by country. Check with your local customs authority for specifics related to rope imports.

9. How can I verify the legitimacy of a Chinese supplier?

– Answer: Use platforms like Alibaba, Global Sources, or Made-in-China to find verified suppliers. Conduct due diligence, check business licenses, and read reviews or ask for references.

10. What payment terms are typically offered by Chinese suppliers?

– Answer: Common payment terms include T/T (Telegraphic Transfer), L/C (Letter of Credit), and PayPal for smaller amounts. Negotiating a small upfront deposit with the balance paid upon delivery is standard practice.

These FAQs provide essential insights for buyers looking to source quality ropes from China efficiently.